What is Laser drilling process?

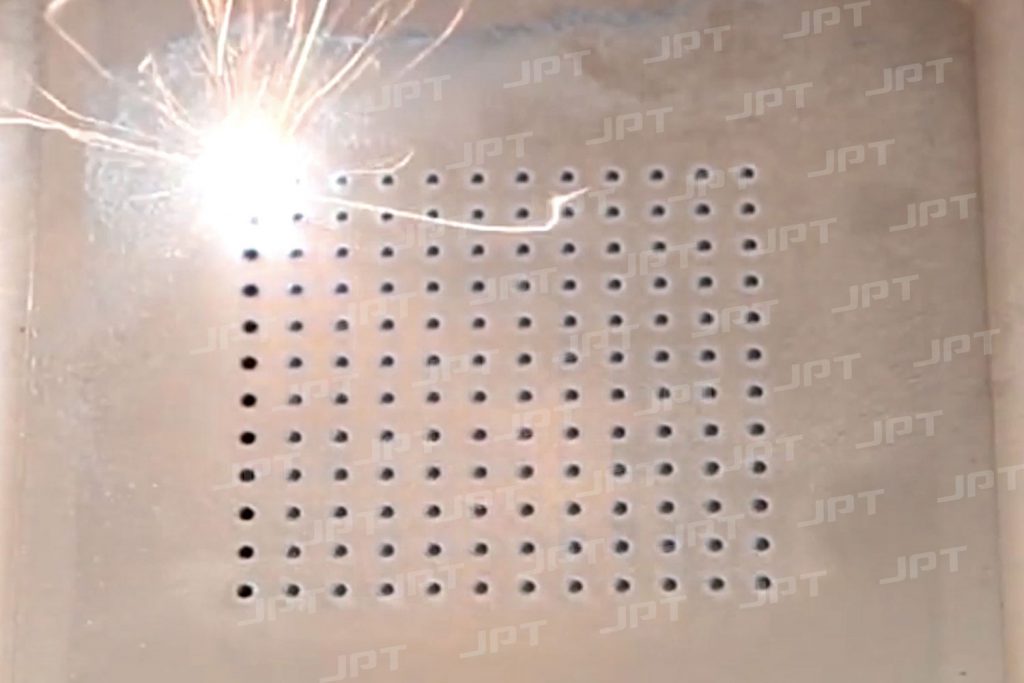

Laser drilling process is a vital part of the manufacturing process. Laser-based drilling uses a fiber laser beam to create micro holes, vias, pinholes, slots or make tiny depression dents in various materials. The beam parameters like intensity, duration, and heat output can be precisely controlled by the operator and can be easily programmed or automated for different drilling tasks.

Unlike conventional drilling, laser drilling is a non-contact process and does not require tooling. It means laser drilling produces consistent results time and time again with minimal or no distortion to the workpiece.

Therefore, laser drilling is a highly efficient process to create holes in multiple materials such as metals, plastics, composites, and semiconductors. With the benefits of accuracy, speed, and flexibility, laser drilling offers numerous advantages over conventional drilling methods.

Mechanical machining is the most commonly used method for drilling, reaming, and milling holes in metals. This method involves the use of different types of machines. Mechanical machining has limitations for drilling holes at shallow angles, and drilled holes often require secondary processes such as deburring.

Laser drilling does not require direct contact between material and laser device, reducing the possibility of any contamination to the material and eliminating secondary processes. Laser drilling has no restrictions on hole type and can drill holes of diameters down to a few microns. Approach angles about 10 degrees are easily possible.

Mechanical punching can create many holes, even of different sizes, in a single operation, making it suitable for multiple holed parts in mass production.

Laser-based drilling does not require press tooling and eliminates the need and cost of making punch, providing a low-cost solution for prototyping. Laser drilling has no parts to wear or break, and nearly any contour can be created without a tool change.

What Is Laser Drilling Used For?

The advantages of laser drilling have been accepted in many industries since it offers superior speed, precision, and control while reducing operating costs. As a result, they find applications in a variety of industries.

Fiber lasers are extensively used for drilling large holes in aerospace components like combustors, nozzle guide vanes, blades, and cooling rings.

Oil and gas exploration industries use high-power fiber lasers for rock drilling applications.

In pharmaceutical industries, laser drilling is used for tablet drilling applications which drill small apertures into osmotic pump tablets with variable sizes and pattern variations.

The automotive industry employs laser systems to drill holes into metal components, such as metal foil, thin sheet metal, and micro tubing.

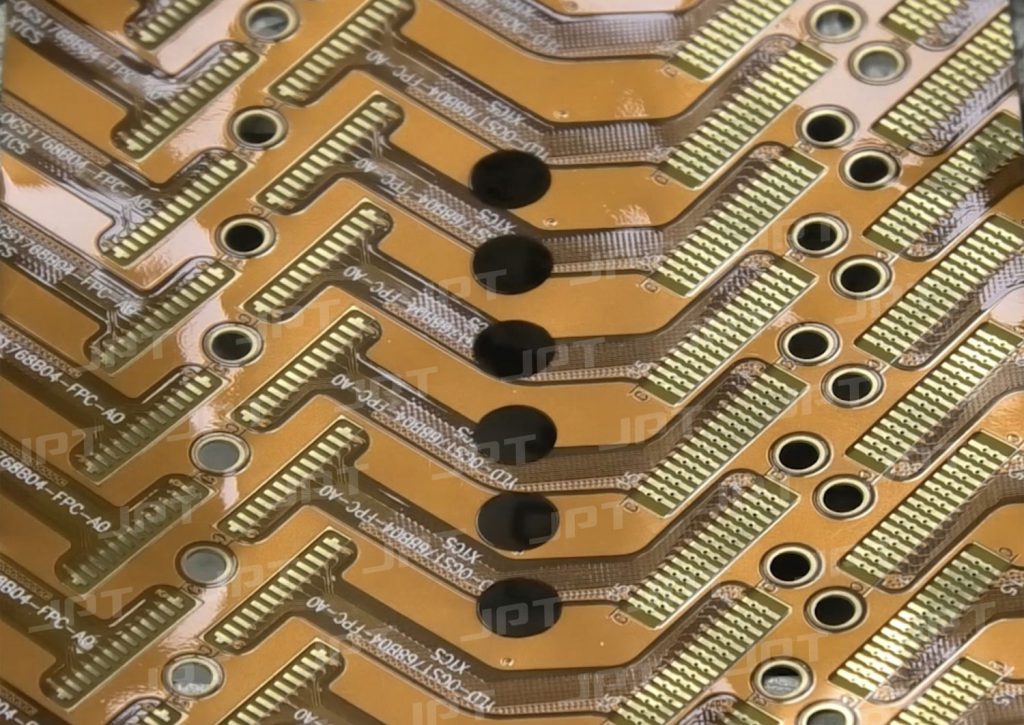

The microelectronics industry uses laser drilling for a wide range of applications, from drilling alumina ceramic substrates to creating micro-vias in printed circuit boards.

Principle of laser drilling

In the laser drilling process, the particular area of the workpiece is exposed to the laser beam. The beam spot and beam energy will depend on the size and depth of the hole that needs to be drilled. The intensity of the beam melts, vaporizes, or evaporates the materials. Materials are then removed by vaporization and liquid expulsion due to high vapor pressure leaving a hole underneath.

What Advantages Does Laser Drilling Have Compared with Conventional Drilling Methods?

Non-contact process

The drill bits used in traditional drilling can become dull, making drilling slower and generating more heat. This can lead to a change in the mechanical properties of the material. No physical contact between the drilling parts and the material in laser drilling prevents contamination and maintains the original quality of the material.

As a result, laser drilling is well suited for applications that require strict chemical and physical composition standards, such as surgical equipment, medical devices, or applications requiring drilling of reactive substances.

No tooling changeovers

Conventional drilling requires tooling, which needs to be replaced from time to time and gradually wears out. Laser drilling is performed using the laser beam, with no bits to be changed or sharpened, providing a repeatable, consistent, and cost-effective process.

Using laser drilling, very thin and delicate sheets and wafers of glass and semiconductors can be drilled with an extremely low threat of stress fractures, cracking, and edge melting.

High aspect ratio holes

Drilling high aspect ratio holes using conventional drills causes the tool to heat up, wobble, and break heads due to torsional stress. On the other hand, the laser creates no frictional resistance.

Laser drilling is one of the few techniques for producing high-aspect-ratio holes with a depth-to-diameter ratio greater than 10:1. High aspect ratio holes are needed in many applications, such as aerospace turbine-engine cooling holes and printed circuit board micro-vias.

Holes at shallow angles from surfaces

Laser drilling is well suited for drilling holes at an angle as small as 10° with the drilling surface, for example, aerospace turbine-engine cooling holes.

High Adaptability

One laser drilling machine can adapt to a wide range of materials that are difficult for conventional drilling. Lasers can create holes in materials of different hardness. For example, it can create holes in a wide range of materials from rubber and wood to very hard materials such as crystals, ceramics, and diamonds.

Recommend Reading

Why You Should Choose Laser to Cut Leather?

Leather cutting is the process of cutting on leather using knives, molds, lasers, or other tools. This process is widely used in automobile production, clothing,

Comparisons of MOPA fiber laser and Q-switched fiber laser

Pulsed fiber laser on current market can mainly be classified into two types, which are based on Q-switching technique and MOPA technique respectively. Between them,