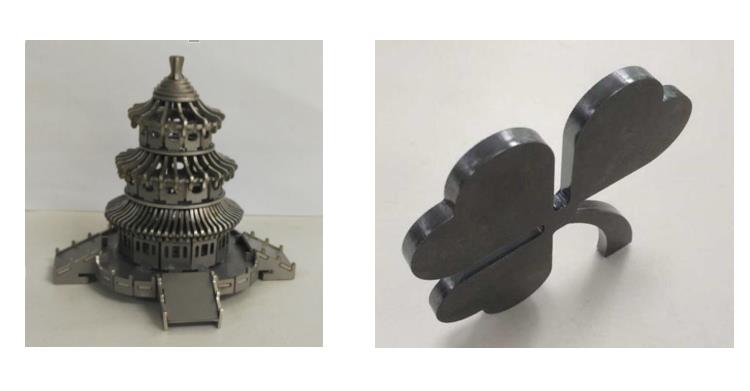

With the powerful technology of JPT CW & QCW laser, you can cut and weld almost metals, including Aluminum, Stainless Steel, Brass, Carbon Steel, Cooper, Titanium, 24K gold, LED cover and Zirconium. Check all creative laser cutting and welding samples here.

CW & QCW laser Applications - Laser cutting

- Carbon steel

- Stainless steel

- Cooper

- Brass

- Aluminum

- Silver

- Gold

- Ceramic

CW & QCW laser Applications - Laser cutting for different material

- Aluminum

- Stainless Steel

- Brass

- Carbon Steel

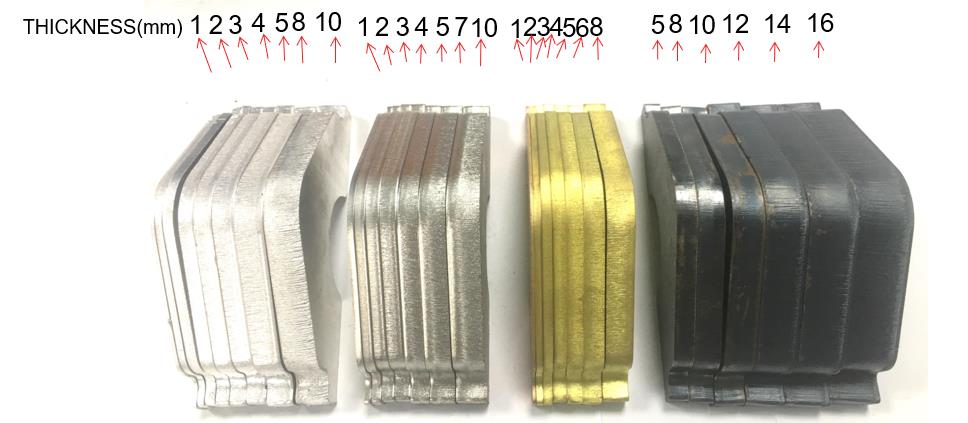

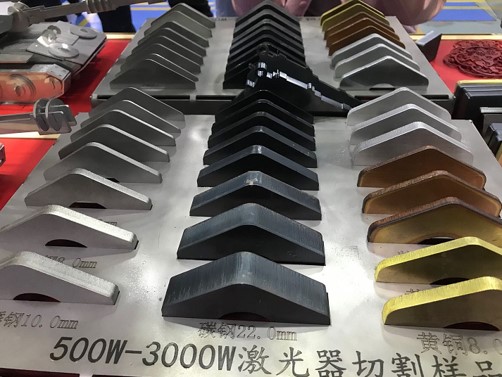

CW laser 500W - 3000W Cutting Sample

- Stailess steel

- Carbo Steel

- Brass

Requirement:

Smooth cutting for 0.5mm, 0.8mm, 1mm round

Setting Matrix

- Cutting head: F100/F125

- Power: 300W

- Focus position: Positive focus

- Cutting Speed: 5m/min

- Duty cycle: 100%

CW & QCW laser Applications - Laser welding

- Carbon steel

- Stainless steel

- Cooper

- Brass

- Aluminum

- Titanium

- Core size: 20µm; Depth of fusion: 3.25mm; Width of fusion: 0.51mm;

- Core size: 50µm; Depth of fusion: 3.06mm; Width of fusion: 0.59mm;

- Core size: 100µm; Depth of fusion: 2.54mm; Width of fusion: 0.65mm;

Power: 800W, Welding speed: 10mm/s, Core size: 20µm 50µm 100µm

CW & QCW laser Applications - Stainless steel welding

Requirement:

Sealed welding and smooth surface

Setting Matrix

- Welding head: F150/F200

- Power: 600W

- Focus position: Positive focus

- Welding Speed:30mm/s

- Duty cycle: 100%

Material:

0.2mm gold

Requirement:

Uniform welding surface for both front and back side

Setting Matrix

- Welding head: F100/F250

- Power: 800W

- Focus position: Defocus 4mm

- Welding Speed: 20mm/s

- Duty cycle: 40%

- Frequency: 50Hz

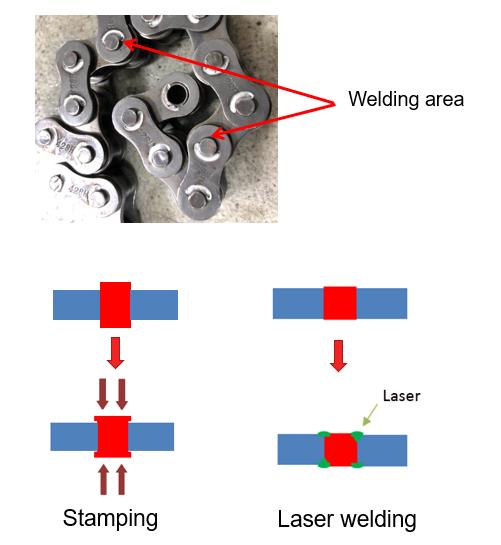

CW & QCW laser Applications- - Laser welding-Chain

Application area: Bicycle, Auto industry, Transmission chain

Setting Matrix

- Welding head: F150/F200

- Power: 600W

- Focus position: positive focus

- Welding Speed:30mm/s

- Duty cycle: 100%

Advantages of laser welding:

- Can get a firmer result;

- The joint is flat and space saving for assemble.

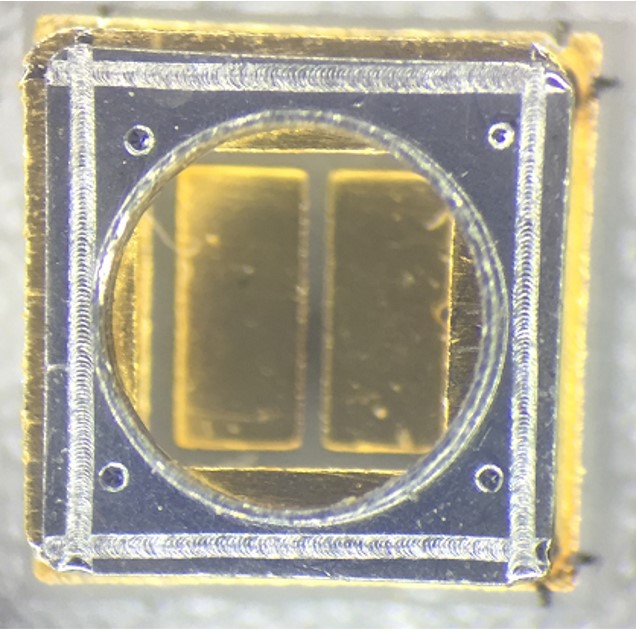

QCW laser Applications - LED cover sealed welding

Requirement:

Sealed welding and bright surface

Setting Matrix

- Laser: JPT-QCW-75/750

- Collimator: f150; Focus: f200

- Pulse width: 500us

- Frequency: 300Hz

- Welding Speed: 20mm/s

Short pulse width and high PRR is better for thin material welding

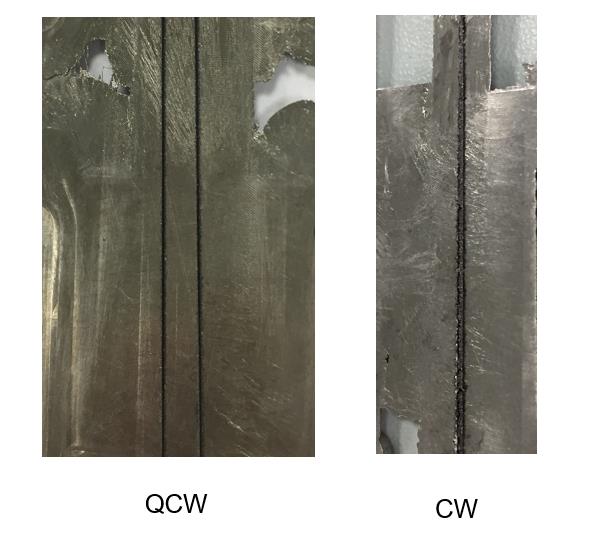

CW & QCW laser Applications - Zirconium cutting

Requirement:

Less bur and no deformation

Setting Matrix

- Laser: JPT-QCW-100/1000

- Collimator: f100; Focus: f150

- Pulse width: 1000us

- Frequency: 100Hz

- Welding Speed: 1m/min

The modulation mode of QCW has high peak power but less heat effect, it’s a better choice for some precise cutting.

You Might Also Like

- HiPA Solutions – Laser Micro Hole Drilling - 09/12/2022

- HiPA Solutions – Laser Ink Removal - 03/12/2022

- JPT Solutions – Thick Glass Cutting with Ultrafast Laser - 03/12/2022