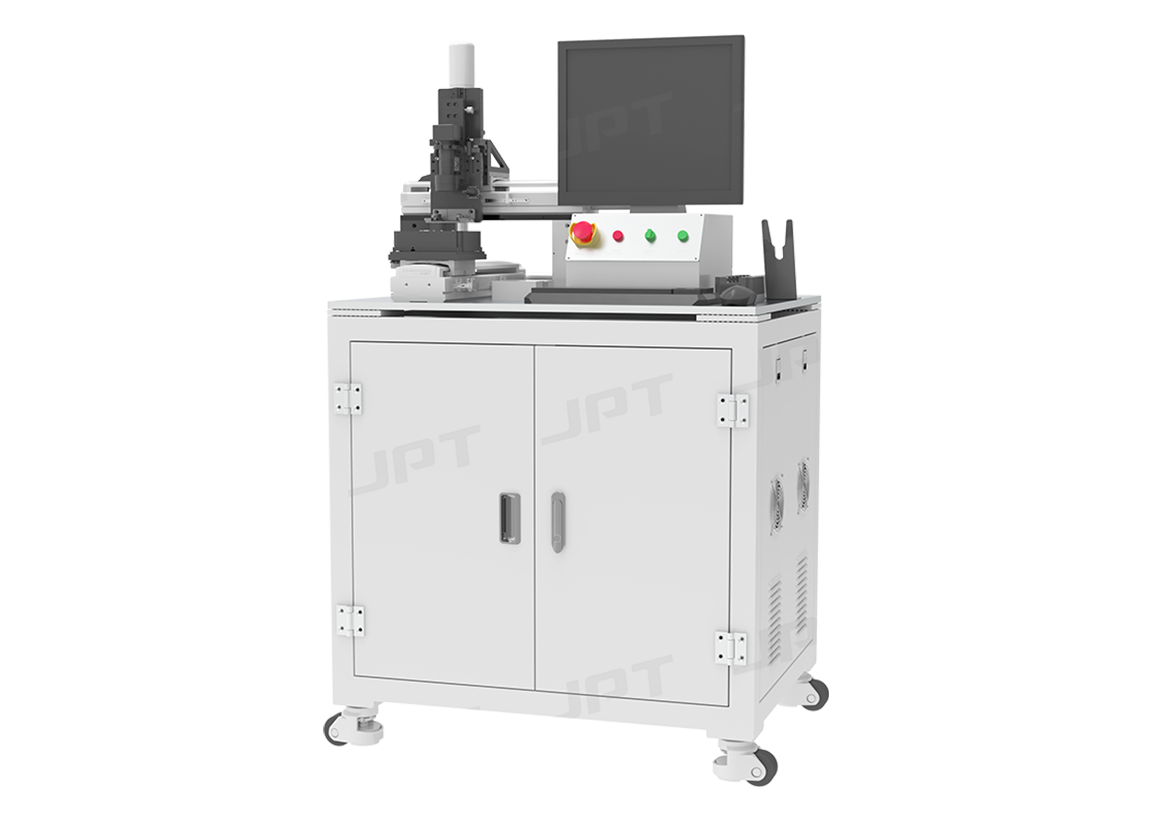

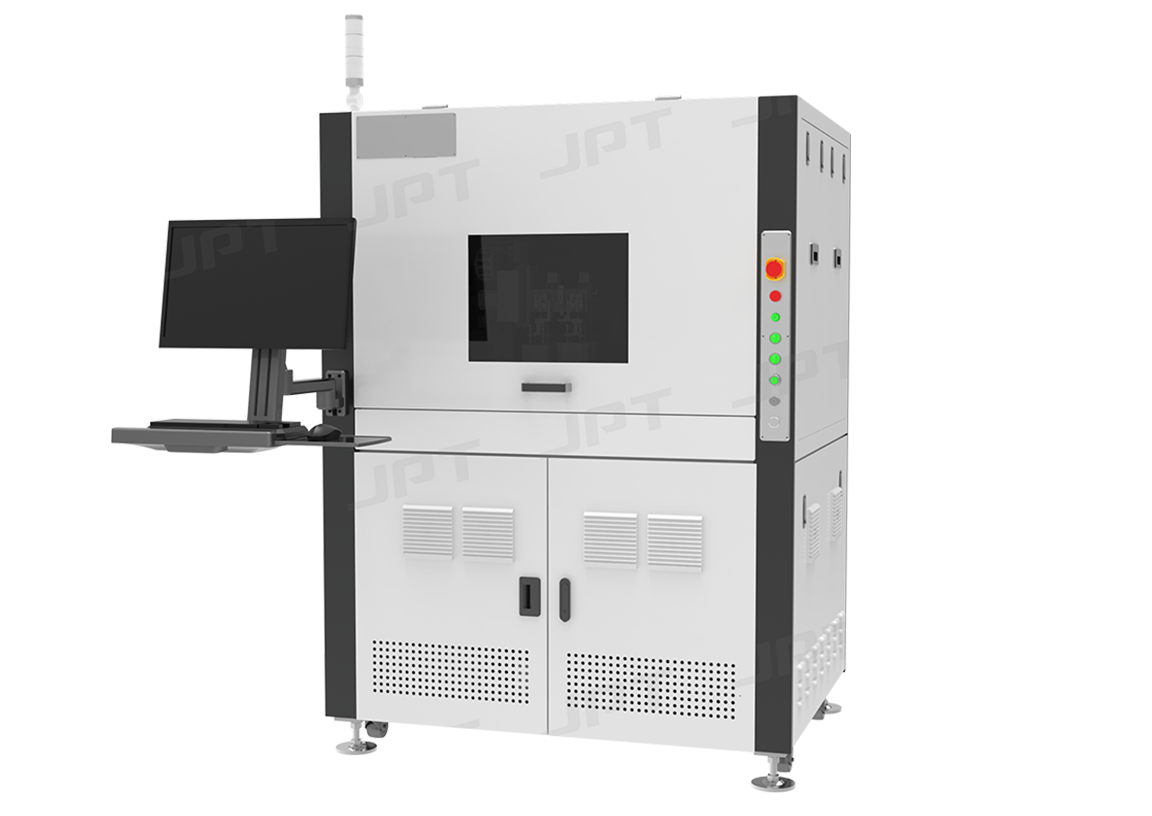

Inductor Laser Peeling Machine

The laser paint stripping machine focuses the laser beam down to the micron level and scans across the surface of the inductor, melting and vaporizing the top resin or coating layer to expose the underlying electrode.

As a key piece of equipment in the inductor manufacturing process, the laser paint stripping machine is used for removing resin or enamel layers of molded inductors and wound inductors.

-

2520/2016/2012Inductor Specifications

-

<±0.05mmStripping Accuracy

-

> 21,000 pcs/h (for reference)Stripping Efficiency

-

Product Advantages

-

Applications

-

Specifications

-

Related Products

Product Advantages

-

Self-Developed Laser – Cost-Effective & Reliable

JPT's proprietary laser can be customized for specific applications at low cost. Built using top-grade components (fiber, crystal, pump source, etc.) and validated with a 72-hour aging test, ensuring long service life and reliability.

-

High-Precision Vision Recognition & Positioning

quipped with a pseudo-coaxial vision system for accurate inductor recognition and positioning. Automatically corrects stripping position and angle deviations, achieving high-precision paint stripping.

-

High-Speed Feeding & Arrangement

Uses a high-speed vibration plate and XY + Theta platform with optimized motion sequence to achieve various arrangements such as linear, spiral, and rectangular distributions.

Applications

-

Application Effect

Application Effect -

Application Effect

Application Effect -

Application Effect

Application Effect

Inductor Laser Peeling Machine

Specifications

-

Inductor Laser Peeling Machine

-

Product Specification

-

Peeling Requirement

-

Peeling Accuracy

-

Laser Parameters

-

Galvo Scanning Area

-

Galvo Cutting Speed

-

Galvo Repeat Positioning Accuracy

-

Marking Card

-

Inductor Laser Peeling Machine

-

Product Specification2520/2016/2012

-

Peeling RequirementSingle-side peeling

-

Peeling Accuracy≤ ±0.05 mm

-

Laser ParametersStandard: UV 15W;

Optional: IR 30W -

Galvo Scanning AreaF254 (Camera lens field of view 76 × 76)

-

Galvo Cutting Speed1 mm/s ~ 7000 mm/s

-

Galvo Repeat Positioning Accuracy0.01mm

-

Marking CardSelf-Developed

-

Related Products

-

Laser Thin Film Trimmer

Laser Thin Film TrimmerMeasurement range 100mΩ-500MΩ, measurement accuracy ±0.01%, supports multiple resistance specifications

-

Laser Thick Film Trimmer

Laser Thick Film TrimmerResistance adjustment range 100mΩ~20MΩ, used for laser resistance adjustment of chip thick film resistors/hybrid circuits (thick film) on ceramic substrates

-

Laser Scriber

Laser ScriberFront and back line repeatability less than ±5 μm, achieving ±0.75μm/70mm straightness and ±1μm positioning accuracy

-

Single Chip-resistor Tester

Single Chip-resistor TesterUsed for first inspection before laser trimming, re-measurement or final inspection after laser trimming

-

High Voltage Resistor Tester

High Voltage Resistor TesterUsed to test single-chip resistor substrates, with the withstand voltage characteristics of each resistor before and after resistance adjustment

-

TCR Tester

TCR TesterUsed for testing the TCR values of individual resistors on single-chip resistor substrates

-

Inductor Laser Peeling Machine

Inductor Laser Peeling MachineFor laser removal of resin layers/enamel layers on molded inductors and wound inductors