Laser Cutting

JPT’s laser cutting solutions, powered by our self-developed high-energy-density lasers and precision optical control systems, enable high-accuracy thermal cutting across a variety of materials. Delivering narrow kerfs, clean edges, and minimal heat-affected zones, these solutions ensure superior quality in every cut. Applicable to metals, power battery materials, flexible printed circuits (FPC), ceramics, and more, JPT laser cutting technology delivers outstanding efficiency and consistency in sectors such as new energy manufacturing, precision electronics, and semiconductor device production.

-

Optical Resin Cutting

-

Carbon Steel Cutting

-

High-Reflective Material Cutting

-

Thick Stainless Steel Cutting

-

Flexible Material Cutting

-

Metal Resistor Cutting

-

Optical Resin Cutting

Optical Resin CuttingJPT’s optical resin cutting technology uses a high-power-density laser beam to instantly vaporize resin lens gate material, producing precise and smooth kerfs. Unlike traditional mechanical or manual cutting, this process eliminates burrs and chipping, ensuring flawless lens surfaces and significantly enhancing both appearance and optical performance. It is especially suited for manufacturing 3C products such as smartphone camera lenses, delivering exceptional cutting accuracy, edge quality, and production efficiency while ensuring consistent quality—meeting the stringent requirements of high-end optical component manufacturing.

-

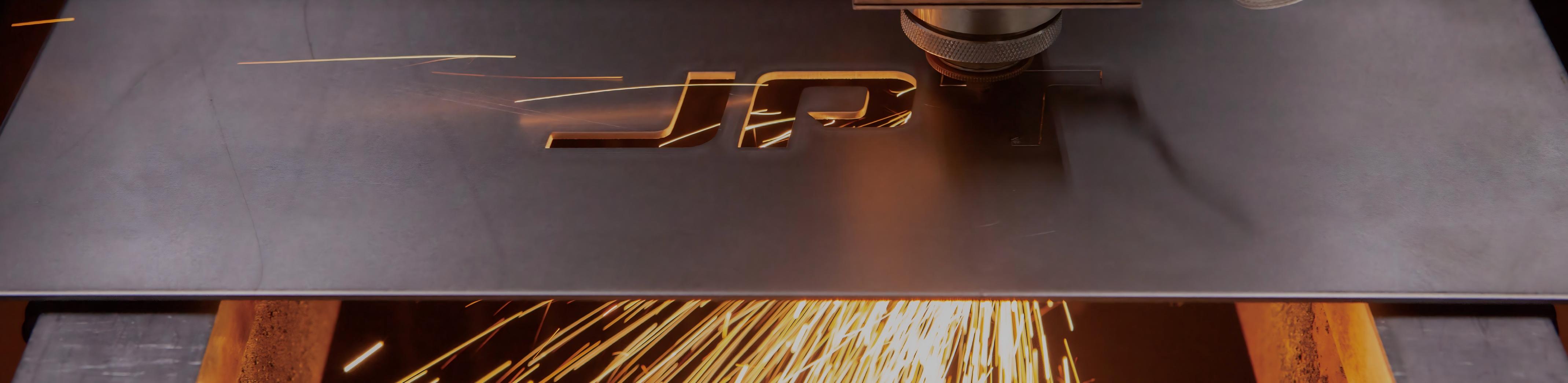

Carbon Steel Cutting

Carbon Steel CuttingJPT’s carbon steel cutting technology uses high-power laser beams as a heat source to melt, vaporize, or ablate carbon steel plates, while high-pressure assist gas (typically oxygen or nitrogen) removes molten material to achieve precise separation and shaping. Offering high peak power, excellent efficiency, and strong reliability, this process is ideal for thick plate cutting, complex contour processing, and other high-power applications. With stable beam quality and flexible parameter configurations, JPT’s carbon steel cutting is widely applied in industrial manufacturing, metalworking, and additive manufacturing, delivering high-quality and consistent cutting results.

-

High-Reflective Material Cutting

High-Reflective Material CuttingJPT's high-reflective material cutting technology is specifically engineered for metals such as copper, aluminum, and gold with high reflectivity. By optimizing laser design and process parameters, it effectively addresses challenges such as high laser energy reflection and potential equipment damage, achieving stable, efficient, and precise cutting performance. This process overcomes traditional cutting limitations, delivering high accuracy, high productivity, and exceptional stability, making it ideal for applications requiring strict quality and consistency. With advanced beam control and cooling systems, JPT’s high-reflective material cutting is widely used in new energy, precision manufacturing, and electronics processing, providing high-quality and reliable cutting solutions.

-

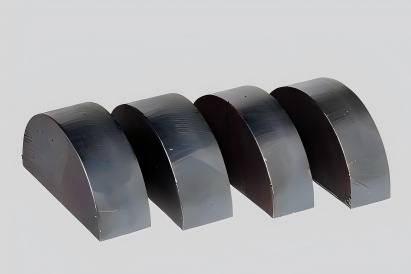

Thick Stainless Steel Cutting

Thick Stainless Steel CuttingJPT’s thick stainless steel cutting technology leverages multi-kilowatt high-power lasers (6 kW and above, typically 12–30 kW) to deliver efficient fusion cutting for stainless steel plates with thicknesses of 12 mm or more. The process utilizes an ultra-high energy density laser beam to rapidly melt the material, combined with high-pressure assist gases (nitrogen/oxygen) to effectively remove molten metal, achieving smooth kerfs and precise separation. Compared to traditional cutting methods, this technology offers narrower cuts, minimal heat-affected zones, and superior surface finish, significantly improving production efficiency and product quality. It is widely used in heavy equipment manufacturing, structural steel fabrication, shipbuilding, and high-end stainless steel product processing.

-

Flexible Material Cutting

Flexible Material CuttingJPT flexible material cutting utilizes high-energy-density laser beams (UV, green, or fiber) for non-contact precision machining of flexible, easily deformed non-metal and thin-metal materials. Using thermal effects or photochemical decomposition, it achieves clean separation, ideal for complex contour cutting of FPC boards, films, and rubber. The UV laser spot can be focused to 20 μm, with edge verticality error under 0.5°, ensuring burr-free, residue-free cuts that prevent circuit shorting. This technology combines high precision, low thermal impact, and processing flexibility, serving electronics manufacturing, flexible displays, and more.

-

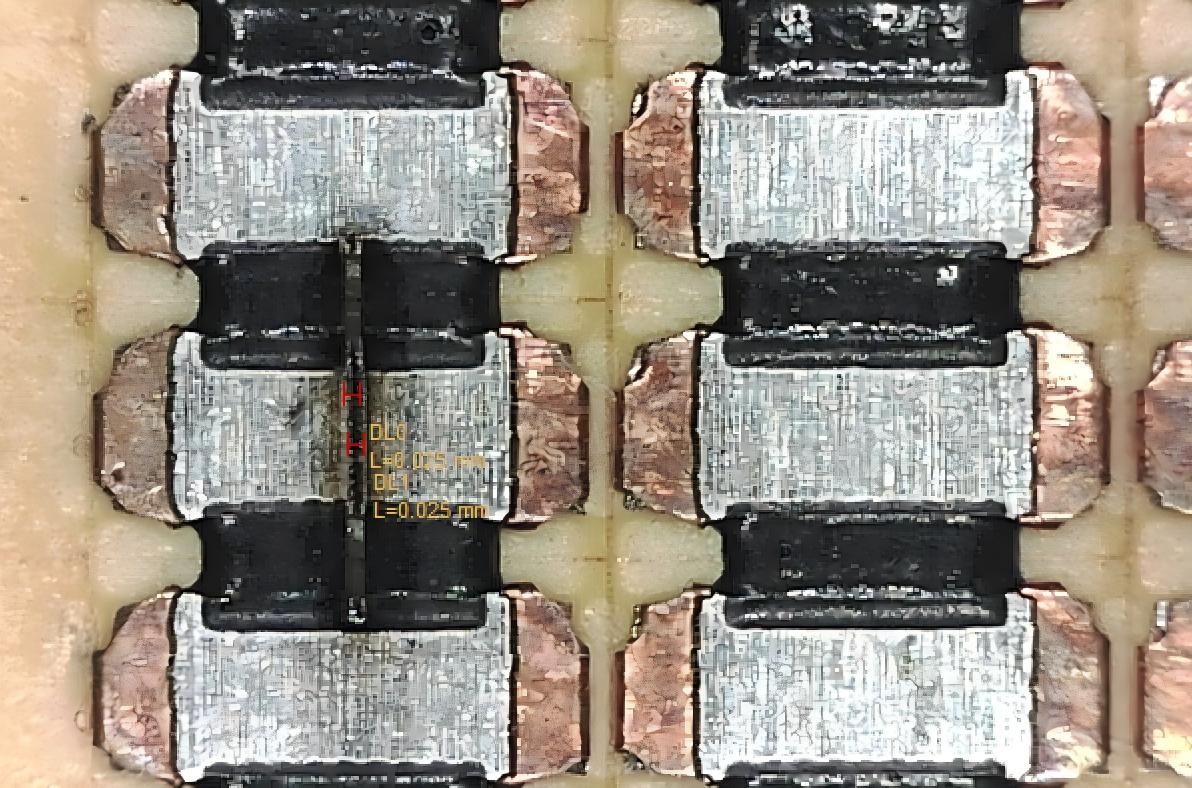

Metal Resistor Cutting

Metal Resistor CuttingJPT metal resistor cutting uses a non-contact, ultra-precise, and minimal heat-affected process to accurately set and fine-tune resistance values while preserving the material’s conductivity and stability. This technique delivers ultra-high precision, ultra-low temperature coefficients, and excellent long-term stability and reliability, making it ideal for producing high-performance resistors used in aerospace, medical devices, precision instruments, and test and measurement equipment, ensuring consistent performance and quality.