JPT welding control modules oversee every stage — before, during, and after welding. With real-time monitoring, adaptive control, and smart diagnostics, they deliver stable quality and illuminate the future of intelligent manufacturing.

-

OPTICAL DEVICES

-

LASERS

-

CORE MODULES

-

INTELLIGENT SOLUTIONS

Pre-welding Modules

JPT Pre-welding Modules focus on preventive preparation before the welding process, including the setup and optimization of key parameters. By ensuring accuracy and stability from the outset, these modules lay a solid foundation for efficient welding, enabling smooth operations through subsequent stages and delivering consistently high-quality results.

-

Full-Field Scanning Vision Positioning Module

Full-Field Scanning Vision Positioning ModuleThe coordinate mapping algorithm corrects CCD light source drift and distortion caused by the F-theta lens

-

Solder Ball Placement & Welding Module

Solder Ball Placement & Welding ModuleDelivers individual solder balls to the nozzle, where they are heated by a laser beam under an inert gas atmosphere to a molten state

-

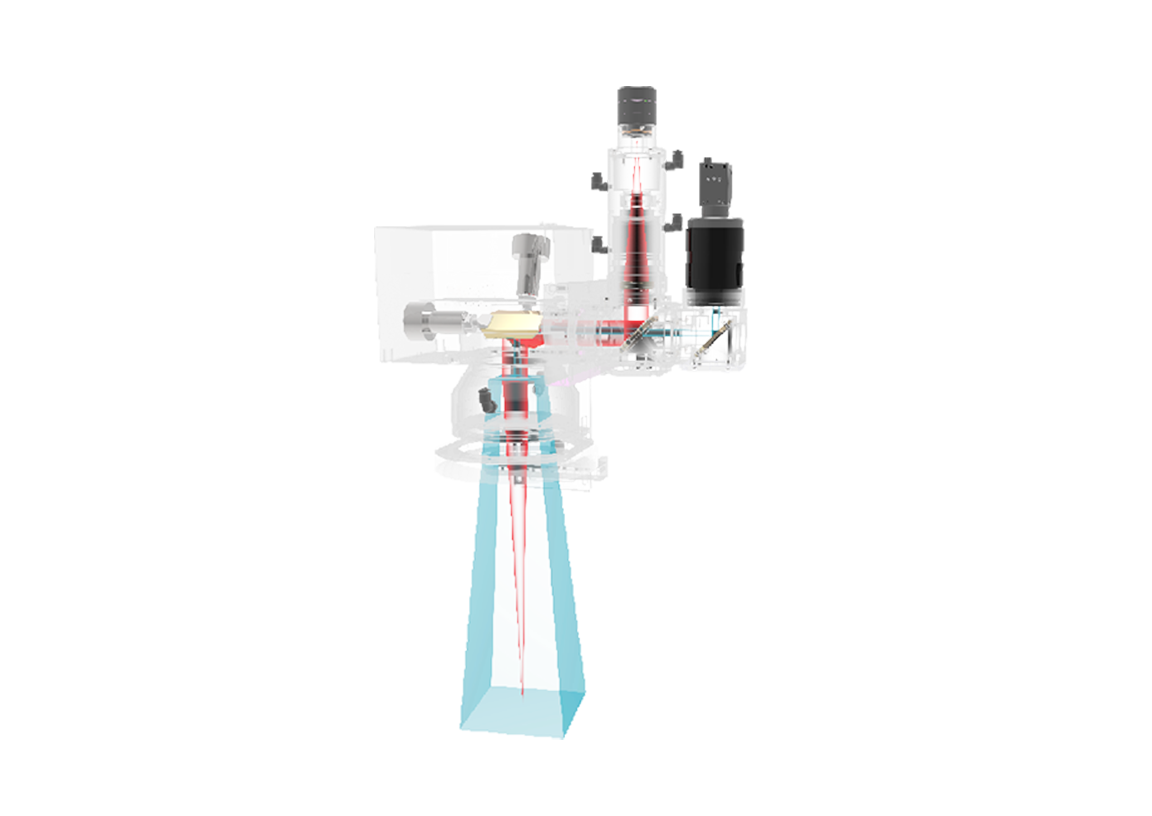

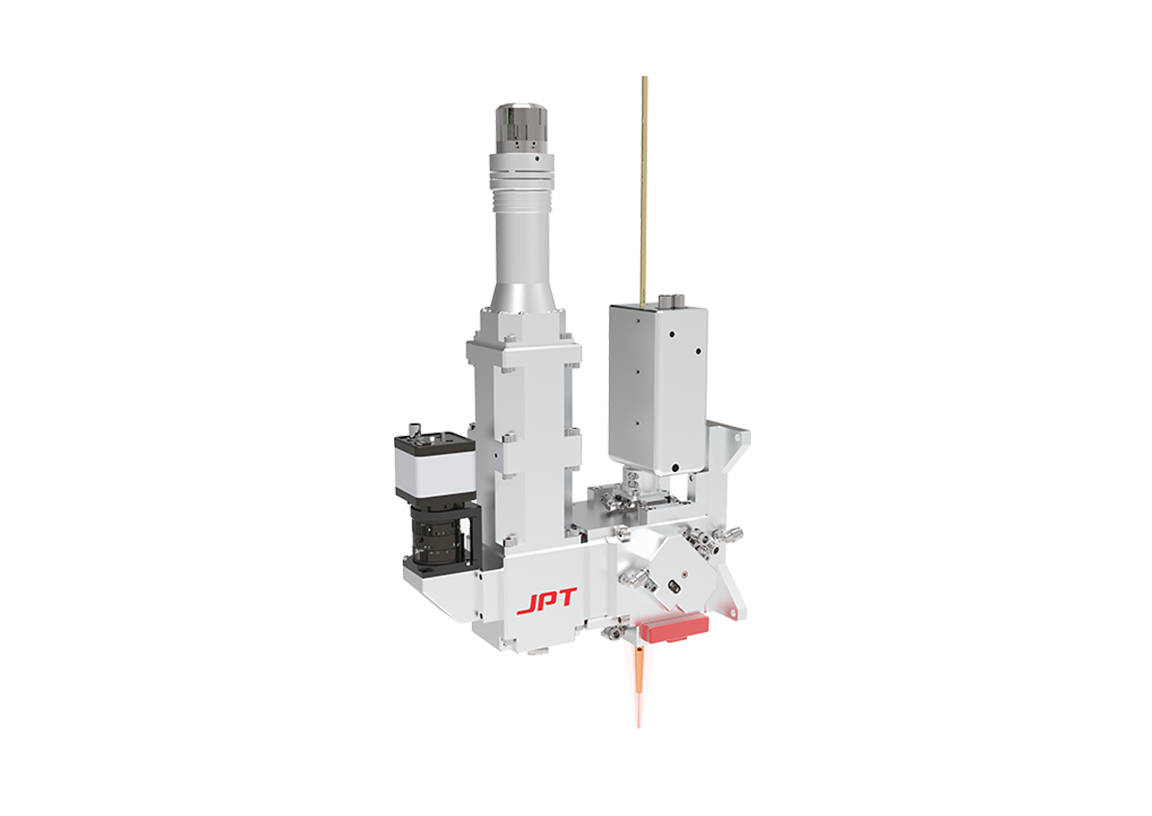

Laser Coaxial Wire Feeding Welding Head

Laser Coaxial Wire Feeding Welding HeadDelivers the metal wire through the center of the ring-shaped spot, where it quickly melts at the laser focal point to form a stable molten pool