New Energy

For batteries, JPT offers one-stop laser solutions from cell processing to PACK assembly. In photovoltaics, our applications span glass drilling, cell cleaving, PERC hole drilling, PL inspection, and perovskite patterning—driving efficient green energy manufacturing.

-

Tab Cutting

-

Cell Assembly

-

PACK Assembly

-

Photovoltaic Cell Manufacturing

-

EV Motor Welding

-

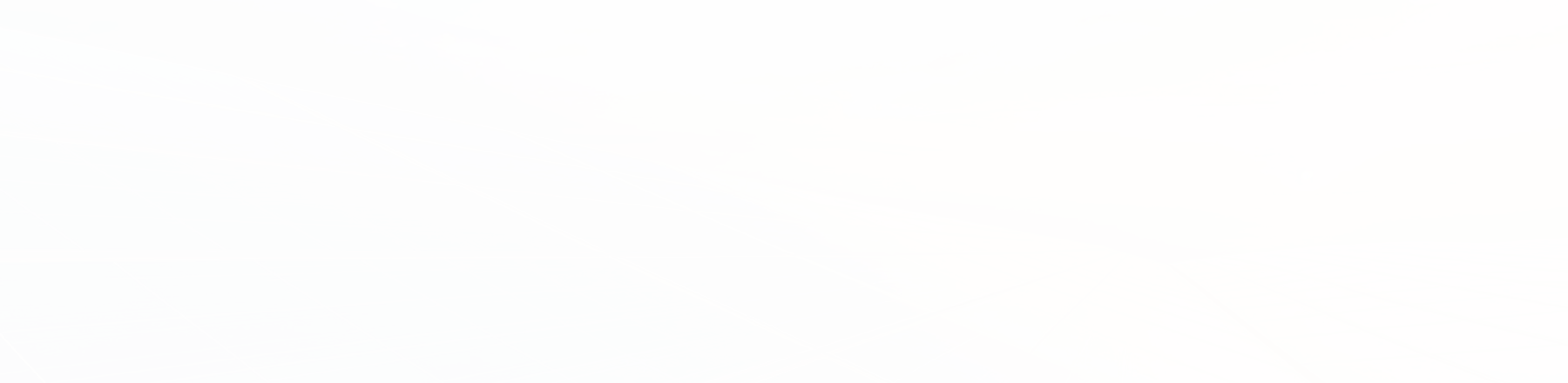

Tab Cutting

Tab CuttingIn the early stages of battery manufacturing, the precision of tab cutting directly impacts welding quality and cell performance. JPT's MOPA pulsed fiber laser-based tab cutting solutions deliver high energy density, adjustable pulse widths, and burr-free cutting of both positive and negative electrode materials. This fine, low-damage process improves welding consistency and battery reliability, meeting high-safety, high-uniformity production standards.

-

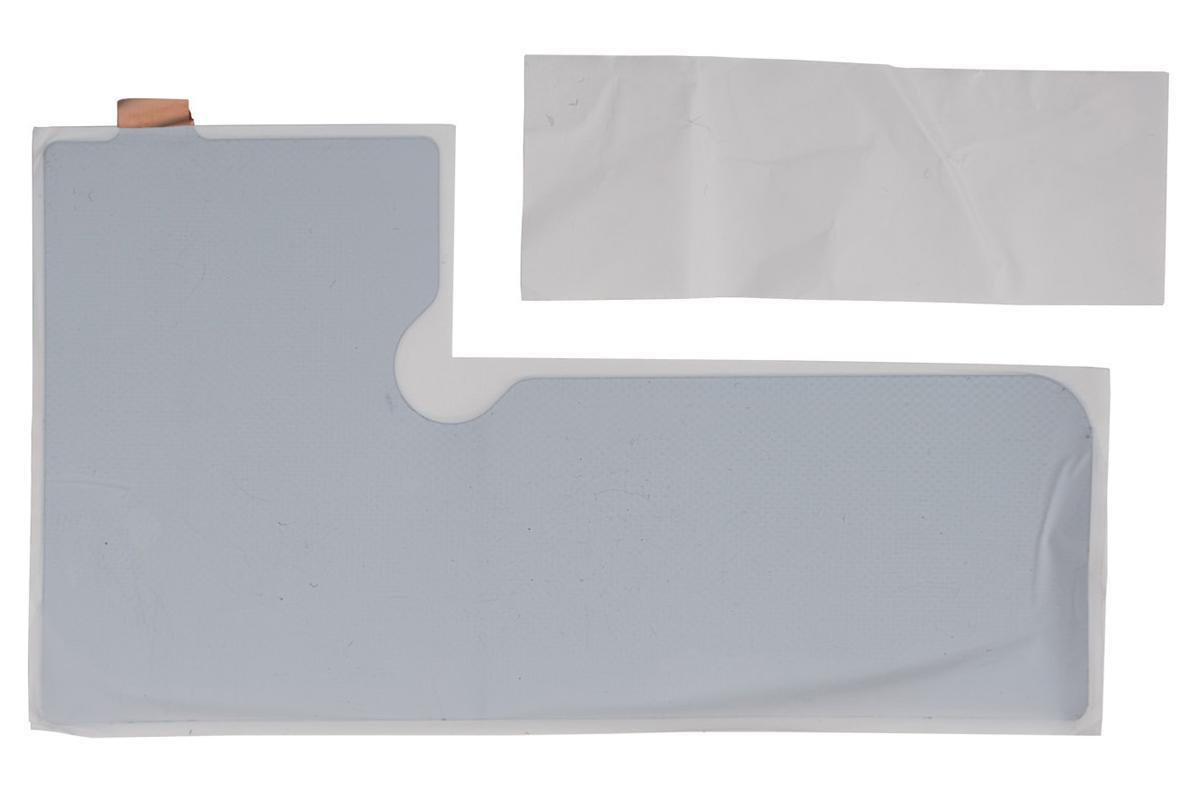

Cell Assembly

Cell AssemblyJPT provides stable, high-performance laser processing solutions for cell assembly processes, including tab welding, flexible connector welding, top cover sealing, and cleaning/welding of sealing pins. MOPA pulsed lasers are used for precision surface cleaning and structural strengthening, while continuous fiber lasers enable deep penetration welding with high connection strength. Integrated with intelligent automation modules, our solutions ensure high first-pass yield for both cylindrical and prismatic cells.

-

PACK Assembly

PACK AssemblyFor PACK-level assembly, JPT offers faster, safer, and more reliable laser processing solutions. Different power-class lasers are applied for welding, cleaning, and texturing processes in module assembly, such as terminal welding, busbar welding, and enclosure seam welding. The resulting welds are flat, splash-free, and highly consistent—supporting large-scale, high-precision production while reducing costs and improving efficiency.

-

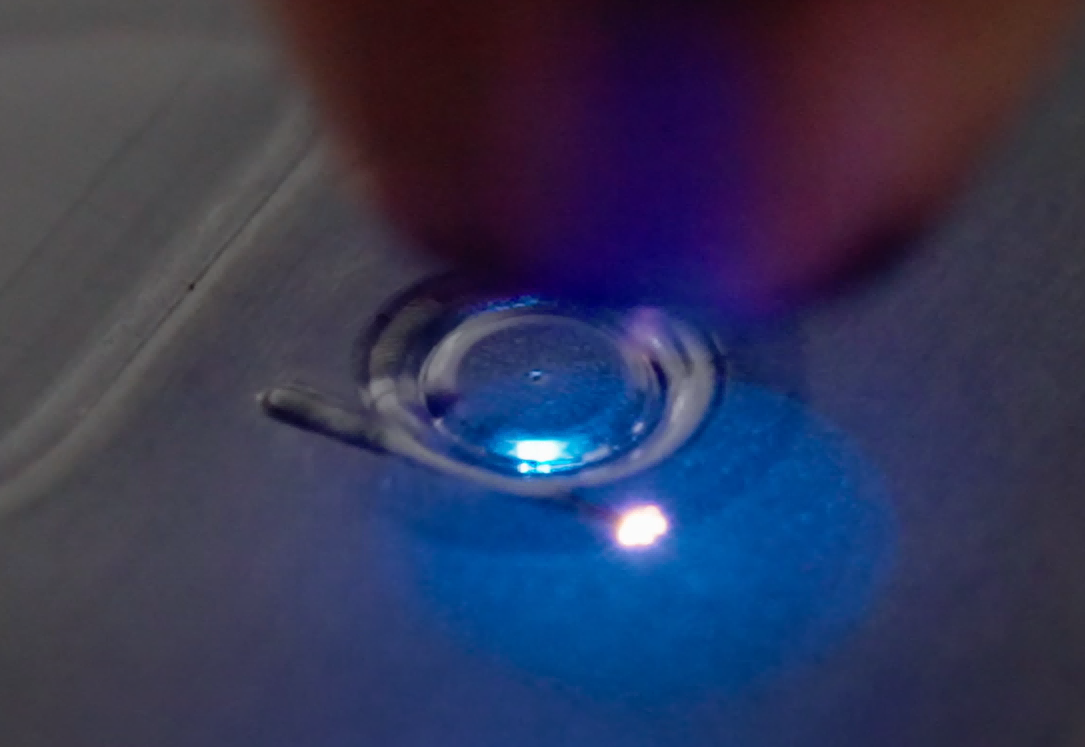

Photovoltaic Cell Manufacturing

Photovoltaic Cell ManufacturingIn the solar industry, JPT covers a wide range of applications, including photovoltaic glass drilling, cell chip non-destructive cleaving, PERC laser hole drilling, PL inspection, photovoltaic glass coding, wafer processing, and perovskite patterning.

For perovskite manufacturing, we offer complete solutions for P1 to P4 laser scribing and edge deletion, enabling high-precision cutting and edge treatment to support large-scale production.

-

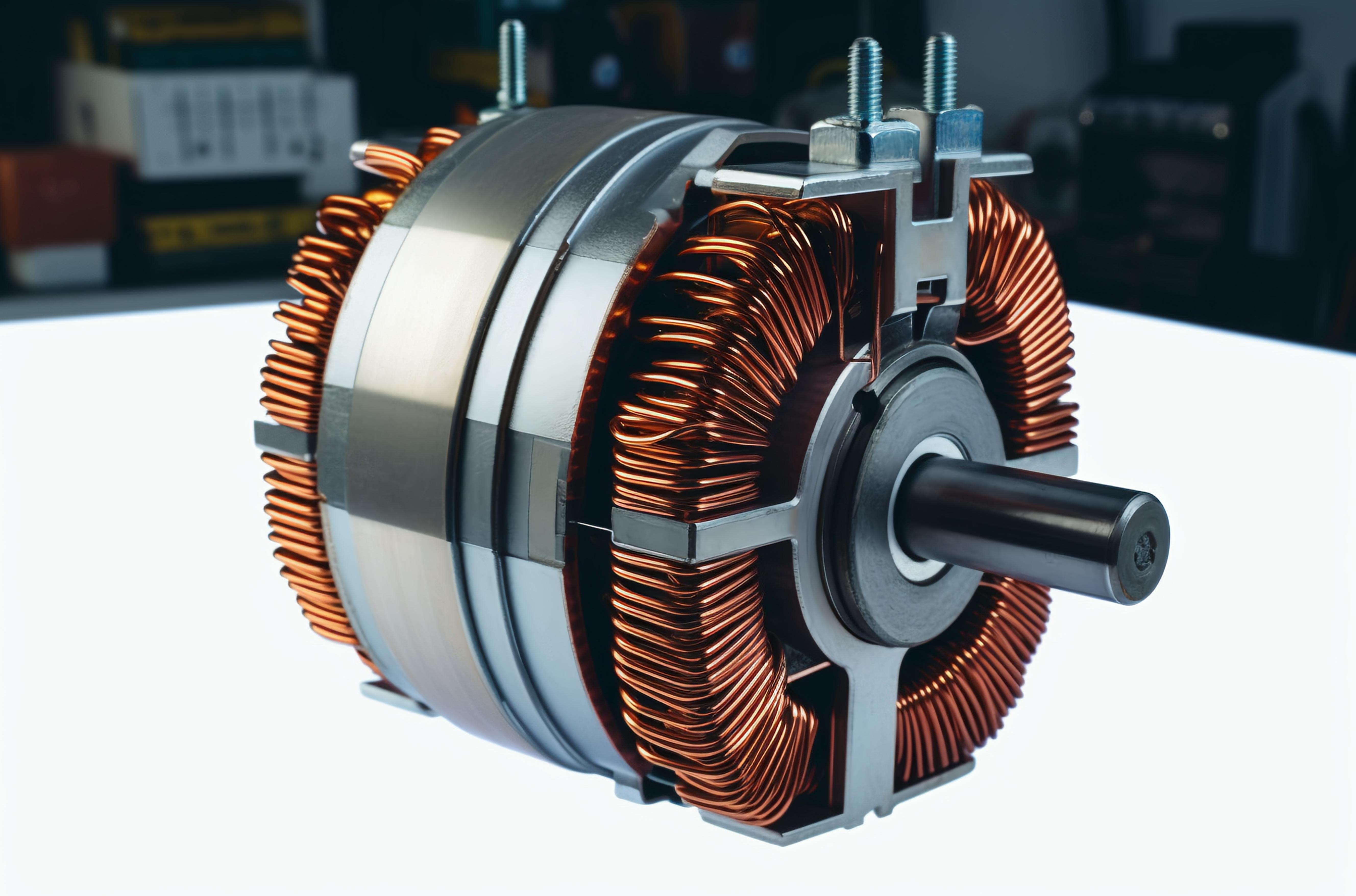

EV Motor Welding

EV Motor WeldingFor electric drive systems, motor welding demands exceptional reliability and efficiency. JPT’s custom-developed laser welding solutions—integrating continuous fiber lasers and MOPA pulsed lasers—deliver splash-free, high-seal-strength welds with strong mechanical bonding. Featuring CCD visual monitoring, three-axis motion control, and intelligent parameter adjustment, our motor welding modules significantly enhance assembly efficiency, safety, and yield for hairpin and other EV motor types.