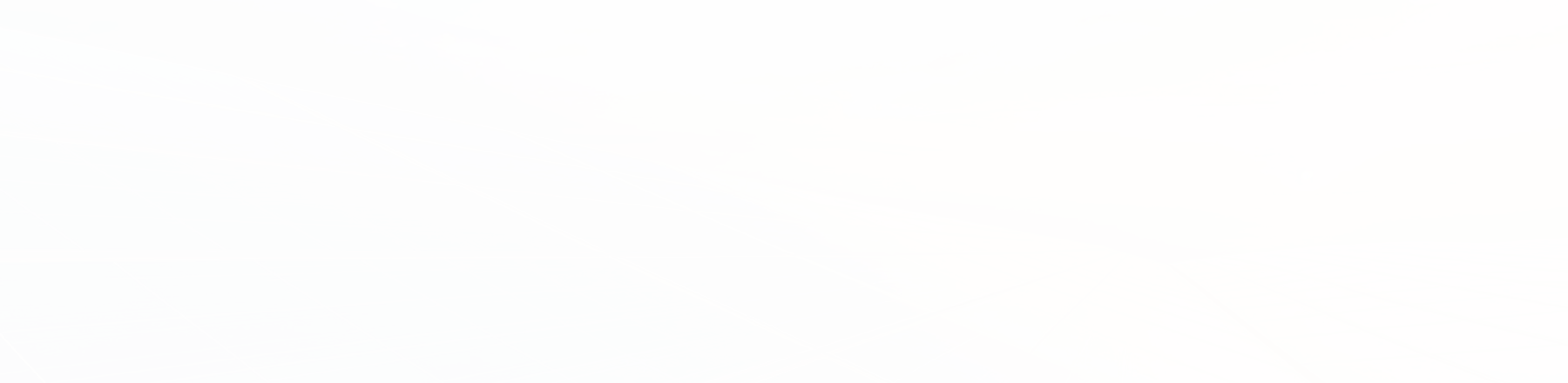

Laser Cladding

JPT’s laser cladding technology is a high-performance surface modification process that uses high-energy lasers to fuse alloy powders onto metal substrates, forming dense, high-adhesion coatings. This process significantly improves wear resistance, corrosion resistance, and fatigue strength, extending component lifespan. It is widely applied in mold repair, automotive parts remanufacturing, and industrial equipment maintenance. With precise process control and stable performance, JPT laser cladding delivers high-quality, cost-effective surface enhancement and repair solutions.

-

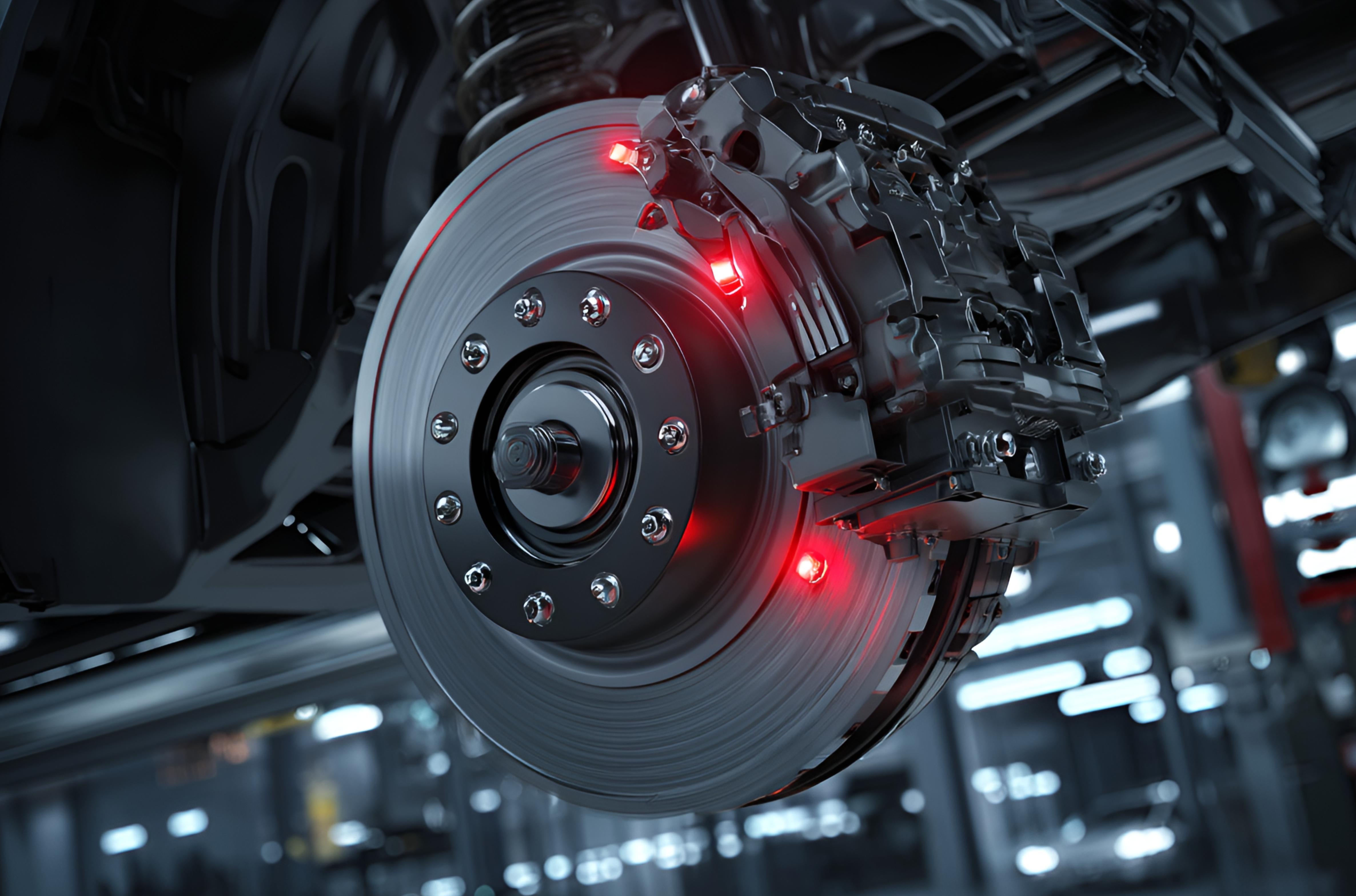

Brake Disc Laser Cladding

-

Brake Disc Laser Cladding

Brake Disc Laser CladdingJPT’s brake disc laser cladding is an efficient surface repair and strengthening technology. It uses a high-energy-density laser beam to clad wear- and heat-resistant alloy materials onto the disc surface, forming a dense metallurgically bonded coating. This process significantly improves wear resistance, thermal stability, and crack resistance, extending service life and restoring surfaces damaged by friction. It is widely used in rail transit, high-end automobiles, and heavy machinery braking systems, ensuring both performance enhancement and cost efficiency.