Applications and Requirements

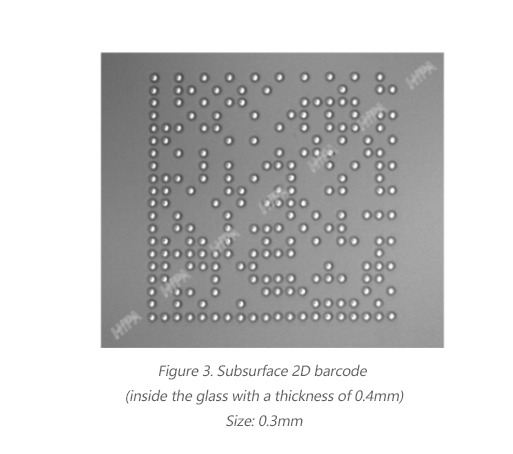

Two-dimensional barcodes have been widely used both industrial environment, as a production process tracking method, and in commercial environment, as a product identifier. As a process tracker, each work piece has its own barcode to be scanned at every station along the production line. This allows real-time yield tracking of the entire production process, which provides a data basis for the process improcement. As a product identifier, the 2D barcode is also used for anti-counterfeiting and ensures the authenticity of products reaching end consumers. The invisible 2D barcode is marked with special laser-engraving equipment. The barcode is engraved inside the glass or sapphire material, which cannot be tampered with or removed. Different from visible barcodes, the invisible 2D barcode is not visible to human eye. It can only be read by certain barcode scanners. This quality can ensure no damage to the product cosmetics while keeping the whole production process traceability.

JPT provides subsurface 2D barcode solutions that can be applied in the following industries or fields:

Common 2D barcode/QR code marking methods are as follows:

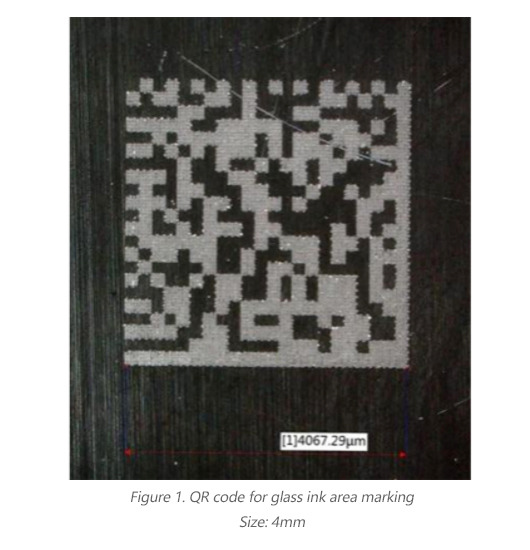

1. Two-dimensional code marked in the glass ink area

2. QR code label

Common invisible barcode marking method is as follows:

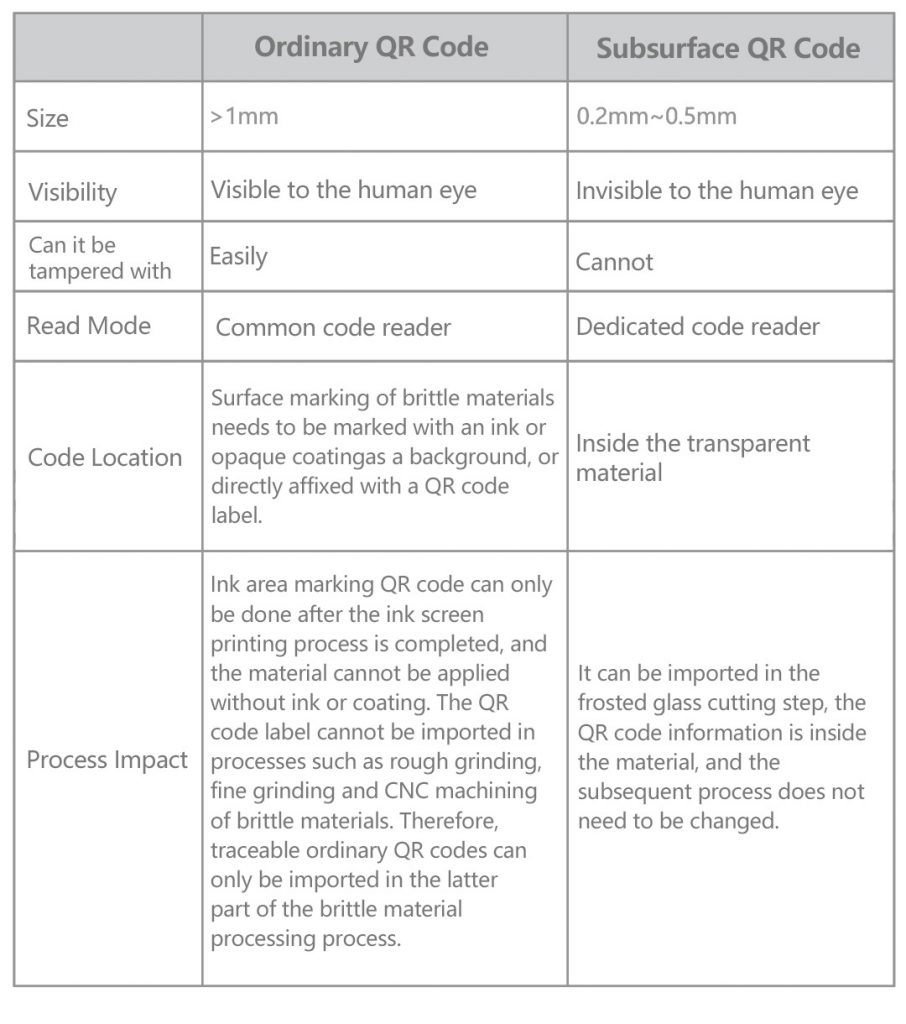

Comparison between invisible barcode and traditional barcode:

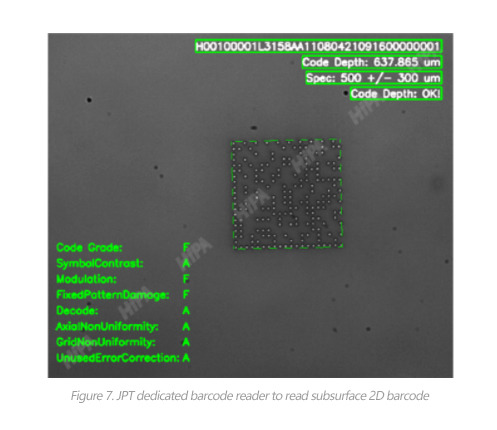

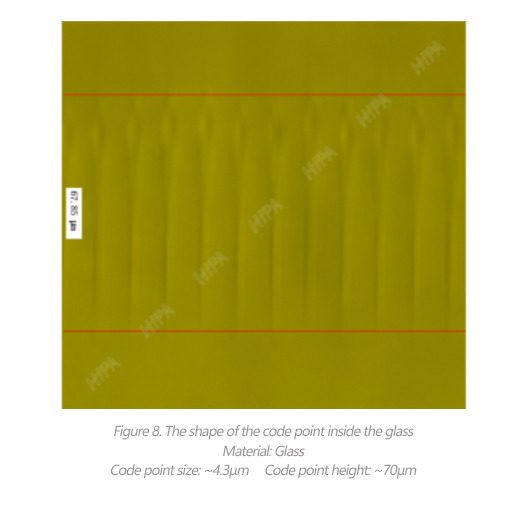

The Principle of Marking

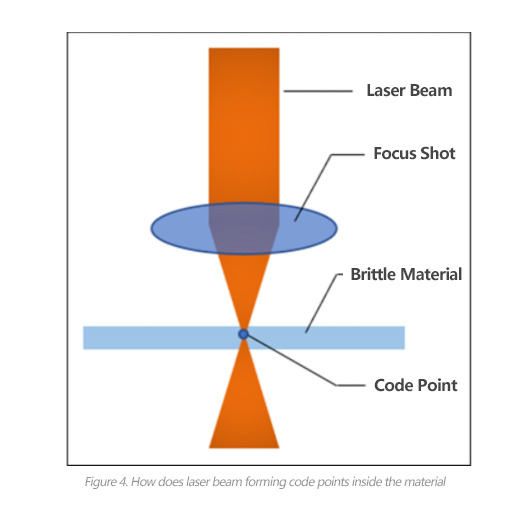

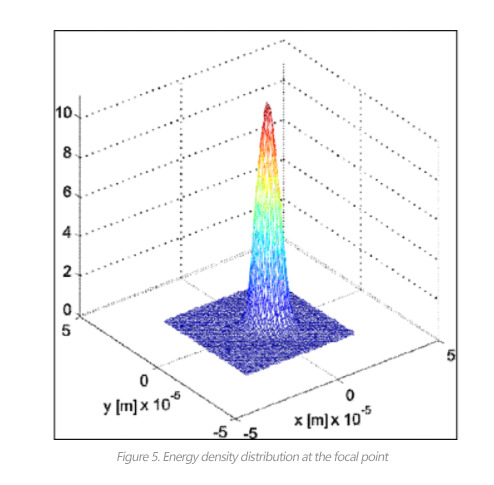

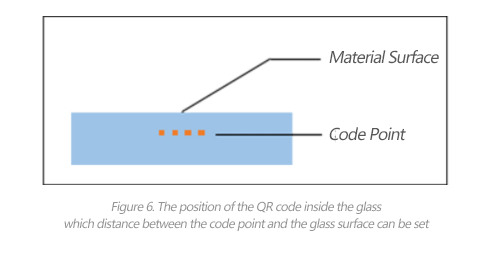

The brittle material subsurface 2D barcode solution provided by JPT uses an ultrafast laser, the principle of which is shown in the figure below. The ultrashort pulse laser energy passes through the transparent brittle material and is focused inside the material by the field mirror. Ultrafast laser acts in the materials in a very short time (0.2-0.5s) and in a very small area (0.1-0.5mm). The temperature of the material in the focus position (energy density above 106MW/mm2) rises sharply in an instant to form a plasma and then cools to form a modified region (ie code point, the diameter is in the order of microns). The light transmittance of the modified area is different from that of the other areas. Due to its extremely small size, it is invisible to the naked eye and must be read by a special code reading device.

Product Highlights

- Invisible marking, invisible to the human eye, and no traces on the surface.

- It has little effect on the strength of the material, and can still pass the 3PB and ROR strength tests after coding.

- Fully customized code reading light source, optical system, and cutting-edge customized image processing algorithm.

- 100% code reading rate (sapphire, light glass, frosted glass).

- Online code depth measurement, which gives precise control of barcode depth.

- Real-time laser power monitoring.

- The code is still readable but invisible after applying ink and coating.

- The code marking and reading functions can be designed as independent or integrated as one solution.

- Customized automatic loading and unloading.

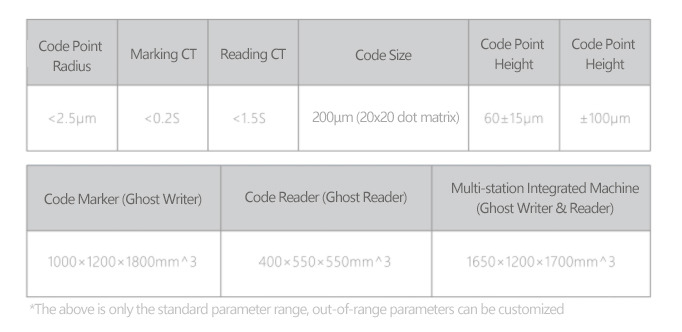

Equipment Parameters

HiPA Solutions – Laser Micro Hole Drilling

Flexible circuit boards, referred to as FPC are widely used in consumer electronic products such as microelectronics, 5G mobile phones, laptop computers, and new energy vehicles. Also as electronic interconnects to connect products.

HiPA Solutions – Laser Ink Removal

Ink is an important material for printing. By printing or inkjet, patterns and characters are displayed on the substrate. Among them, screen printing inks are widely used on the cover glass of various display panels such as mobile phones, computers, smart watches, cameras, etc.

- HiPA Solutions – Laser Micro Hole Drilling - 09/12/2022

- HiPA Solutions – Laser Ink Removal - 03/12/2022

- JPT Solutions – Thick Glass Cutting with Ultrafast Laser - 03/12/2022