Laser ink removal markets and applications

Ink is an important material for printing. By printing or inkjet, patterns and characters are displayed on the substrate. Among them, screen printing inks are widely used on the cover glass of various display panels such as mobile phones, computers, smart watches, cameras, etc.

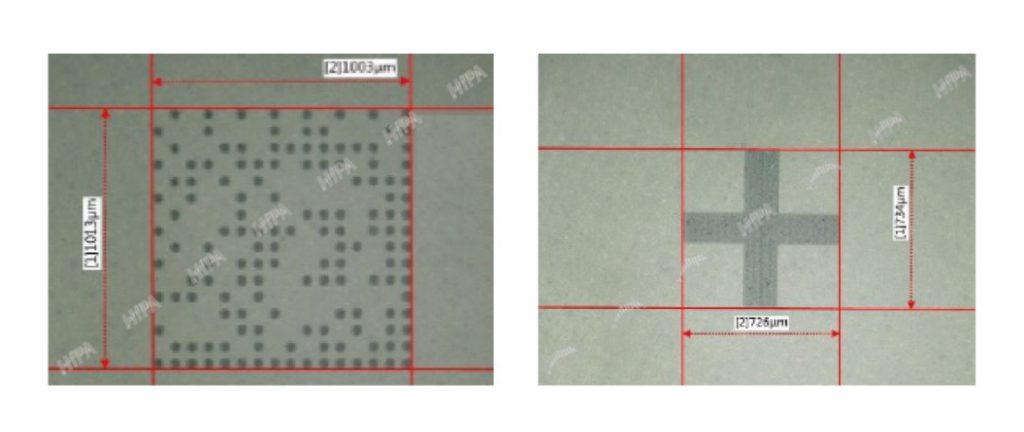

Screen printing ink has some defects, such as the inability to make micro-holes and micro-circles, and there may be ink overflow after screen printing, so ink removal by laser is required. For high-precision ink removal needs, HiPA’s brittle material product line provides full-featured, ultra-high-precision laser ink removal solutions that can be used in the following industries and fields:

Smartphones, laptops, desktop computers, LCD TVs, car displays, smart watches, VR Headsets, medical displays, etc.

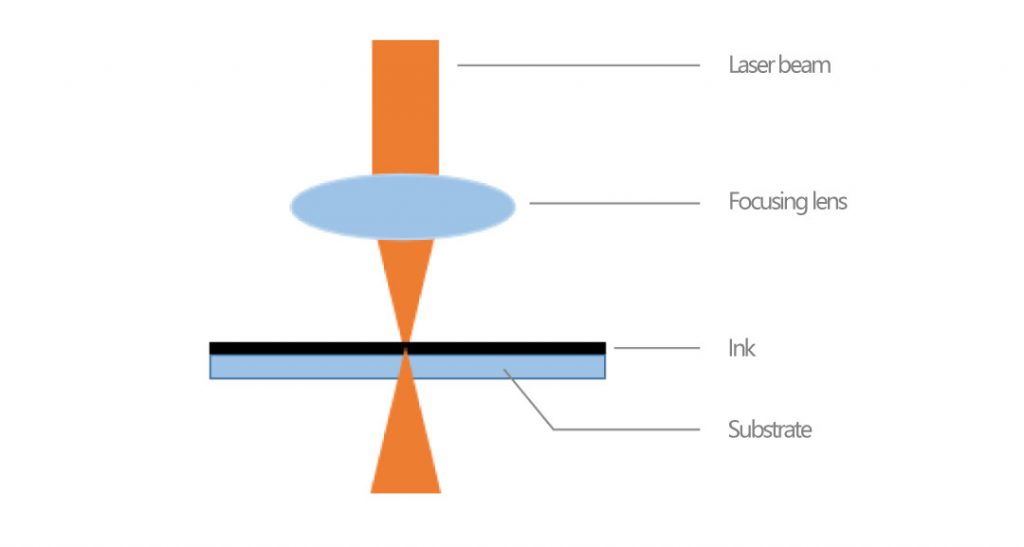

How does laser ink removal work?

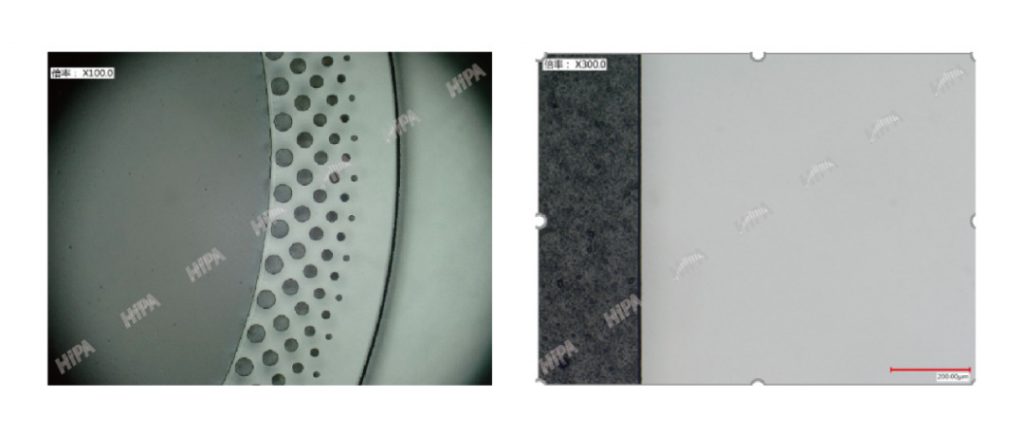

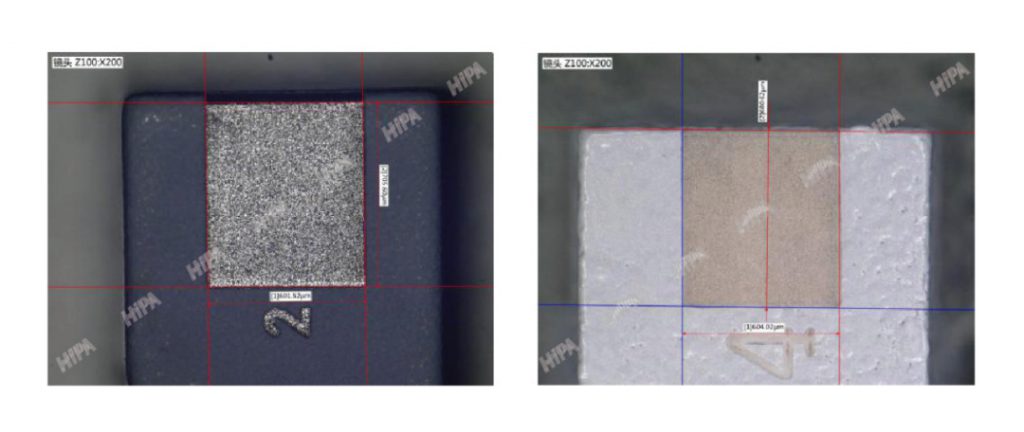

The ink removal equipment provided by JPT uses a narrow pulse width laser, which can instantly vaporize the ink material by focusing the laser energy on the ink surface. And through the galvanometer to scan on the ink to confirm the set pattern, the ink in the set area is removed cleanly without damaging the substrate. As shown in Figure 2-Figure 4.

Advantages of HiPA laser ink removal solutions

(1) Ink removal without residue. The device can integrate AOI detection and transmittance detection functions.

(2) It does not damage the product substrate. The product substrate can pass 4PB, ROR and other strength tests after removing the ink.

(3) Compatible with glass, ceramic, sapphire and other substrates.

(4) Compatible with black, white, blue, red and other color inks, as well as PVD inks.

(5) High-precision XY platform module to ensure laser processing accuracy.

(6) Compatible with ink surface QR code, Mark point, text marking, providing customized 3D ablation solutions.

(7) Power monitoring, real-time compensation.

(8) Support customized automatic loading and unloading materials.

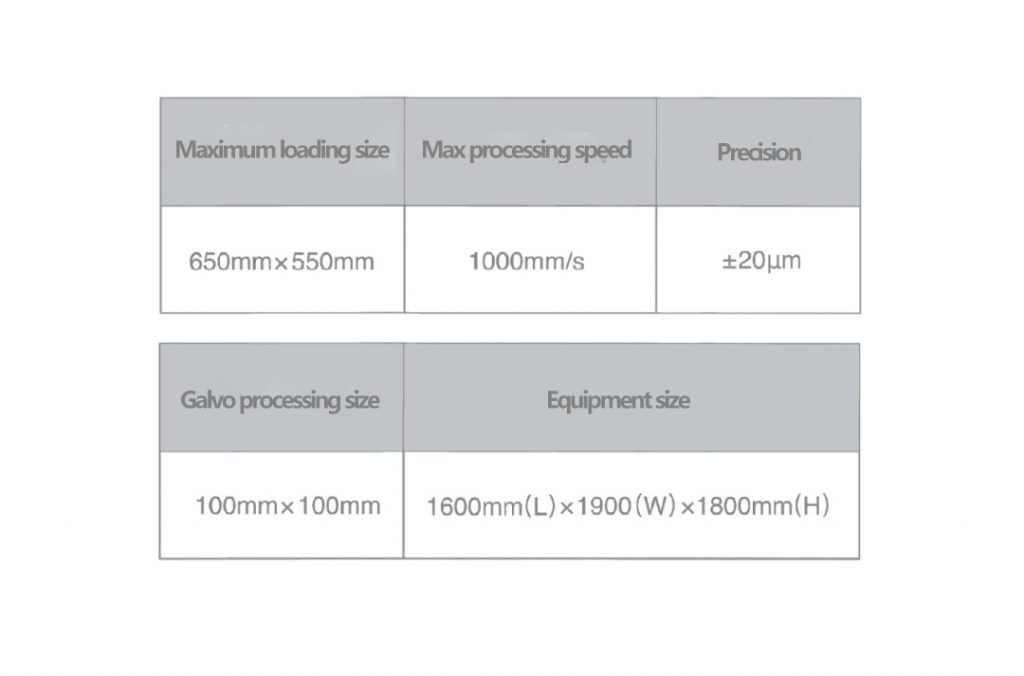

Performance parameters of HiPA laser ink removal equipment

Practical application samples of HiPA laser ink removal equipment

HiPA Solutions – Laser Micro Hole Drilling

Flexible circuit boards, referred to as FPC are widely used in consumer electronic products such as microelectronics, 5G mobile phones, laptop computers, and new energy vehicles. Also as electronic interconnects to connect products.

HiPA Solutions – Laser Ink Removal

Ink is an important material for printing. By printing or inkjet, patterns and characters are displayed on the substrate. Among them, screen printing inks are widely used on the cover glass of various display panels such as mobile phones, computers, smart watches, cameras, etc.

- HiPA Solutions – Laser Micro Hole Drilling - 09/12/2022

- HiPA Solutions – Laser Ink Removal - 03/12/2022

- JPT Solutions – Thick Glass Cutting with Ultrafast Laser - 03/12/2022