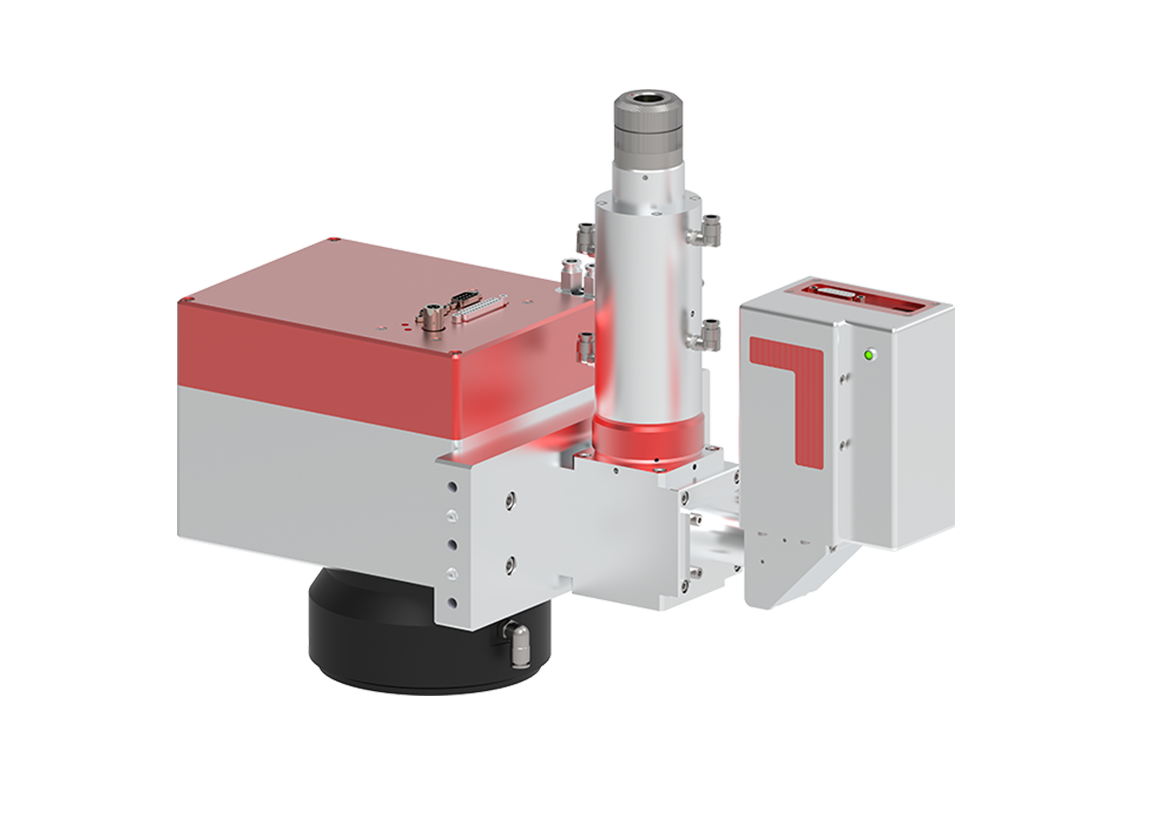

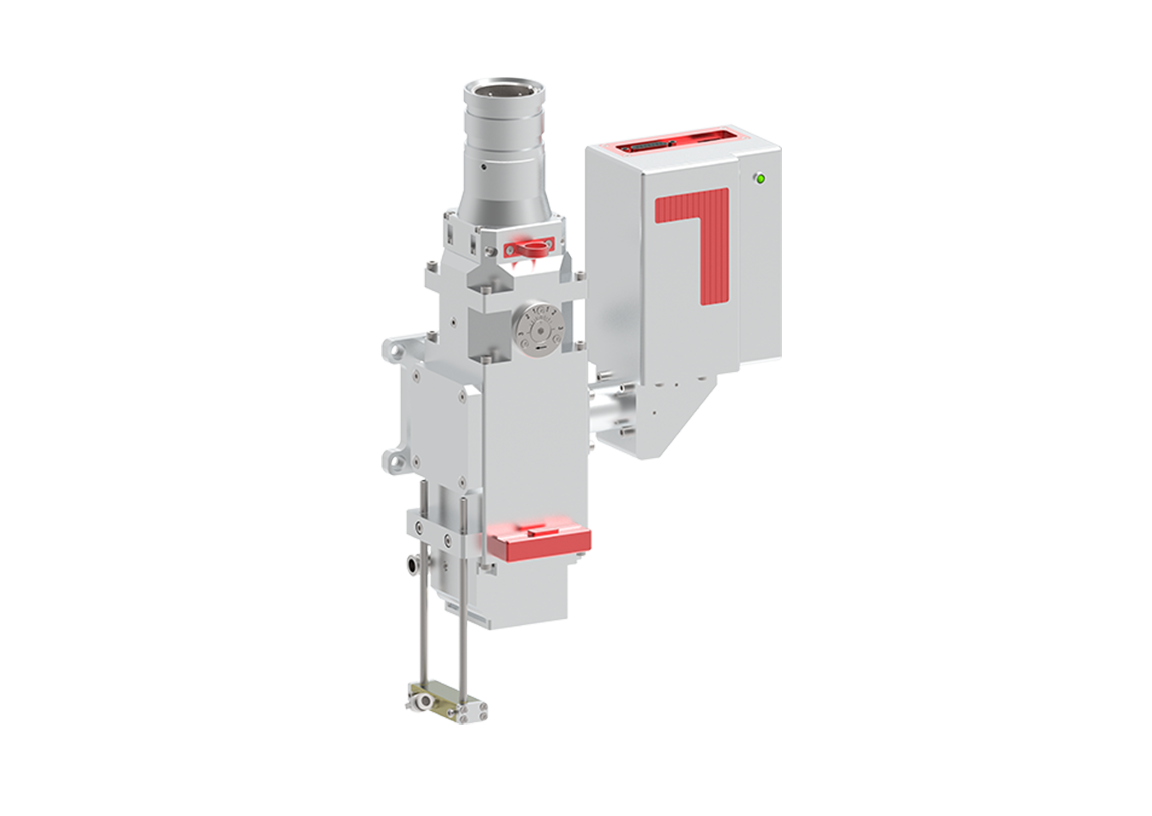

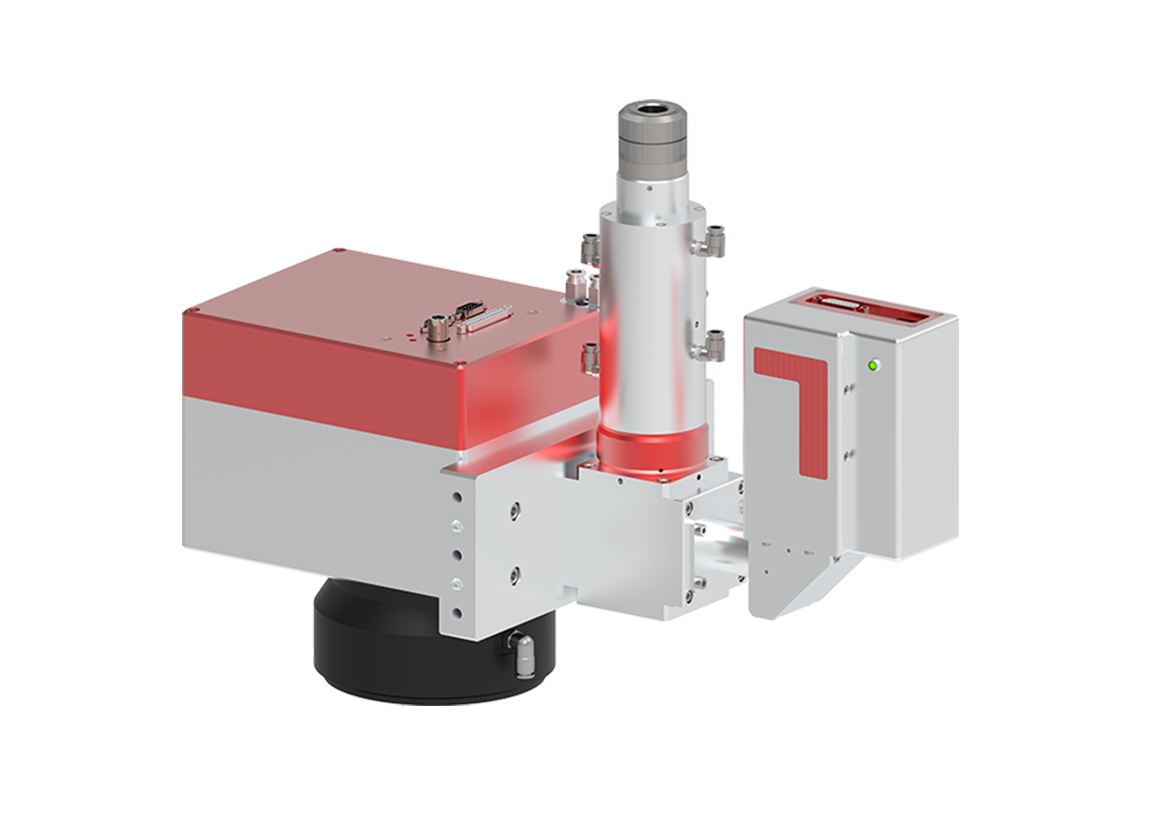

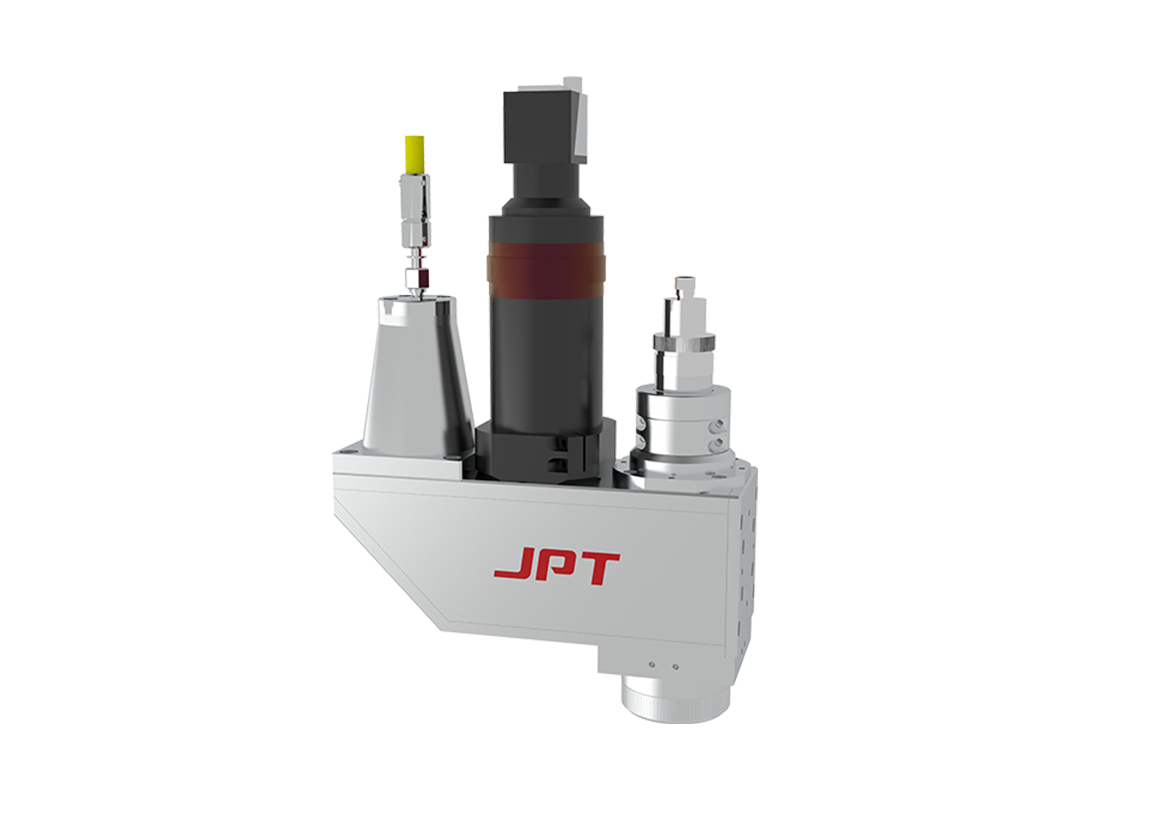

Welding Process Detection System

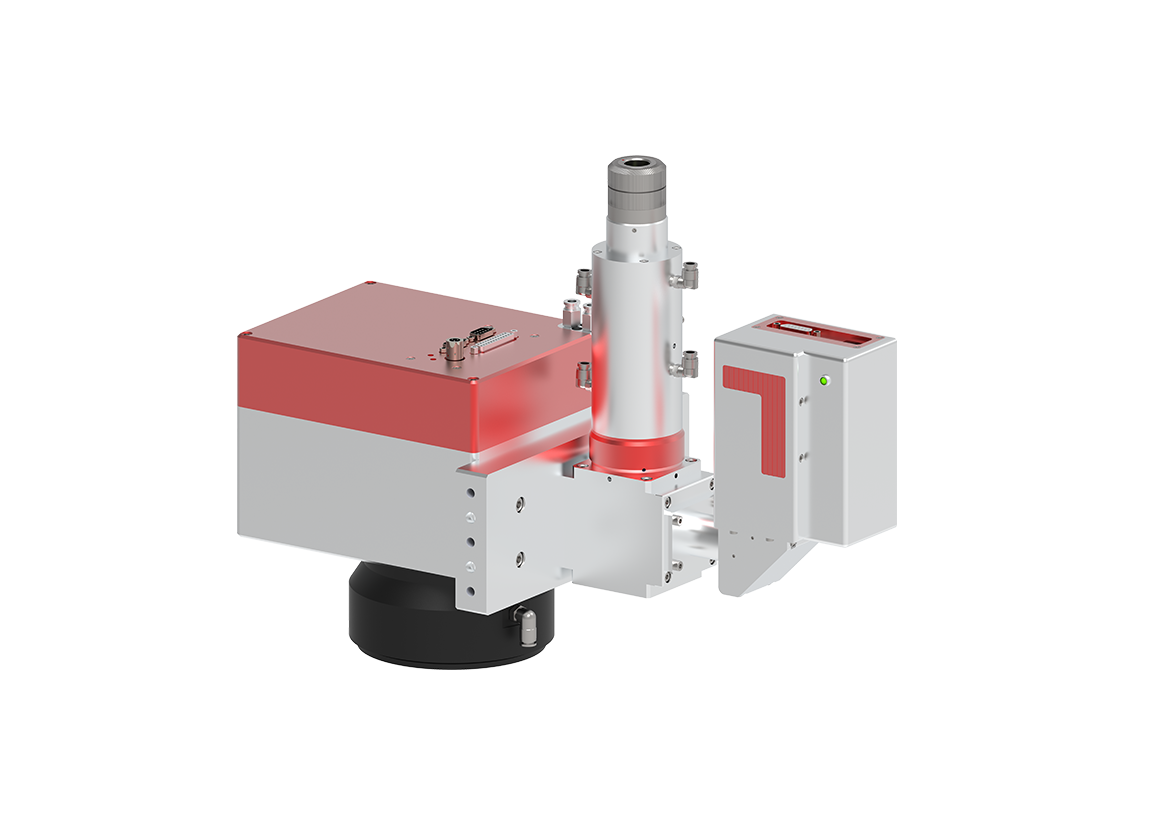

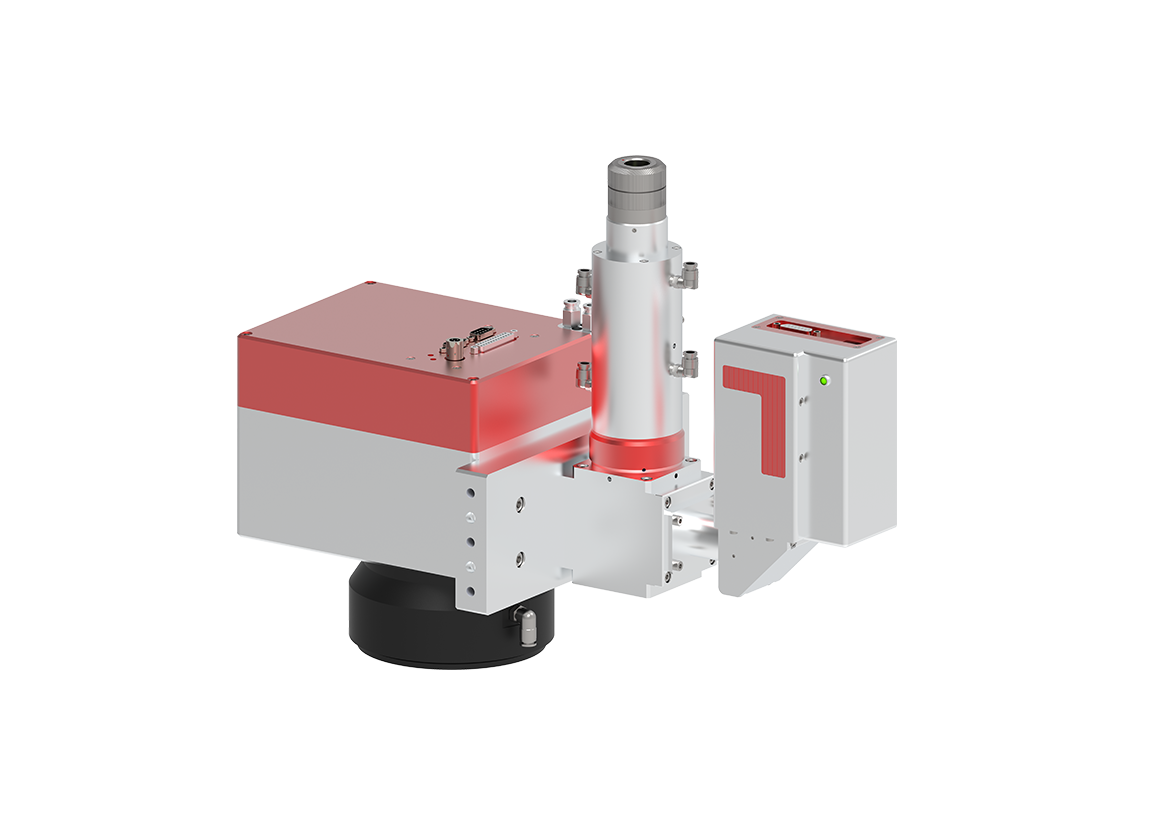

During the laser welding process, optical radiation phenomena occur, including plasma radiation, molten pool thermal radiation, and laser back-reflection. These radiation signals can reflect the welding status and indicate whether defects are generated during the process. Using photodetectors, the optical radiation produced during welding is converted into electrical signals. Through sufficient data acquisition, a reliable signal envelope is formed. By analyzing variations in the electrical signal parameters throughout the welding process, the system can evaluate the welding quality of the workpiece, thereby achieving defect detection and quality monitoring.

-

Product Advantages

-

Specifications

-

Related Products

Product Advantages

-

Cost-Effective & Independently Developed

Fully self-designed to ensure optimal cost performance, meeting high market demand.

-

Accurate Welding Quality Monitoring

Embedded welding process database provides precise molten pool monitoring and more reliable quality assessment.

-

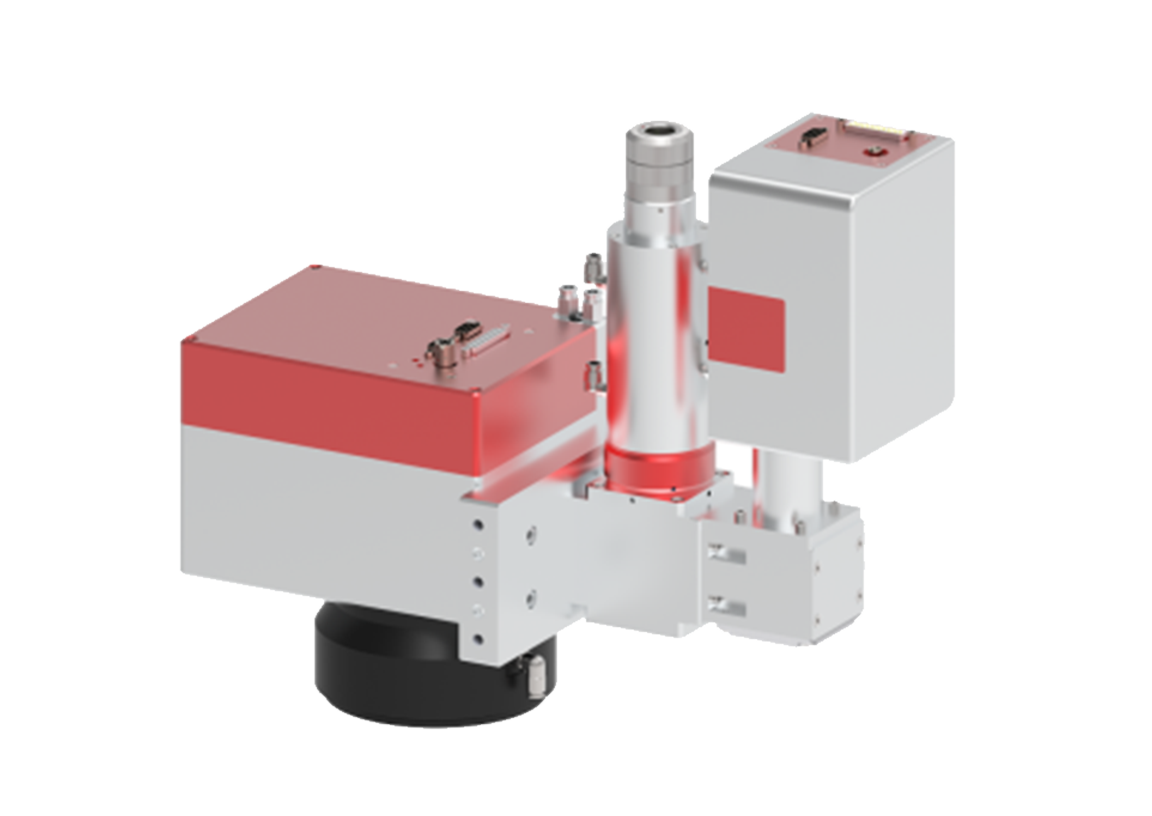

Broad Welding Head Compatibility

Supports both collimation + focusing and galvo welding heads, enhancing flexibility across different systems.

-

Flexible Customization & Quick Response

Offers tailored solutions with fast response to customer needs, accelerating time-to-market.

-

Seamless Communication Integration

Compatible with multiple communication protocols including I/O and EtherCAT, ensuring easy integration with diverse control systems.

Better, Faster Precision Machining

Specifications

-

Welding Process Detection System

-

Measurement Method

-

I/O Quantity

-

Number of Detectors

-

Sensor Types

-

Maximum Sampling Frequency

-

Operating Voltage

-

Communication Interface

-

Welding Process Detection System

-

Measurement MethodCoaxial Measurement

-

I/O Quantity16 / 16

-

Number of Detectors3

-

Sensor TypesPlasma Radiation, Molten Pool Thermal Radiation, Laser Back Reflection

-

Maximum Sampling Frequency200 kHz

-

Operating VoltageDC 24 V

-

Communication InterfaceI/O / Ethernet / Bus

-

Related Products

-

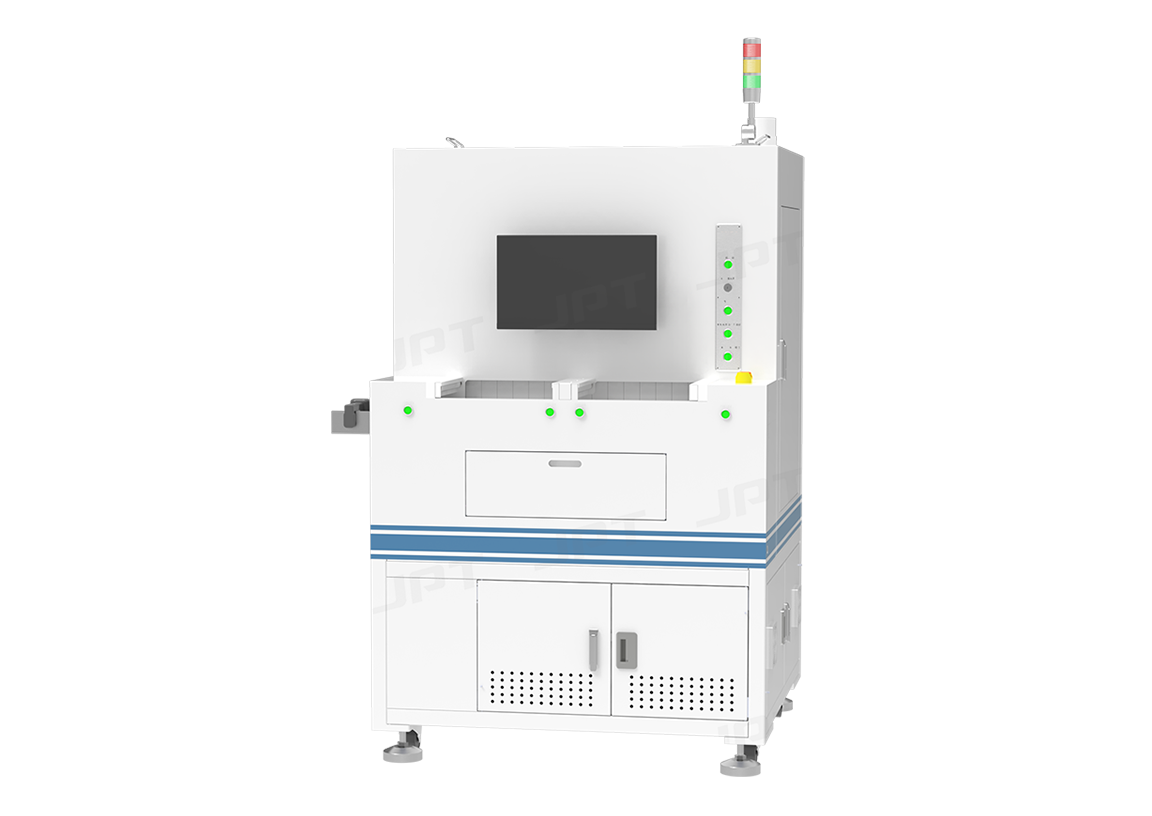

Dual-Station Five-Axis Galvo Welding System

Dual-Station Five-Axis Galvo Welding SystemEquipped with a WPD in-process welding quality monitoring module, the system enables real-time closed-loop control during welding, ensuring a yield rate of 99.9%.

-

OCT Penetration Online Detection System

OCT Penetration Online Detection SystemEnables high-resolution, real-time imaging of weld penetration during the welding process, effectively improving welding quality and consistency.

-

Welding Process Detection System

Welding Process Detection SystemReal-time analysis for welding defect detection and quality monitoring

-

Laser Temperature Feedback Compensation Module

Laser Temperature Feedback Compensation ModuleReal-time monitoring of weld temperature, achieving closed-loop control and significantly improving welding yield.