Company introduction: Established in 2006 , JPT Opto-electronics is a ‘National High-tech Enterprise’ with over 1000 employees. The company now focuses on the R&D, production, sales and technology service of fiber lasers and solid-state lasers.

JPT has a very strong R&D team with many PhDs and Masters having overseas academic experience, and owns a large number of patents and other intellectual properties. The products are widely used in optical communication, optical sensing, laser inspection, laser machining, medical laser care, etc.

‘Leading optical technologies for people‘ is the mission of JPT. With the rapid development, JPT will become a global outstanding solutions provider of fiber optics and fiber lasers in the near future.

Since founded in 2006, JPT has over 13-years experience in the research, development and sales of Master Oscillator Power-Amplifier (MOPA) fiber lasers, and thereof, possesses leading technology in MOPA fiber laser.

As compared to the Q-switching technology, the pulsed repetition frequency (PRF) and pulse width can be controlled independently in MOPA configuration, through adjusting different combination of the above parameters, the peak power of laser can be well maintained.

This enables JPT laser suitable for more material processing which Q-switched limited. JPT laser is able to provide arbitrary pulse width and repetition rate in the wide ranges of 1ns-500ns and 1Hz-4000kHz in pulsed mode, respectively.

The extended function of waveform-editing can further contribute to increasing pulse energy for high-efficiency laser processing.

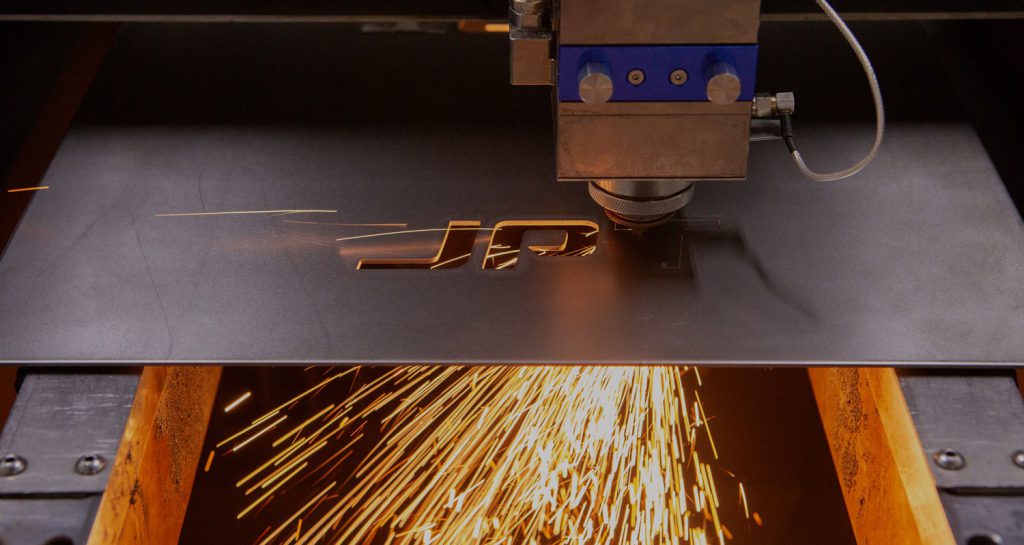

Laser material processing is to focus a high-energy laser beam on the surface of the substrate for the purposes of cutting, welding, marking, and stripping etc.

Owing to the advantages of non-contacting, wide range of applicable objects, very little pollution, high precision and easy to auto-control, laser technology has replaced conventional methods in the filed of marking, welding, and is expected to work efficiently in surface cleaning where chemicals and abrasive blasting are currently used.

Chemicals and abrasive blasting cause environmental pollution and damage delicate surfaces, and these problems prompt the development of laser technology in this field.

Furthermore, MOPA fiber lasers enables precise adjustment of pulse width, pulse energy and waveform, thereof, showing great potential in high-quality surface cleaning as a non–abrasive and non–hazardous alternative.

Laser stripping from ships is one of the related investigations since shipboard corrosion repair and surface preparation for new paint are currently two of the main maintenance challenges that ship operators have to face. Fortunately, laser technology offers utmost flexibility in removing the rust/oxide from the native metal surface.

- The physics of laser process make it unprecedentedly effective in removing corrosion from any complex details in ships’ body and components.

- The laser energy absorption is highly selective, thus, can remove metal oxides while keeping the native metal substrate intact. The rust/oxide is either vaporized or suctioned away as particles.

- It is possible to selectively remove coatings in a multi–layer paint system. The ablation depth for single scan can be controlled within a few micrometer and this process is repeated until reach the desired depth.

- Laser technology can precisely clean certain spots on that surface, giving the focus beam spot size can be as small as tens of micrometers.

- Laser process can produce roughness surface characteristics while removing corrosion to get ready for re-painting without any further preparation.

To improve cleaning efficiency, laser derusting uses high energy, high frequency, high power characteristics. JPT’s MOPA fiber laser can produce pulses with large single pulse energy of 30mJ, high average power of 500W, and high repetition frequency up to 2000kHz for efficient laser derusting.

By adjusting different combination of the above parameters, JPT laser can remove various types of rust/painting.

The corrosion products of steel are normally made of iron sesquioxide (Fe2O3) in the color of red or yellow. The iron sesquioxide on the metal surface can be removed with rapidly with large beam diameter and high average power.

Corrosion product of ferriferrous oxide / ferrous oxide layer is stubborn and requires higher power density for removal, therefore, small beam diameter and large pulse energy are needed.

In addition, the design of JPT’s 500W MOPA fiber laser enables composite pulses (as well as continuous wave) for composite welding/cutting of high-reflection metal materials.

Copper/silver has litter absorption in the near-infrared wavelength range, resulting in large waste of laser energy and splashing during the process of machining. Such problems can be released by adding a pretreatment with high peak power pulse to destroy the high reflectance at surface by producing oxides or creating roughness.

Generally, simultaneous composite welding/cutting is realized by focusing two different laser source beams onto the same location which requires complex motion controlling and bulky components.

However, with JPT’s 500W fiber laser, a laser source that can produce composite pulses transmitting in a single fiber, composite welding/cutting can be carried out in the simplest way.

JPT’s 500W MOPA fiber laser show excellent laser performance as well as high level of temporal pulse shaping and pulse width controllability, enables the utmost flexibility in achieving high-quality and high-efficiency laser surface processing for industry use.

You May Also Like

HiPA Solutions – Laser Micro Hole Drilling

Flexible circuit boards, referred to as FPC are widely used in consumer electronic products such as microelectronics, 5G mobile phones, laptop computers, and new energy vehicles. Also as electronic interconnects to connect products.

HiPA Solutions – Laser Ink Removal

Ink is an important material for printing. By printing or inkjet, patterns and characters are displayed on the substrate. Among them, screen printing inks are widely used on the cover glass of various display panels such as mobile phones, computers, smart watches, cameras, etc.

JPT Solutions – Thick Glass Cutting with Ultrafast Laser

Table of Contents Applied Industry Because of its excellent optical properties and unique wear resistance, cover glass is used in automotive display screens. The continuous

- How to Avoid Common Mistakes in Laser Engraving - 27/07/2021

- Leading-edge Laser Solutions for Surface Processing - 16/11/2020