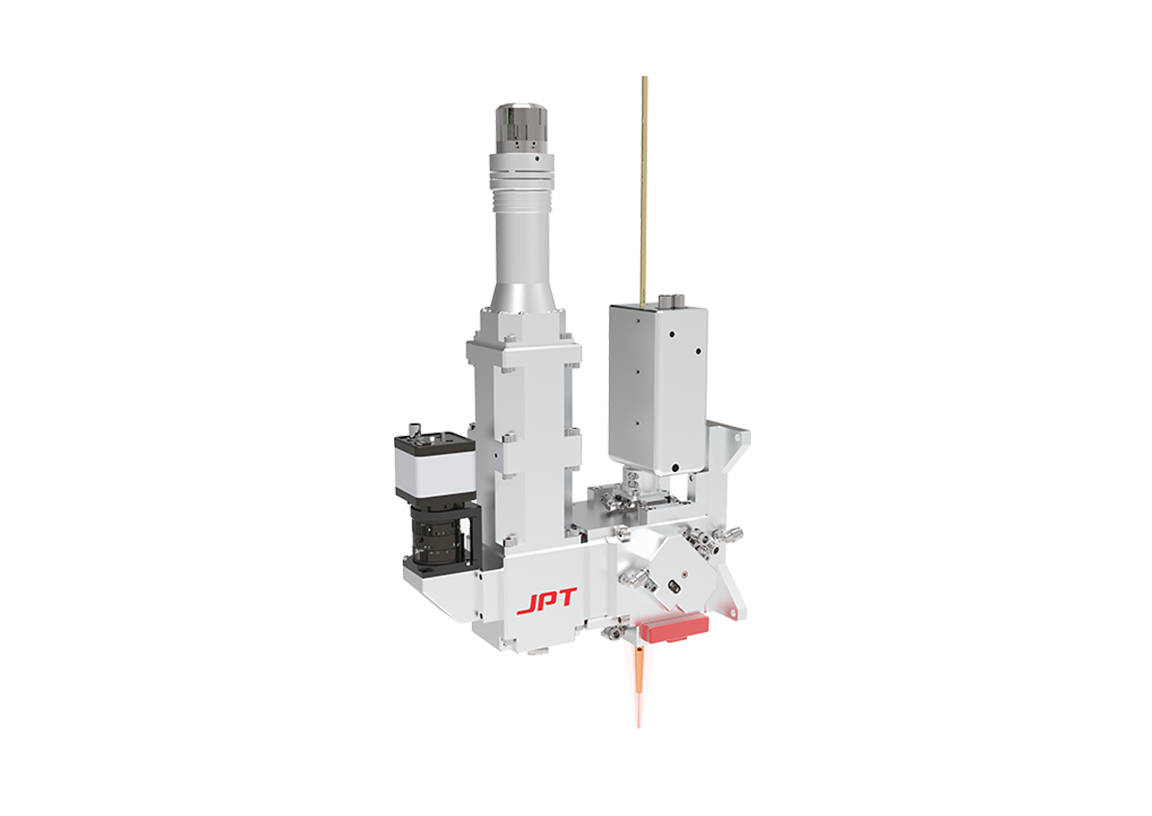

Laser Coaxial Wire Feeding Welding Head

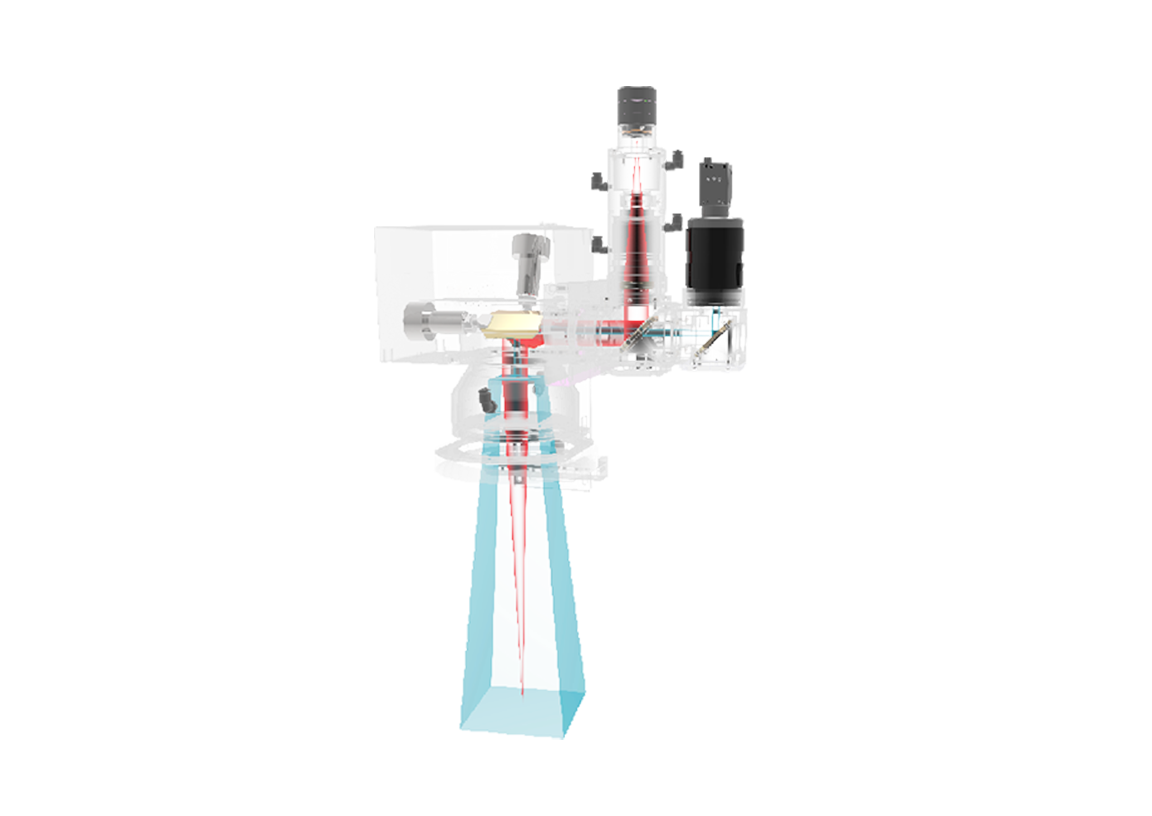

The module reshapes the laser beam into a ring-shaped spot and precisely focuses it on the welding area. The wire feeding system delivers the metal wire through the center of the ring-shaped spot, where it quickly melts at the laser focal point to form a stable molten pool. By synchronizing the welding head with the workpiece along a pre-set path, layers are stacked to achieve high-precision additive manufacturing (3D printing) or precision welding of complex metal components.

-

Product Advantages

-

Related Products

Product Advantages

-

Ring-Shaped Hollow Beam, Coaxial Wire Feeding

Wire passes through the center of the hollow ring spot with no directional constraints, ensuring stable melting.

-

Wide Material Compatibility, High Utilization

Supports a broad range of wire materials with up to 100% utilization efficiency.

-

High Sealing for Long Service Life

Ensures lens cleanliness and durability, extending the lifespan of the welding head.

-

Efficient After-Sales & Lower Maintenance Costs

Quick service response and cost-effective spare parts minimize downtime and expenses.

Related Products

-

Full-Field Scanning Vision Positioning Module

Full-Field Scanning Vision Positioning ModuleThe coordinate mapping algorithm corrects CCD light source drift and distortion caused by the F-theta lens

-

Solder Ball Placement & Welding Module

Solder Ball Placement & Welding ModuleDelivers individual solder balls to the nozzle, where they are heated by a laser beam under an inert gas atmosphere to a molten state

-

Laser Coaxial Wire Feeding Welding Head

Laser Coaxial Wire Feeding Welding HeadDelivers the metal wire through the center of the ring-shaped spot, where it quickly melts at the laser focal point to form a stable molten pool