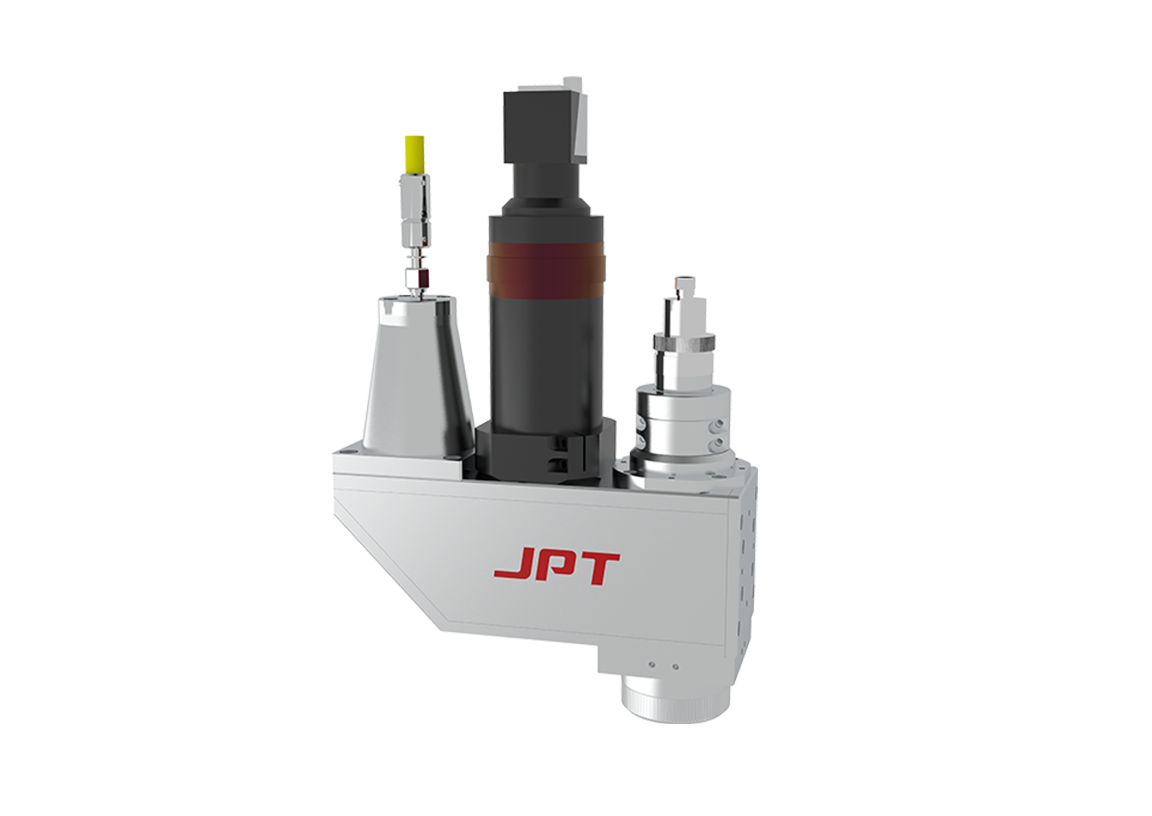

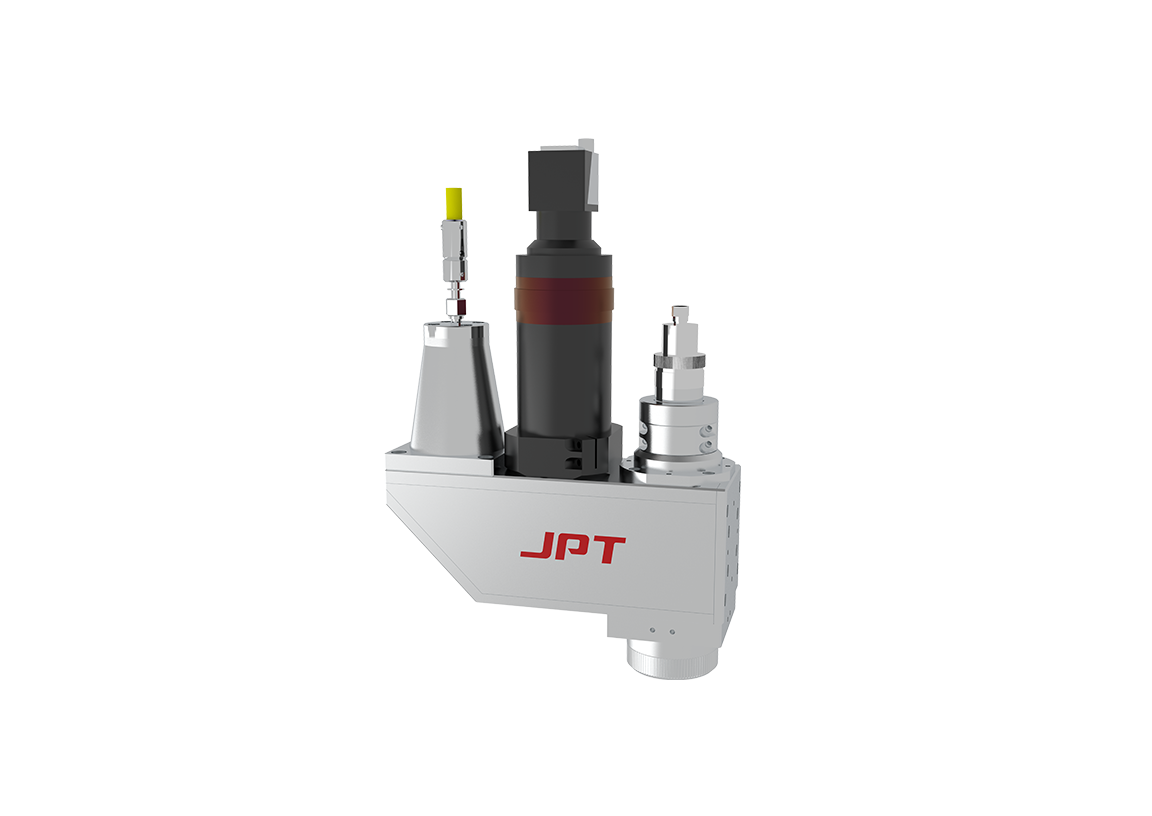

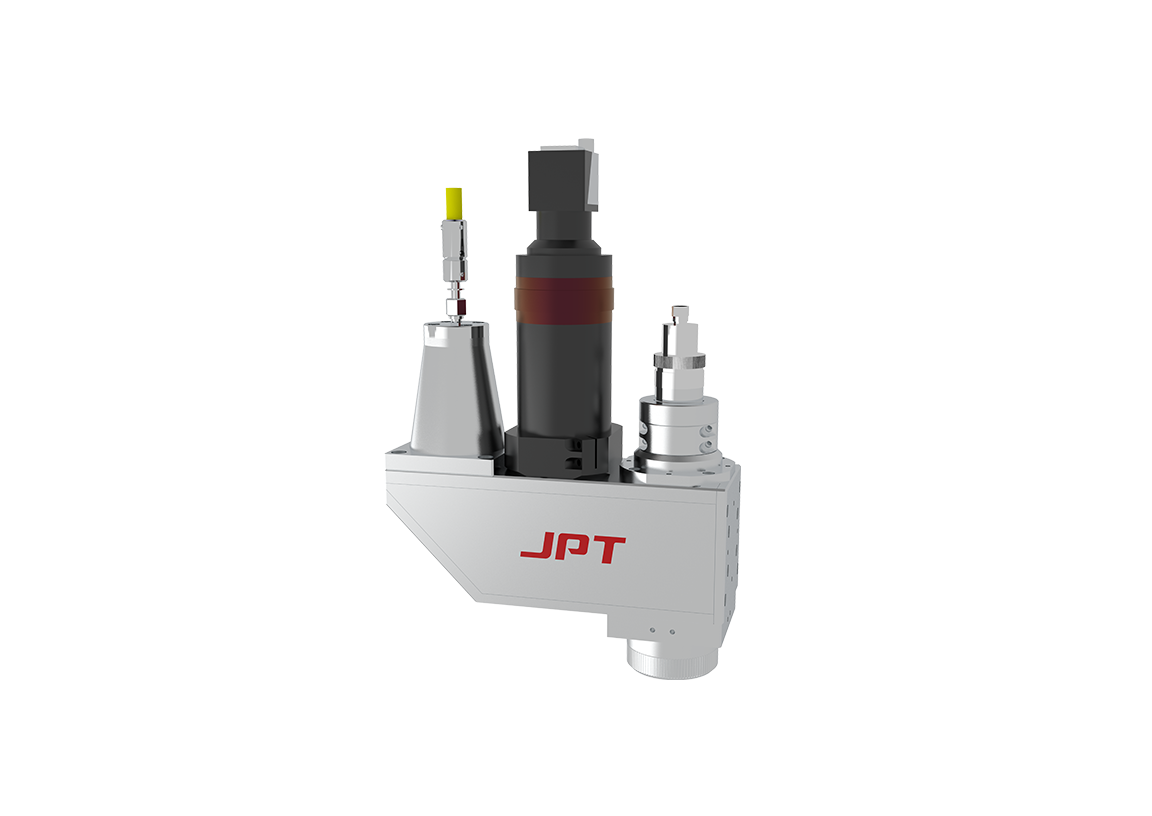

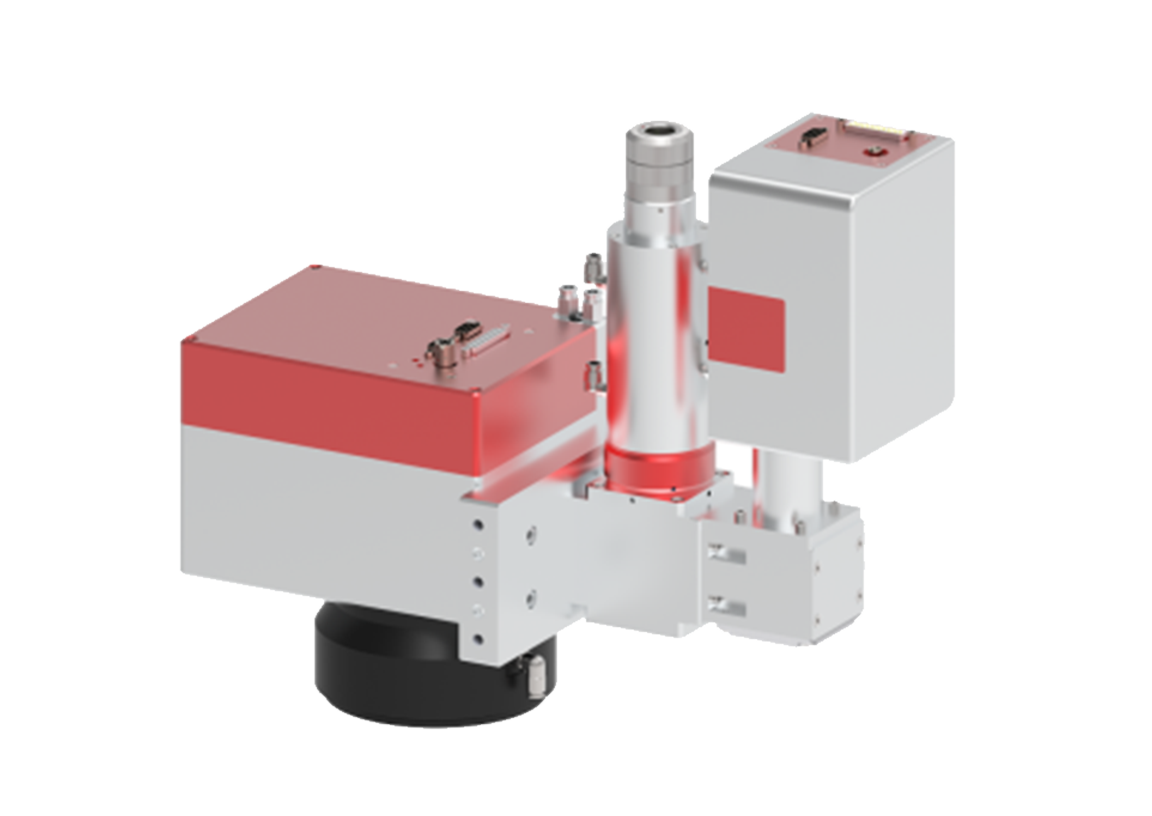

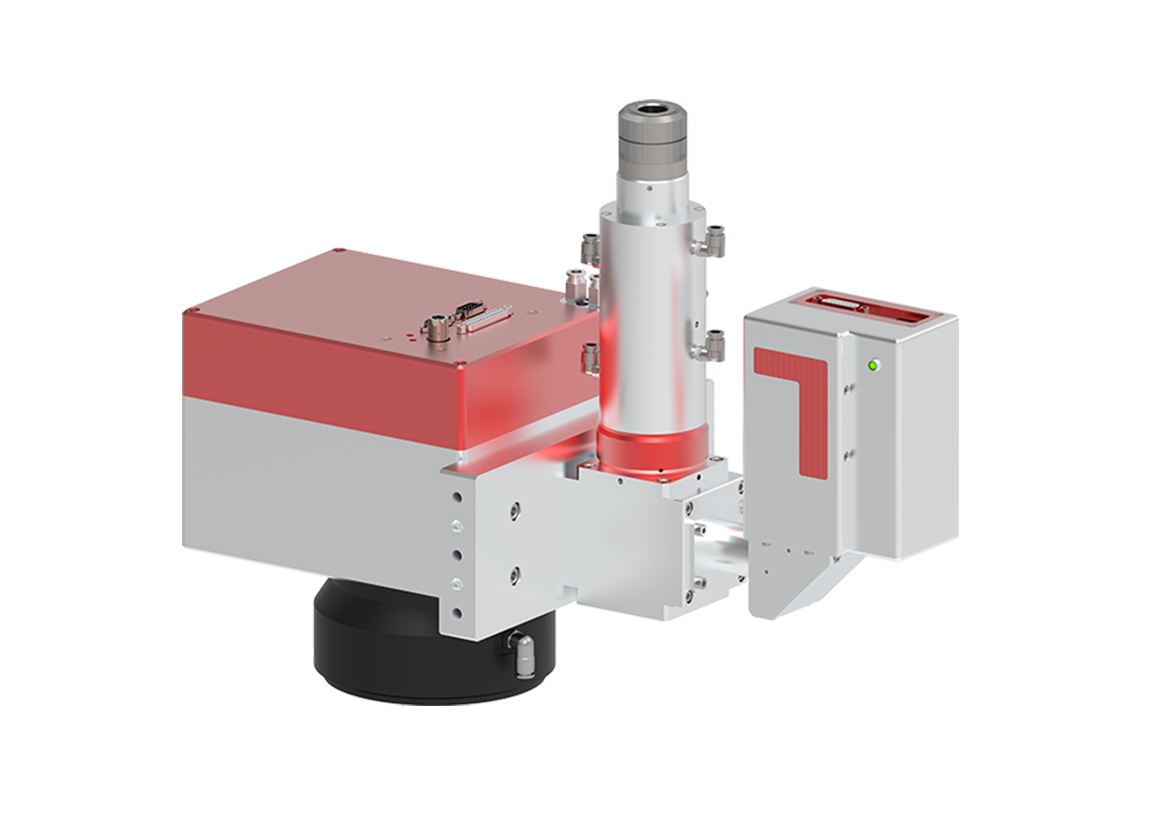

Laser Temperature Feedback Compensation Module

Laser processing temperature monitoring and feedback compensation technology uses infrared temperature sensors to collect and measure the weld surface temperature in real time. The temperature data is then fed back to the laser control system, which dynamically adjusts the laser output power to effectively regulate the weld surface temperature. Compared with traditional open-loop control, this compensation technology achieves a higher welding yield rate.

-

±5 ℃Compensation Accuracy

-

0-10 VOutput Range

-

100-1500 ℃Temperature Range

-

Product Advantages

-

Specifications

-

Related Products

Product Advantages

-

Real-Time Infrared Monitoring

Equipped with infrared sensors for precise digital temperature regulation, enabling stable closed-loop control.

-

Multi-Stage Temperature Profiles

Supports customized multi-segment temperature curves, adaptable to different processes and materials.

-

Smart PID Control & Easy Integration

Independently developed PID software with digital I/O and USB communication interfaces allows easy task configuration and programming.

-

High Yield & Consistent Quality

Effectively stabilizes weld surface temperature, achieving higher finished product yield compared to traditional open-loop systems.

-

Proven in Semiconductor Precision Soldering

Widely applied in semiconductor laser precision soldering, ensuring process reliability and scalability.

Specifications

-

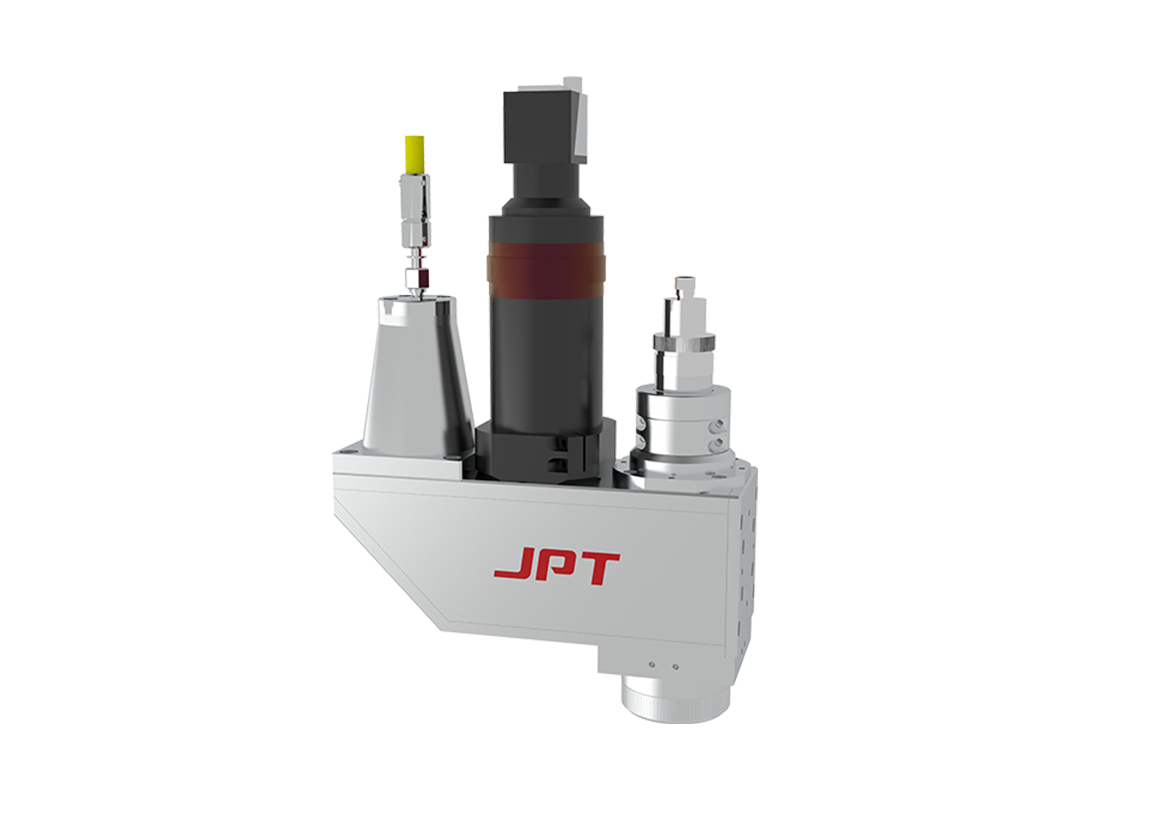

Temperature Feedback Compensation Module

-

Response Time

-

Compensation Accuracy

-

Programmable Segments

-

Single Continuous Operation Time

-

Output Range

-

Visual Positioning

-

Temperature Range

-

Temperature Feedback Compensation Module

-

Response Time≤ 1 ms

-

Compensation Accuracy± 5 ℃

-

Programmable Segments15

-

Single Continuous Operation Time1 ms – 90 s

-

Output Range0 - 10 V

-

Visual PositioningSupported

-

Temperature Range100 - 1500 ℃

-

Related Products

-

OCT Penetration Online Detection System

OCT Penetration Online Detection SystemEnables high-resolution, real-time imaging of weld penetration during the welding process, effectively improving welding quality and consistency.

-

Welding Process Detection System

Welding Process Detection SystemReal-time analysis for welding defect detection and quality monitoring

-

Laser Temperature Feedback Compensation Module

Laser Temperature Feedback Compensation ModuleReal-time monitoring of weld temperature, achieving closed-loop control and significantly improving welding yield.