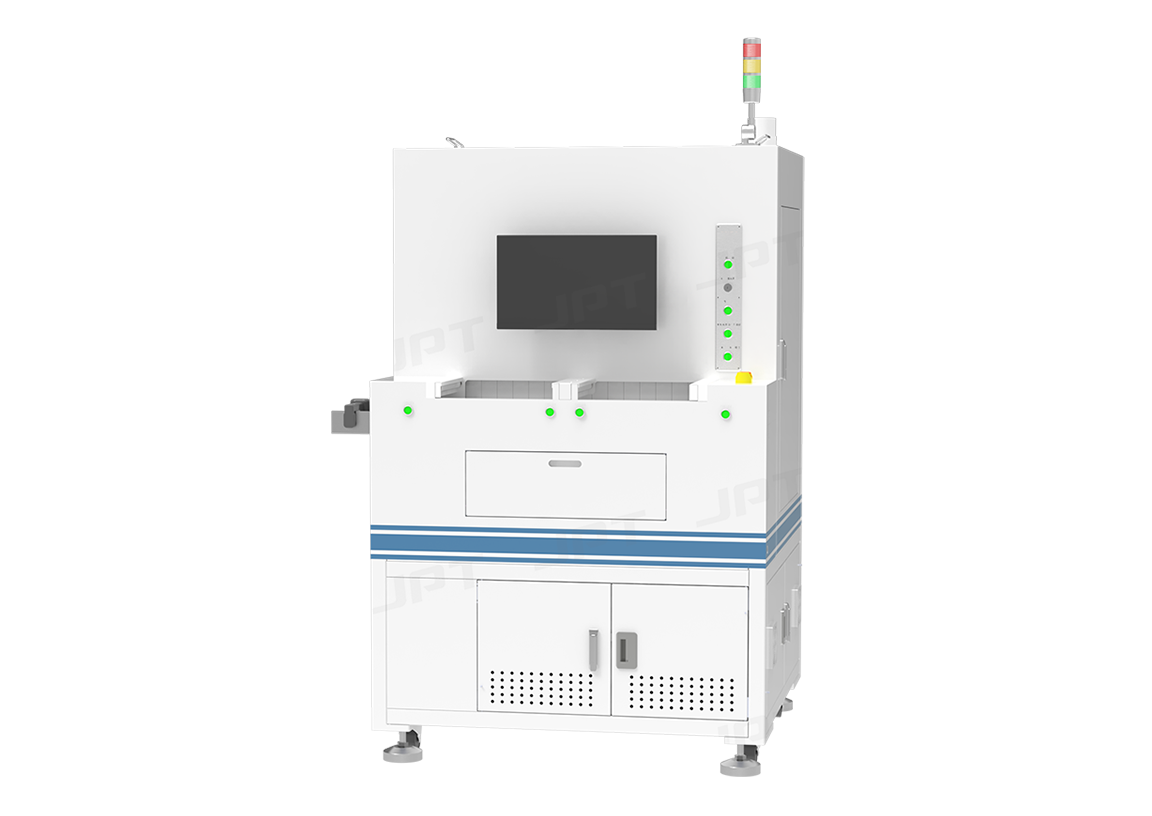

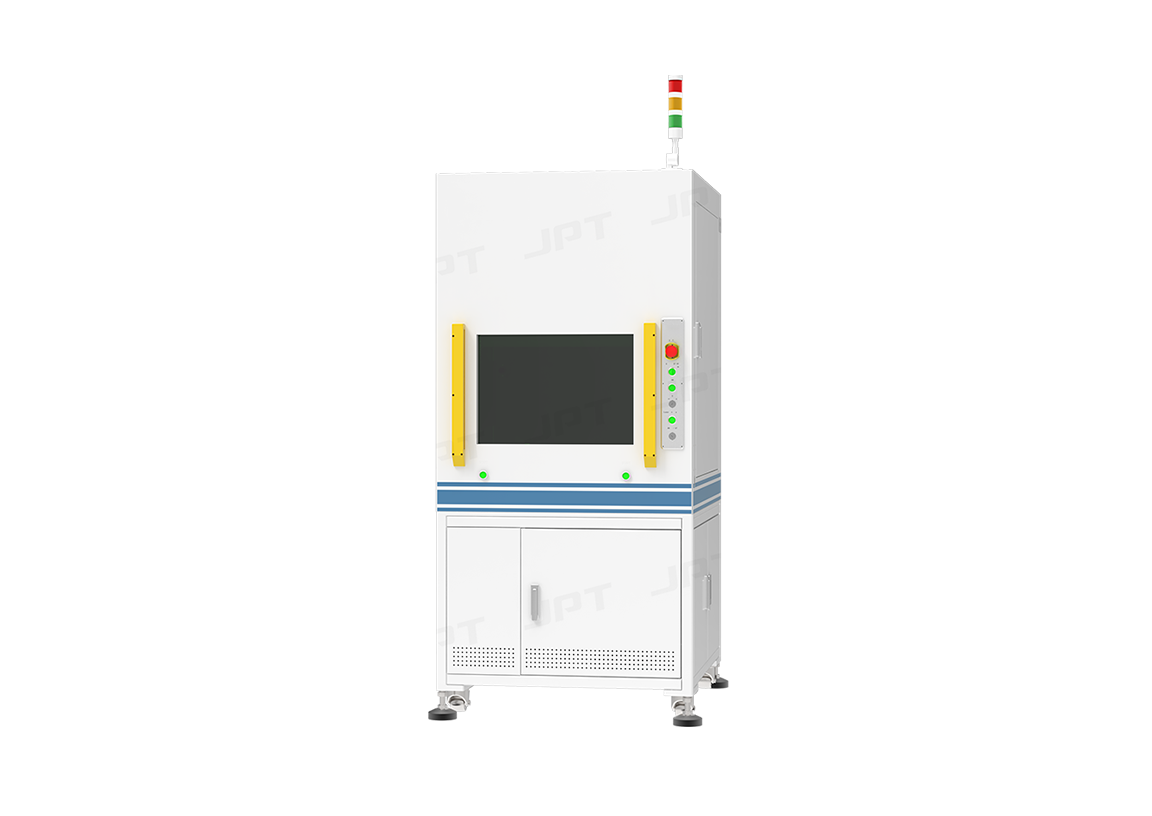

Fully Automatic Laser Invisible QR Code Equipment

The Fully Automatic Laser Invisible QR Code Equipment adopts a rotary table with integrated automatic loading and unloading modules, achieving high productivity, efficiency, precision, and yield. It enables marking of unique invisible QR codes, with a single QR dot size smaller than 2.5 µm, on each piece of glass or sapphire, ensuring process traceability and anti-counterfeiting protection.

-

±50umDepth Control Accuracy

-

±20mmPositioning Accuracy

-

>99.5%Marking & Reading Yield

-

Product Advantages

-

Specifications

-

Related Products

-

Application Solutions

Product Advantages

-

Invisible Marking for Traceability

Laser marking is invisible to the human eye, leaves no surface residue, and remains scannable even after screen printing coverage.

-

Strength Integrity & Reliable Performance

Products remain unaffected in strength tests such as 3PB and ROR, ensuring both functionality and reliability for high-standard applications.

-

Intelligent Recognition System – 100% Read Rate

Equipped with customized light sources and image processing algorithms, ensuring stable, high-accuracy recognition across sapphire, optical glass, and similar materials.

-

Precision Depth Control with Auto Compensation

Integrated online measurement and power monitoring system provides real-time laser power compensation, ensuring uniform QR code depth.

-

Flexible Integration with Automated Handling

Marking and code-reading functions can operate independently or in linkage mode, supporting automated loading/unloading to enhance overall production efficiency.

Specifications

-

QR Code Equipment

-

Laser Source

-

Laser Power

-

Cooling Method

-

Beam Quality

-

Focusing Method

-

Focal Spot Size

-

Equipment Dimensions

-

UPH (Units per Hour)

-

Depth Control Accuracy

-

Positioning Accuracy

-

Code Dot Size

-

Marking & Reading Yield

-

Control Software

-

QR Code Equipment

-

Laser SourceUV Picosecond

-

Laser Power3 W / 5 W

-

Cooling MethodConstant Temperature Water Cooling

-

Beam QualityM² < 1.3

-

Focusing MethodGalvanometer

-

Focal Spot Size3 μm

-

Equipment Dimensions3100 mm (L) × 2500 mm (W) × 1700 mm (H)

-

UPH (Units per Hour)1200 pcs/h

-

Depth Control Accuracy± 50 µm

-

Positioning Accuracy± 0.2 mm

-

Code Dot Size3 ± 1 µm

-

Marking & Reading Yield> 99.5%

-

Control SoftwareJPT

-

Related Products

-

Fully Automatic High-Precision Laser Marking Equipment

Fully Automatic High-Precision Laser Marking EquipmentEquipment for marking processing on glass, resin, wafers, etc.

-

Dual-Station Five-Axis Galvo Welding System

Dual-Station Five-Axis Galvo Welding SystemEquipped with a WPD in-process welding quality monitoring module, the system enables real-time closed-loop control during welding, ensuring a yield rate of 99.9%.

-

Glass Ink Drilling Equipment

Glass Ink Drilling EquipmentDesigned for drilling glass ink layers in displays for smartphones, tablets, and computers.

-

Fully Automatic Laser Invisible QR Code Equipment

Fully Automatic Laser Invisible QR Code EquipmentQR codes provide traceability and anti-counterfeiting functionality throughout subsequent processes

-

3C Five-Axis Laser Linkage Universal Platform

3C Five-Axis Laser Linkage Universal PlatformIntegrates large-range five-axis precision positioning with localized three-axis high-speed laser scanning and tracking.