Table of Contents

Laser cutting is an excellent option if you need to carve intricate shapes out of glass. Although there are less precise ways to cut glass, such as with a glass cutter and bottle clamp, laser cutting is indeed the preferred technique for accuracy. Glass can be cut using conventional techniques, but it is frequently impossible to accurately cut complex shapes without spending a lot of time, effort, and material. In comparison, cutting glass with a laser is just as simple as cutting plastic.

How Does Laser Cutting Glass Differ from the Traditional Glass Cutting Process?

Whether it’s about the process, the equipment, the efficiency or the final results – traditional glass cutting and laser cutting largely differ from each other.

Traditional Glass Cutting

Speaking of the traditional glass cutting process, the three most used methods for cutting and drilling glass in industrial production are CNC grind, water jet cutting, & cutter wheel cutting.

Water jet cutting: To process the glass, use pressurizing equipment to blow high-pressure water mixed with hard sand. Automatic water jet slicing can create curved cuts and holes in the midst of the glass with excellent graphic accuracy. However, the procedure of use necessitates the need for a significant quantity of water & sand that not only has a massive price but also has a significant environmental impact.

Knife wheel cutting: Using a knife wheel to scribe lines on the glass and then applying mechanical pressure to split the completed result is known as “knife wheel cutting.” Although easy to use and inexpensive, knife-cut glass has huge chips and jagged edges but it is frequently challenging to achieve the precise demands of small sizes. The safety precautions of construction workers throughout the cutting process should receive special attention at the same time.

CNC grind: Drilling through the glass to process its shape and contour is known as CNC grinding. However, a water-cooled drill, as well as a cold-water recovery mechanism, are necessary for the drilling operation, and the drill bit requires replacement frequently, increasing the overall cost and lengthening the grinding process.

Laser Glass Cutting

However, the use of lasers in glass drilling and cutting is seeing greater advancements as a result of the progressively fine, precise, and rigorous standards of glass applications across all spheres of life. Laser cutting mainly bifurcates into two different forms – laser glass cutting and laser glass drilling. Laser cutting glass is employed in picosecond lasers that involve ultra-short pulses and high laser power. And laser glass drilling can come into play with just regular laser machines. The choice of laser light sources also needs to take a variety of applications into account, as well as strike a balance between cost, efficiency, and quality.

Can Tempered Glass be Cut with a Laser?

Yes, but tempered glass requires a picosecond laser to be cut, nanosecond pulses are not able to achieve. Regular laser machine such as MOPA lasers can cut glasses such as soda-lime glasses. Soda-lime glasses are the type of glass that is currently used the most. For the majority of consumer goods, it is the standard glass. For how extensively it is used, soda-lime glasses are almost always meant when the word “glass” is used. 75% of the glass that is currently produced is soda-lime glass.

Borosilicate, lead, aluminosilicate, and fiberglass are common glasses that can be laser-cut. Stained glass is doped with additives for decorative wall uses and can also be sliced using a laser. Unfortunately, this makes them extremely fracture-prone. This glass is not the only one that uses laser cutting. It can also cut toughened glass, heat-strengthened glass, and reflecting glass.

Can Fiber Laser Cut Glass?

Yes, fiber lasers are very efficient in cutting glass. In fact, they deliver excellent results in cutting reflective materials as compared to their CO2 counterparts.

A fiber laser glass cutting machine employs active optical fibers to yield a laser beam and a transport fiber to send the same to the head of the cutting machine. This incredibly hot laser then condenses down to form a thin beam, further cutting through the glass of different thicknesses to make cleaner cutting edges. And it’s enhanced efficiency and strength are the reason why fiber cutting works wonders for various infrastructure and industrial applications.

The fact that fiber laser machines produce lasers with shorter wavelengths as compared to CO2 gives them a higher cutting quality, increased speed, and better absorption power. These machines can adjust themselves to a spectrum of speeds and wavelengths, while also reducing downtime. Lastly, less power consumption and a lower rate of material consumption of fiber laser machines reduce running costs.

How to Laser Cut Glass?

Glass can be sliced using a laser to create intricate curved designs. An intense laser can quickly cut through glass. There are a few simple processes involved in operating a laser engraver to make clean cuts in the glass.

Designing the Concept

Making the essential designs that will later be cut out of the glass is the first stage. Use the free laser-cut designs offered by many sources online if creating the design is not among your talents.

Implementing Test Cuts

You must do some test cuts in order to determine the correct settings required to cut a particular type of glass. You can determine the best settings for the material type by experimenting with various laser power, velocity, and feed settings. While performing test cuts results in material waste, you might learn more about the materials you are cutting. Additionally, the proper cut setting prevents you from making any costly errors. You can use the laser cutting thicknesses and speed graph for glass to select the most appropriate settings to start your test runs, which will help you lower the necessary number of test runs.

Creating the Cut

You can efficiently cut glass once you know the ideal settings. Using a given glass sheet to process more cutouts and reduce material waste. Microfractures that may form in the cutting route are minimized by chilling the glass edges with an air assist. A smoother cut is another benefit.

Favorable Settings for Laser Glass Cutting

- Laser power:According to the thickness and structural makeup of the glass, a laser with a power range of 30W to 800W must be used while cutting glass. This is due to the fact that glass absorbs light at a decent rate within its operational wavelength.

- Cutting Velocity:The speed at which you can cut glass with a laser depends on the thickness of the material. You can cut glasses more quickly by boosting the laser’s power. In general, an 80W laser versus 0.10″ thick glass should cut at a speed of about 15 ipm.

- Area of Work:The workspace of the laser engraver is a crucial factor that you should take into account. Depending on the dimensions of the sheets of glass you intend to use, you should make your choice of the laser cutter.

- Lenses:Choose lenses with an ISO-10110 standard certification to be used in crystals and glassware materials when working with glass. For laser cutting glass, you require a short focal length laser lens with a deep point of focus. It guarantees that a thick piece of glass is covered by a laser beam that is centered on a small focal spot. A lens with a 2″ focal length, 0.03″ depths of field and 0.001″ spot size is advised for effective glass cutting.

- Expulsion system: Due to the typical lack of contaminants, visible dust or gasses are not produced when cutting glass with a laser. The absence of visible emissions does not essentially mean that they are not hazardous. Depending on the additives applied to the substance, the produced fumes’ toxicity will vary. For instance, when some stained glass is laser cut, dark, visible vapors are released. It is always preferable to set up your laser cutter with a robust ventilation system. It can swiftly expel the fumes produced while preventing corrosion and staining of the machine parts.

Best Laser Cutting Glass Machine

The finesse of the final glass cut largely depends on the machine used for working up the process. Here’s a highly powerful and efficient device that yields fine-cut edges while also calling for minimum maintenance.

JPT Picosecond Laser Machine functions with a compact dual-layer cavity while featuring a clever optoelectronic design. It is highly capable of adjusting itself to the industrial machining environment and working according to various scientific characterizations. You can go for a minimum pulse duration of 6 ps, and can purchase an infrared or ultraviolet version of the machine. Some of its other notable features are the tunable repetition rate that can change from a single shot to 1MHz, the Burst Mode, and position synchronized output. The central wavelength of the machine is 1064 nm/532 nm/355 nm.

Advantages

- The laser cutting machine of glass produces edges with a natural finish and great smoothness.

- Compared to conventional glass cutting methods, the output generated has a high break strength and requires little maintenance.

- The automated and computer-driven processes enable cutting, resulting in quick and cost-effective outcomes.

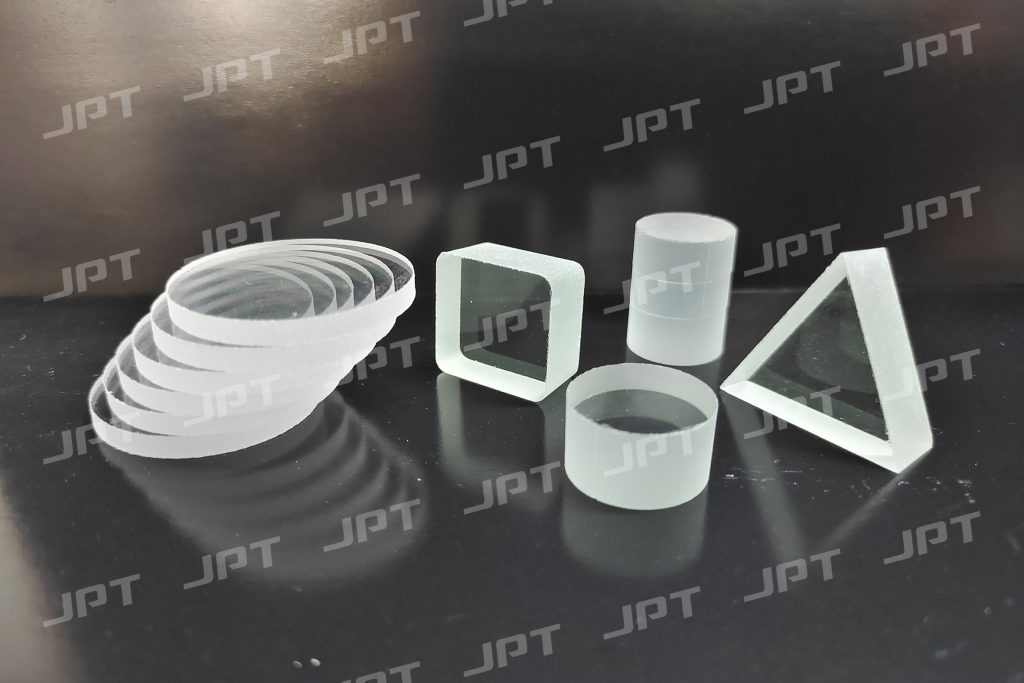

- Glass of different thicknesses can be sliced with lasers into almost any shape. For many companies in a variety of industries, the cutting process is the method of choice since it is quick, clean, accurate, and customizable.

- Industrial laser cutters are able to cut any form with the greatest flexibility, producing fine details with the smallest pieces with the highest precision.

- It produces fine details on the laser-cut glass with the highest precision, and reduces costs because there is a lot less material waste.

Conclusion

Glass laser cutting and engraving devices deliver high-impact designs and a perfect finish to the laser-cut glass. Due to its several advantages and many capabilities, laser-cut and engraving machines are unquestionably the finest choices for cutting and designing glass.

HiPA Solutions – Laser Micro Hole Drilling

Flexible circuit boards, referred to as FPC are widely used in consumer electronic products such as microelectronics, 5G mobile phones, laptop computers, and new energy vehicles. Also as electronic interconnects to connect products.

HiPA Solutions – Laser Ink Removal

Ink is an important material for printing. By printing or inkjet, patterns and characters are displayed on the substrate. Among them, screen printing inks are widely used on the cover glass of various display panels such as mobile phones, computers, smart watches, cameras, etc.

- HiPA Solutions – Laser Micro Hole Drilling - 09/12/2022

- HiPA Solutions – Laser Ink Removal - 03/12/2022

- JPT Solutions – Thick Glass Cutting with Ultrafast Laser - 03/12/2022