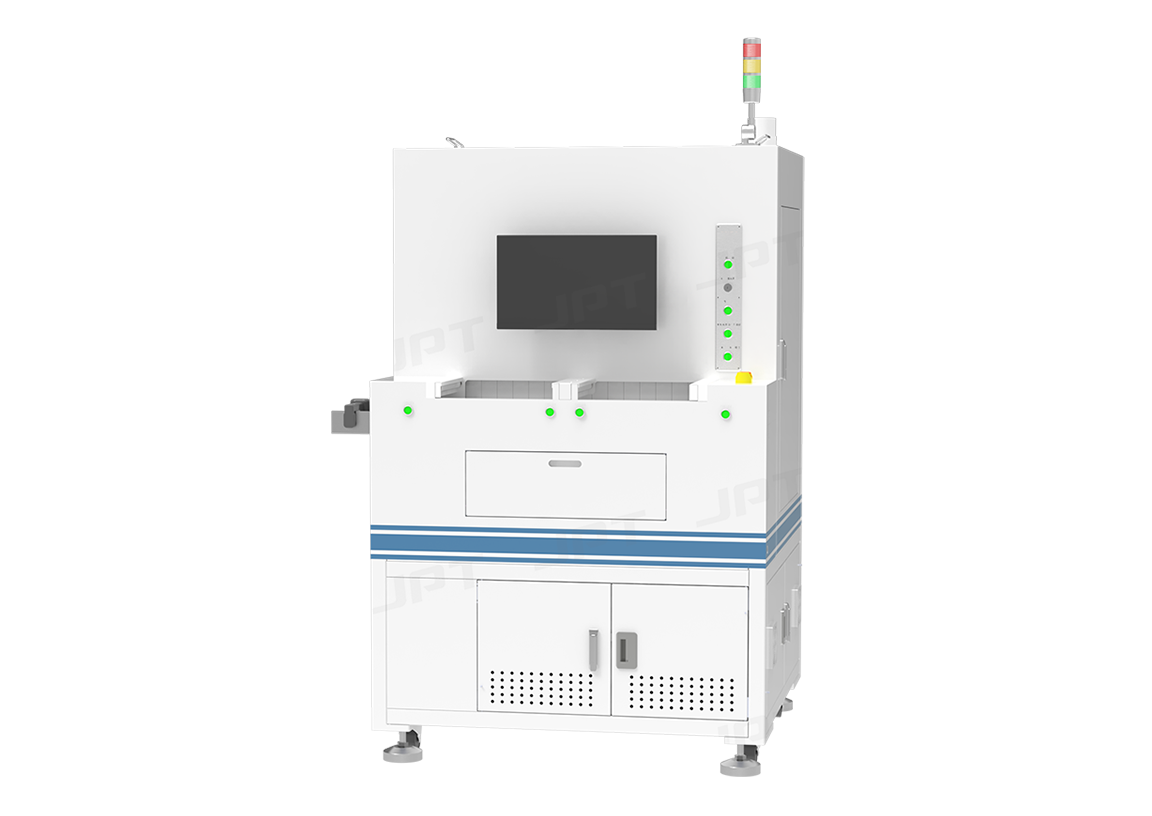

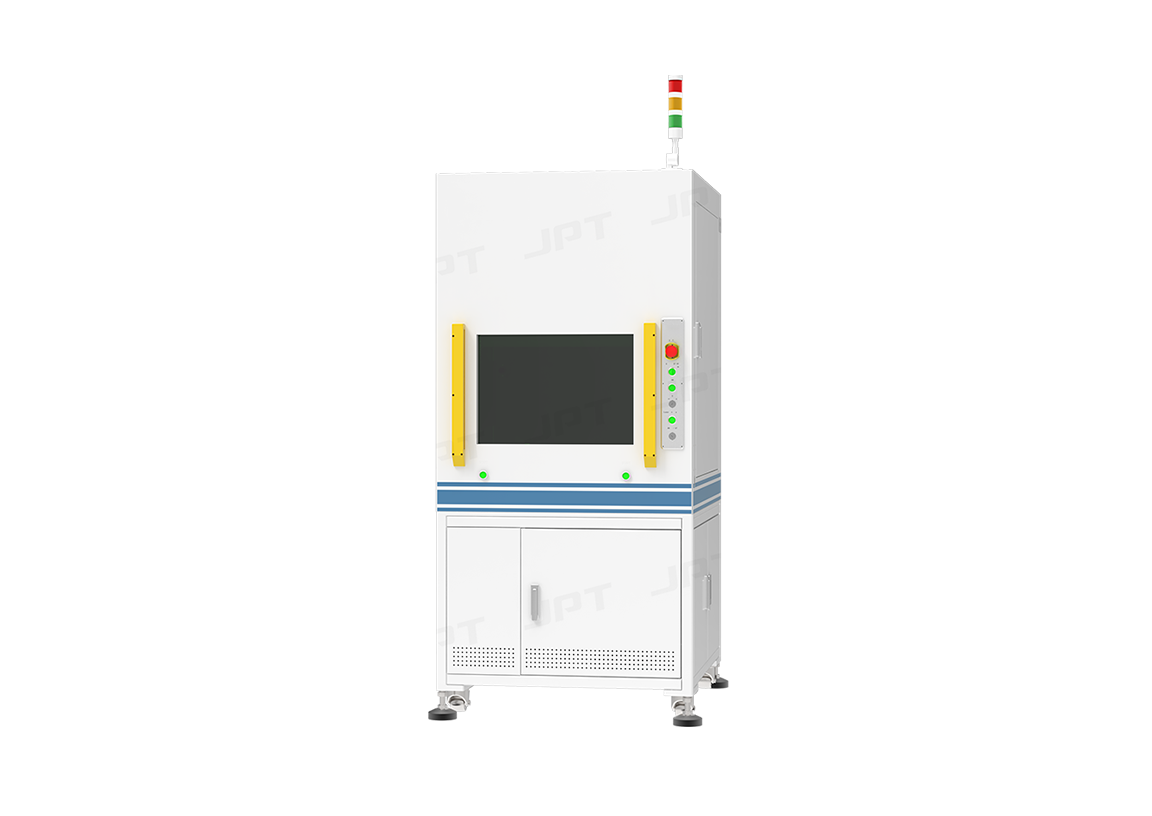

Fully Automatic High-Precision Laser Marking Equipment

The Fully Automatic High-Precision Laser Marking Equipment integrates JPT's self-developed laser source, galvanometer system, and optical focusing system. It is designed for marking on glass, resin, wafers, and other materials. Precision laser processing replaces traditional methods, becoming an indispensable step in wafer fabrication.

-

1000mm/sMaximum Processing Speed

-

± 20μmProcessing Accuracy

-

± 5μmPositioning Accuracy

-

Product Advantages

-

Specifications

-

Related Products

Product Advantages

-

Multi-Spec Wafer Compatibility, Wide Marking Range

Supports various wafer sizes, including 4-inch, 6-inch, 8-inch, and 12-inch, meeting marking requirements across different process stages.

-

Dual-Side Processing for Flexible Workflows

Capable of automatic recognition and processing on both wafer front and back sides, enabling flexible adaptation to diverse process paths and requirements.

-

Automated Loading & Unloading System for High Efficiency

Equipped with LoadPort/SMIF modules, edge finders, and wafer handling robots to achieve fully automated operation and minimize manual intervention.

-

Ultrafast Laser Marking, Clear & Damage-Free

Utilizes advanced ultrafast laser technology for fine, high-clarity marking with minimal heat-affected zones, ensuring wafer integrity and yield.

-

Modular Structure, Cost-Effective & Scalable

Modular machine design supports functional expansion and flexible production line integration, enhancing overall equipment efficiency and productivity.

Specifications

-

Laser Marking Equipment

-

Laser Source

-

Laser Power

-

Cooling Method

-

Beam Quality

-

Focusing Method

-

Focal Spot Size

-

Equipment Dimensions

-

Maximum Processing Speed

-

Maximum Workpiece Size

-

Processing Accuracy

-

UPH (Units per Hour)

-

Positioning Accuracy

-

Control Software

-

Laser Marking Equipment

-

Laser SourceUltraviolet Picosecond

-

Laser Power5W/10W

-

Cooling MethodConstant Temperature Water Cooling

-

Beam QualityM2<1.3

-

Focusing MethodGalvanometer

-

Focal Spot Size<10μm

-

Equipment Dimensions1710 mm (L)x2200 mm (W)x2200mm (H)

-

Maximum Processing Speed1000mm/s

-

Maximum Workpiece Size4-inch, 6-inch, 8-inch, 12-inch (customizable)

-

Processing Accuracy± 20μm

-

UPH (Units per Hour)35-50pcs/H

-

Positioning Accuracy±5μm

-

Control SoftwareJPT

-

Related Products

-

Fully Automatic High-Precision Laser Marking Equipment

Fully Automatic High-Precision Laser Marking EquipmentEquipment for marking processing on glass, resin, wafers, etc.

-

Dual-Station Five-Axis Galvo Welding System

Dual-Station Five-Axis Galvo Welding SystemEquipped with a WPD in-process welding quality monitoring module, the system enables real-time closed-loop control during welding, ensuring a yield rate of 99.9%.

-

Glass Ink Drilling Equipment

Glass Ink Drilling EquipmentDesigned for drilling glass ink layers in displays for smartphones, tablets, and computers.

-

Fully Automatic Laser Invisible QR Code Equipment

Fully Automatic Laser Invisible QR Code EquipmentQR codes provide traceability and anti-counterfeiting functionality throughout subsequent processes

-

3C Five-Axis Laser Linkage Universal Platform

3C Five-Axis Laser Linkage Universal PlatformIntegrates large-range five-axis precision positioning with localized three-axis high-speed laser scanning and tracking.