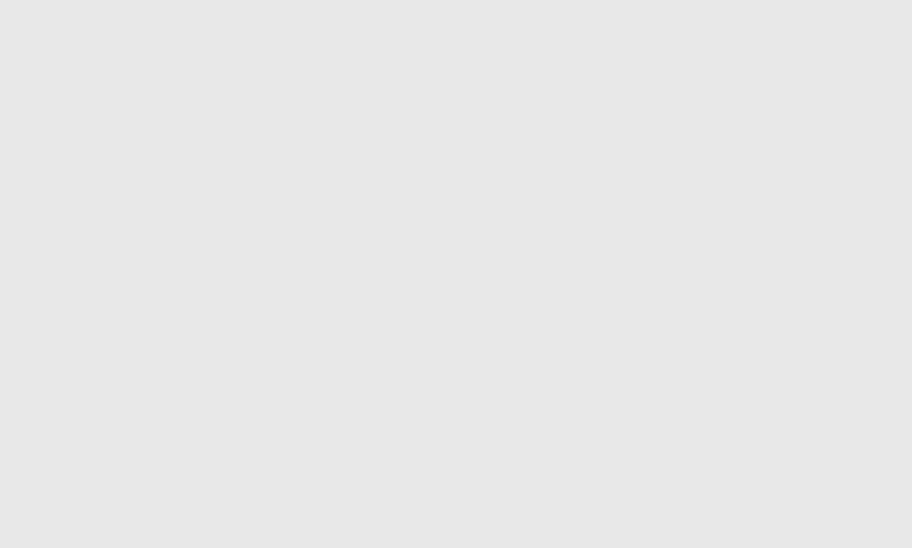

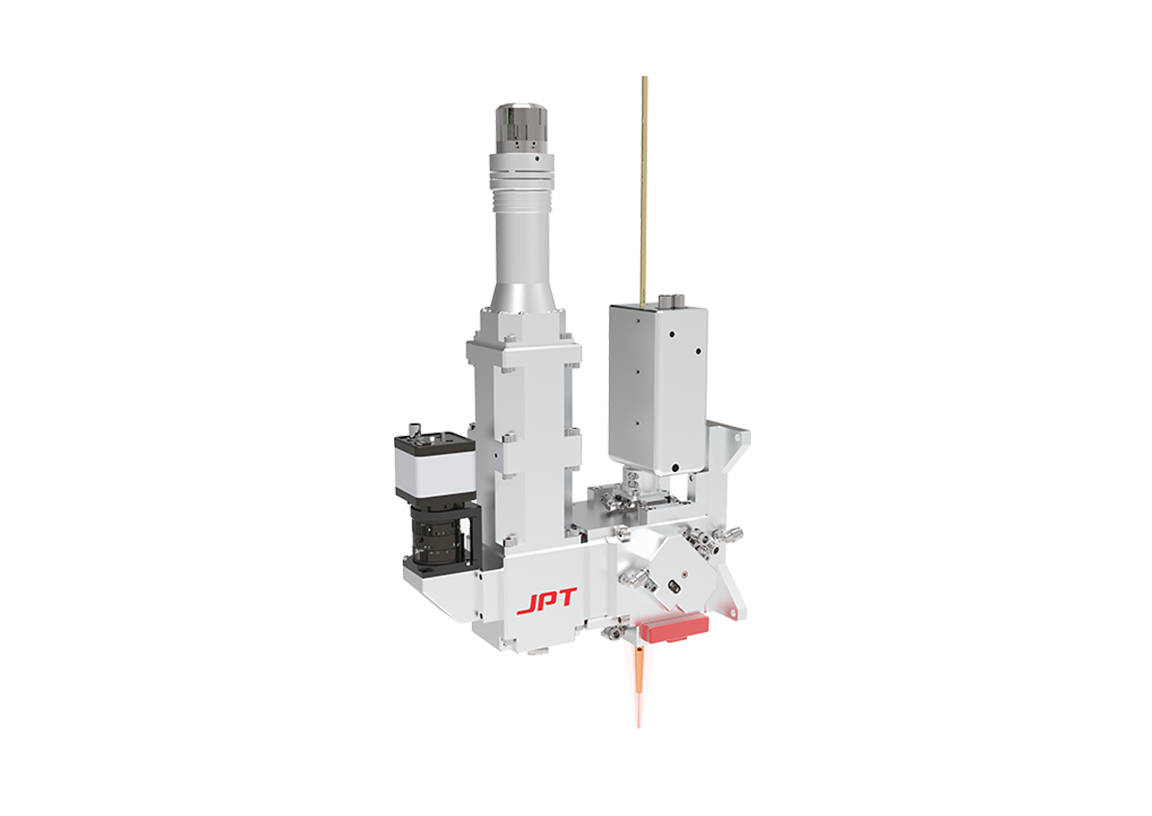

Solder Ball Placement & Welding Module

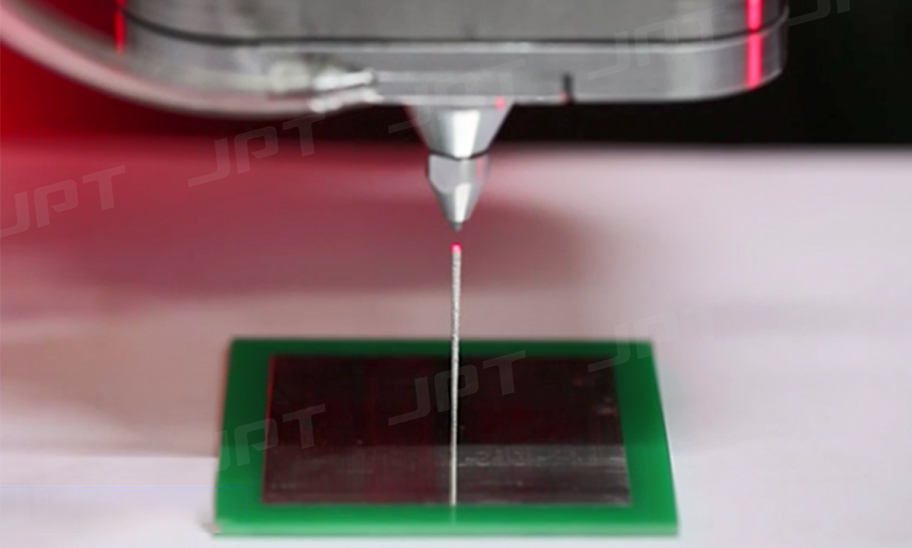

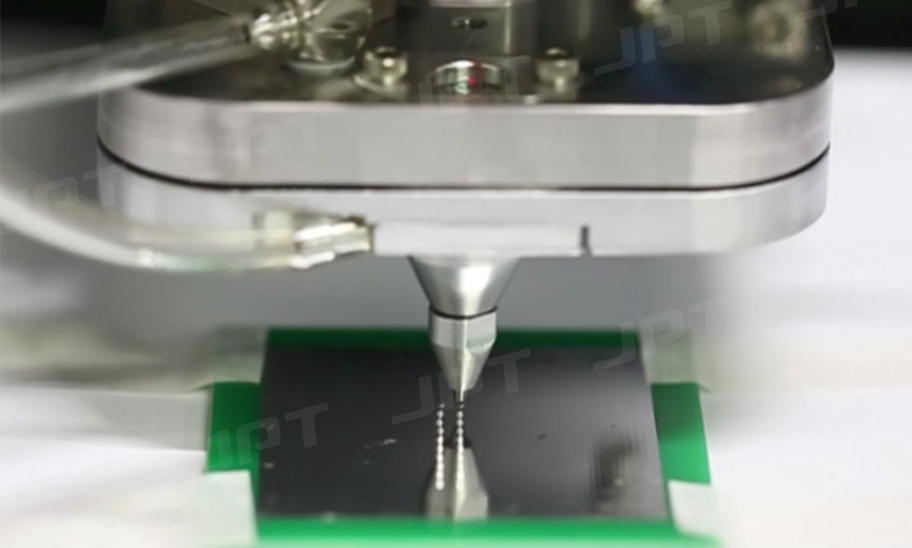

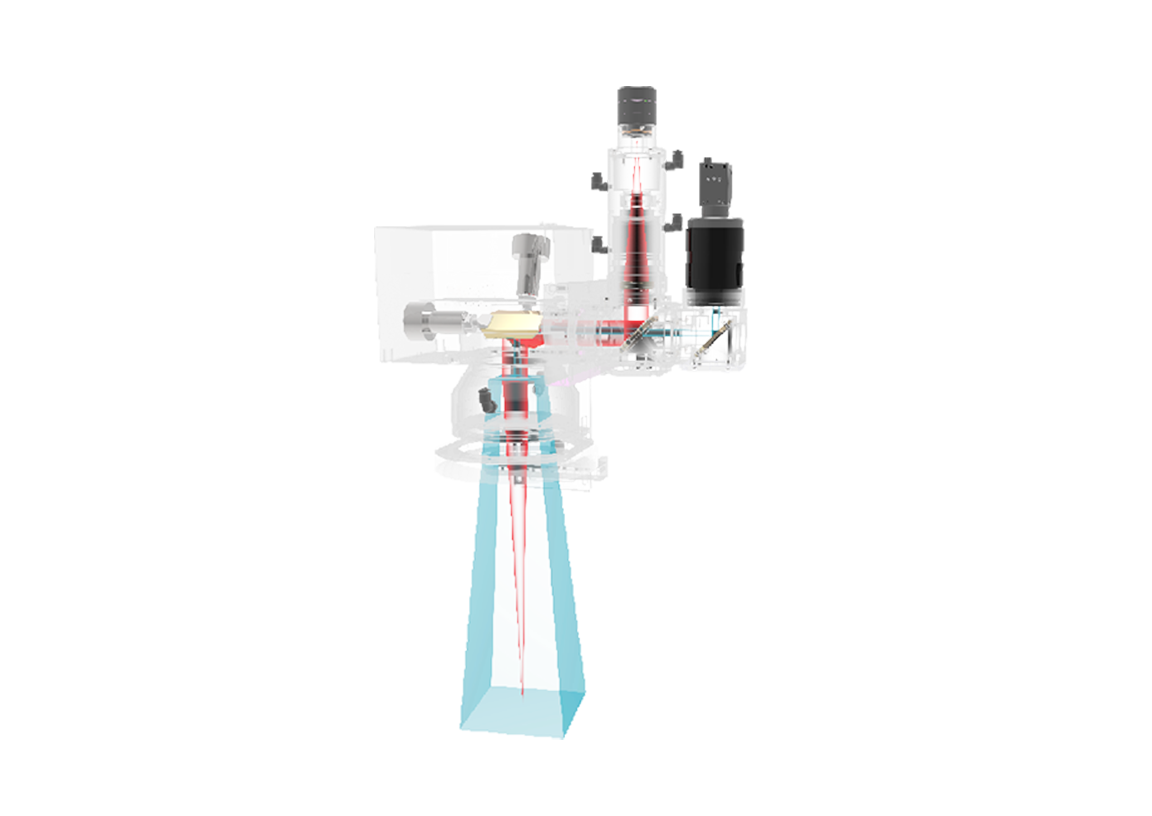

The solder ball placement module delivers individual solder balls to the nozzle, where they are heated by a laser beam under an inert gas atmosphere to a molten state. The molten solder droplet is then ejected onto the workpiece surface, where it wets, diffuses, and forms a bonding layer, ensuring a reliable connection.

-

0.2≤Φ≤1.8mmSolder ball size

-

4-6 pxs/sPlacement speed

-

±5 umVision Positioning Accuracy

-

Product Advantages

-

Applications

-

Specifications

-

Related Products

Product Advantages

-

High-Speed Precision

Fast solder ball welding in an inert gas atmosphere with placement efficiency up to 4–6 pcs/s. The entire laser heating and droplet ejection process is completed within 0.2 seconds.

-

Independent & Flexible Control

Proprietary ball placement mechanism and control system with flexible configuration and easy maintenance.

-

Wide Size Compatibility

Supports a broad range of solder ball diameters (0.2–1.8 mm), meeting diverse workpiece size requirements.

-

Micro-Precision Positioning

Equipped with a high-precision CCD vision system, enabling accurate soldering of micro-components and delicate devices.

Applications

-

Single-Point Matrix Welding

Single-Point Matrix Welding -

Fixed-Point Consistency Test

Fixed-Point Consistency Test -

Matrix Repeated Welding

Matrix Repeated Welding

Specifications

-

Solder Ball Placement & Welding Module

-

Laser Wavelength

-

Laser Power

-

Solder Ball Size

-

Placement Speed

-

Optical Fiber Interface

-

Vision Positioning Accuracy

-

Cooling Method

-

Collimation Distance

-

Focal Length

-

Overall Dimensions

-

Weight

-

Solder Ball Placement & Welding Module

-

Laser Wavelength1070 nm, 976 nm, 915 nm

-

Laser Power75-300W

-

Solder Ball Size0.2 mm ≤ Φ ≤ 1.8 mm

-

Placement Speed4 - 6 pxs/s

-

Optical Fiber InterfaceD80 SMA905 FC

-

Vision Positioning Accuracy±5 µm

-

Cooling MethodAir Cooled

-

Collimation Distance18 mm, 40 mm

-

Focal Length45mm, 70mm

-

Overall Dimensions150 × 300 × 90 mm

-

Weight2.5 kg

-

Related Products

-

Full-Field Scanning Vision Positioning Module

Full-Field Scanning Vision Positioning ModuleThe coordinate mapping algorithm corrects CCD light source drift and distortion caused by the F-theta lens

-

Solder Ball Placement & Welding Module

Solder Ball Placement & Welding ModuleDelivers individual solder balls to the nozzle, where they are heated by a laser beam under an inert gas atmosphere to a molten state

-

Laser Coaxial Wire Feeding Welding Head

Laser Coaxial Wire Feeding Welding HeadDelivers the metal wire through the center of the ring-shaped spot, where it quickly melts at the laser focal point to form a stable molten pool