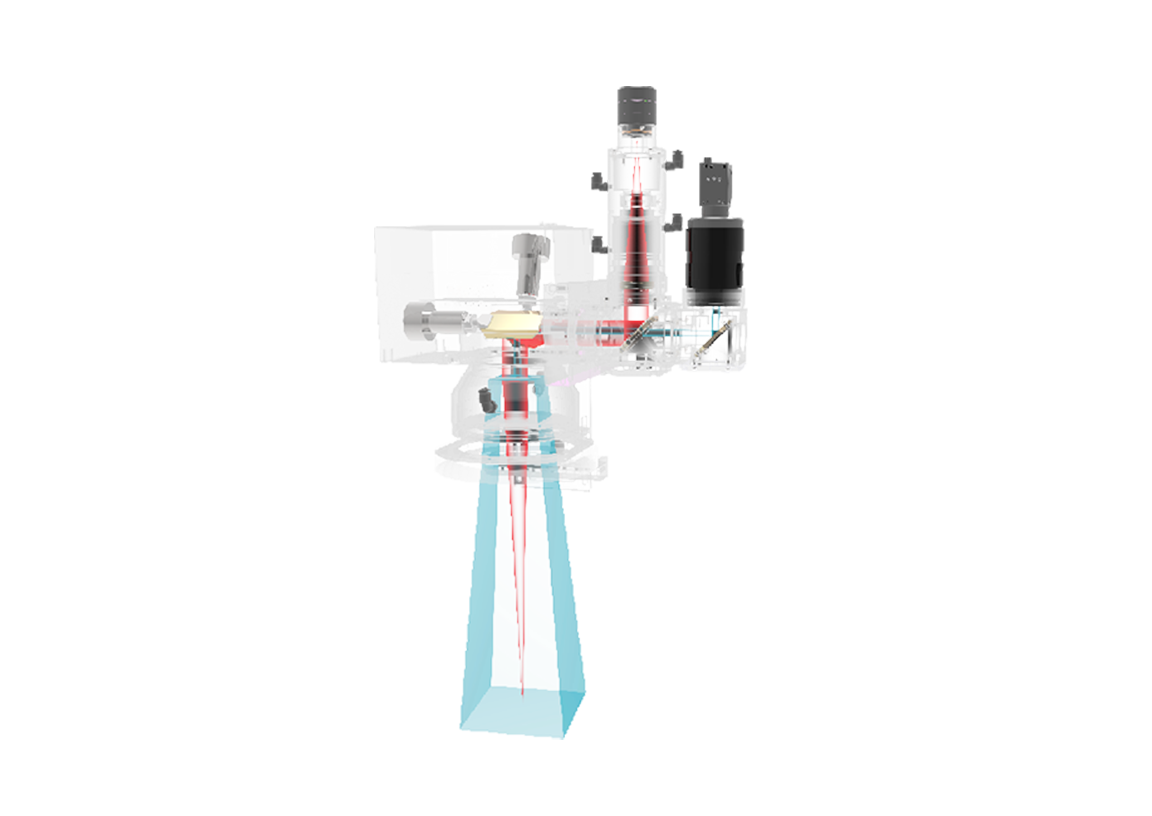

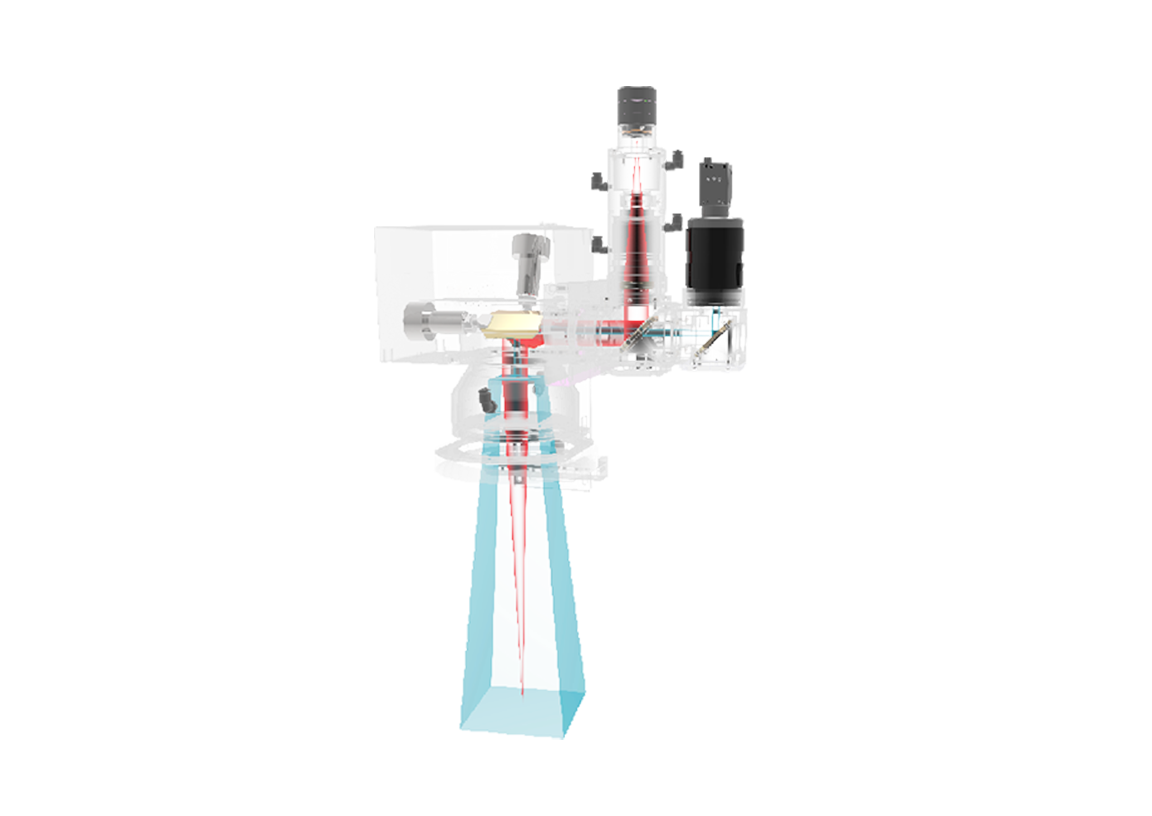

Full-Field Scanning Vision Positioning Module

By coupling lenses, the CCD optical path and the laser optical path are precisely aligned. Galvo scanning is digitally mapped to the CCD position matrix, allowing coordinate mapping algorithms to correct drift and distortion induced by the F-theta lens. This enables accurate CCD positioning across the entire galvo scanning field without external X and Y axis movement.

-

Product Advantages

-

Related Products

Product Advantages

-

Axis-Free Precision

Eliminates motion errors, achieving superior positioning accuracy without expensive fixtures, while still supporting high-precision welding.

-

Static Full-Field Operation

Wide-field galvo scanning at high speed requires no X or Y axis assistance. Products remain static while full-field CCD positioning is achieved. Recognition and welding are synchronized, significantly improving processing efficiency.

-

Long-Term Stability

Proprietary digital calibration algorithms precisely compensate for lens drift and distortion. With one-time calibration, accurate positioning across the entire field is ensured—eliminating repetitive, time-consuming recalibrations.

Full-Field Scanning Vision Positioning Module

Related Products

-

Full-Field Scanning Vision Positioning Module

Full-Field Scanning Vision Positioning ModuleThe coordinate mapping algorithm corrects CCD light source drift and distortion caused by the F-theta lens

-

Solder Ball Placement & Welding Module

Solder Ball Placement & Welding ModuleDelivers individual solder balls to the nozzle, where they are heated by a laser beam under an inert gas atmosphere to a molten state

-

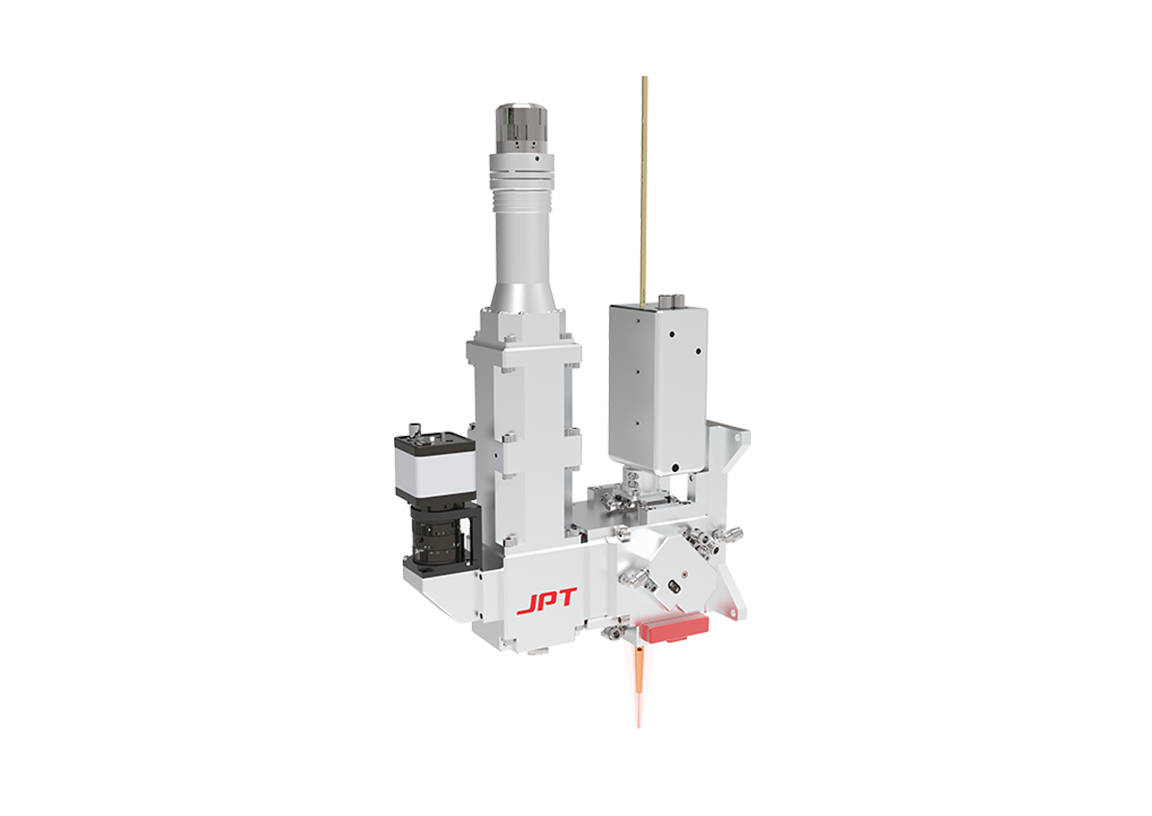

Laser Coaxial Wire Feeding Welding Head

Laser Coaxial Wire Feeding Welding HeadDelivers the metal wire through the center of the ring-shaped spot, where it quickly melts at the laser focal point to form a stable molten pool