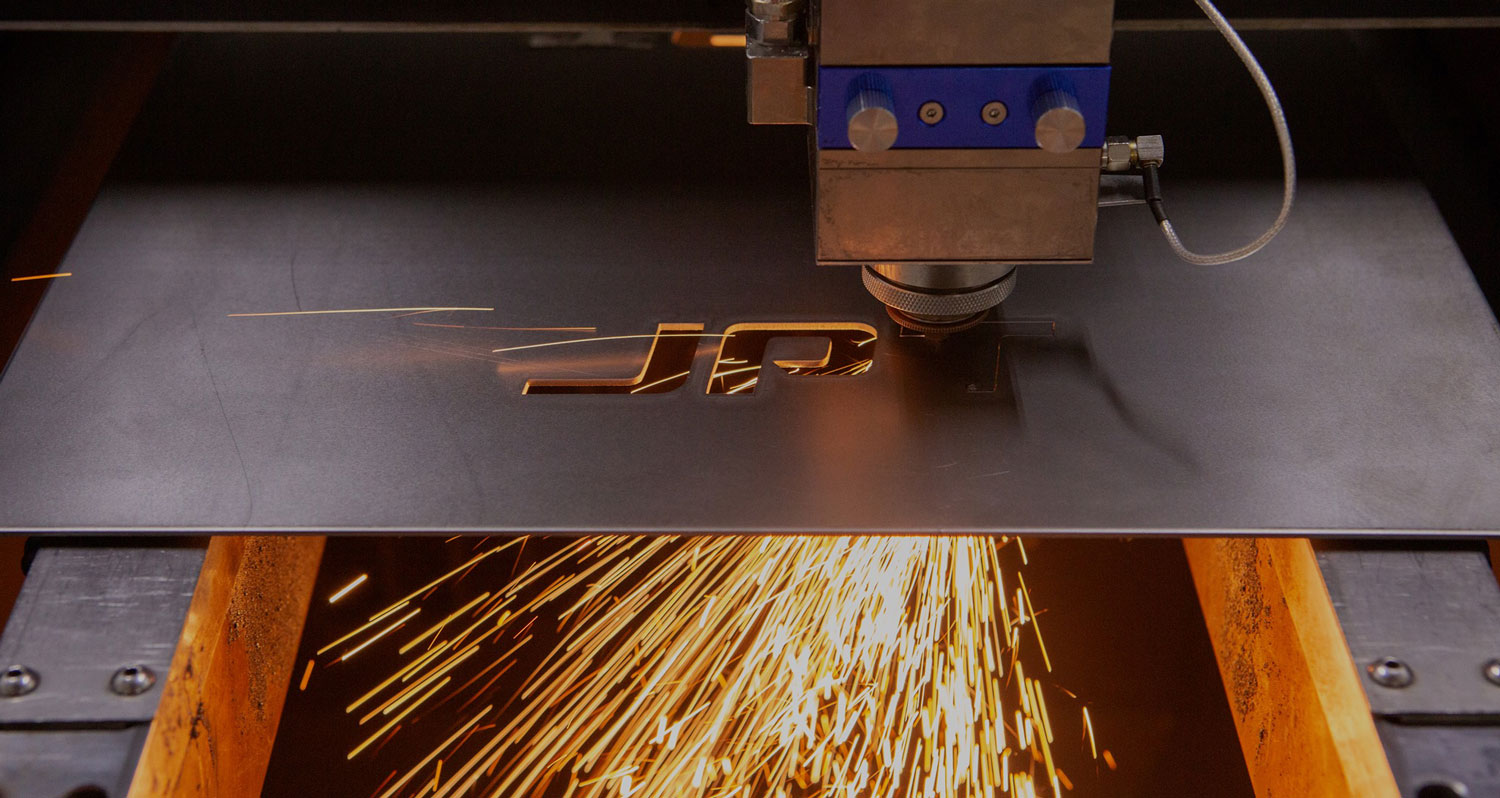

Laser Welding

It can be divided into three categories.

The first type: Thermal conductivity welding, refers to energy density less than 105w/cm² welding method. It is characterized by wide and shallow welding pool section.

The second type: Deep penetration welding, refers to energy density at 105w-107w/cm² welding method. It is characterized by a narrow and deep keyhole in the welded pool section welding.

The third type: MOPA laser welding, using the characteristics of high peak and short pulse of MOPA laser, This enables MOPA laser welding to be used for welding between two or more dissimilar metals with different melting points. It is characterized by sawtooth welding pool section. It also can be call "micro keyhole welding".

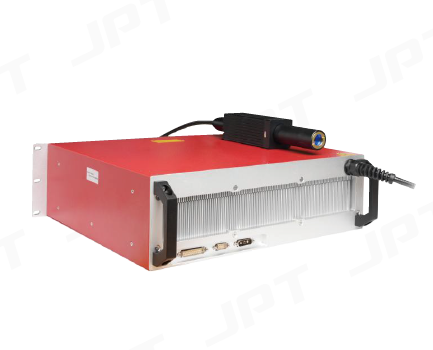

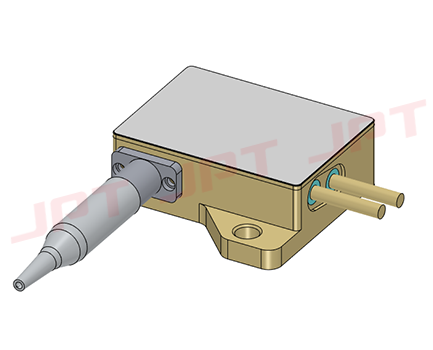

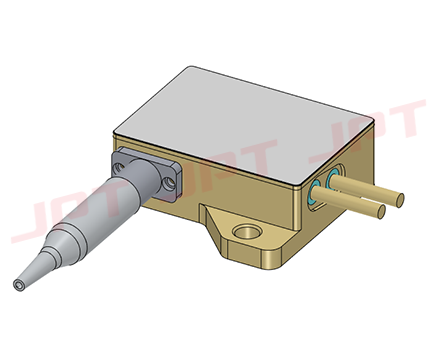

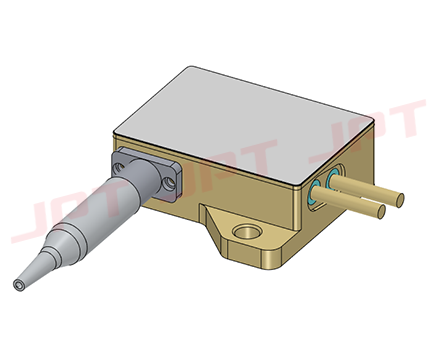

M7 20W-100W

M7 20W-100W

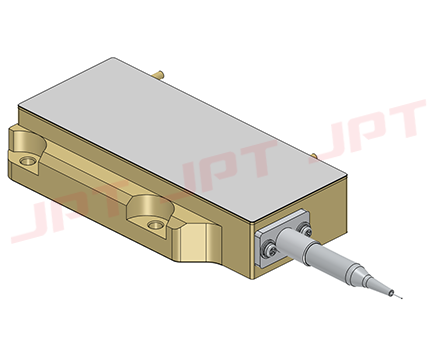

M7 200W-300W

M7 200W-300W

M7 500 - 1000W

M7 500 - 1000W

M8 20 - 50W

M8 20 - 50W

M8 120 - 300W

M8 120 - 300W

CL2 200W-300W

CL2 200W-300W

CL 500W~1000W

CL 500W~1000W

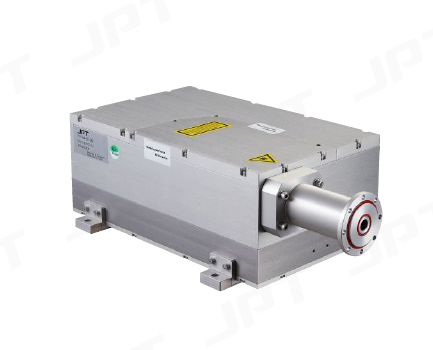

CL 2000W

CL 2000W

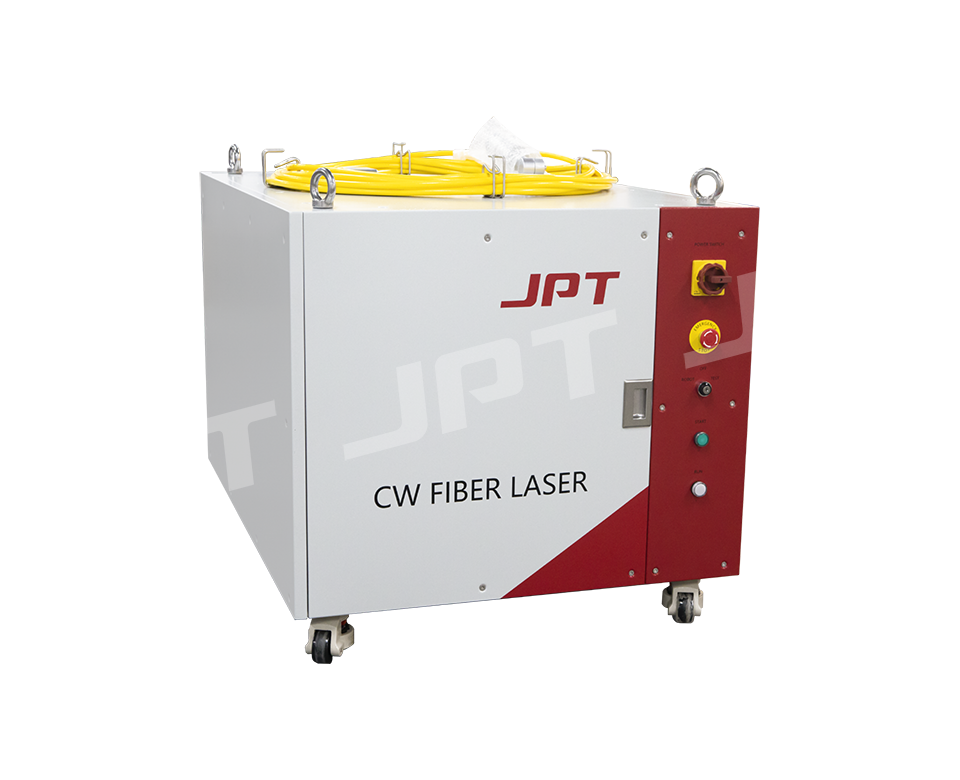

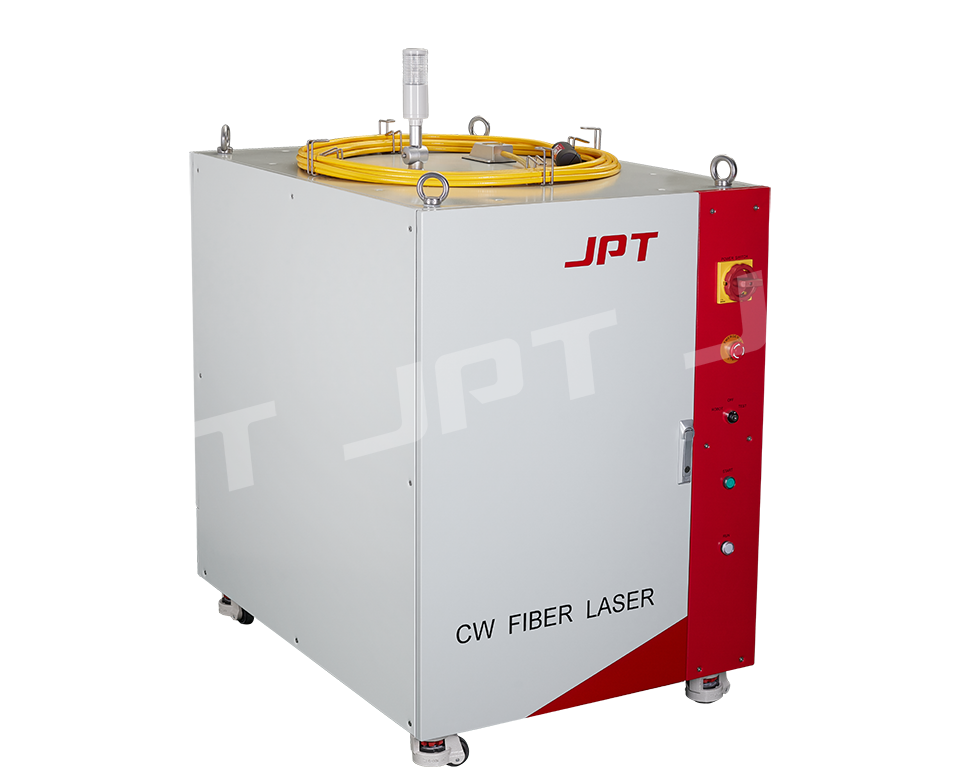

Multi-Module CW 6000W

Multi-Module CW 6000W

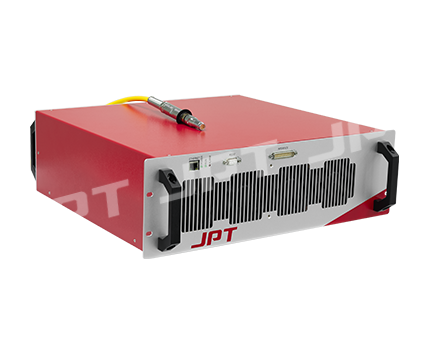

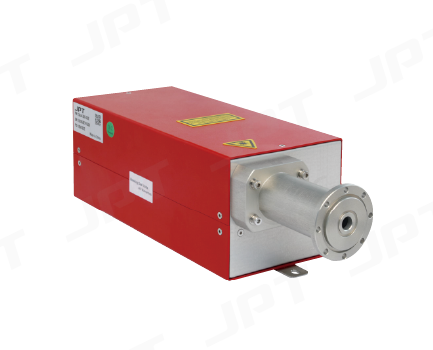

QCW 150W/1500W

QCW 150W/1500W

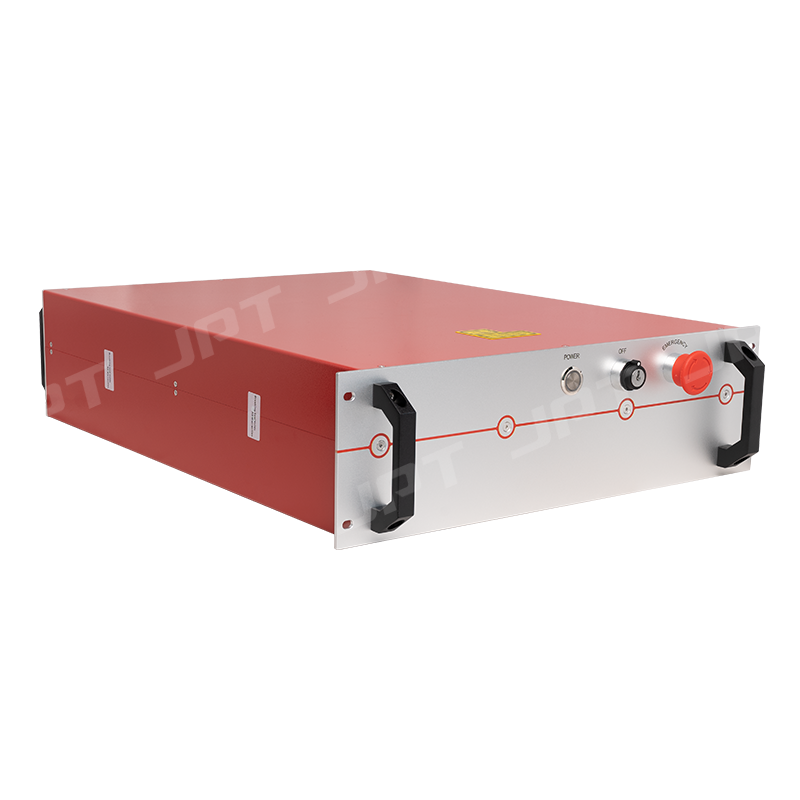

Multi-Module CW 12000W

Multi-Module CW 12000W

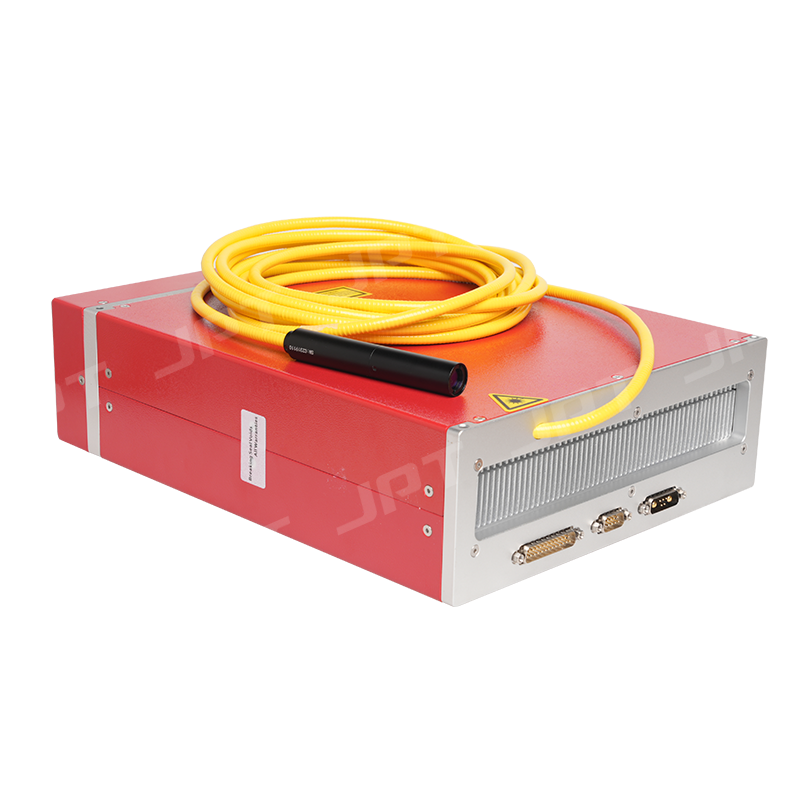

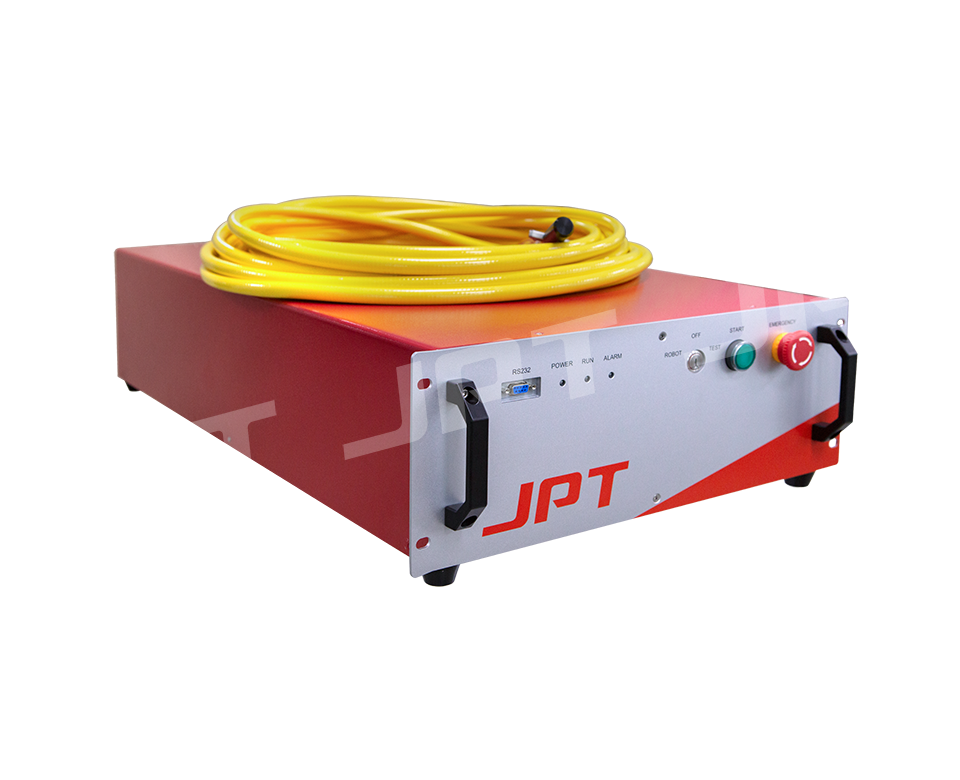

Single-Module CW 1500W-3000W

Single-Module CW 1500W-3000W

SEAL 355-3/5

SEAL 355-3/5

SEAL 532

SEAL 532

LARK 355-3/5

LARK 355-3/5

PS IR/GR/UV Picosecond Laser

PS IR/GR/UV Picosecond Laser

SEAL 355-10/15/20/30

SEAL 355-10/15/20/30

Semiconductor Laser with Red Light Series 200W

Semiconductor Laser with Red Light Series 200W

450nm—100W High Power Diode Laser

450nm—100W High Power Diode Laser

10W-1064-01 Silicon Transmission Series Detection Moduler

10W-1064-01 Silicon Transmission Series Detection Moduler

1060nm Series

1060nm Series

880nm Series

880nm Series

808nm Series

808nm Series

976nm Series

976nm Series

915nm Series

915nm Series

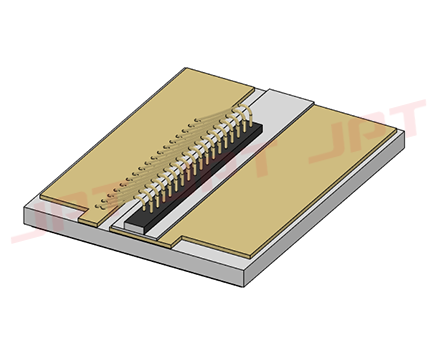

COS Encapsulated Semiconductor Laser

COS Encapsulated Semiconductor Laser

Laser Scriber

Laser Scriber

High Voltage Resistor Tester

High Voltage Resistor Tester

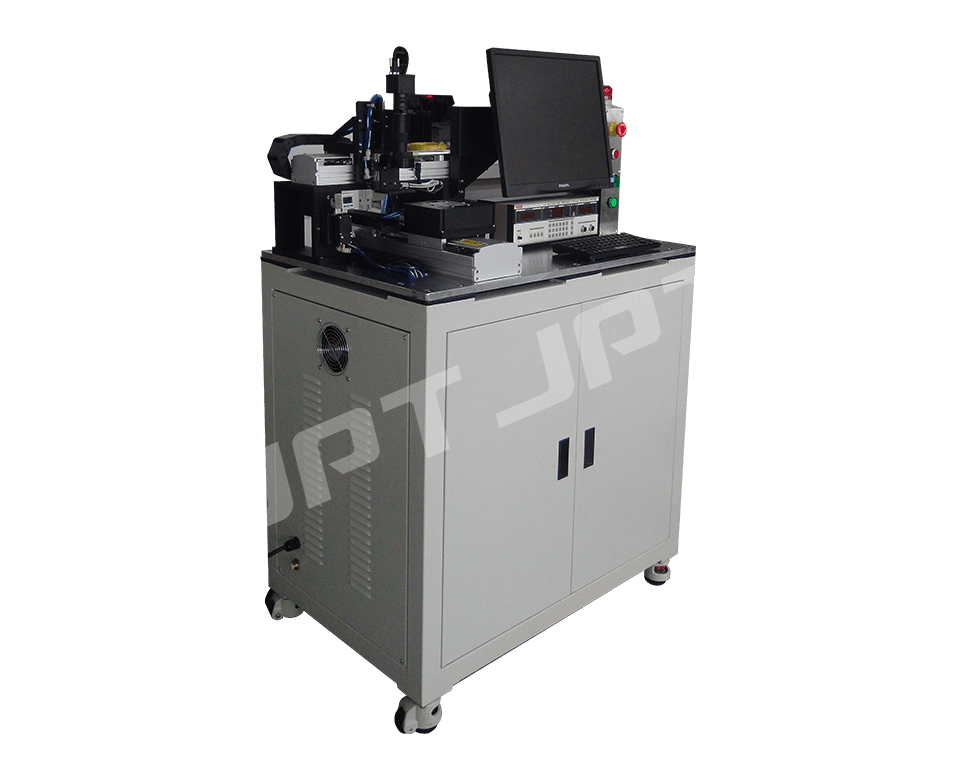

Single Chip Resistor Tester

Single Chip Resistor Tester

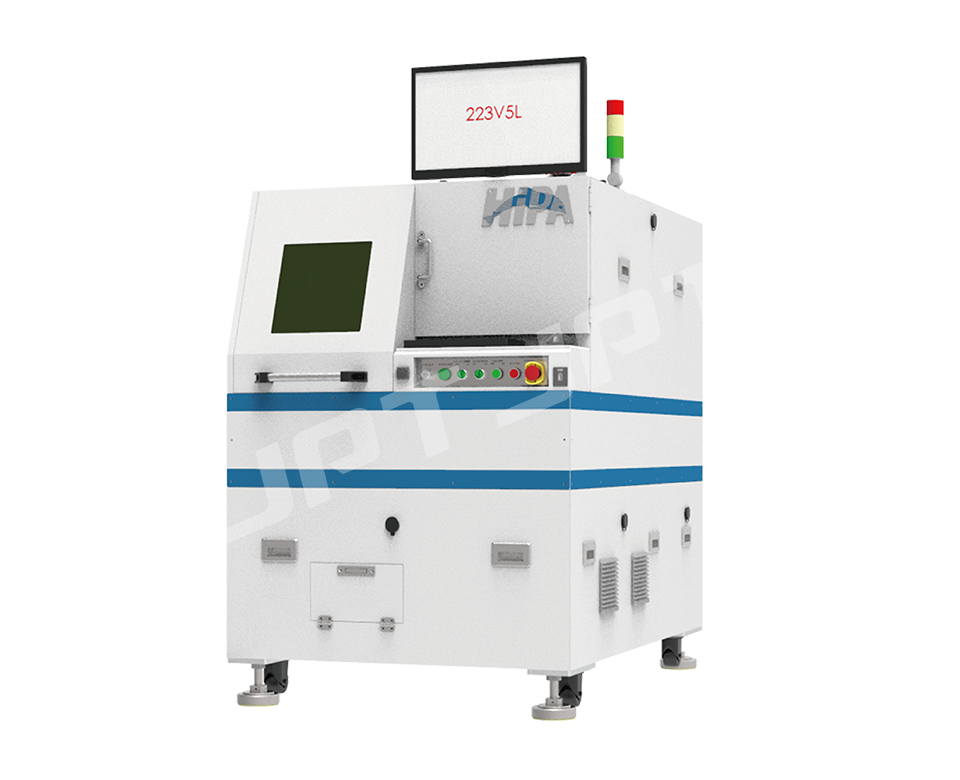

Laser Trimmer

Laser Trimmer

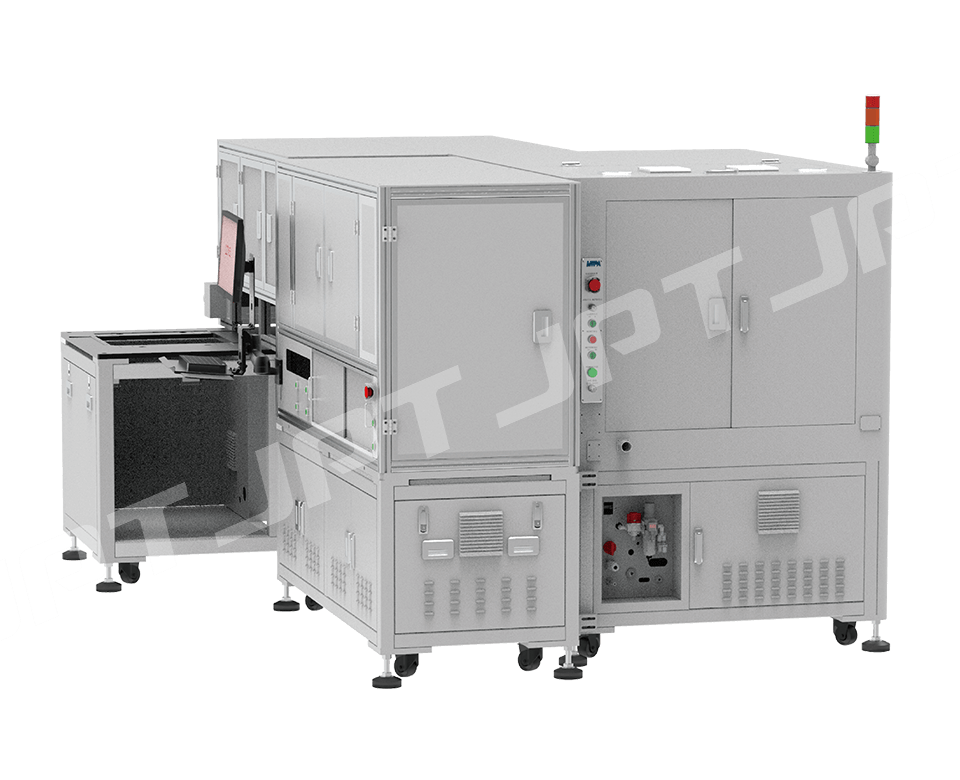

Hybrid Trimmer

Hybrid Trimmer

HiPA-TT Light Transmittance Tester

HiPA-TT Light Transmittance Tester

PCB Laser Marking System

PCB Laser Marking System

Ghost Writer & Reader - Subsurface 2D Barcode Marking & Reading System

Ghost Writer & Reader - Subsurface 2D Barcode Marking & Reading System

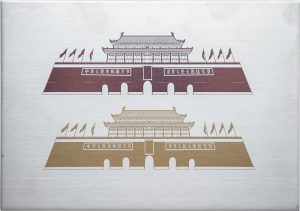

High Precision 2DBC Laser-marking

High Precision 2DBC Laser-marking

Comprehensive VCSEL Module tester

Comprehensive VCSEL Module tester

Comprehensive LED-PD Integrated Module Testing

Comprehensive LED-PD Integrated Module Testing

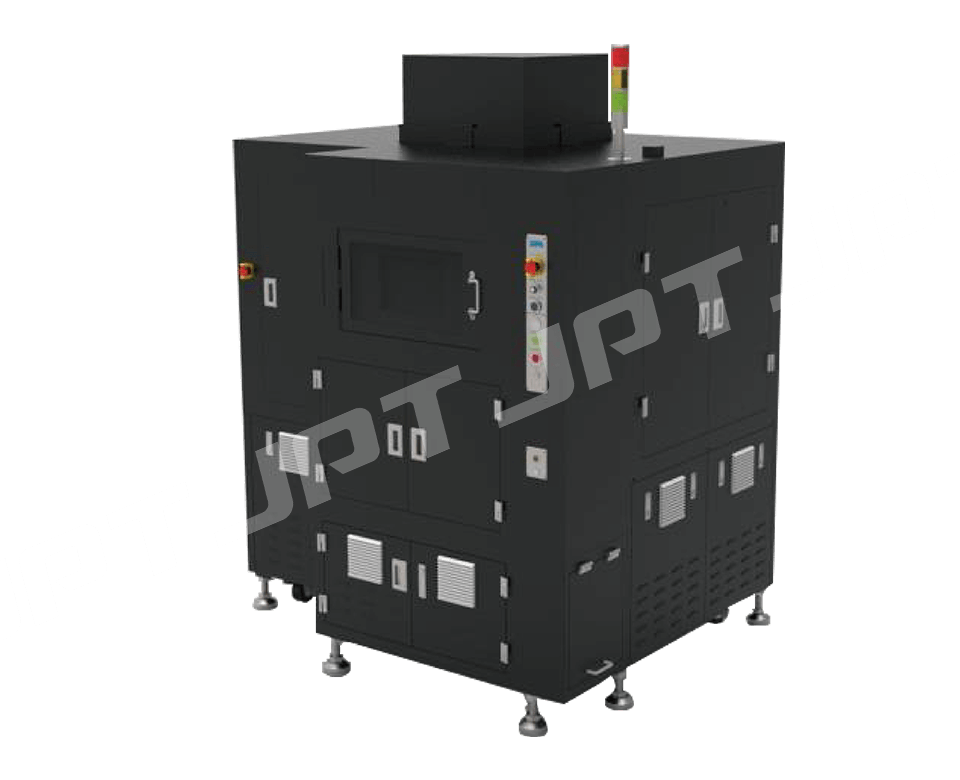

Six-sided Inspection Machine

Six-sided Inspection Machine