Used exclusively by industrial manufacturers before, laser marking technology is today used by small business enterprises, makers, hobbyists, and product designers in many different ways. Overall, the laser maker has proved to be a cutting edge in the manufacturing technology regardless of the application.

But what do you know about laser marking technology? To get you started, we have gathered everything you need to know about laser marking. Read on to know more about what laser marking technology and the marking processes involved.

What is Laser Marking Technology?

Laser marking technology consists of a high-frequency beam produced by a laser source, amplified and directed to a material to be marked. Even though laser marking technology is considered new technology, however, it has existed for more than 50 years now. Perhaps, its applications are what have made it popular today.

Types of Laser Marking Technology

Laser marking technology comes in four common types; fiber laser technology, CO2 laser technology, and Nd:YAG, Nd:YVO (crystal lasers). However, fibre laser technology is the most recognized and widely used due to its effectiveness. Besides, it provides a host of solutions for different industries.

Fiber Laser Technology

In fiber laser technology, a beam is produced and contained in the core of the fibre. It is doped with ions such as ytterbium. As such, a high-intensity laser is generated, which is ideal for engraving metals as well as in high-contrast plastic markings.

The fiber laser is capable of marking flexible packaging material that has no special laser field. Moreover, due to its stable beam, the fiber laser doesn’t perforate flexible films like those used in modern packaging. For this reason, fiber laser technology is used widely in the food and grocery industries.

The fiber laser technology is advantageous as it is maintenance-free for over thousands of marking hours. With this technology, you can expect more than four times life expectance compared to the average CO2 laser tube technology.

CO2 Laser Technology

CO2 laser technology is a bit old-fashioned type of laser marking compared to fiber laser. It utilizes a CO2 gas mixture that is electrically excited to generate high efficiency and quality beam. The CO2 laser technology is used mainly due to its cost-effectiveness, low maintenance, and low costs of operations. Besides, you don’t need consumables to use this laser technology.

The CO2 laser machines are versatile and can mark a wide variety of materials at high line speed. Such materials include foils, wood, plastics, cardboard, paper, coated metals, and glass, among others.

Nd:YAG, Nd:YVO (crystal lasers)

Crystal lasers belong to the solid-state lasers just like fiber laser. The most common laser types pumped by diodes are Nd:YAG (neodymium-doped yttrium aluminum garnet) and Nd:YVO (neodymium-doped yttrium ortho-vanadate), named after the doping element neodymium and the carrier crystal. Crystal lasers have the same wavelength as fiber lasers and are thus also suited for marking metals and plastic

What’s different with fiber lasers is that these laser types include the relatively expensive pump diodes, which are wearing parts. They must be replaced after approx. 8,000 to max. 15,000 laser hours. The crystal itself also has a shorter service life than a fiber laser.

What’s the Process of Laser Marking?

The process of laser marking involves the use of a focused beam of light to mark different surfaces of materials. The marking happens when the beam acts on the material surface to alter the material’s chemical properties and appearance.

For laser marking to work, the beam has to concentrate on a specific area for the laser beam to create accurate, high-quality, and extremely contrasting marks for easy reading or scanning on nearly any surface.

Unlike non-permanent marking processes like labeling or printing, laser marking requires no consumables to create the permanent markings. Besides, laser marking machines require very little or no maintenance.

Different laser marking systems require different operation techniques. The correct process of operation is dependent on the kind of material you mark and the type of application you are using. However, whatever the laser machines you are using, be sure to consider all the safety guidelines required.

Different Types of Laser Marking

Depending on the kind of application, you can use one of the different types of laser markings available. Let’s have a look at some of the laser marking methods that you can use.

Annealing

Annealing is a type of laser marking involving focused heating of a metal surface or other material you intend to mark with a laser beam to create a mark. A mark is created when the focused beam heats to cause structural change on the metal due to color alteration. The markings created are commonly black, however, it can also be green, red, or yellow depending on the extent to which the layers of the material are heated.

Annealing creates a permanent abrasion-proof marking and is used in different industries like in medicine, automotive, dental, and manufacturing. For instance, marking a nameplate for listing or identifying the specifications of a machine requires an annealing laser marking technique.

Colour Marking

The color marking technique is used mainly in laser marking stainless steel materials, and it essentially depends on the material composition. A laser beam interacts with the material pigments, which are added during the manufacturing of the metal material.

Through the photoelectric effect, a color change is experienced on the material, thereby marking the materials.

Engraving

Engraving is a laser marking method that is ideal for creating marks on coated materials. The entire process involves concentrating the laser beam on the material to reveal the substrate layer. If the two layers feature different colors, a contrast is created.

For coated materials like anodized aluminum, they display excellent markings, especially when marked with this laser method. Engraving is used mainly in materials such as stones, ceramics, metals, and plastics.

Since there are no consumables needed, the engraving laser technique attracts low operational costs compared to when you want to engrave using inks or drill bits.

Foaming

Foaming is a laser marking technique that is employed when producing a light color marking, and carbonizing is not of any help. The foaming process entails heating of the surface of a material to a melting point, and gas bubbles are generated.

The oxidized resulting in gas bubbles create a frothing and reflect light. The mark created raises above the other surface with high contrast from the rest. The discoloration effect appears in polymer surfaces. The foaming laser marking is ideal for dark-colored objects.

Carbonizing

Carbonizing is a laser marking method used exclusively in marking organic materials and synthetic polymers. The process of carbonizing involves heating the material to break down the plastic bonds to release oxygen and hydrogen. A reaction takes place to darken the heated areas.

Since carbonizing creates between grey and blue-grey colors, the process is always ideal for dark-colored items. As such, low contrast between the marked area and the rest of the material is established. The Carbonising laser method is used mainly on leather, wood, paper, and packaging materials, and more.

Night and Day Marking

This laser marking technology involves the concentration of the laser beam to remove subsequent layers of paint to when your desired color is a visible and transparent surface that lights up to show a symbol of reference component. The night and day laser marking method is referred to as selective ablation.

However, the laser beam focus should not be on material as it can easily burn the material. Nonetheless, the layers of the paint should be removed to create contrast. Night and day laser marking method is used in backlit electronic components that feature special symbols or log, automotive, aerospace, and home appliance industries.

Laser Marking Applications

The laser marking process has applications in a wide range of industries and sectors. The laser marking is used mainly in processes such as labeling bar codes, QR codes, part numbers, date codes, serial numbers as well as adding copyright and logos to several materials across various industries.

Night and day laser marking is applied in the marking of backlit electronic components for clear seeing both at night and during the day. Also, it is used in the marking of signage, car dashboard, mobile phone buttons, and more.

Laser marking is popular in the manufacturing industries with integration to different sub-processes in various production lines. For instance, in the automotive industry, laser marking is evident in component marking like in spark plugs. In the electronic industry, laser marking is used in marking printed circuit boards, while in the medical field, it is used in labeling medical implants.

Laser marking technology is widely used in the aerospace industry in marking various components of aircraft, especially in the cockpit and dot peen marking. Without a doubt, laser marking technology is widely applied virtually in every industry.

Are any target incompatible with laser marking?

Laser marking can be done with any material. Nonetheless, some materials tend to accept specific types of laser makers. As such, use the right laser machines in marking materials that are acceptable to the marker, otherwise, the marking may not be successful.

Benefits of Laser Marking

Laser marking comes with several benefits unique to different industries. Let’s look at some of the benefits that come with laser marking.

Laser marking delivers high accurate markings even with delicate graphics. Regardless of the font or small geometric, information is marked clearly and eligibly. Besides, laser marking assures constant high-quality marking on materials.

Laser marking is arguably the fastest marking process you can get in the market. Its high speed significantly increases productivity while lowering the cost of manufacturing.

Laser marking delivers permanent markings that are abrasion, acids, and heat resistant. With appropriate laser settings, you can mark your materials without damaging the surface.

When compared to other methods of marking, laser marking stands out as safer. It generates no toxic fumes or any waste during marking. As such, it offers a safe environment for anyone operating the laser during the marking process.

A laser marking system can mark different kinds of materials. As such, it provides more versatility in terms of usage. With a single laser machine, you can label different types of metals without a hassle.

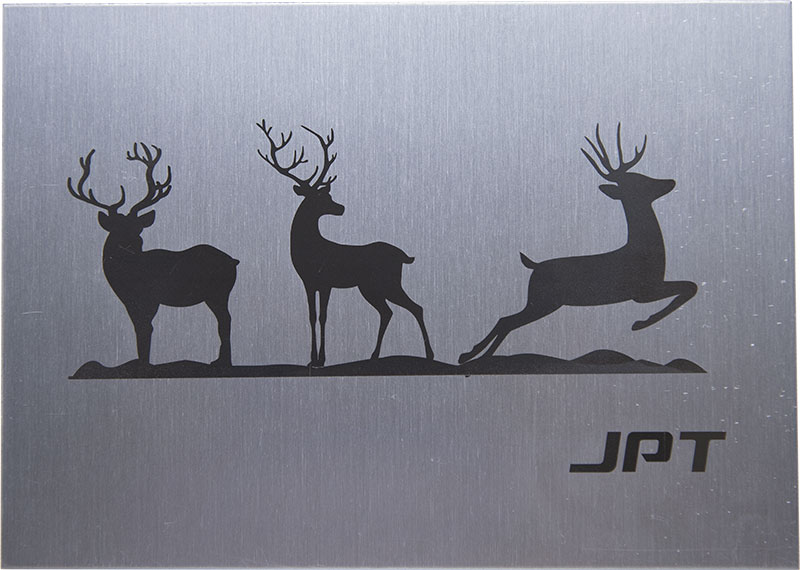

JPT’s Laser Source Advantages for Laser Marking

The JPT laser has a different laser source, which makes it deliver outstanding high resolution engraves while maintaining stability during marking. This laser source also allows the marking of various types of materials.

Moreover, it has an extensive range of frequency to allow you to set different parameters to mark more material, especially the non-metal materials compared to lasers with fiber sources.

Laser marking technology has made the operation of various processes seamless and cost effects. With the versatility of laser marking, you can mark virtually any surface. Different laser marking processes stems out from this technology to allow for creating excellent markings on materials. If you are planning to mark your items permanently, do not look further than laser marking technology!

- HiPA Solutions – Laser Micro Hole Drilling - 09/12/2022

- HiPA Solutions – Laser Ink Removal - 03/12/2022

- JPT Solutions – Thick Glass Cutting with Ultrafast Laser - 03/12/2022