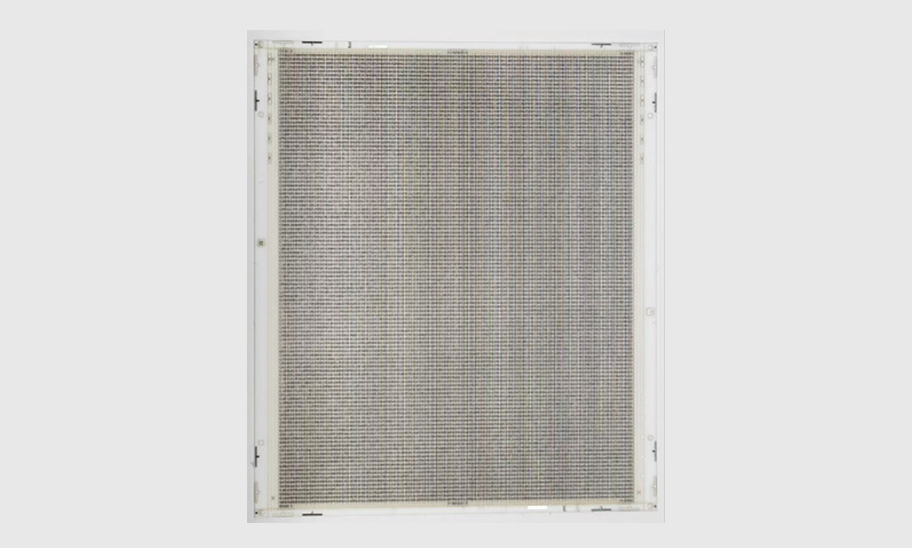

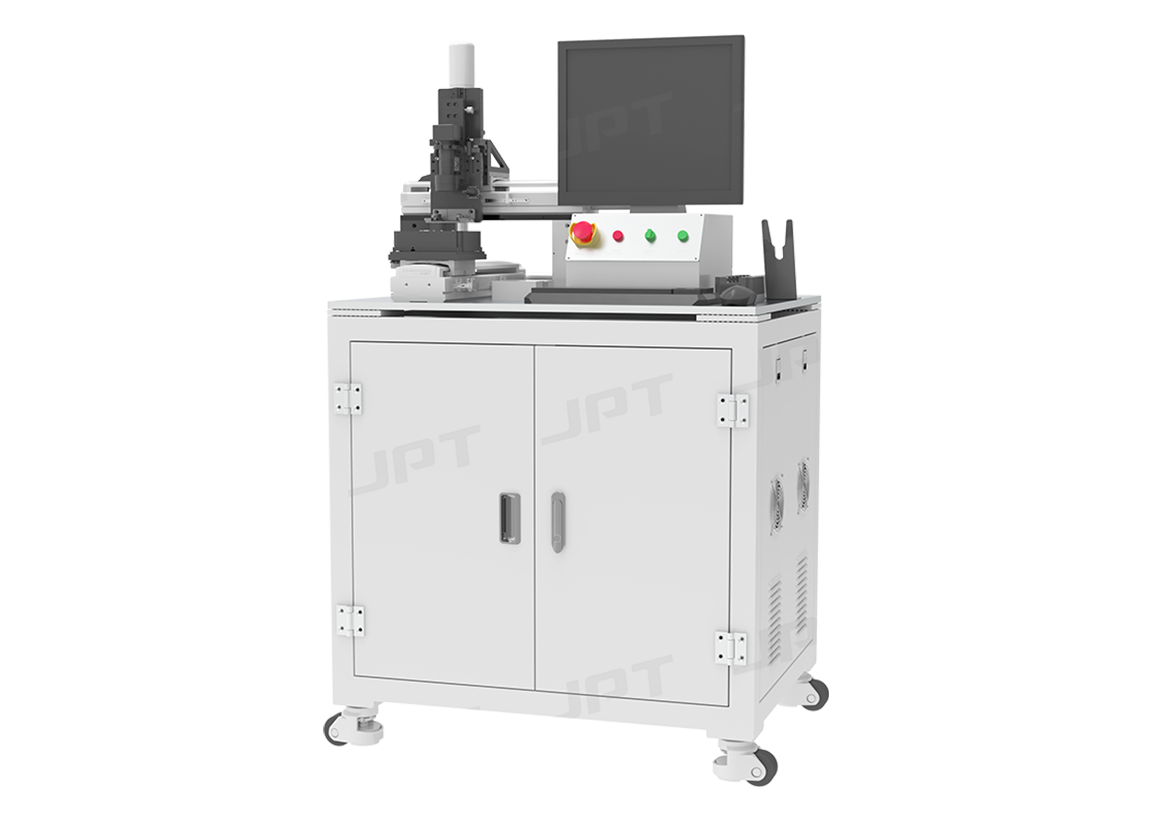

Laser Thick Film Trimmer

The Laser Thick Film Trimmer focuses the laser beam to the micron level and scans across the resistor surface, melting and vaporizing the resistive paste layer to form grooves of a defined depth. This process changes the conductive cross-sectional area or length of the resistor. A precision measurement system simultaneously monitors resistance in real time and automatically stops laser output once the target resistance is achieved, adjusting resistors below the target value into the specified tolerance range.

As a key piece of equipment in chip resistor manufacturing, the laser trimming machine is used for trimming thick-film/thin-film resistors on ceramic substrates, or alloy resistors on PCB/lead frame substrates.

-

01005-2512Resistor Specifications

-

100mΩ~20MΩResistance Range

-

±0.1%, ±1%, ±5%Trimming Accuracy

-

Product Advantages

-

Applications

-

Specifications

-

Related Products

Product Advantages

-

Self-Developed Laser – Cost-Effective & Reliable

JPT's proprietary laser can be customized for specific applications at low cost. Built using high-performance components (fiber, crystal, pump source, etc.) and tested with a 72-hour aging process for long-term reliability.

-

High Trimming Efficiency & Accuracy

Integrates high-speed, high-precision galvanometers, JPT's self-developed fiber lasers, and precision measurement systems to achieve closed-loop trimming control with superior speed and accuracy.

-

Advanced Automation & Intelligent Functions

Equipped with power monitoring, automatic calibration of the measurement system, auto-alignment for trimming, and motorized material handling, fully meeting modern automation requirements.

Applications

-

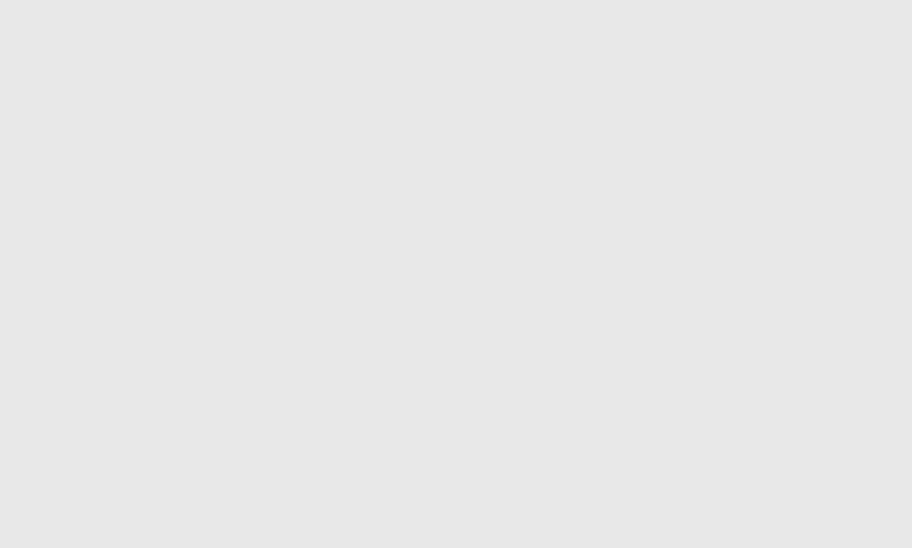

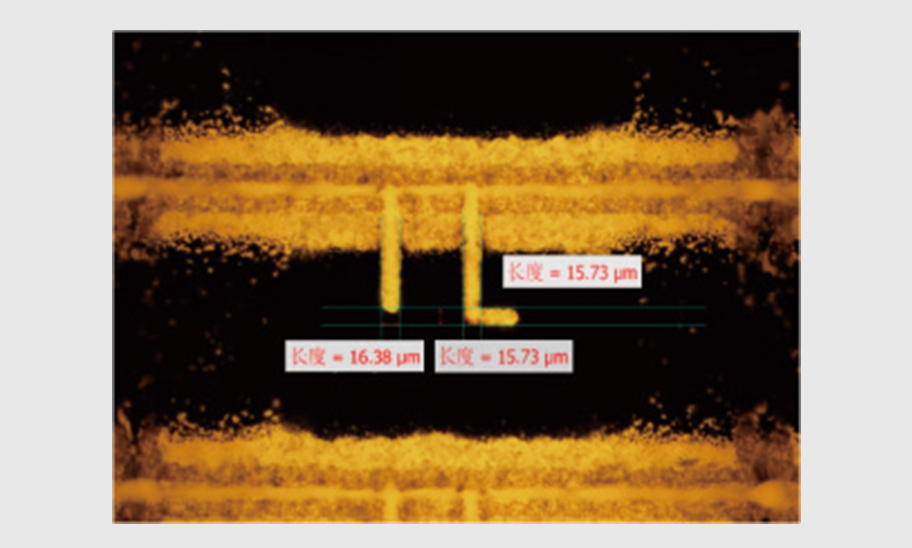

Infrared Blade Width 19–20 μm

Infrared Blade Width 19–20 μm -

Substrate Image

Substrate Image -

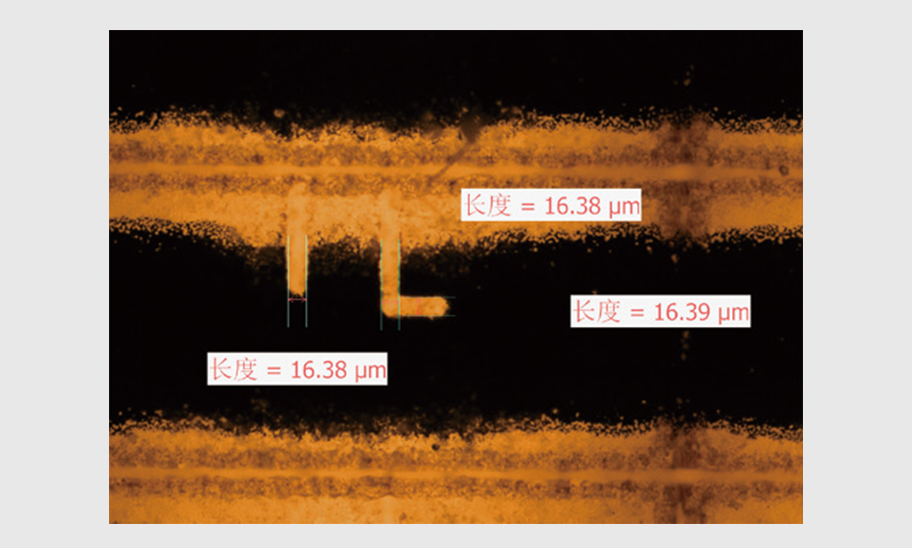

Green Light Blade Width 16–17 μm

Green Light Blade Width 16–17 μm -

Green Light Blade Width 16–17 μm

Green Light Blade Width 16–17 μm

Specifications

-

Standard

-

Optional Configuration

-

Substrate Size

-

Product Specification

-

Trimming Range

-

Trimming Accuracy

-

Channel Quantity

-

Laser Parameters

-

Galvo Scanning Area

-

Cutting Speed

-

Blade Types

-

Line Width

-

Standard

-

Substrate Size5060 / 6070 / 8084

-

Product Specification01005-2512

-

Trimming Range100mΩ~20MΩ

-

Trimming Accuracy±0.1%、±1%、±5%

-

Channel Quantity15 standard relay boards, 240 channels

-

Laser ParametersIR > 30 W @ 23 kHz; GR > 4 W @ 10 kHz; UV ≥ 3 W @ 40 kHz

-

Galvo Scanning AreaIR: 12 mm × 75 mm @ F125;

GR: 12 mm × 60 mm @ F100;

UV: 12 mm × 60 mm @ F103 -

Cutting Speed1mm/s~ 600mm/s

-

Blade TypesSingle Blade, L-Blade, Double Blade, IL-Blade, Multi-Blade (serpentine), U-Blade, Chamfer Blade, J-Blade

-

Line WidthIR: 20 µm ~ 40 µm @ F125;

GR: 15 µm ~ 20 µm @ F100;

UV: 10 µm ~ 20 µm @ F103

-

-

Optional Configuration

-

Substrate SizeCustomized according to customer chip size

-

Product Specification/

-

Trimming Range20 MΩ ~ 500 MΩ

-

Trimming Accuracy/

-

Channel Quantity/

-

Laser Parameters/

-

Galvo Scanning Area12 mm × 100 mm @ F160

-

Cutting Speed/

-

Blade Types/

-

Line WidthIR: 30 µm ~ 50 µm @ F160

-

Related Products

-

Laser Thin Film Trimmer

Laser Thin Film TrimmerMeasurement range 100mΩ-500MΩ, measurement accuracy ±0.01%, supports multiple resistance specifications

-

Laser Thick Film Trimmer

Laser Thick Film TrimmerResistance adjustment range 100mΩ~20MΩ, used for laser resistance adjustment of chip thick film resistors/hybrid circuits (thick film) on ceramic substrates

-

Laser Scriber

Laser ScriberFront and back line repeatability less than ±5 μm, achieving ±0.75μm/70mm straightness and ±1μm positioning accuracy

-

Single Chip-resistor Tester

Single Chip-resistor TesterUsed for first inspection before laser trimming, re-measurement or final inspection after laser trimming

-

High Voltage Resistor Tester

High Voltage Resistor TesterUsed to test single-chip resistor substrates, with the withstand voltage characteristics of each resistor before and after resistance adjustment

-

TCR Tester

TCR TesterUsed for testing the TCR values of individual resistors on single-chip resistor substrates

-

Inductor Laser Peeling Machine

Inductor Laser Peeling MachineFor laser removal of resin layers/enamel layers on molded inductors and wound inductors