Laser Drilling

JPT's laser drilling technology is an advanced non-contact microfabrication process that uses high-energy laser beams to precisely create micro-holes, through-holes, or custom-shaped holes on or within material surfaces. By leveraging the interaction between the laser and the material—such as melting, vaporization, or photochemical decomposition—this process achieves highly efficient material removal. Offering high precision, high efficiency, and zero mechanical stress, it is suitable for processing metals, ceramics, glass, films, and more, with wide applications in electronics manufacturing, aerospace, medical devices, and new energy industries.

-

Foil Perforation

-

Glass Drilling

-

Metal Drilling

-

Ceramic Drilling

-

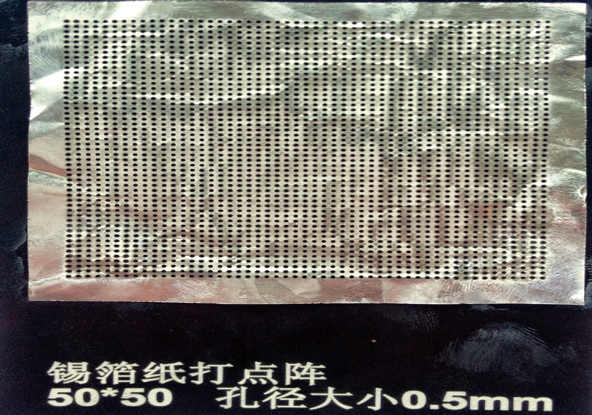

Foil Perforation

Foil PerforationJPT foil perforation technology uses a high-energy-density laser to interact with foil materials through melting, vaporization, or plasma ablation, achieving highly precise micro-holes without deformation. This process is especially suited for flexible, ultra-thin, and fragile foils, offering non-contact, high-efficiency, and stable performance, with broad applications in electronics packaging, precision sensors, and new energy battery manufacturing.

-

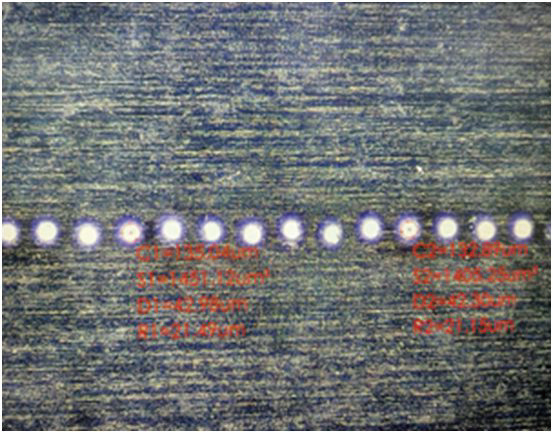

Glass Drilling

Glass DrillingJPT glass drilling technology uses non-contact laser melting, vaporization, or photothermal modification to achieve high-precision micro-holes without cracks or chipping. Unlike traditional mechanical drilling, this process prevents brittle amorphous glass (such as quartz, borosilicate, and sapphire glass) from fracturing due to stress. It delivers high efficiency, stability, and compatibility with various thicknesses, making it ideal for optical components, electronic displays, and precision instrument manufacturing.

-

Metal Drilling

Metal DrillingJPT metal drilling uses high-energy laser beams to perform non-contact precision drilling of through holes, blind holes, and micro-holes in metals such as steel, aluminum, copper, and titanium alloys. The laser–metal interaction enables micro, deep, and complex hole machining that is difficult with traditional methods, delivering high precision, efficiency, and repeatability for aerospace, precision manufacturing, and electronics.

-

Ceramic Drilling

Ceramic DrillingJPT ceramic drilling employs high-energy laser beams to machine micro-holes, through holes, and special-shaped holes in ceramic materials with high hardness, brittleness, and heat resistance. Unlike conventional drilling, which can cause chipping and cracks, laser processing achieves high precision and low damage, ideal for electronic packaging, precision devices, and specialized industrial components.