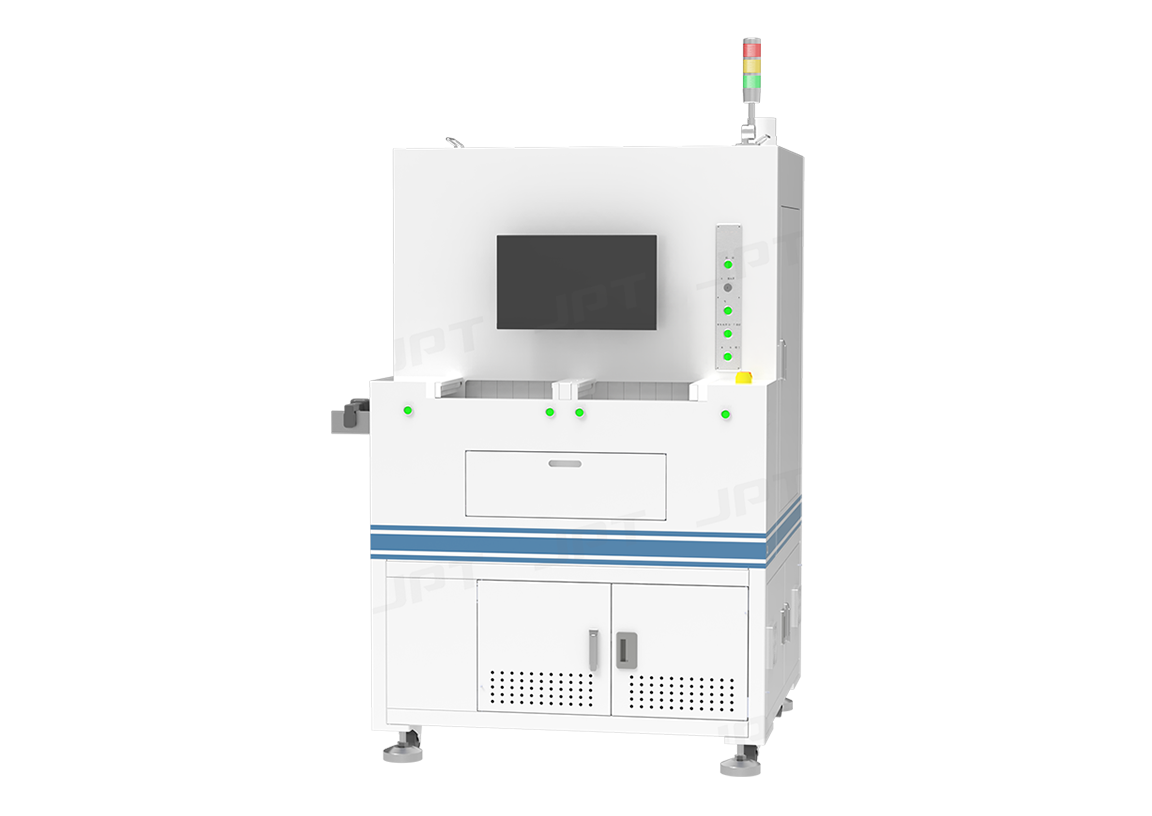

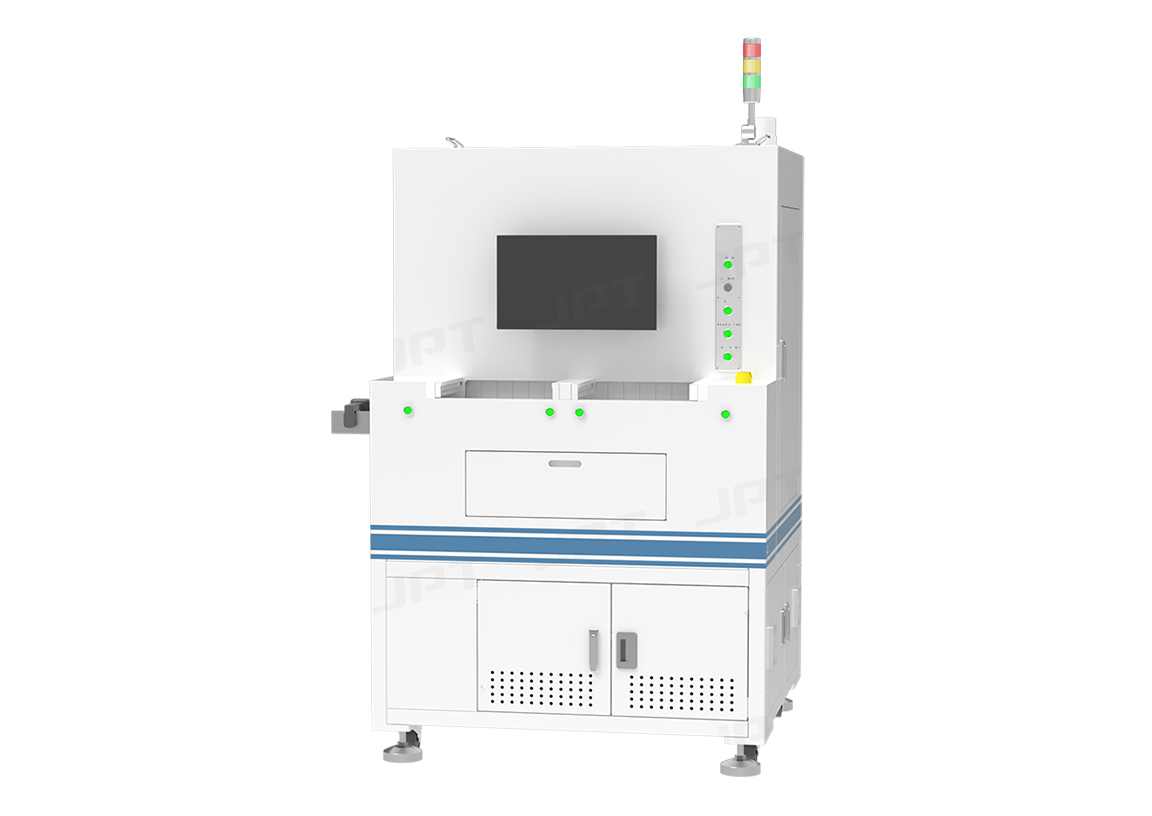

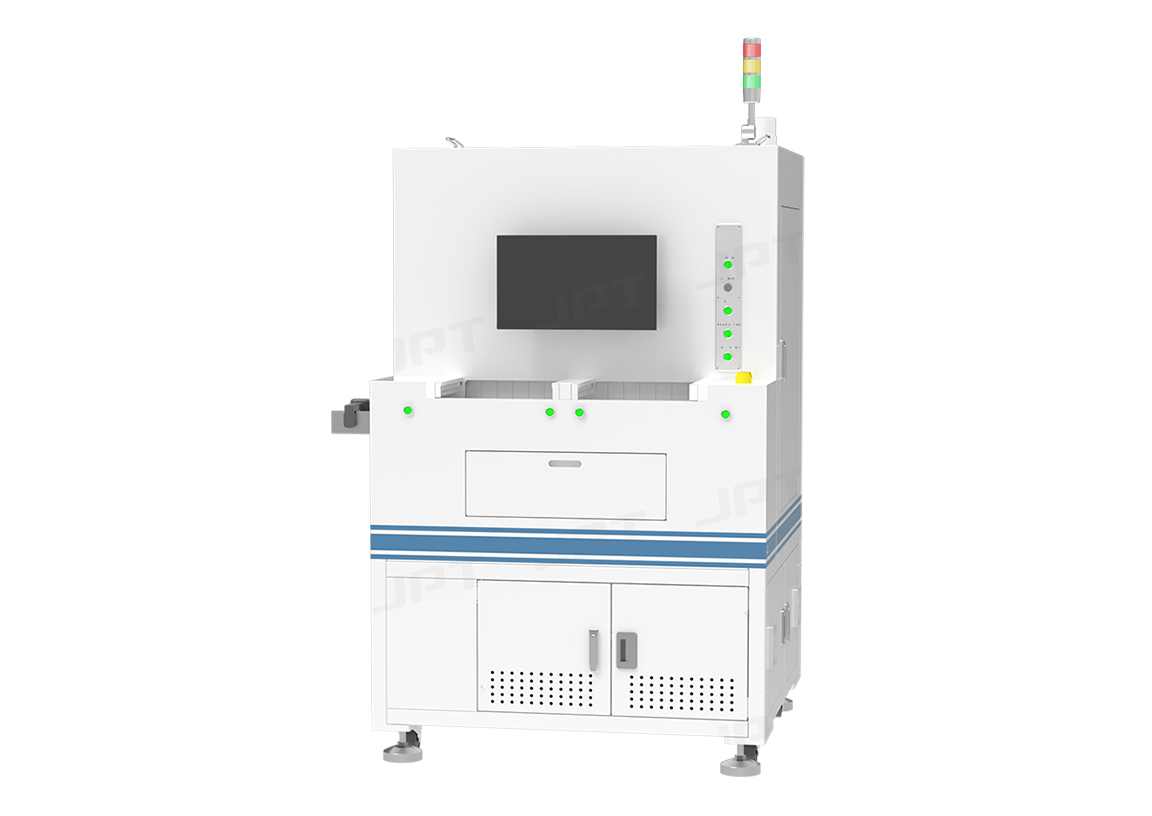

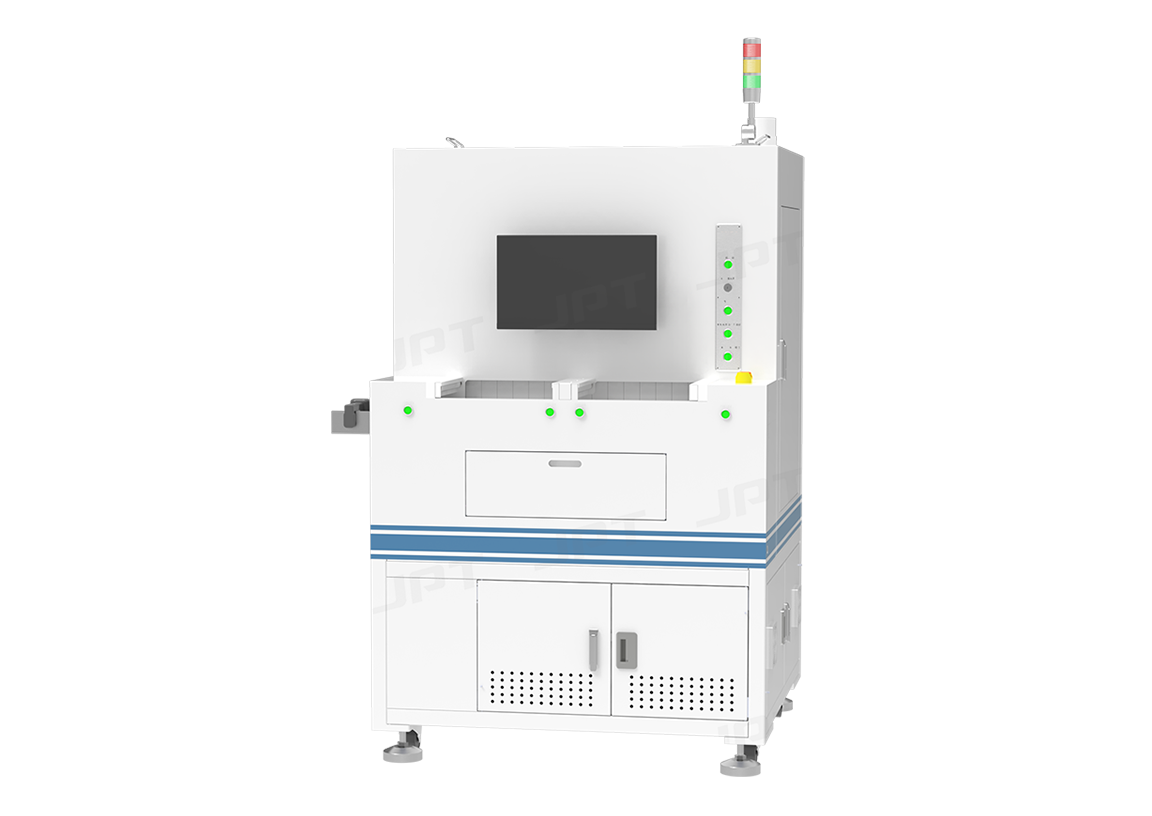

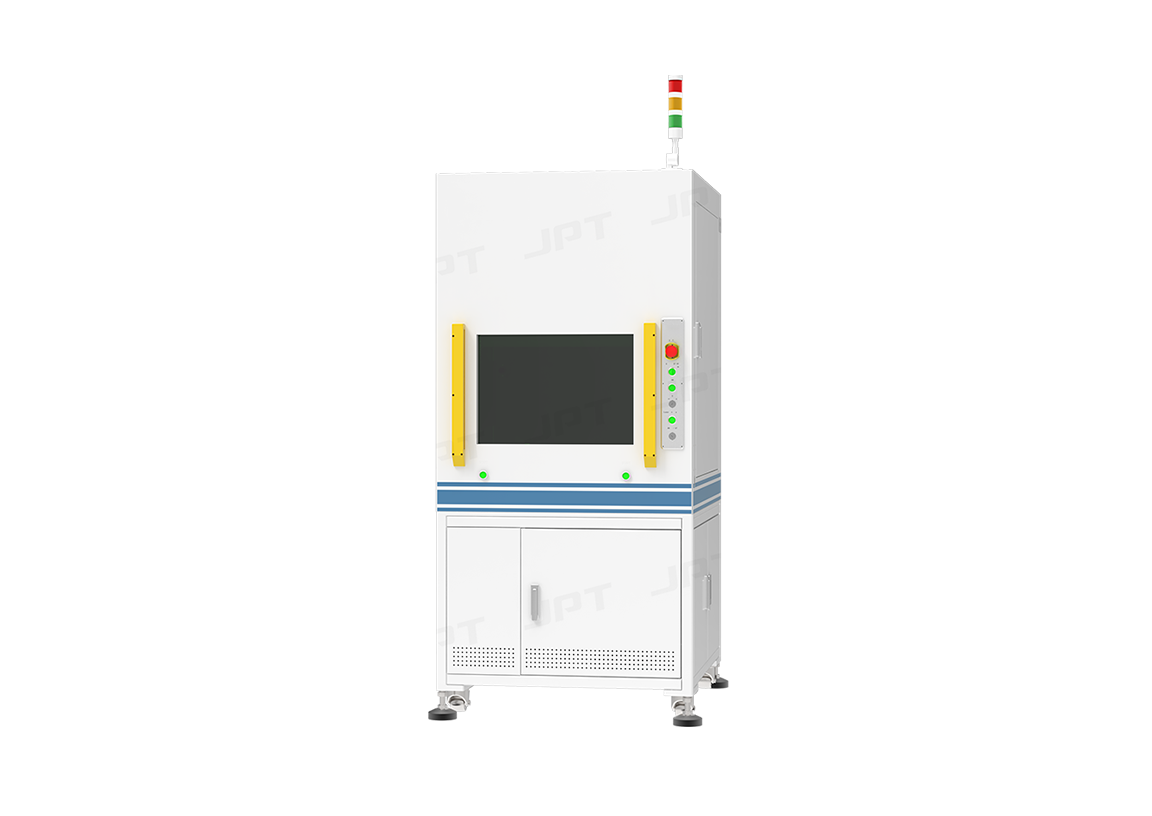

Dual-Station Five-Axis Galvo Welding System

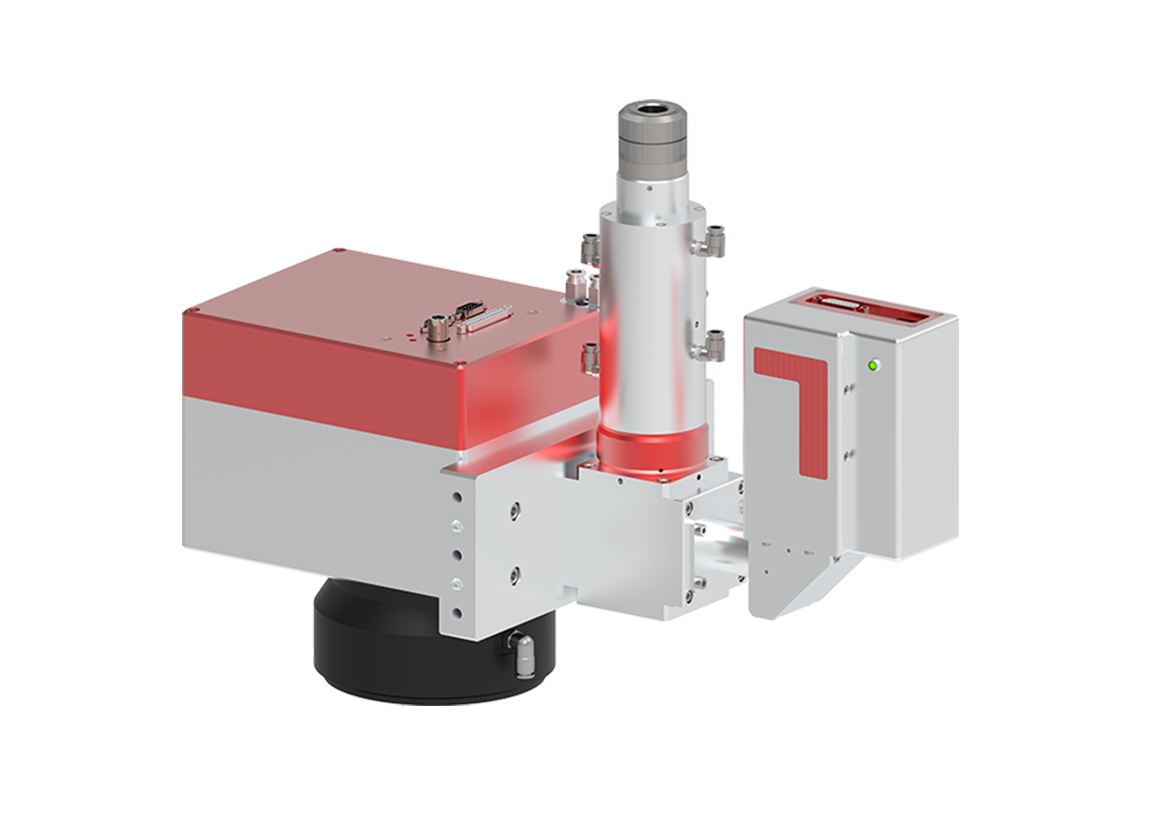

This system integrates JPT's self-developed MOPA fiber laser with an innovative dual-station five-axis linkage structure and coaxial vision positioning system. Through galvo scanning, it achieves precise trajectory control of weld seams on complex 3D surfaces.

-

± 40μmPositioning Accuracy

-

50μmMinimum Drilling Diameter

-

M² < 1.3Beam Quality

-

Product Advantages

-

Specifications

-

Related Products

-

Application Solutions

Product Advantages

-

Self-Developed Laser Source

Powered by JPT's proprietary MOPA fiber laser, offering superior pulse control capability to meet diverse precision welding process requirements.

-

In-Process Monitoring, Real-Time Control

Built-in WPD welding quality monitoring module provides real-time feedback on welding quality fluctuations, ensuring weld consistency and reliability.

-

Programmable Welding Paths for Multi-Spec Products

Supports flexible editing of welding trajectories to adapt to different product sizes and structures, achieving excellent weld appearance and mechanical strength.

-

Dual Five-Axis Linkage Platform for Enhanced Precision

Integrated with an XYZR1R2 five-axis system and coaxial vision platform, enabling high-precision welding of complex three-dimensional products.

Specifications

-

Dual-Station Welding System

-

Laser Source

-

Average Power

-

Wavelength

-

Beam Quality

-

Focusing Method

-

Equipment Dimensions

-

Positioning Accuracy

-

Repeat Positioning Accuracy

-

Minimum Drilling Diameter

-

Applicable Materials

-

Control Software

-

Dual-Station Welding System

-

Laser SourceIR ns

-

Average Power80W

-

Wavelength1064nm

-

Beam QualityM² < 1.3

-

Focusing MethodGalvanometer

-

Equipment Dimensions1200 mm (L) × 1200 mm (W) × 2000 mm (H)

-

Positioning Accuracy± 40 µm

-

Repeat Positioning Accuracy± 10 µm

-

Minimum Drilling Diameter50 μm

-

Applicable MaterialsTitanium, Stainless Steel, Aluminum

-

Control SoftwareJPT

-

Related Products

-

Fully Automatic High-Precision Laser Marking Equipment

Fully Automatic High-Precision Laser Marking EquipmentEquipment for marking processing on glass, resin, wafers, etc.

-

Dual-Station Five-Axis Galvo Welding System

Dual-Station Five-Axis Galvo Welding SystemEquipped with a WPD in-process welding quality monitoring module, the system enables real-time closed-loop control during welding, ensuring a yield rate of 99.9%.

-

Glass Ink Drilling Equipment

Glass Ink Drilling EquipmentDesigned for drilling glass ink layers in displays for smartphones, tablets, and computers.

-

Fully Automatic Laser Invisible QR Code Equipment

Fully Automatic Laser Invisible QR Code EquipmentQR codes provide traceability and anti-counterfeiting functionality throughout subsequent processes

-

3C Five-Axis Laser Linkage Universal Platform

3C Five-Axis Laser Linkage Universal PlatformIntegrates large-range five-axis precision positioning with localized three-axis high-speed laser scanning and tracking.

-

Welding Process Detection System

Welding Process Detection SystemReal-time analysis for welding defect detection and quality monitoring