Laser Welding

JPT’s laser welding solutions, powered by our self-developed high-power continuous fiber lasers and precision optical control technologies, offer deep penetration, narrow weld seams, low heat input, and minimal distortion—making them ideal for high-precision, high-speed welding applications such as new energy manufacturing, automotive components, and precision electronics, covering applications including power battery casing welding, copper tab welding, cover sealing, and modular metal structure welding.

-

Metal Welding

-

Lithium Battery Welding

-

Silicon Steel Welding

-

Copper Welding

-

Cap Plate, Busbar, and Tab Welding

-

Plastic Welding

-

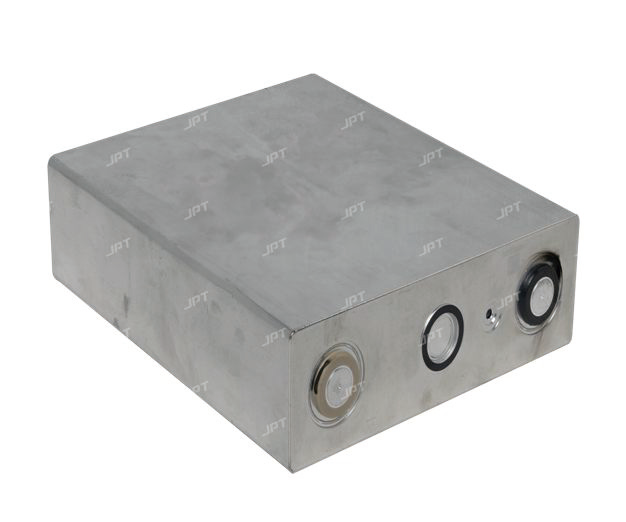

Metal Welding

Metal WeldingJPT’s metal welding technology uses heat, pressure, or both to create strong atomic or molecular bonds at the joint, delivering high-strength, permanent structural connections. It is widely applied in manufacturing, construction, automotive, and aerospace industries—particularly for bridge steel structures, high-speed train carriages, and aircraft engine components where weld quality and structural safety are critical. With advanced laser welding processes and equipment, JPT ensures consistent strength, improved efficiency, and reduced manufacturing costs.

-

Lithium Battery Welding

Lithium Battery WeldingJPT’s lithium battery welding technology uses high-energy laser beams to deliver efficient, precise, and non-contact connections, serving as a critical process in cell manufacturing and assembly. It directly impacts battery performance, safety, and lifespan. Widely applied in tab welding, casing sealing, and module/PACK assembly, the process produces smooth welds with minimal heat-affected zones and high joint strength—improving production efficiency and product consistency to meet the demanding standards of new energy battery manufacturing.

-

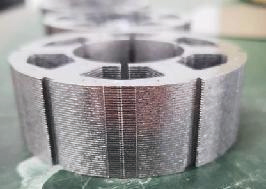

Silicon Steel Welding

Silicon Steel WeldingJPT’s silicon steel laser welding technology uses high-energy laser beams as a heat source to achieve efficient, precise, and low-deformation joining of silicon steel sheets. It is widely applied in the core manufacturing of motors, transformers, and other electromagnetic equipment. The process is designed to maintain mechanical strength while optimizing electromagnetic performance and minimizing thermal impact. With stable beam quality and precise heat input control, JPT’s welding solutions deliver exceptional consistency and efficiency, meeting the stringent requirements of high-end electromagnetic equipment manufacturing.

-

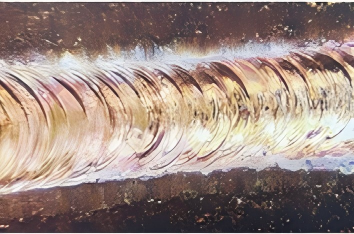

Copper Welding

Copper WeldingJPT's copper laser welding technology addresses the material’s exceptional electrical conductivity, thermal conductivity, and ductility to deliver high-quality joints for applications in electronics, power, and refrigeration. Due to copper’s high reflectivity—especially to infrared lasers—and high thermal conductivity, it is one of the most challenging materials to weld with lasers. By optimizing beam profiles, energy coupling, and welding parameters, JPT achieves uniform weld formation, high joint strength, and minimal thermal impact, making it ideal for high-end manufacturing in new energy batteries, power equipment, electronic packaging, and cooling systems.

-

Cap Plate, Busbar, and Tab Welding

Cap Plate, Busbar, and Tab WeldingJPT offers high-precision laser welding solutions for cap plates, busbars, and tabs to meet the demanding requirements of power battery assembly. The cap plate is the top seal of prismatic or cylindrical cells, typically made of aluminum, stainless steel, or composite materials. The busbar connects internal electrodes to external circuits and requires ultrasonic welding to the coated area, while tab welding firmly joins the cell’s metal lead to the cap plate or busbar. By optimizing beam control and heat input, JPT ensures smooth weld seams, minimal thermal impact, and high joint strength—improving battery safety and production consistency.

-

Plastic Welding

Plastic WeldingJPT’s plastic welding technology uses heat, pressure, or both to melt and solidify the joint between plastic components, creating strong, permanent bonds without adhesives. Suitable for a wide range of thermoplastics, the process ensures secure sealing, uniform weld seams, and a clean finish. With precise heat input control and stable processing performance, JPT’s solutions minimize heat damage and deformation. Plastic welding is widely applied in automotive interiors, electronic housings, medical devices, and packaging containers, providing efficient and reliable non-metallic joining solutions.