Table of Contents

Need for PCB marking

Printed circuit boards or PCBs are used in almost every type of electronic equipment. For the better functioning of the board and traceability, circuit boards are coded during raw board creation to the final assembly. PCBs are branded or marked using barcodes or 2D codes in various formats. Due to the increasing packing densities on PCBs, the region available for coding is diminishing all the time.

Different techniques are used for PCB marking, but few are as rapid and cost-effective as PCB laser marking systems. Conventional mechanical processes have apparent drawbacks when compared to lasers. Traditional methods use inks, acids, and other solvents, which work much less cleanly than lasers. At worst, this can result in contamination and breakage of the entire PCB panel or of the circuits and soldered joints.

The laser marking system employs the new age technology with full automation support and long-lasting permanent marking. This revolutionary process uses the latest laser marking technology and offers new options to any electronic equipment manufacturers.

Advantages of PCB laser marking machine

The PCB laser marking system dramatically differs from the conventional older methods of PCM marking. Some of the advantages of the JPT laser marking system are presented below.

Cost-saving

High-volume manufacturers can significantly reduce costs with laser marking system; consumable costs for ink or chemical marking exceed the initial price of a laser marking system. It also reduces expenditure resulting from no consumables, reduces marking times and lower labor costs, and reduces overall production costs.

Permanent marking

When you use laser marking, you have a permanent mark that will last for a long duration. Laser marking machine creates permanent marking with high-resolution.

High contrast and precise marking

A laser marking is easy to read, high contrast, and vibrant, making it far better than a printed mark. The machine program controls the laser beam precisely in adjusting the beam’s position, which eliminates the need to use a resistive mask to prevent the shaft from deviating from the actual trajectory.

Fast Speed

Laser engraving is quick and straightforward. Laser marking is faster and with less time spent on the process and tooling. The laser system does not involve any other equipment that needs to be changed or refueled.

Flexibility

Laser marking works on different materials. Whether you are working with plastics, metals, ceramics, or natural materials, a laser marking solution works best for any material. The adjustable track width and easy loading and unloading allow rapid design changes, reproducing the original sample, and user-friendly operation.

Minimal maintenance

Avoid downtime associated with cleaning or unclogging since laser marking systems do not use consumables.

Applications of PCB laser marking machine

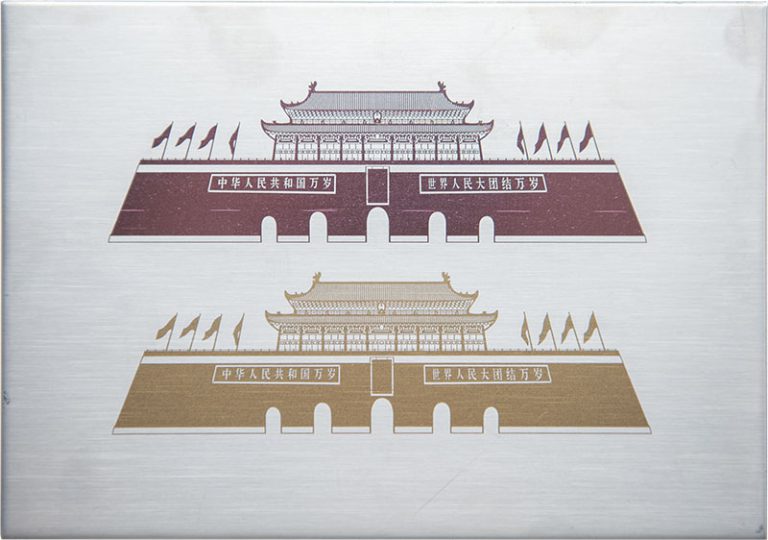

The applications of the PCB laser marking system are not limited to only code marking; besides, it can code high-resolution logos for brand protection, barcodes, QR codes, manufacturing dates, batch codes, lot no, expiry date, and other text.

It can also print high-resolution, permanent marking on the alphanumeric logo, 100% scannable 2D QR codes, etc. The possible application includes all types of metals, plastics such as polycarbonate, polyamide, polyester: coated metals, coated glass, shipper cartons, and foam.

JPT’s Laser Source Advantages for Laser Marking

The JPT laser has a different laser source, which makes it deliver outstanding high resolution engraves while maintaining stability during marking. This laser source also allows the marking of various types of materials. Moreover, it has an extensive range of frequency to allow you to set different parameters to mark more material, especially the non-metal materials compared to lasers with fiber sources.

Contact JPT laser today to learn more about our laser marking applications. If you’re interested in utilizing these laser marking electronics applications for your business, please contact us.

Recommend Reading

Simple Guidance In JPT MOPA Fiber Laser

JPT high power pulsed fiber lasers make use of master oscillator power amplifier (MOPA) configuration, and show excellent laser performance with high level of temporal

Laser Marking: Everything You Need to Know

Used exclusively by industrial manufacturers before, laser marking technology is today used by small business enterprises, makers, hobbyists, and product designers in many different ways.