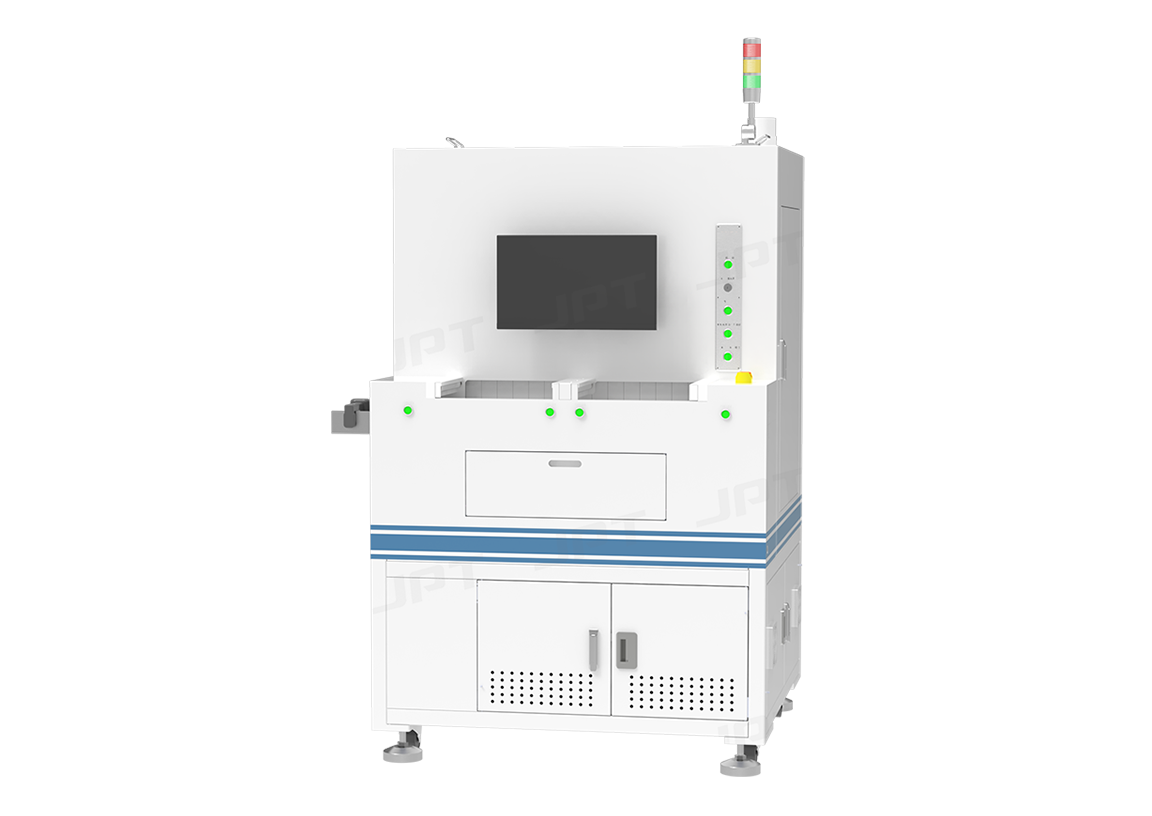

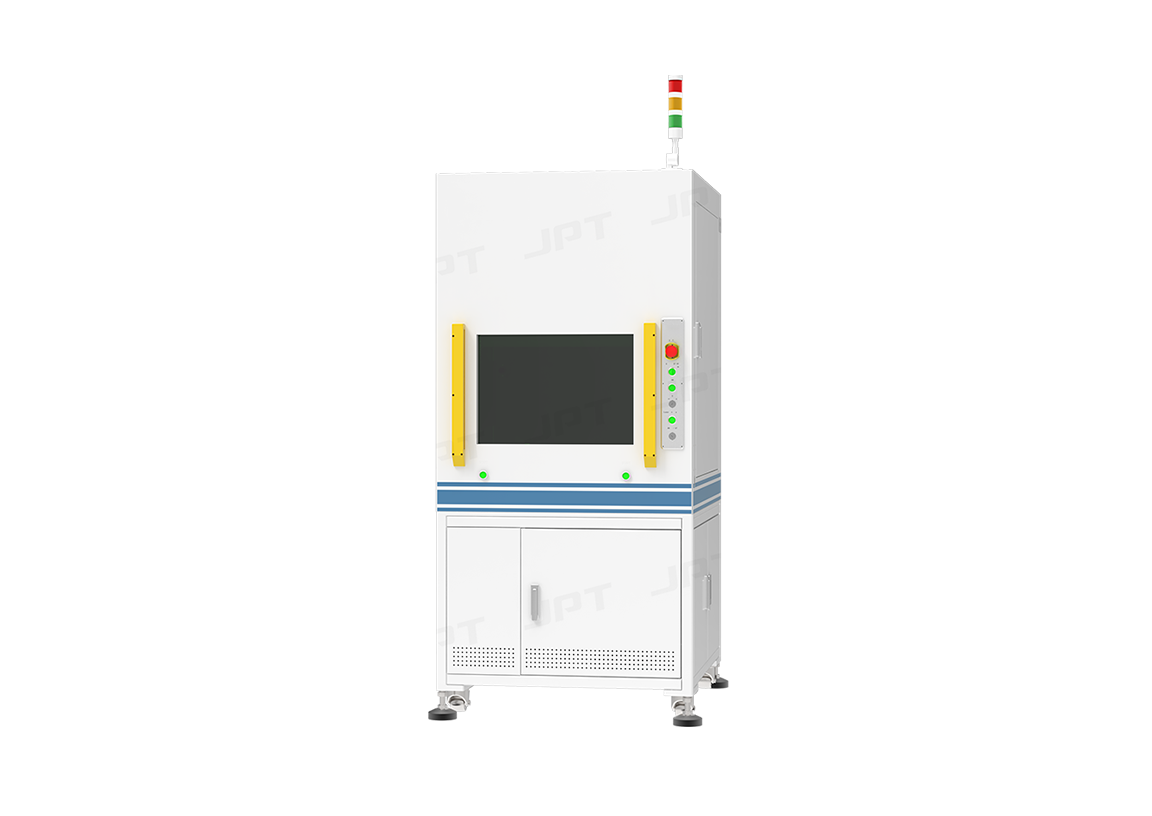

Glass Ink Drilling Equipment

The Glass Ink Drilling Equipment is specifically developed for display applications, such as mobile phones, tablets, and computers. It is equipped with a CCD vision positioning system, HSC laser module, AOI, and transmittance detection module.

-

1000mm/sMaximum Processing Speed

-

650×550mmMaximum Work Area

-

±20umProcessing Accuracy

-

Product Advantages

-

Specifications

-

Related Products

-

Application Solutions

Product Advantages

-

High-Precision Module for Consistent Drilling

Equipped with a high-precision XY platform module to ensure drilling accuracy and repeatability, meeting strict process requirements.

-

Fully Enclosed Optical Path for Stable, Clean Operation

The optical cavity adopts a fully enclosed design, providing dustproof and contamination-free protection, ensuring long-term stable performance of the laser module.

-

Customized HSC Laser Module for Diverse Applications

Supports customization of various hole diameters and taper designs, adaptable to different glass ink materials and application needs.

-

Intelligent Inspection System for Quality Assurance

Integrated with online aperture and transmittance monitoring, providing real-time feedback on processing quality to ensure consistency and yield.

Specifications

-

Glass Ink Drilling Equipment

-

Laser Source

-

Laser Power

-

Cooling Method

-

Beam Quality

-

Focusing Method

-

Focal Spot Size

-

Equipment Dimensions

-

Maximum Processing Speed

-

Maximum Work Area

-

Galvo Processing Area

-

Processing Accuracy

-

Glass Ink Drilling Equipment

-

Laser SourceUV Nanosecond

-

Laser Power10W

-

Cooling MethodConstant Temperature Water Cooling

-

Beam QualityM² < 1.3

-

Focusing MethodGalvanometer

-

Focal Spot Size10 ± 5 µm

-

Equipment Dimensions1600 mm (L) × 1900 mm (W) × 1800 mm (H)

-

Maximum Processing Speed1000 mm/s

-

Maximum Work Area650 mm × 550 mm

-

Galvo Processing Area50 mm × 50 mm

-

Processing Accuracy± 20 μm

-

Related Products

-

Fully Automatic High-Precision Laser Marking Equipment

Fully Automatic High-Precision Laser Marking EquipmentEquipment for marking processing on glass, resin, wafers, etc.

-

Dual-Station Five-Axis Galvo Welding System

Dual-Station Five-Axis Galvo Welding SystemEquipped with a WPD in-process welding quality monitoring module, the system enables real-time closed-loop control during welding, ensuring a yield rate of 99.9%.

-

Glass Ink Drilling Equipment

Glass Ink Drilling EquipmentDesigned for drilling glass ink layers in displays for smartphones, tablets, and computers.

-

Fully Automatic Laser Invisible QR Code Equipment

Fully Automatic Laser Invisible QR Code EquipmentQR codes provide traceability and anti-counterfeiting functionality throughout subsequent processes

-

3C Five-Axis Laser Linkage Universal Platform

3C Five-Axis Laser Linkage Universal PlatformIntegrates large-range five-axis precision positioning with localized three-axis high-speed laser scanning and tracking.