Table of Contents

Anodized Aluminum Overview

Aluminum is a versatile material and has found applications in various industries due to its high malleability and ductility. However, high malleability presents challenges for creating long-lasting marks on aluminum surfaces.

Anodized aluminum – which is essentially aluminum enhanced with a corrosive resistant layer – comes to the rescue. Anodizing is the process of transferring an aluminum surface into aluminum oxide through an electrochemical process. Anodized aluminum is more resilient to corrosion and abrasion. It is best suited for creating long-lasting marks and does not rust, damage, or scratch easily.

Moreover, anodized aluminum layer color can be of the color blue, black, white, or any other color dye. With the help of a laser machine, the anodized layer is heated by laser pulses evaporates, requiring little or no cleanup after the process.

Anodized aluminum produces stunning bright high contrast marking on the product. The anodized aluminum is extensively used for a wide range of laser marking applications, including tags, barcodes, QR codes, serialization, brand logos, sign plaques, award trophies, and so on.

Can Laser Etch/Engrave/Cut Anodized Aluminum?

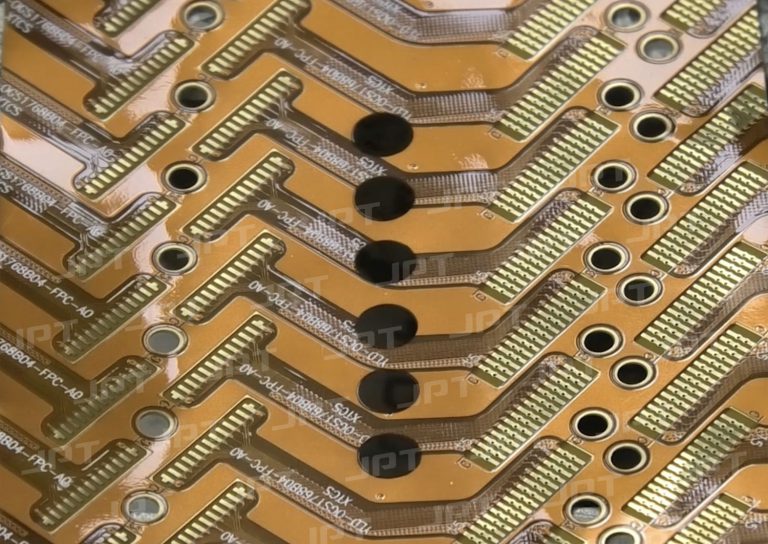

Using fiber lasers, you can easily etch, engrave, or cut anodized aluminum. Although these processes are often used interchangeably, there are specific differences between these processes. Each type of process has its uses and applications that make it ideal for particular jobs. JPT M7 series fiber lasers available in different power range – M7 20-30W for marking, 60-120W for deep engraving, and CW or pulse laser M7 200W for cutting – are best suited for anodized aluminum.

In the laser etching process, the cover layer of material is vaporized, producing minimal to no depth but high contrast marking. Laser etching works best on materials with bare, plated metal surfaces, as well as on anodized aluminum. Anodizing affects the surface of the aluminum to a depth in the range of 0.1 to 1.0 mm. The laser etching is the best way to etch the anodized aluminum surface since they produce a depth of around 0.25 mm. JPT fiber laser M7 20-30W can be used to mark black anodized aluminum and create bright high contrast marking for barcodes, jewelry, tags, etc.

Laser engraving works by vaporizing some of the base material and affects the surface to a depth of about 3 mm. It creates a cavity in the surface that is noticeable to the eye and touch. Engraving affects the aluminum layer underneath the anodized aluminum. It forms deeper marks in the material, which are long-lasting and more vulnerable to damage. Laser engraving is mainly used for engraving serial numbers, logos, and marking parts of automobiles, phones, and aircraft, among other things. JPT M7 60-120W fiber laser is best suited for deep engraving anodized aluminum.

Laser cutting happens when you apply enough power to completely remove the material. Laser cutting with correct power configurations can cut materials with various degrees of hardness. Therefore, anodized aluminum can be easily cut using the laser cutting process. JPT M7 200W CW or high-power pulse filer laser works well for cutting the anodized aluminum.

Steps For Laser Etching Anodized Aluminum?

Place the anodized aluminum object flat on the space provided in the laser etching machine.

Focus laser on your material. Focus the distance such that the laser is above the material. Adjust the work holding board up or down so that material just touches the lens focus tool. Then, move the laser head assembly to its standard starting position. Now, the laser is ready to start.

Import design file into the graphical editor. The laser etching works like a computer numerically controlled router. It imports designs from design software and transforms them into a vector map that tells the laser machine correct areas to mark.

Set the speed and power of the laser. Different results can be obtained by adjusting the speed, frequency, energy, and the number of passes. Select laser settings according to your application. Settings for different kinds of laser applications are provided in the manual that comes with the laser marking system. Suppose correct settings that will generate the required results are not known. In that case, it is recommended to etch the material using different settings to find which one produces the required results.

Set the height and width of your material. This makes sure that the laser knows precisely where to print the text. Click on the start button to begin the etching process. The laser will be activated and rapidly oscillate in a pattern that etches design onto the anodized aluminum material. Once the process is over, look inside the laser machine and take out newly laser etched anodized aluminum.

Tips to Guarantee Successful Laser Marking Anodized Aluminum

Laser making that is bright, clear, and high contrast and looks professional can be easily created by following these simple tips.

1. Prepare the specimen

First clean the specimen of all dust marks, debris, and oils. Next, wipe the specimen surface using ethanol or acetone. Make sure that the sample is lying flat with respect to the flat surface.

2. Create vector graphic

Use AutoCAD, Adobe Illustrator, Corel Draw, or any other vector graphic design software to draw your design. You must draw the design in vector graphic format since it can be scaled without any fear of resolution issues.

3. Select correct laser settings

You need first to ask yourself what you are looking for? The ideal mark is the one that is bright, high resolution, and consistent across the marked area.

Fiber laser settings for creating black marks on anodized aluminum are listed below:

- Power: 70-90%,

- Pulse width 2-9ns,

- Frequency: 200-500kHz

And for creating white marks on anodized aluminum, there is a little bit difference, here are the reference:

- Power: 70-90,

- Frequency: 50-100kHz,

- Speed: 1000-2000mm/s

But further trial and error may be required due to the variability of the material and coatings.

4. Second pass

Multiple passes of the laser etching can be considered if bright high contrast etching is desired. A second-high speed, high-frequency pass brightens the marking and produces a much better result.

How to Remove Laser Etching from Anodized Aluminum?

Before removing laser etching, one should consider the initial etching and the depth of the marks. Some laser etching requires nothing more than buffing the metal to provide a clear surface, while others may need laser ablation to remove the etching.

In the laser ablation process, an intense laser pulse is focused on the anodized aluminum surface. The energy transferred to the surface is enough to remove layers of material by vaporization. It removes the surface material accurately without damaging the material underneath.

The ablation phenomenon only happens when the intensity of the laser beam is superior to the material’s ablation threshold. The process can be controlled considering the depth of the oxide layer by raising or lowering the laser’s pulse power, wavelength and intensity. Therefore, laser ablation provides more flexibility and better results for removing the laser etching from anodized aluminum as compared to the buffing.

Laser Etching Projects Gift Ideas with Anodized Aluminum

Anodized aluminum is a versatile material, and a range of products can be marked using laser etching. Here are some suggestions for designing and printing your unique ideas using anodized aluminum.

Gifts

You can add a personal touch to gift items by creating something unique for your special someone. Plenty of cool gifts ranging from phone cases, keyrings, lighters, jewelry items, and even personalized nameplates can easily be marked using laser etching anodized aluminum.

Greeting Cards

Laser cut and designed greeting cards for someone special in your life are an excellent means of celebrating any occasion. Custom design greeting cards for memorable events like Christmas, Birthday, or Anniversary can be easily created using laser etching. These cards look great when laser cut into your choice of paper for the cover of greeting cards.

Promotional Items

Souvenir with your business name or logo creates a lasting impression on your clients. Laser-marked anodized aluminum items such as pens, water bottles, and pen drives are a great way to promote your business in any promotional events or conferences.

Recommend Reading About Laser Applications

Comprehensive Laser Cleaning Guide – Advantages and Benefits

Table of Contents What is Laser Cleaning? Laser Cleaning is the process of removing the unwanted contaminants or impurities from the surface of a material

The Complete Guide to Laser Drilling

What is Laser drilling process? Laser drilling process is a vital part of the manufacturing process. Laser-based drilling uses a fiber laser beam to create