Applications and development status of laser drilling industry

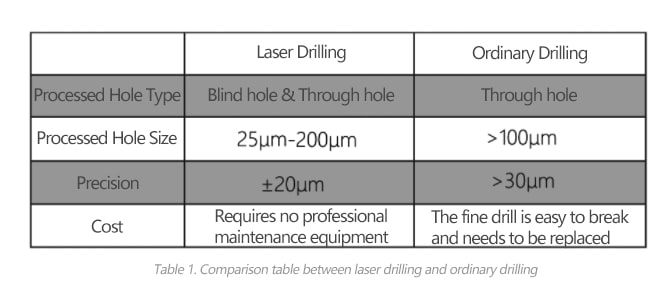

Flexible circuit boards, referred to as FPC are widely used in consumer electronic products such as microelectronics, 5G mobile phones, laptop computers, and new energy vehicles. Also as electronic interconnects to connect products. With the continuous iterative update of 3C electronic products, the use of flexible circuit boards not only reduces the design volume relatively, but also greatly reduces the overall product volume due to material properties.

Laser micro-hole drilling equipment used in the circuit board industry requires relatively high laser control technology. At present, this core technology is mastered by foreign manufacturers including the United States, South Korea. Due to the common problems of domestic laser drilling machnie in China, such as the insufficiency of the taper and roundness of micro holes, poor laser power stability, and insufficient drilling positioning accuracy, domestic PCB factories are more willing to purchase such equipment from foreign manufacturers. However, foreign equipment is not only expensive, but also unstable in delivery. With the increasingly severe international competition situation, once the United States and South Korea stop supplying such equipment to China, the production of domestic PCB manufacturers will be greatly affected, which will cause a series of product supply chain problems.

How does laser drilling work and why should you choose laser drilling?

1.How does laser drilling work?

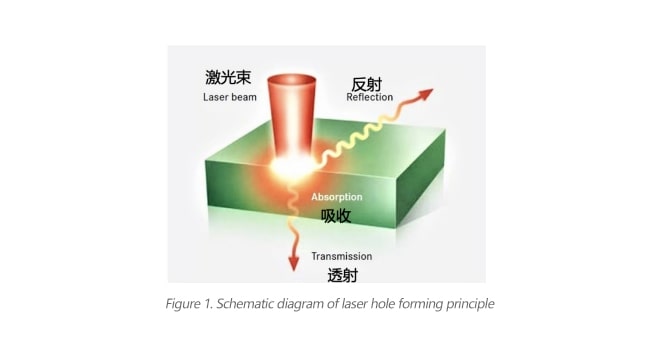

Laser means that the electrons in atoms absorb energy and transition from a low energy level to a high energy level, and then fall back from a high energy level to a low energy level, the released energy is released in the form of photons. Among them, infrared light and visible light have thermal energy, and ultraviolet light has optical energy. When the laser irradiates the surface of the workpiece, three phenomena occur, Reflection, Absorption and Transmission. The principle of laser drilling is to use a laser to rapidly irradiate the processing point to generate thermal ablation and photochemical ablation reactions, thereby removing the material that needs to be processed.

2.Two types of laser drilling

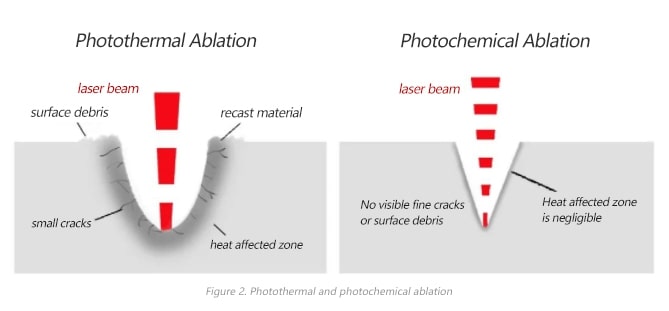

(1) Photothermal ablation:

The principle in which the processed material absorbs high-energy laser light and is heated to melt and evaporate in a very short time to form holes. Using this method, carbonized residues are left on the walls of the pores formed by the high-energy action of the substrate material, which must be cleaned before micro-hole formation.

(2) Photochemical ablation:

The effect of high photon energy over 2 eV electron volts in the ultraviolet region and the action of high energy photons with laser wavelengths over 400 nm. Such high-energy photons are able to break down the long molecular chains of organic materials, turning them into smaller particles. The energy of these particles is greater than that of the original molecules, and can escape from the raw material under the action of external force, so that the substrate material is quickly removed to form micropores. This processing method does not contain the form of hot burning, and does not produce carbonization, so it is very simple to clean up before the holes form.

Laser drilling technique

(1) Single-Pulse Drilling vs Multi-Pulse Drilling

Single-Pulse Drilling: In the simplest case, many holes are maked very quickly by a single-pulse laser beam with relatively high pulse energy.

Multi-Pulse Drilling: The holes are generated using a multi-pulse laser beam with very small pulse energy and a faster pulse period. The holes maked by the multi-pulse drilling process are deeper and more precise than single-pulse drilling. In addition, the multi-pulse drilling can obtain relatively small diameter holes.

(2) Rotary Drilling

In the case of rotary drilling, the holes are likewise generated by a multi-pulse laser beam. First, the laser uses an impact drilling process to obtain an initial hole, and then moves in several larger and larger circular orbits above the workpiece to enlarge the initial hole. During this process, most of the workpiece material melt is pushed downward from the hole.

(3) Spiral Drilling

Unlike rotary drilling, spiral trepanning does not generate initial holes. At the start of the laser pulse, it moves in a circular orbit above the workpiece, spilling a lot of material upwards. The trajectory of the laser is like a spiral staircase, gradually extending downward. During this process, the position of the focal point can be directed so that it is always at the bottom of the eyelet. If the laser has penetrated the workpiece material, the machine has to make a few more turns to widen the bottom side of the eyelet and make the edge smoother. The holes produced by spiral trepanning are large, deep and of high quality.

HiPA laser drilling equipment

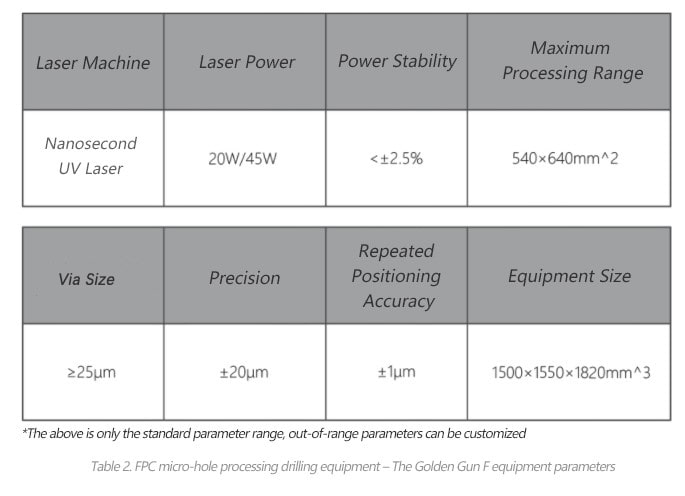

FPC Laser Drilling Equipment – Golden Gun F

1. Equipment Description

High output and low cost, equipped with groundbreaking HiPA laser control technology , Golden Gun F is a high-speed and high-precision FPC micro-hole drilling equipment, which can be used for various types of FPC board to fabricate blind hole , through hole , cutting, removing and etc.

2. Equipment Highlights

- The overall structure design of the equipment is flexible and compact, option for Reel-to-Reel.

- Equipped with high power UV laser, which power is stable to ensure drilling quality and efficiency.

- Equipped with HiPA groundbreaking laser control technology, it can precisely control laser power, frequency and position during high-speed processing, improving drilling quality, processing speed and accuracy.

- Independent research and development drilling software to achieve various processingmethods, which can be customized according to customer needs.

- Equippedwith power monitoring and position compensation system

- Equipped with high accuracy vision positioning system

HiPA software is compatible with various types of functions and easy operation interface which can be learned in a short time.

Advantages of HiPA Laser Drilling Solution

1. Innovative ultrafast laser control technology

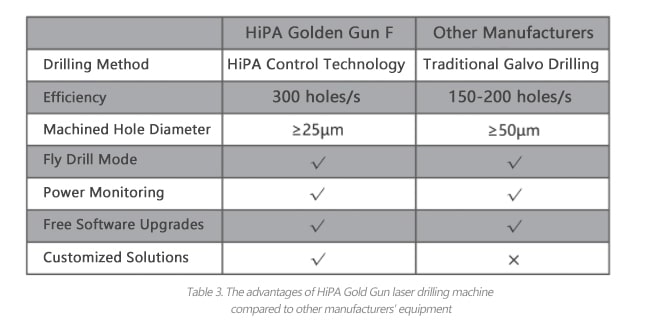

The golden gun laser drilling machine breaks through the limitation of traditional galvanometer drilling. It adopts a new generation of HiPA laser control technology and cooperates with the IFOV technology, which is 1-2 times faster than other domestic laser drilling equipment. Facing the problem of tens of thousands holes, the efficiency improvement is more significant, which helps maximize the production capacity.

2. Excellent techniqueresult

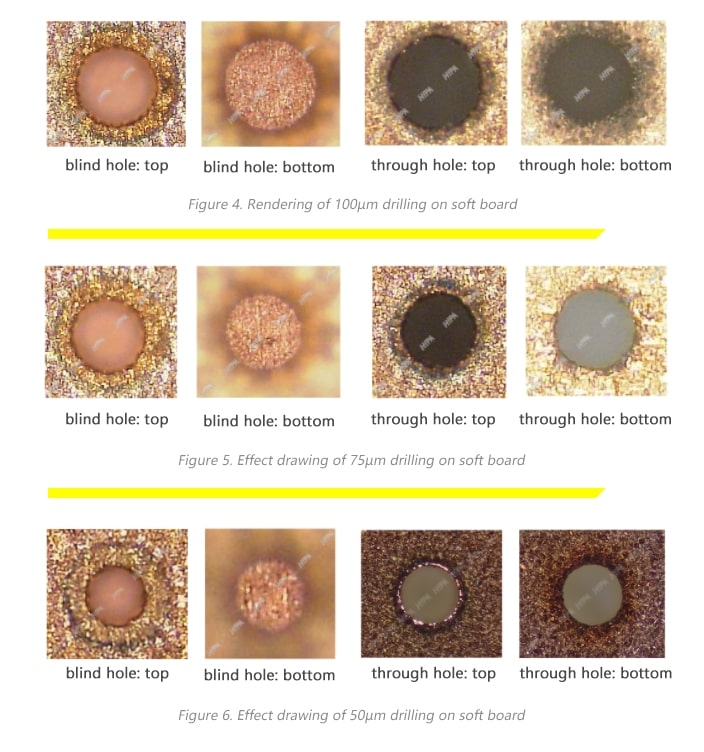

Generally, as the hole diameter is smaller, the processing difficulty is greater, and the product processing effect is more difficult to guarantee. HiPA golden gun laser drilling machine adopts a new generation of laser control technology, which can process drilling diameters from 25μm to more than 200μm, which can meet the needs of customers for various through holes and blind holes.

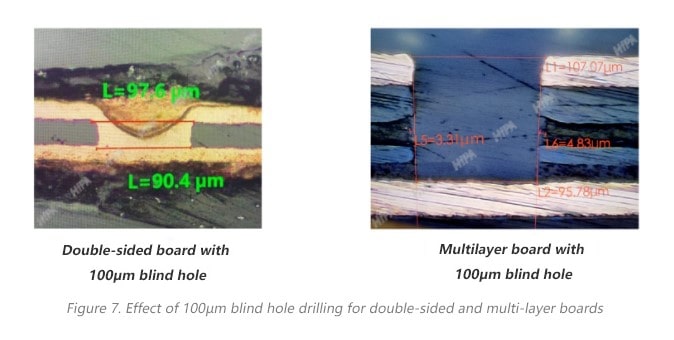

The new generation of HiPA laser control technology can precisely control the laser during high-speed processing, improving the quality and accuracy of blind hole drilling. At the same time, the golden gun can still maintain the drilling efficiency, which is two times faster than the domestic equipment.

3. High equipment stability to ensure product quality

The golden gun laser drilling machine is equipped with a high power UV laser, with stable power and small attenuation, ensuring processing quality and efficiency. At the same time, it is equipped with laser power monitoring and position compensation system to ensure drilling stability and yield.

The golden gun has two versions, the standard version and the high-end version, which can realize various drilling methods for customers to choose. And with independent research software, can be customized and changed according to customer needs to meet the needs of different scenarios.

Laser micro-hole drilling effect

Effect drawing of 100µm aperture

Golden gun F operation video

HiPA Solutions – Laser Micro Hole Drilling

Flexible circuit boards, referred to as FPC are widely used in consumer electronic products such as microelectronics, 5G mobile phones, laptop computers, and new energy vehicles. Also as electronic interconnects to connect products.

HiPA Solutions – Laser Ink Removal

Ink is an important material for printing. By printing or inkjet, patterns and characters are displayed on the substrate. Among them, screen printing inks are widely used on the cover glass of various display panels such as mobile phones, computers, smart watches, cameras, etc.

- HiPA Solutions – Laser Micro Hole Drilling - 09/12/2022

- HiPA Solutions – Laser Ink Removal - 03/12/2022

- JPT Solutions – Thick Glass Cutting with Ultrafast Laser - 03/12/2022