JPT intelligent equipment covers Chip Resistor, Module Tester, Green Energy, and Advance Laser solutions. Leveraging lasers and precision control, our systems optimize key processes in batteries, automotive electronics, and other industries.

-

OPTICAL DEVICES

-

LASERS

-

CORE MODULES

-

INTELLIGENT SOLUTIONS

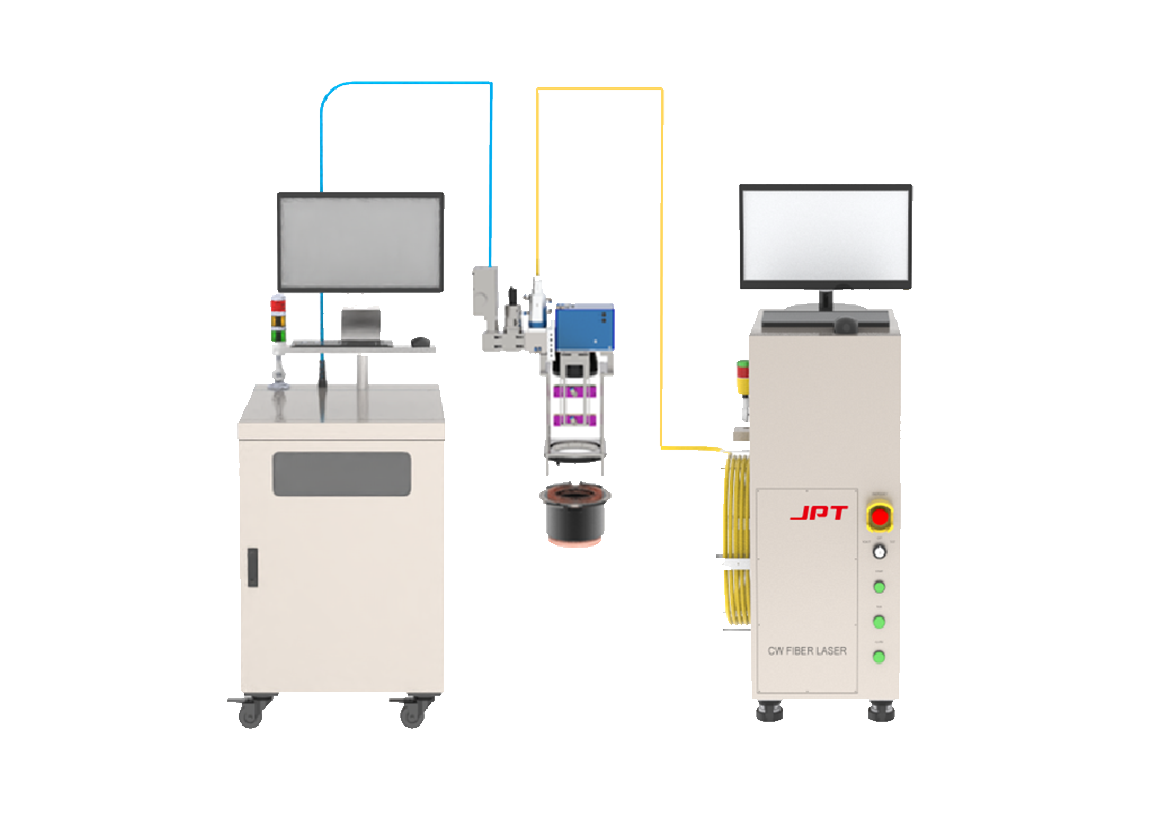

Green Energy Solution

JPT Green Energy Solution enables next-generation battery manufacturing with solutions for tab cutting, cap welding, motor welding, and laser cleaning. Built on in-house lasers and motion systems, our equipment ensures high precision, speed, and adaptability across EV and energy storage applications.

-

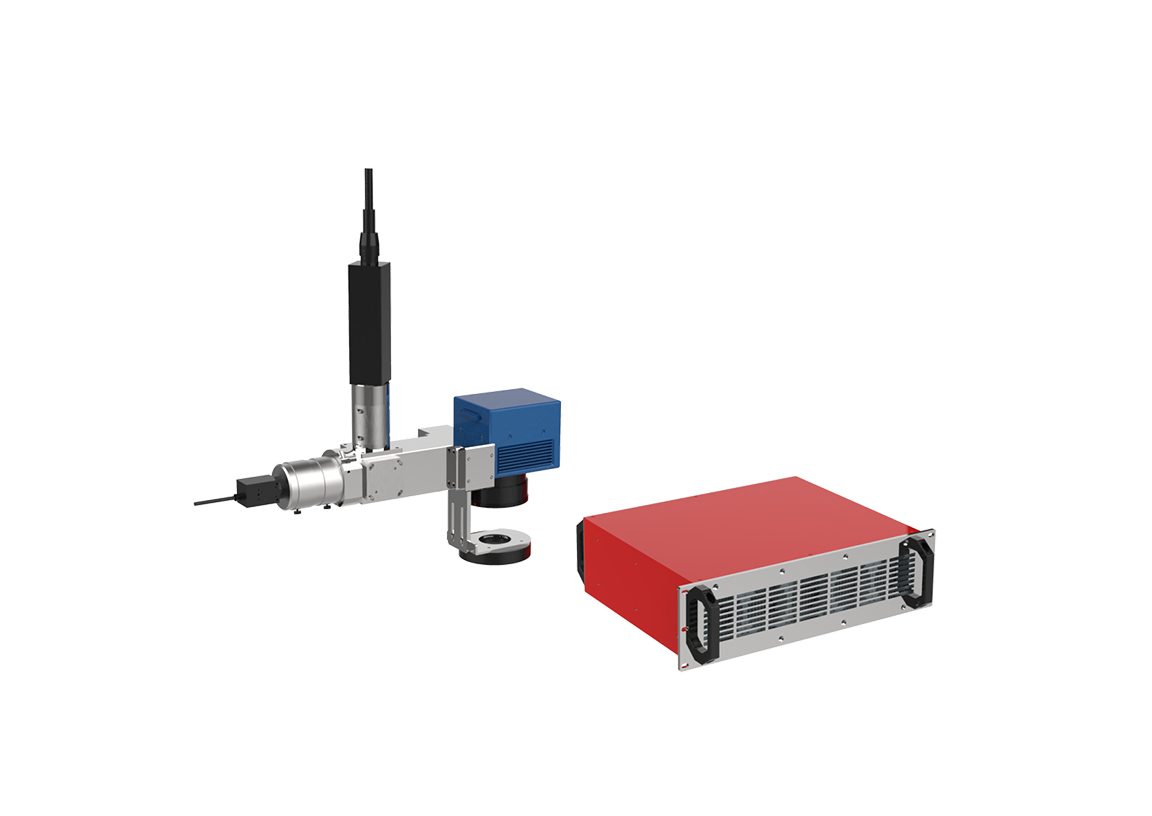

Hairpin Motor Laser Welding Module

Hairpin Motor Laser Welding ModuleBuild for high-precision, high-quality laser welding of hairpin stator windings

-

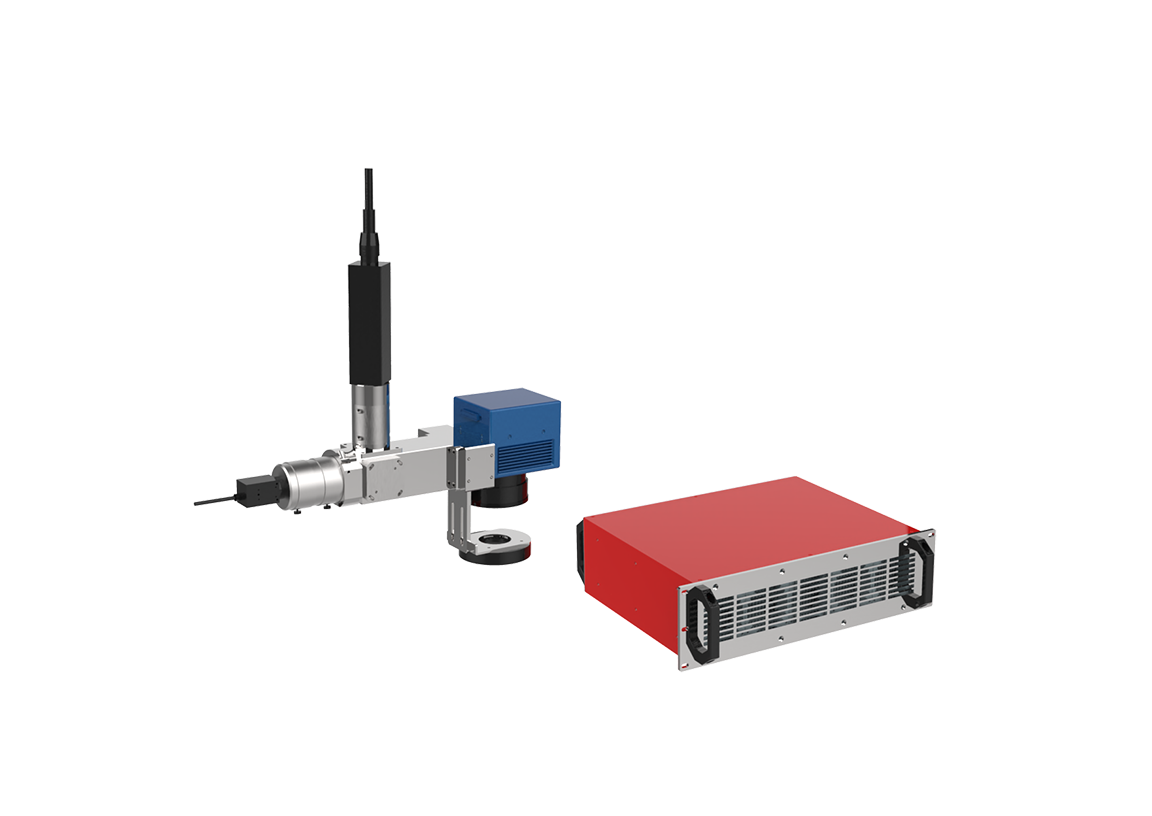

Battery Sealing Welding Module

Battery Sealing Welding ModuleSignificantly reducing spatter and welding defects, ensuring high production yield. It has been widely applied in the power battery industry.

-

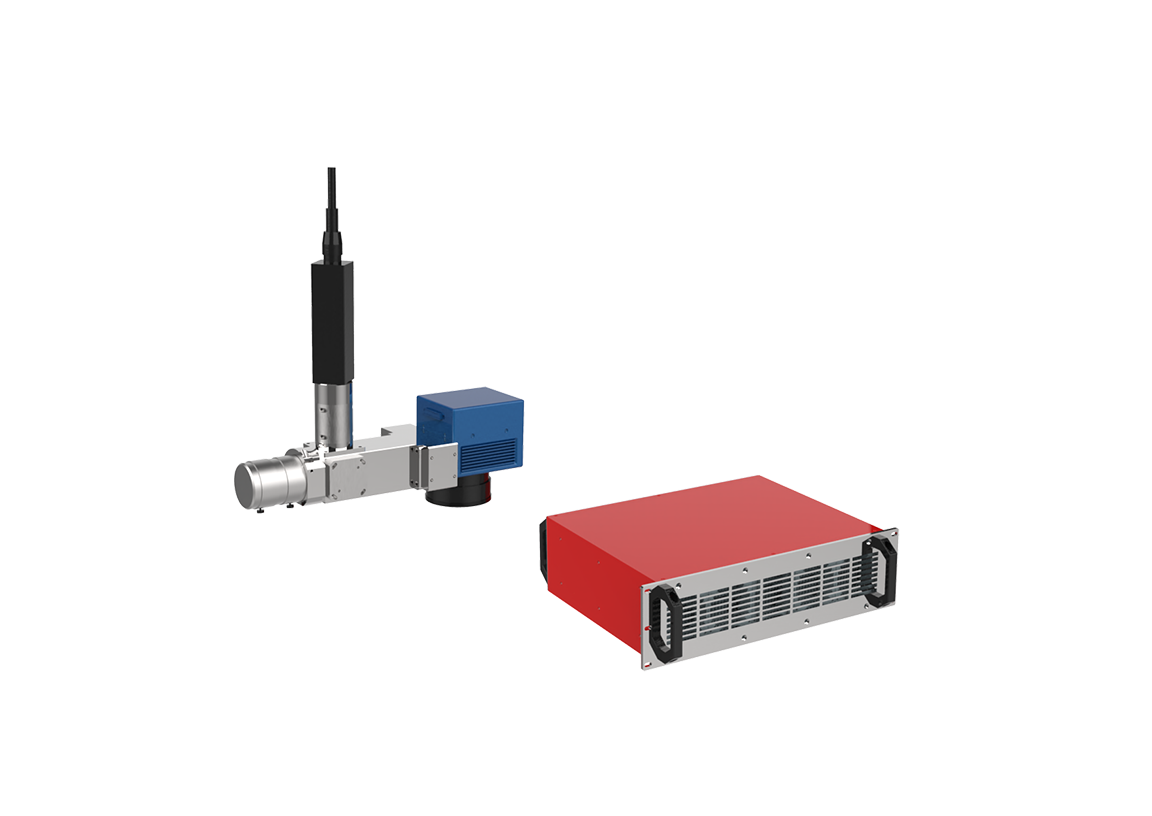

Multi-mode Laser Cleaning Module

Multi-mode Laser Cleaning ModulePrimarily used for cleaning blue films in battery cells, cleaning rollers used in electrode sheet rolling, and cleaning gravure rollers used in pre-coating processes, etc.

-

Single-mode Laser Cleaning Module

Single-mode Laser Cleaning ModuleUsed in cleaning of liquid injection holes in power batteries, cleaning of battery cell terminals, cleaning of shell surfaces, etc

-

Tab Cutting Module

Tab Cutting ModulePrimarily used in the field of cutting tabs for cathodes and anodes of power batteries