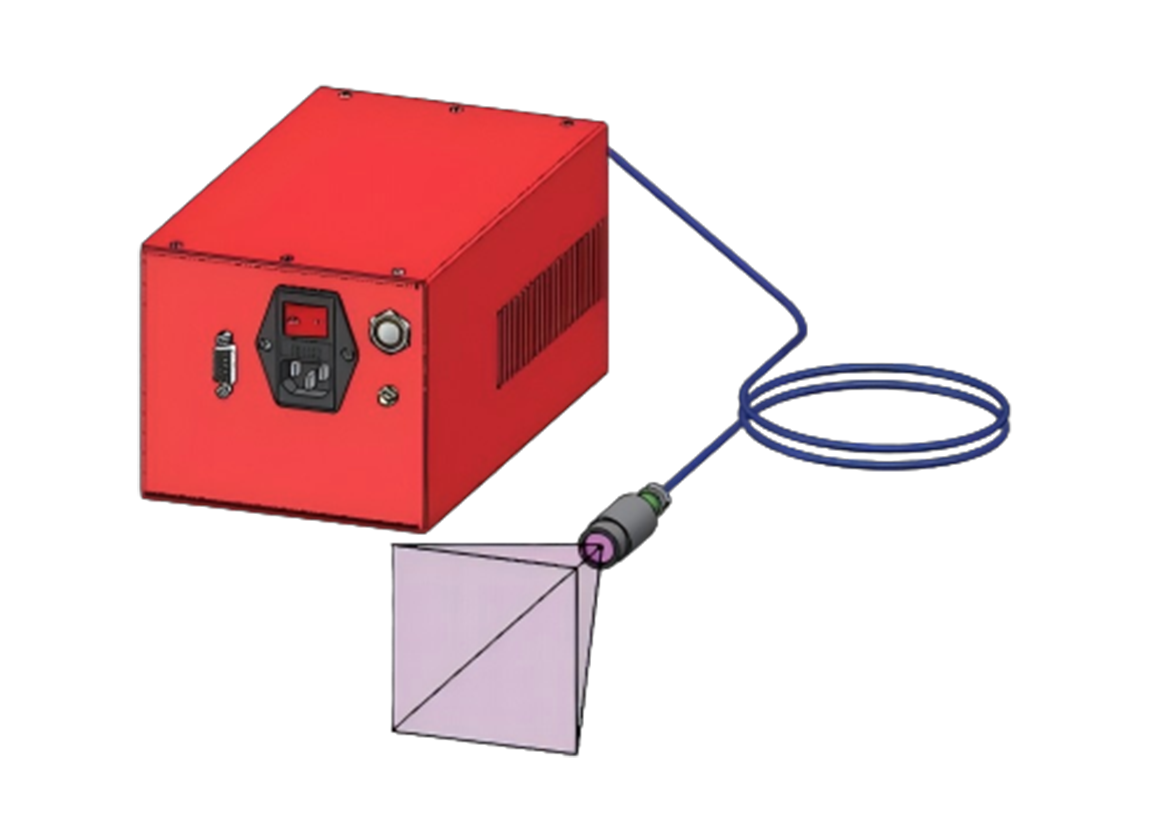

30W-200W Semiconductor Laser

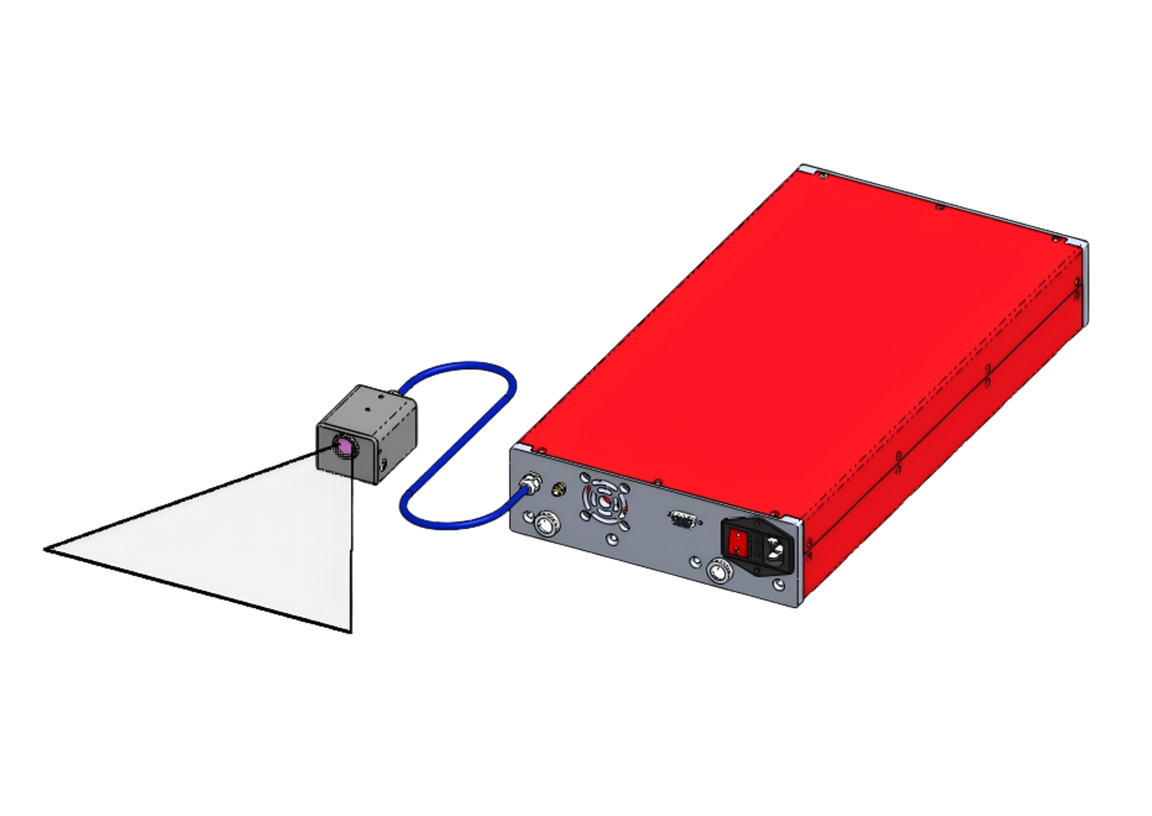

30W/50W/200W PL inspection is a non-contact detection method based on optical excitation and high-sensitivity camera imaging, widely used for quality inspection of silicon wafers, solar cells, and other semiconductor materials.

-

30/50/200WOutput Power

-

808±5/915±10nmCentral Emission Wavelength

-

10nmSpectral Width

-

Product Advantages

-

Specification

-

Related Products

Product Advantages

-

Non-Contact Inspection

The PL method ensures zero physical damage or contamination to silicon wafers, preserving sample integrity during inspection.

-

High Sensitivity

Capable of detecting micron- and even nano-scale defects and impurities, with significantly higher sensitivity than conventional inspection methods.

-

High Throughput

Enables rapid processing of large sample volumes, dramatically improving production efficiency and quality control performance.

Specification

-

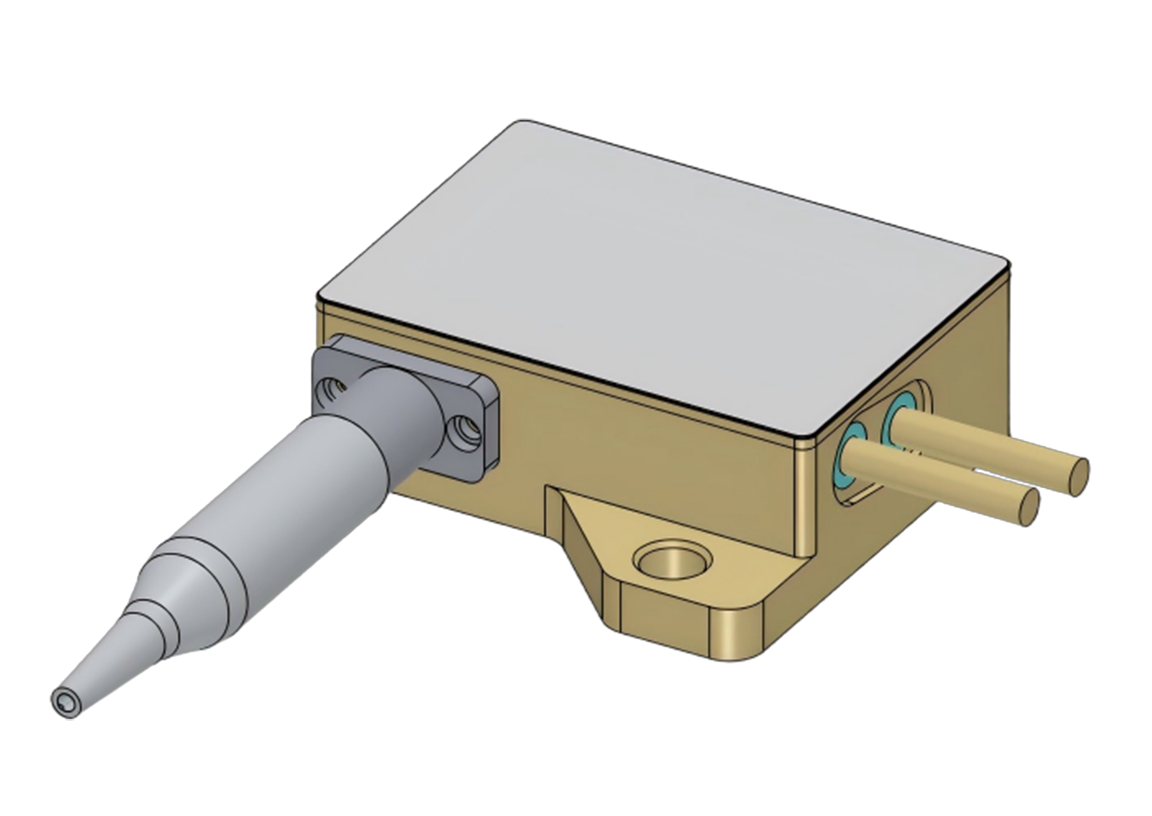

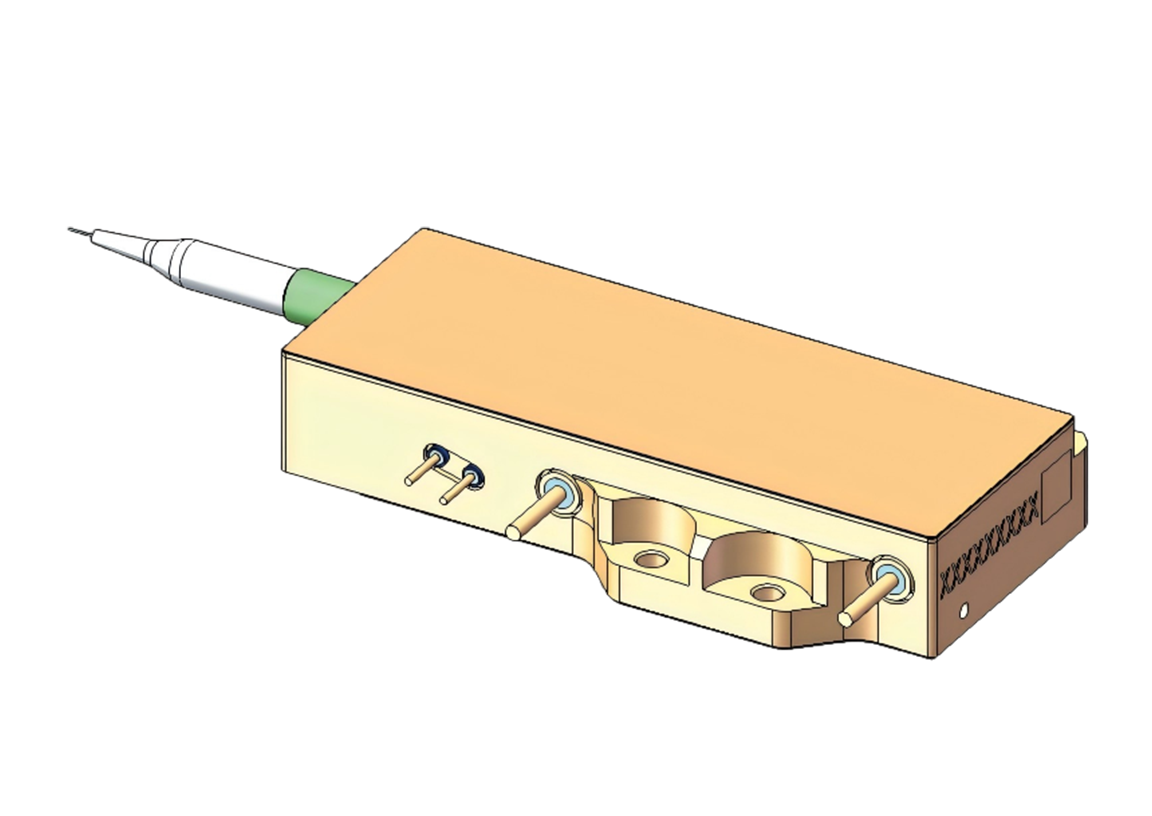

JPT-30W

-

JPT-50W

-

JPT-200W

-

Output Power(W)

-

Central Wavelength(nm)

-

Center Wavelength Deviation

-

Typical Working Distance(mm)

-

Detectable Wafer Size(mm)

-

Power Requirements(V)

-

IO Interface(V)

-

Average Power Consumption(W)

-

Beam Emission Control

-

Power Regulation Mode

-

Operating Temp.&Rh(℃)

-

Dimension(mm)

-

Weight(kg)

-

Applicable Technology

-

Cooling

-

JPT-30W

-

Output Power(W)30

-

Central Wavelength(nm)808

-

Center Wavelength Deviation±5

-

Typical Working Distance(mm)230~260

-

Detectable Wafer Size(mm)≤230

-

Power Requirements(V)220

-

IO Interface(V)White 0~24+/ Black 0~0.5-

-

Average Power Consumption(W)100

-

Beam Emission ControlIO Interface

-

Power Regulation ModeGUI

-

Operating Temp.&Rh(℃)20~30;<80%

-

Dimension(mm)205×111×123

-

Weight(kg)≈4

-

Applicable TechnologyProcess After Silicon Wafer Coating

-

CoolingAir-Cooled

-

-

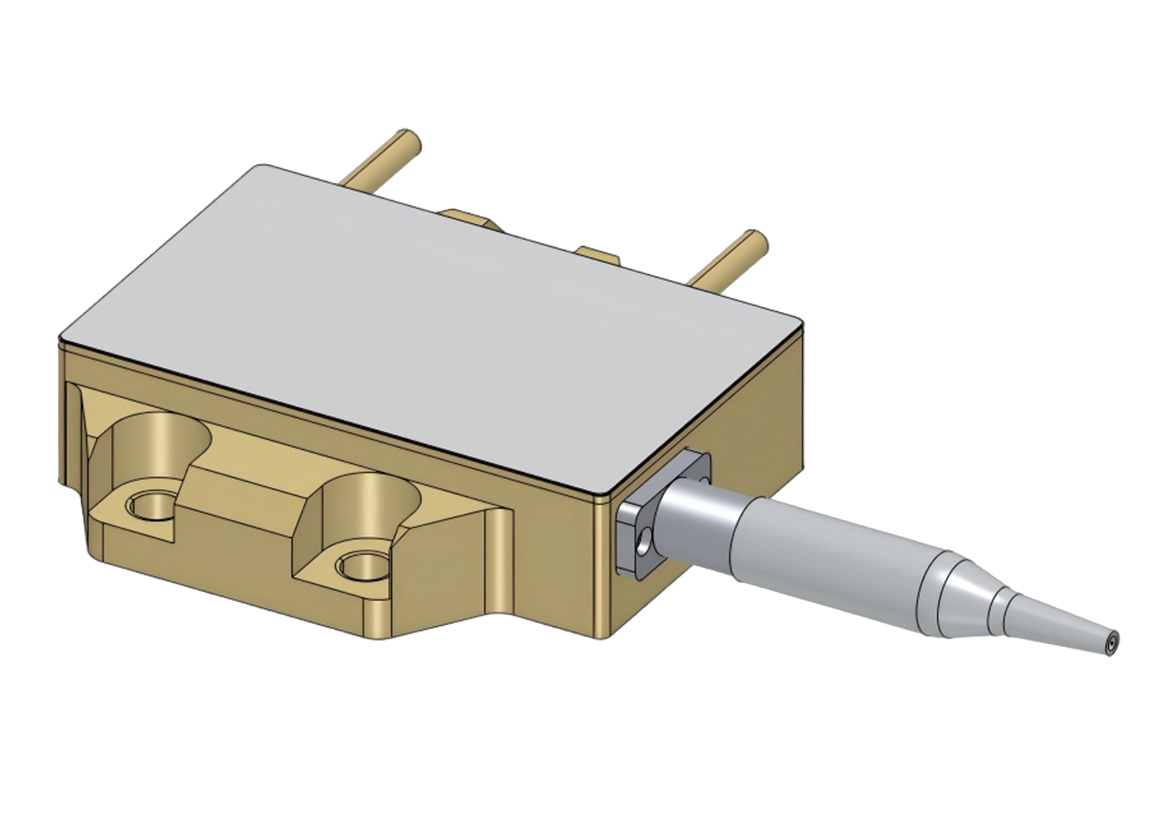

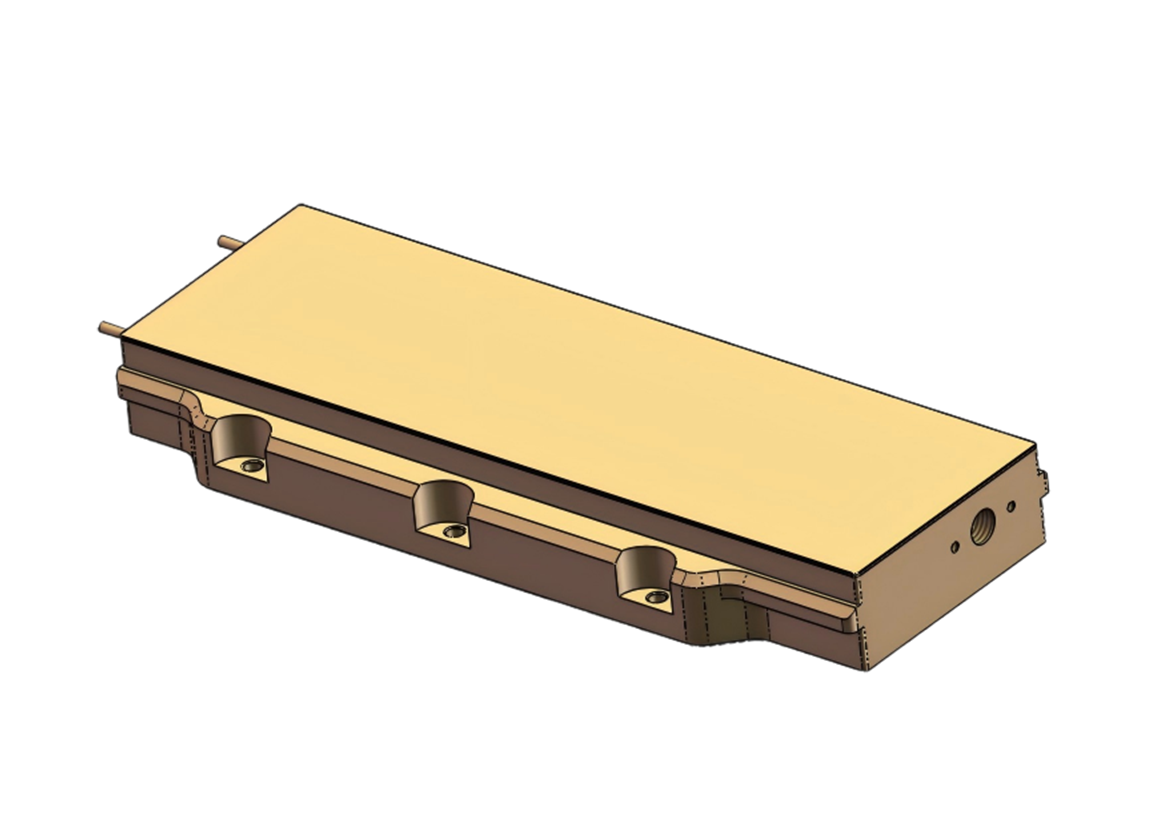

JPT-50W

-

Output Power(W)50

-

Central Wavelength(nm)808

-

Center Wavelength Deviation±5

-

Typical Working Distance(mm)230~260

-

Detectable Wafer Size(mm)≤230

-

Power Requirements(V)220

-

IO Interface(V)White 0~24+/ Black 0~0.5-

-

Average Power Consumption(W)130

-

Beam Emission ControlIO Interface

-

Power Regulation ModeGUI

-

Operating Temp.&Rh(℃)20~30;<80%

-

Dimension(mm)232×140×122

-

Weight(kg)≈5

-

Applicable TechnologyProcess After Silicon Wafer Diffusion

-

CoolingAir-Cooled

-

-

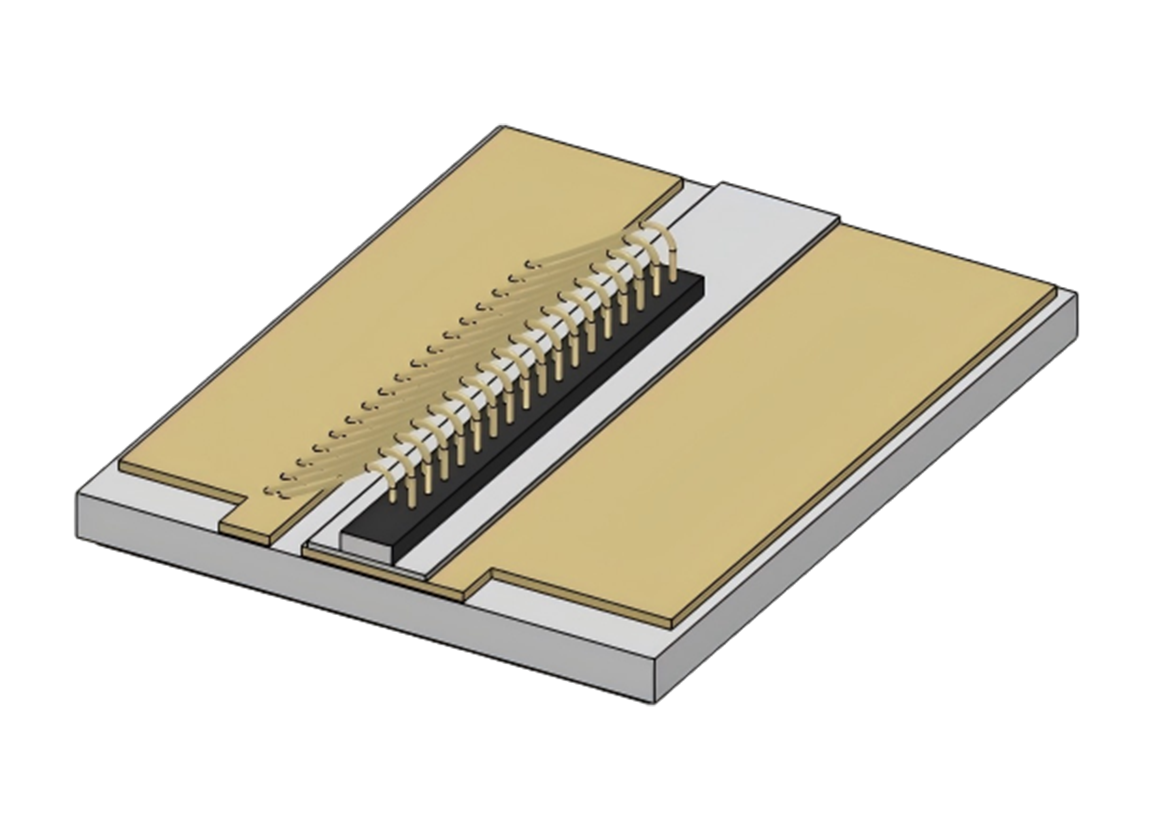

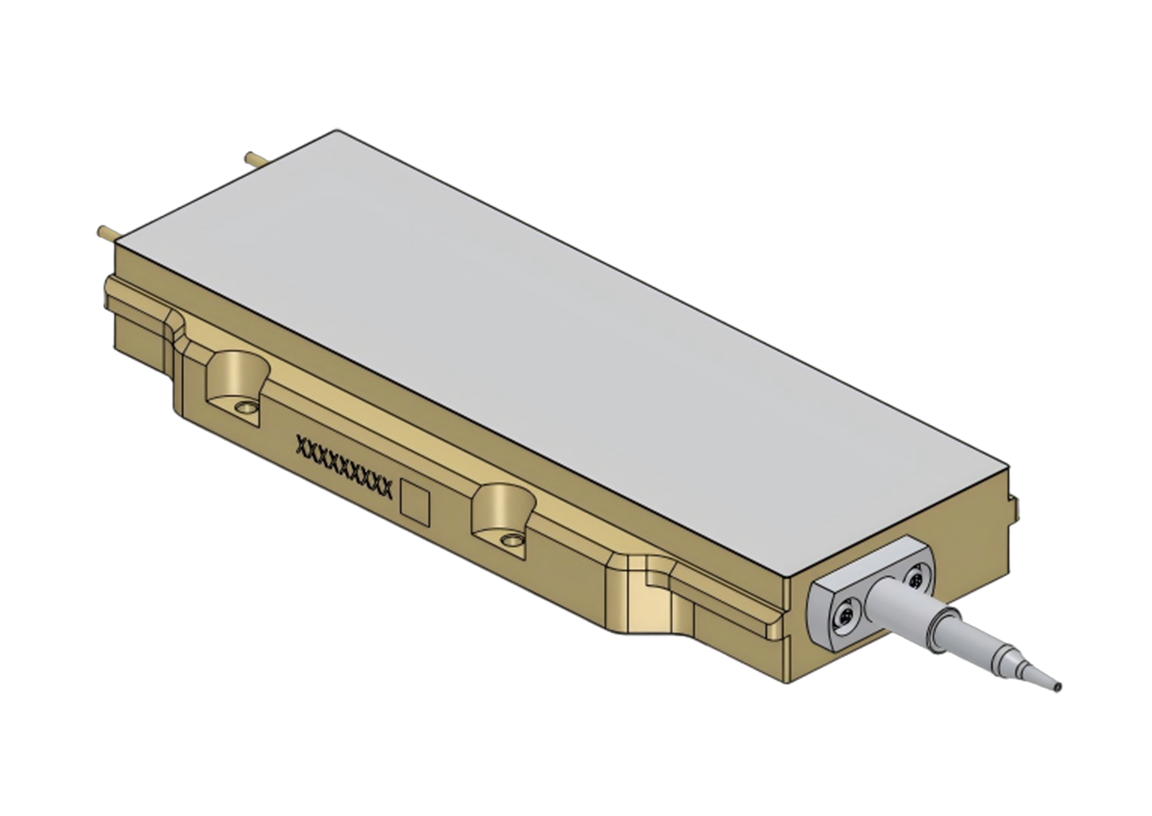

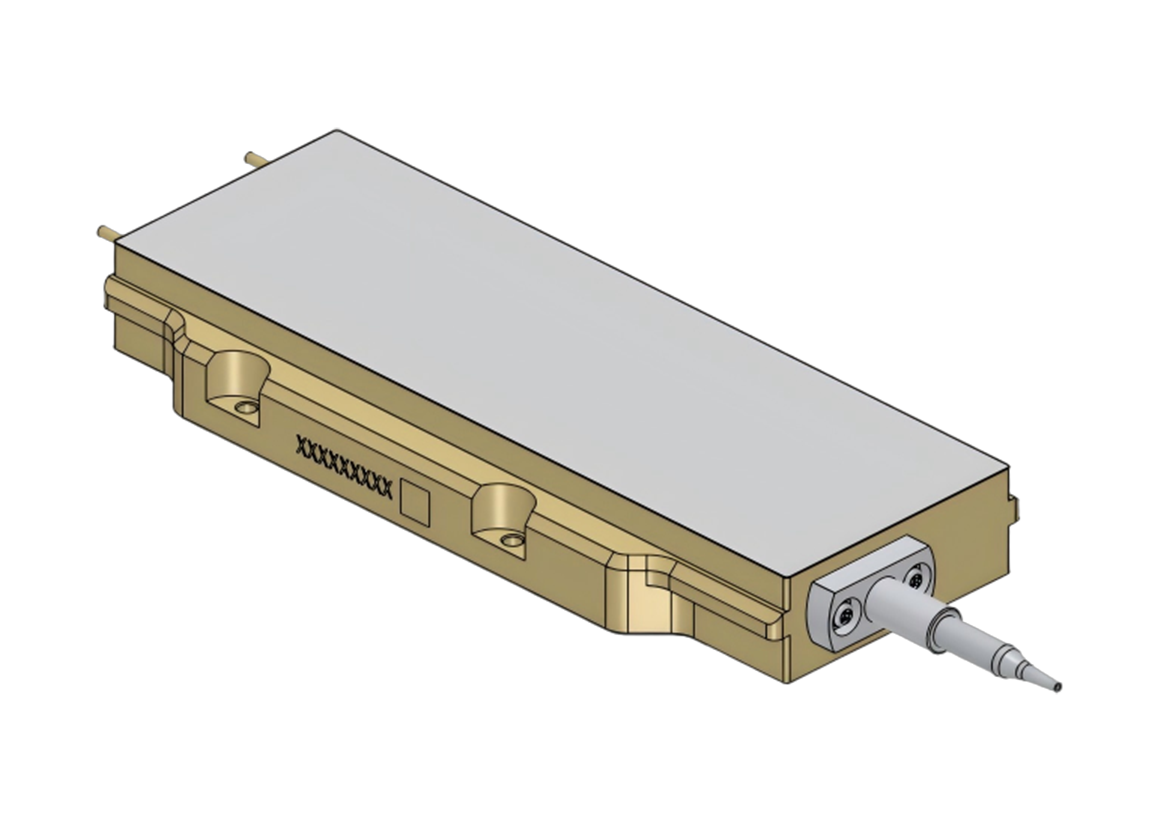

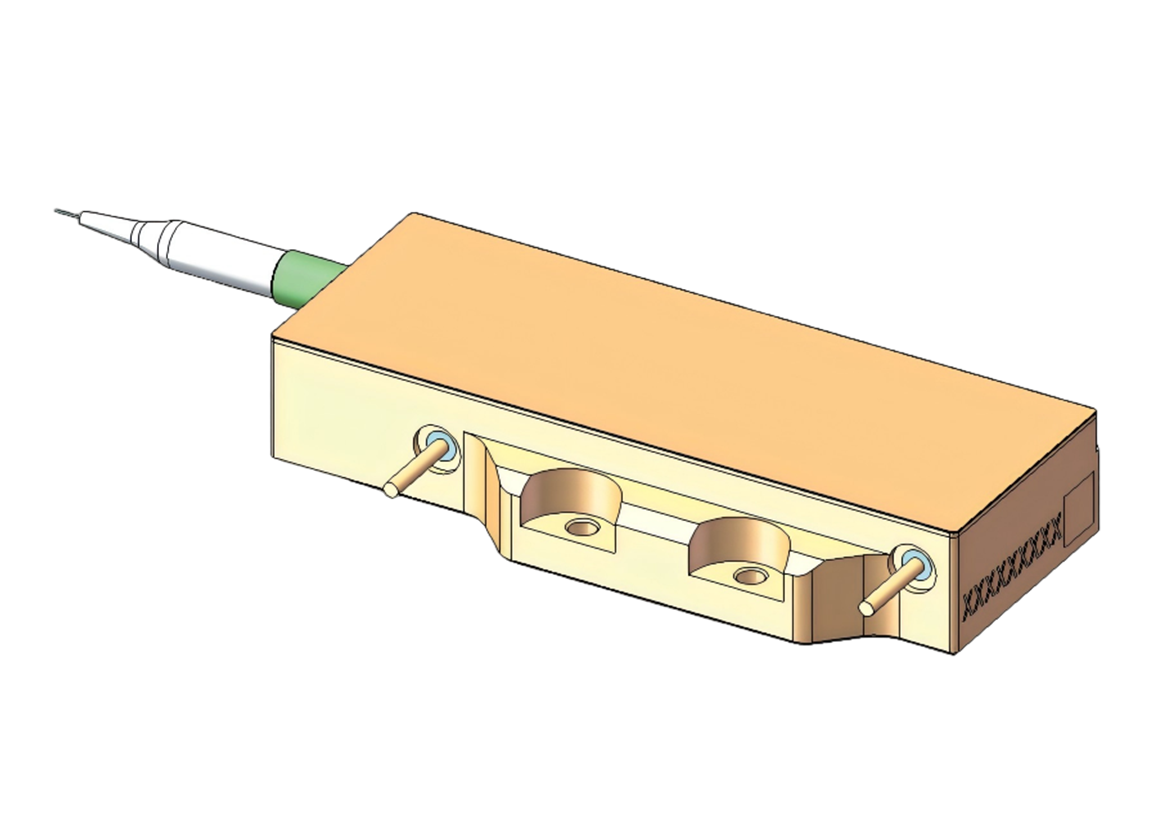

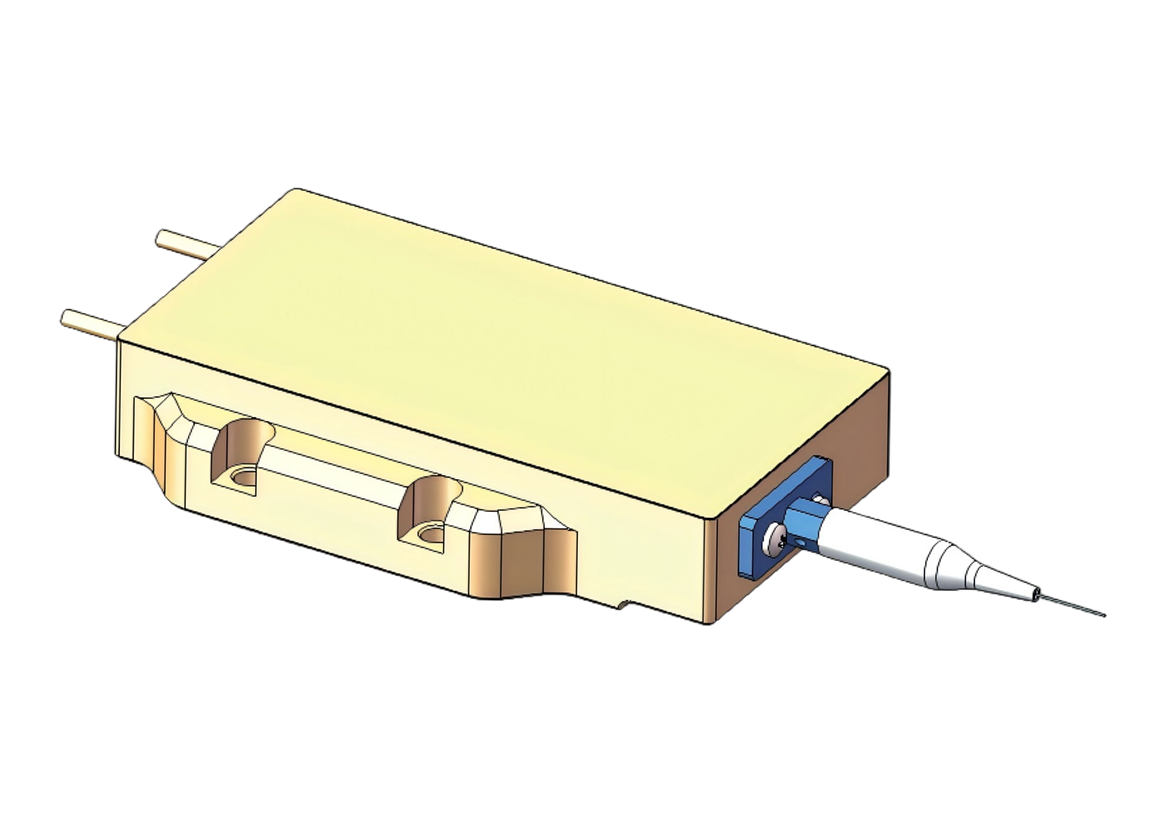

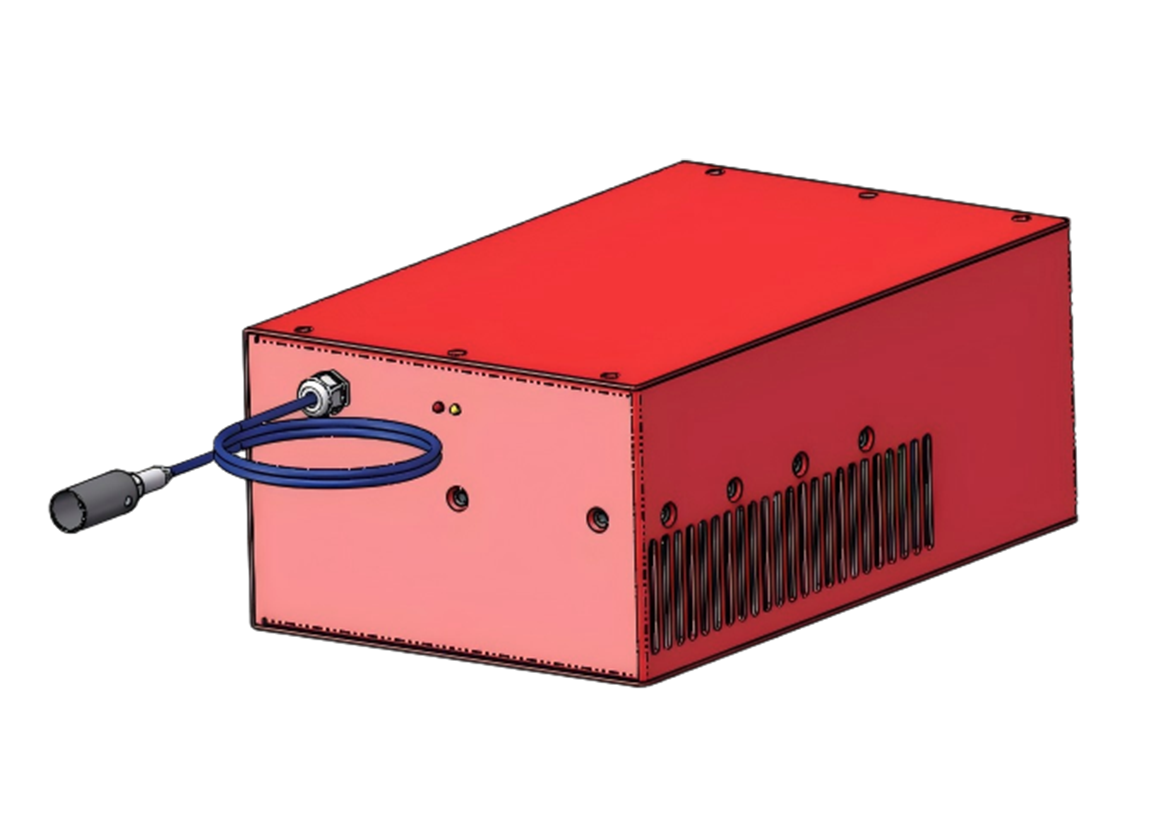

JPT-200W

-

Output Power(W)200

-

Central Wavelength(nm)915

-

Center Wavelength Deviation±10

-

Typical Working Distance(mm)230~260

-

Detectable Wafer Size(mm)≤230

-

Power Requirements(V)220

-

IO Interface(V)White 0~24+/ Black 0~0.5-

-

Average Power Consumption(W)560

-

Beam Emission ControlIO Interface

-

Power Regulation ModeGUI

-

Operating Temp.&Rh(℃)20~30;<80%

-

Dimension(mm)450×235×70

-

Weight(kg)≈10

-

Applicable TechnologySubsequent Processes of Silicon Wafers

-

CoolingWater-Cooled

-

Related Products

-

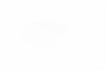

COS Encapsulated Semiconductor Laser

COS Encapsulated Semiconductor LaserCOS Encapsulatedtechnology offers high efficiency, low thermal resistance, and enhanced reliability, applicable in industrial processing, medical equipment, and communications fields

-

915nm Semiconductor Laser

915nm Semiconductor LaserSuitable for fiber laser pumping applications across industrial processing, medical, cosmetic, and scientific research sectors

-

976nm Semiconductor Laser

976nm Semiconductor LaserNear-infrared laser equipment, used as a pump source for fiber lasers

-

808nm Semiconductor Laser

808nm Semiconductor LaserNear-infrared lasers serving as solid-state laser pumping sources

-

880nm Semiconductor Laser

880nm Semiconductor LaserHigh-efficiency laser equipment in the near-infrared band, also serving as a pump source for solid-state lasers

-

1060nm Semiconductor Laser

1060nm Semiconductor LaserUsed for quality inspection of silicon wafers, solar cells, and other semiconductor materials

-

1470nm Semiconductor Laser

1470nm Semiconductor LaserHigh efficiency and excellent stability, 1470nm widely used in medical, cosmetic, and scientific research fields

-

1550nm Red Light Semiconductor Laser

1550nm Red Light Semiconductor LaserHigh-power, visible light marking, widely used in material processing, medical equipment, and scientific research experiments

-

450nm - 100W High Power Diode Laser

450nm - 100W High Power Diode LaserUtilizing blue laser wavelengths, it features high output power, excellent stability, and high efficiency

-

Silicon Transmission Series Detection Module

Silicon Transmission Series Detection ModuleWidely used for quality inspection of silicon wafers, solar cells, and other semiconductor materials

-

200W Red Light Series Semiconductor Laser

200W Red Light Series Semiconductor LaserWidely used in material processing, medical equipment, and scientific research experiments

-

30W Fiber Coupled High Power Laser

30W Fiber Coupled High Power LaserUtilizing blue light wavelengths, applied in material processing, display technology, laser imaging, etc.

-

30W-200W Semiconductor Laser

30W-200W Semiconductor LaserUsed for quality inspection of silicon wafers, solar cells

-

50W Square Light Semiconductor Laser

50W Square Light Semiconductor LaserUtilizes a fiber-coupled diode laser source with integrated precision control circuitry