Laser Cleaning

JPT’s laser cleaning solutions precisely target workpiece surfaces to instantly vaporize or remove oil, rust, coatings, and oxides—delivering high-efficiency, eco-friendly, non-contact cleaning. Ideal for applications such as metal component refurbishment, mold maintenance, and coating pretreatment, this technology not only removes contaminants effectively but also preserves the structural integrity of the base material, extending the service life of both equipment and workpieces. With flexible process configurations and stable performance, JPT laser cleaning provides green, efficient surface treatment solutions for industries including new energy, automotive manufacturing, and precision engineering.

-

Laser Rust Removal

-

Mold Surface Cleaning

-

Laser Paint Removal

-

Laser Surface Texturing

-

Oil Stain Removal

-

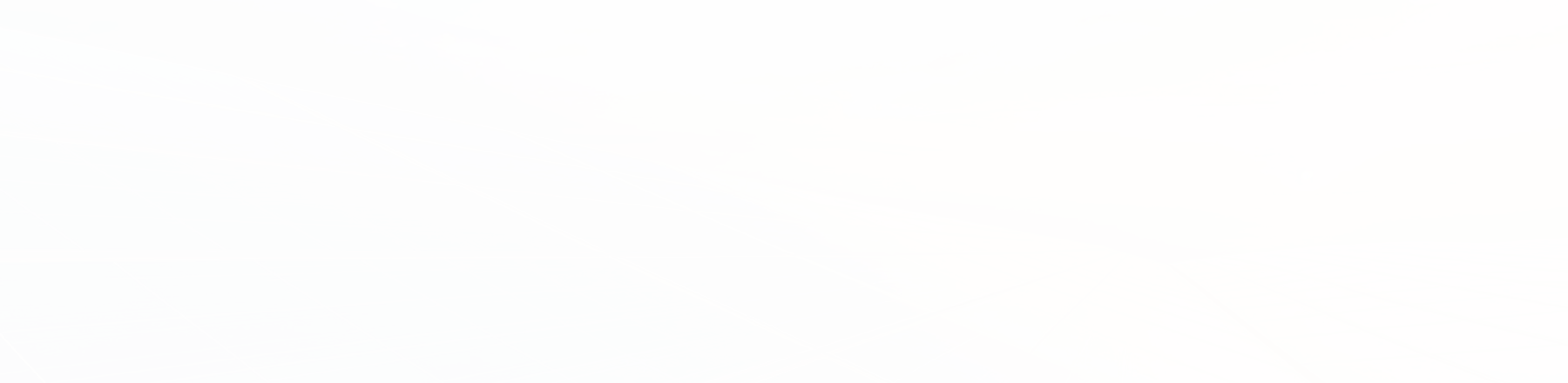

Laser Rust Removal

Laser Rust RemovalJPT’s laser rust removal technology uses high-energy-density pulsed lasers to instantly strip oxide scales and rust from metal surfaces without chemicals or abrasives, ensuring zero substrate damage. Compared with traditional pickling or sandblasting, this solution offers eco-friendliness, high efficiency, and low maintenance. It is especially suitable for corrosion protection and refurbishment of large metal structures such as ships, bridges, and pipelines, significantly extending service life and reducing secondary processing costs.

-

Mold Surface Cleaning

Mold Surface CleaningJPT’s mold surface cleaning solution uses non-contact, high-precision laser cleaning to efficiently remove release agent residues, carbon deposits, and fine particles from mold surfaces, avoiding dimensional accuracy loss caused by traditional grinding. This technology supports complex curves and intricate structures, significantly improving product yield, reducing downtime, and extending mold service life. It is widely applied in the maintenance and refurbishment of plastic, die-casting, and rubber molds.

-

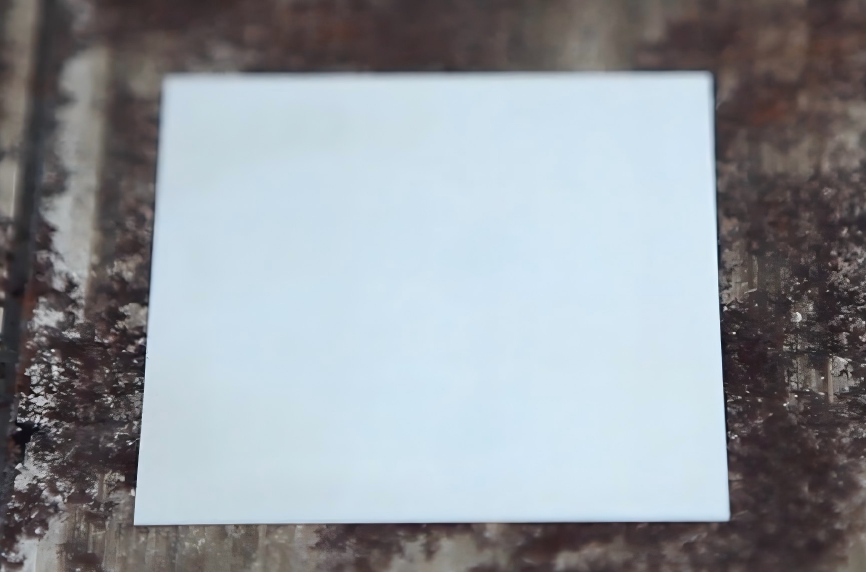

Laser Paint Removal

Laser Paint RemovalJPT’s laser paint removal technology uses a high-energy-density laser beam to achieve selective layer stripping, precisely removing coatings such as paint and plating from metal or composite surfaces while controlling depth to the micron level, ensuring zero damage to the substrate. With its high precision, efficiency, and eco-friendly non-contact process, it is widely used in aircraft skin maintenance, automotive part refurbishment, and high-end equipment surface treatment, significantly improving repair quality and productivity.

-

Laser Surface Texturing

Laser Surface TexturingJPT’s laser surface texturing technology uses a high-energy-density laser beam to create controlled micro-pore structures on the workpiece surface, significantly enhancing adhesion for coatings and bonding processes. Compared to traditional sandblasting or phosphating, it is dust-free, eco-friendly, and offers high precision with excellent controllability. It is ideal for industries such as automotive and aerospace where superior coating adhesion and surface treatment quality are essential, making it an advanced alternative to conventional roughening methods.

-

Oil Stain Removal

Oil Stain RemovalJPT’s oil stain removal technology employs a high-energy-density laser beam to instantly vaporize oils, lubricants, and residues, achieving industrial-grade cleanliness through non-contact surface treatment. This eco-friendly process avoids chemical solvent pollution and prevents secondary damage to precision components. It is widely used for the maintenance and manufacturing of engine parts, bearings, gears, and other high-precision mechanical components, ensuring long-term operational stability.