To prevent laser condensation in summer, this article is enough!

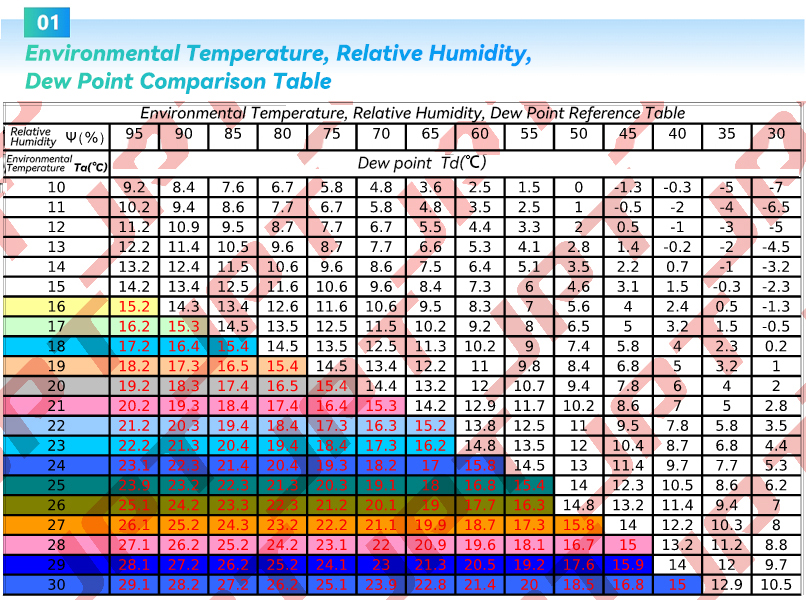

Condensation means that when the surface temperature of an object is lower than the dew point temperature of the surrounding air, water vapor in the air condenses into water droplets on the surface of the object.

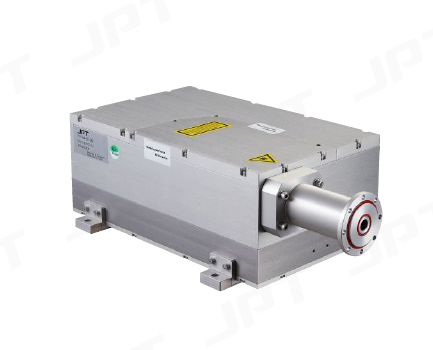

Recently, high temperatures have continued throughout the country and the seasons have continued. The high temperature and high humidity environment can easily cause condensation inside the laser, affecting the performance of the laser. When the exposure problem is serious, water on the surface will enter the inside of the laser, causing the performance of the laser to decrease, and even damage the laser (circuit) board (dewdrop accumulation, sensor corrosion, severe corrosion of the circuit board, QBH end surface coating damage, etc.).

Don’t worry about laser condensation prevention in summer, Xiaojie has a trick!

Xiaojie recommends that you always pay attention to the laser. When water droplets appear on the wall of the cold water pipe on the laser, anti-condensation measures should be taken in advance to avoid condensation from spreading to the inside of the laser and causing serious consequences.

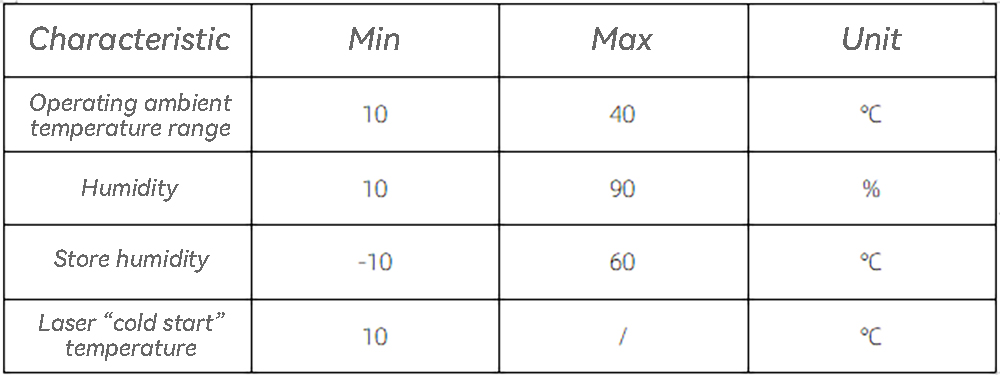

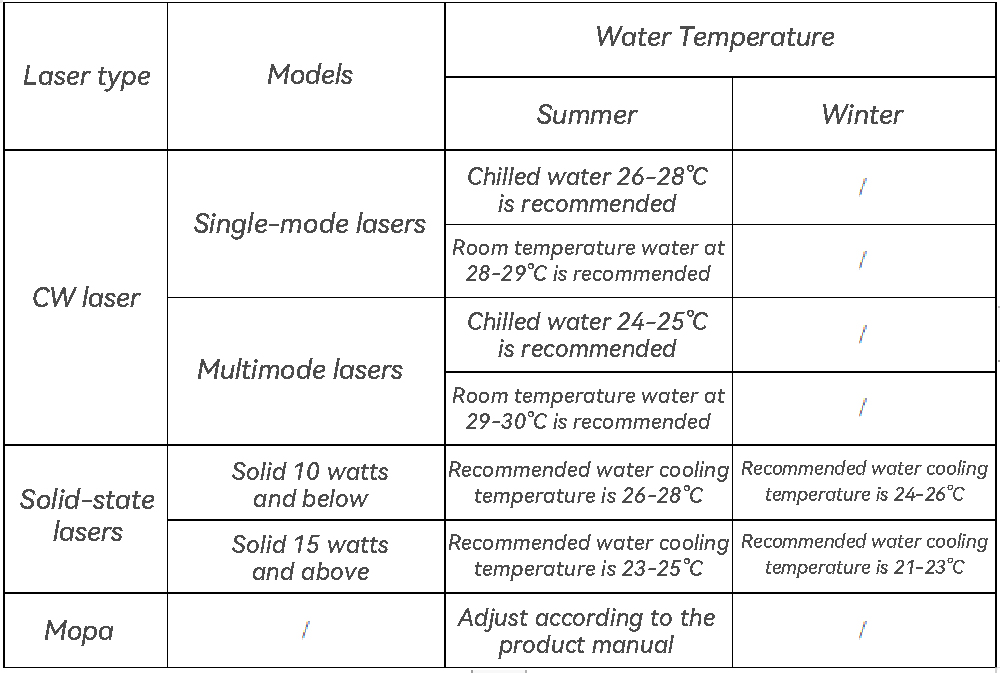

Different types and powers of lasers have slightly different requirements for the working environment. Please check each product manual for details.

It should be noted that for the cooling of continuous fiber lasers, chilled water and normal temperature water must be separated. QBH will cause condensation due to too low water temperature. As for the solid-state laser, due to the fully sealed and waterproof structural design of the laser, the laser can work normally even if there is partial condensation on the surface of the laser. Pulsed fiber laser will stop emitting light and alarm when the temperature is inappropriate. Please refer to the product manual for settings.

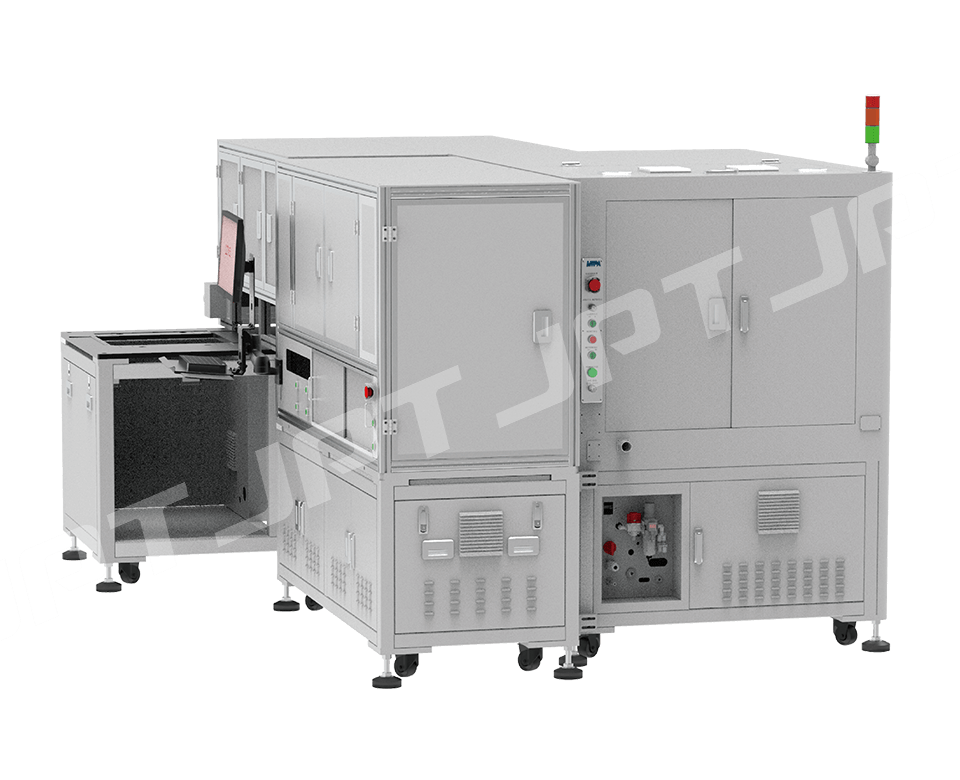

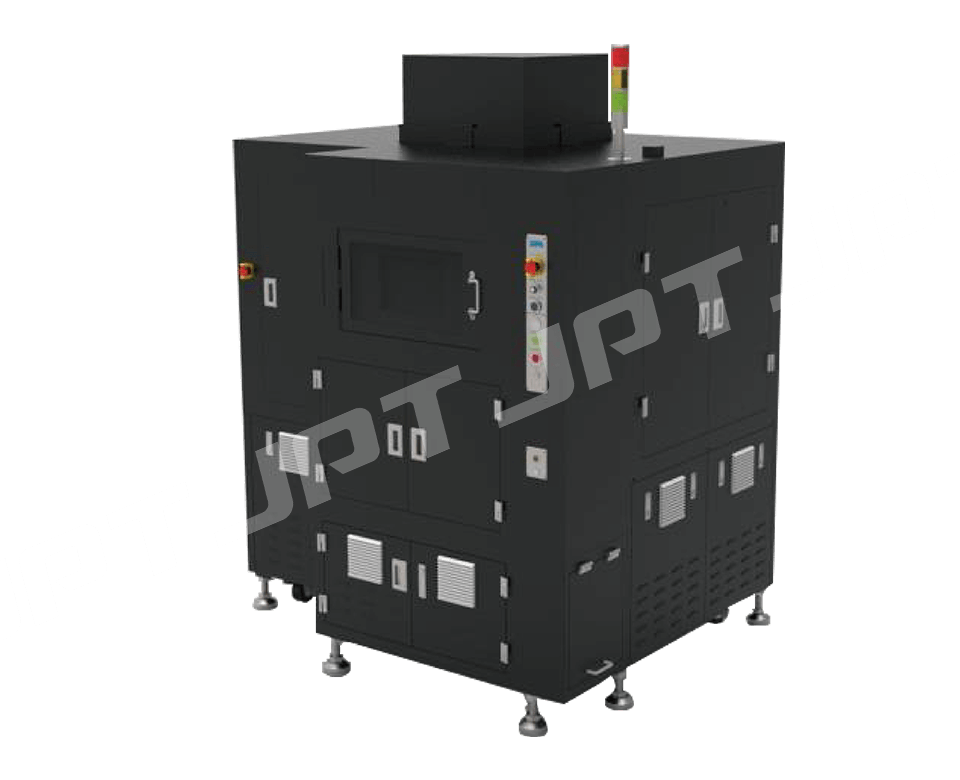

If possible, place the laser in a temperature and humidity balance and air suction system cabinet (the placement environment must be smooth and free of shock and vibration). In such an environment, the safety of the laser and the safety of the laser can be ensured. Clean, it can also effectively extend the service life of the laser and ensure personal safety.

When starting up, turn on the constant temperature and exhaust system first, wait for the system to run for a period of time, then turn on the water cooler, and finally turn on the laser. When shutting down, turn off the laser first, and then turn off the water cooler to prevent condensation caused by excessive temperature differences.

Use deionized water or distilled water for cooling water, and change the water regularly (change water once every 1-3 months depending on the power); check the water inlet and outlet to prevent reverse connection; in case of long-term shutdown, the inside of the cooling system must be drained and Cooling water inside the laser.

If it is in an environment of high temperature and high humidity (too high humidity) when it is turned on, the continuous fiber laser alarm will cause a 30-minute dehumidification process, which is within the normal range. At the same time, if condensation is found on the laser during use, the condensation water should be wiped clean after shutting down and the environment should be cooled down at the same time.

If it is in an environment of high temperature and high humidity (too high humidity) when it is turned on, the continuous fiber laser alarm will cause a 30-minute dehumidification process, which is within the normal range. At the same time, if condensation is found on the laser during use, the condensation water should be wiped clean after shutting down and the environment should be cooled down at the same time.

Harsh natural environments such as high temperatures, lightning, and rain are common in summer. If you have questions during the use of JPT laser, or your laser has been attacked by extreme environments, you can contact us through the JPT laser official account or JPT official website ( www.jptoe.com) or other methods to contact our technical support engineers.

Recommended content

Boosting Efficiency | JPT Laser Solutions Help Improve Charging Efficiency of New Energy Lithium Batteries!

DateTime:2024/08/21

Laser metal engraving, first choice JPT MOPA fiber laser!

DateTime:2024/08/08

To prevent laser condensation in summer, this article is enough!

DateTime:2024/07/19

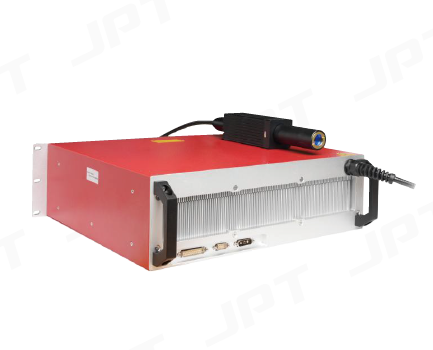

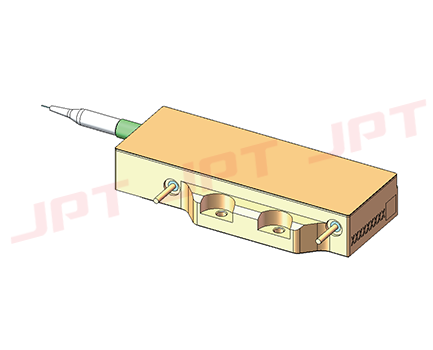

M7 20W-100W

M7 20W-100W

M7 200W-300W

M7 200W-300W

M7 500 - 1000W

M7 500 - 1000W

M8 20 - 50W

M8 20 - 50W

M8 120 - 300W

M8 120 - 300W

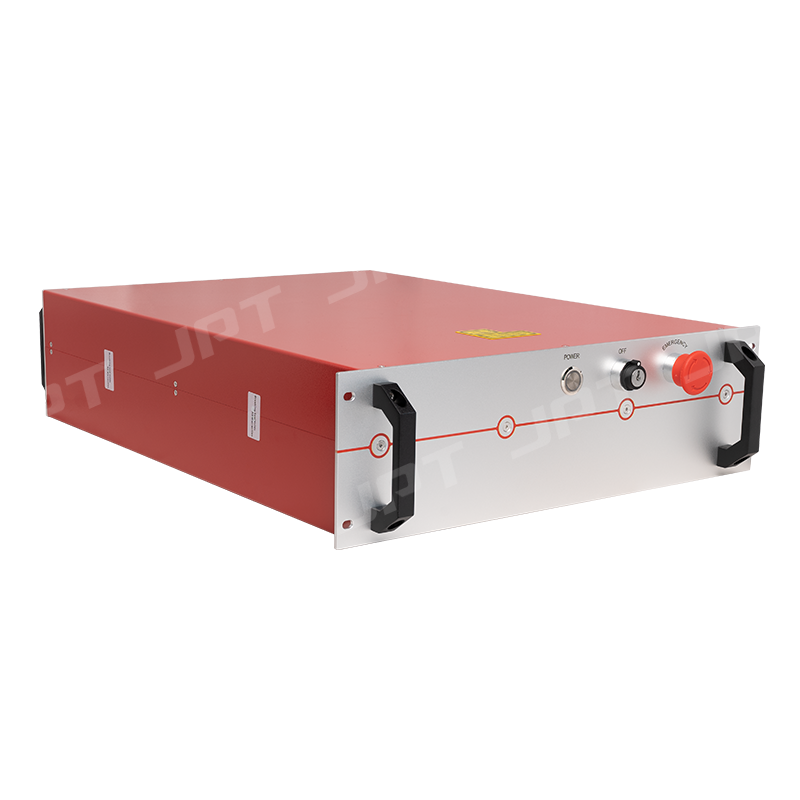

CL2 200W-300W

CL2 200W-300W

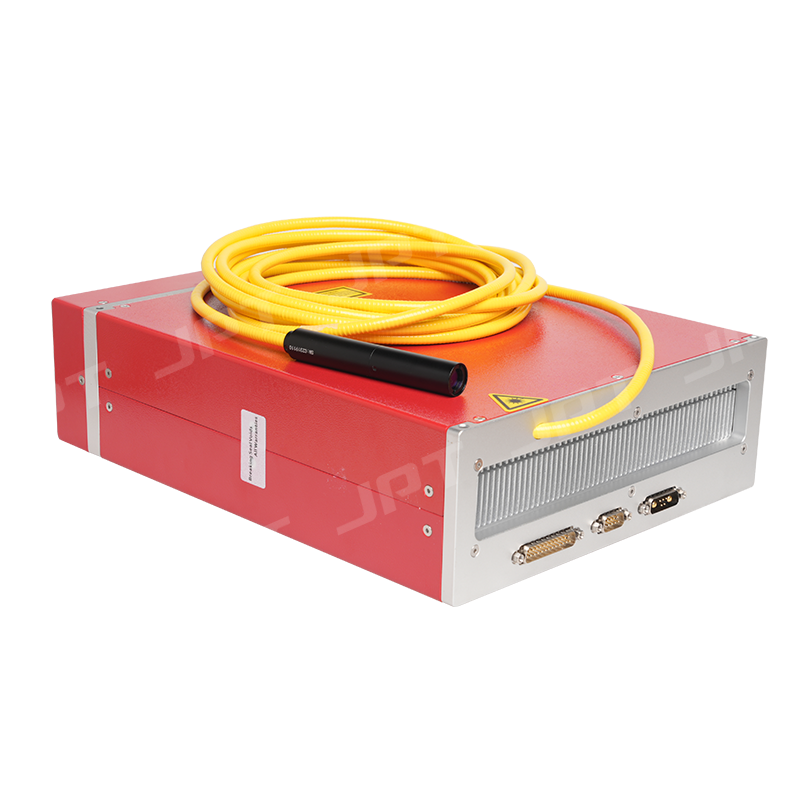

CL 500W~1000W

CL 500W~1000W

CL 2000W

CL 2000W

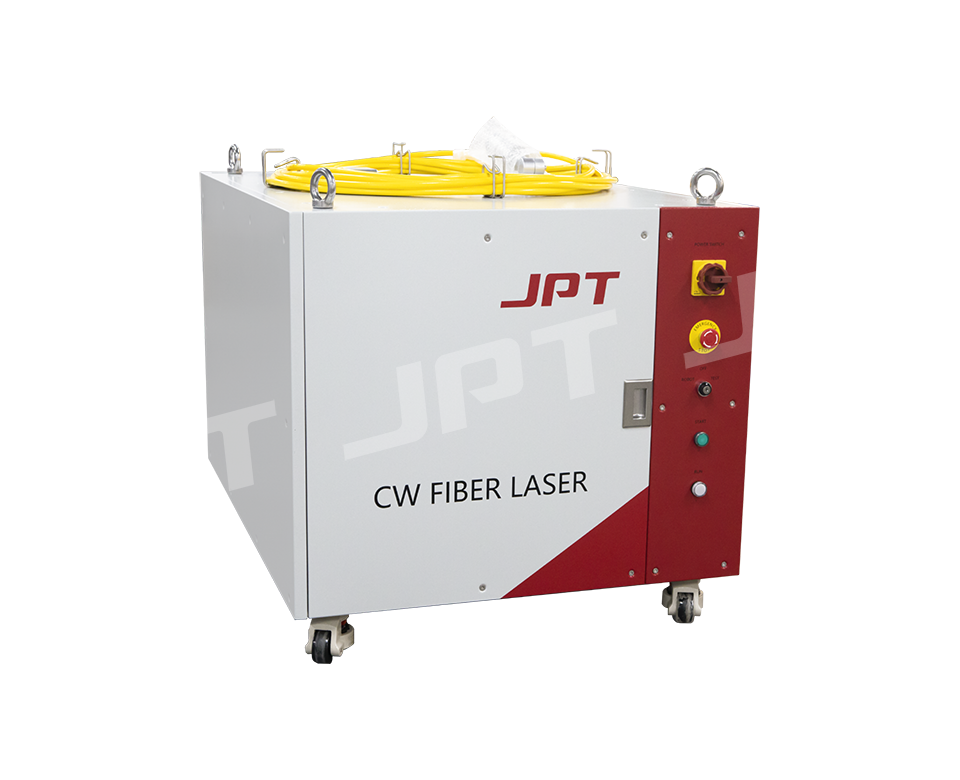

Multi-Module CW 6000W

Multi-Module CW 6000W

QCW 150W/1500W

QCW 150W/1500W

Multi-Module CW 12000W

Multi-Module CW 12000W

Single-Module CW 1500W-3000W

Single-Module CW 1500W-3000W

SEAL 355-3/5

SEAL 355-3/5

SEAL 532

SEAL 532

LARK 355-3/5

LARK 355-3/5

PS IR/GR/UV Picosecond Laser

PS IR/GR/UV Picosecond Laser

SEAL 355-10/15/20/30

SEAL 355-10/15/20/30

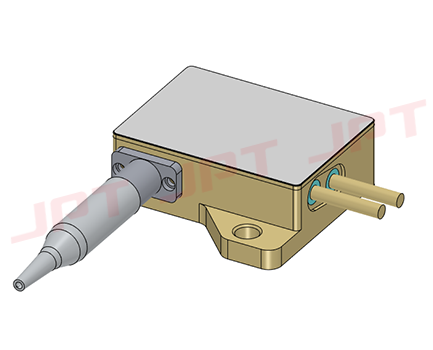

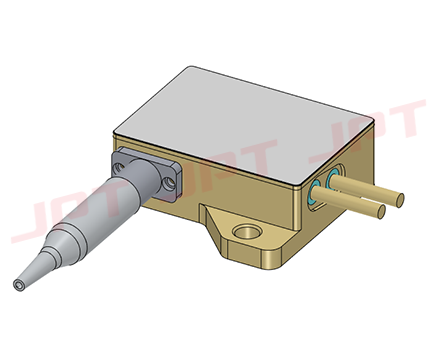

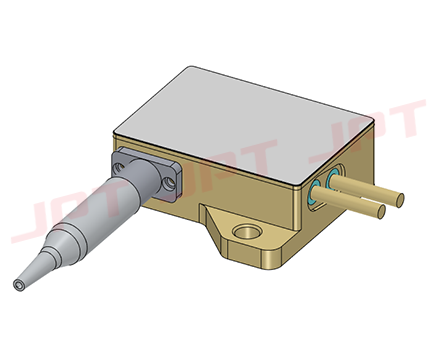

Semiconductor Laser with Red Light Series 200W

Semiconductor Laser with Red Light Series 200W

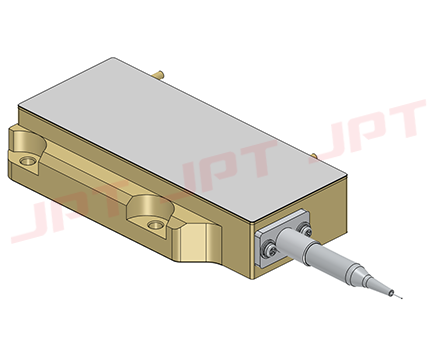

450nm—100W High Power Diode Laser

450nm—100W High Power Diode Laser

10W-1064-01 Silicon Transmission Series Detection Moduler

10W-1064-01 Silicon Transmission Series Detection Moduler

1060nm Series

1060nm Series

880nm Series

880nm Series

808nm Series

808nm Series

976nm Series

976nm Series

915nm Series

915nm Series

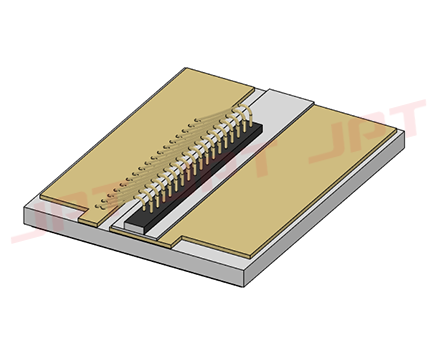

COS Encapsulated Semiconductor Laser

COS Encapsulated Semiconductor Laser

Laser Scriber

Laser Scriber

High Voltage Resistor Tester

High Voltage Resistor Tester

Single Chip Resistor Tester

Single Chip Resistor Tester

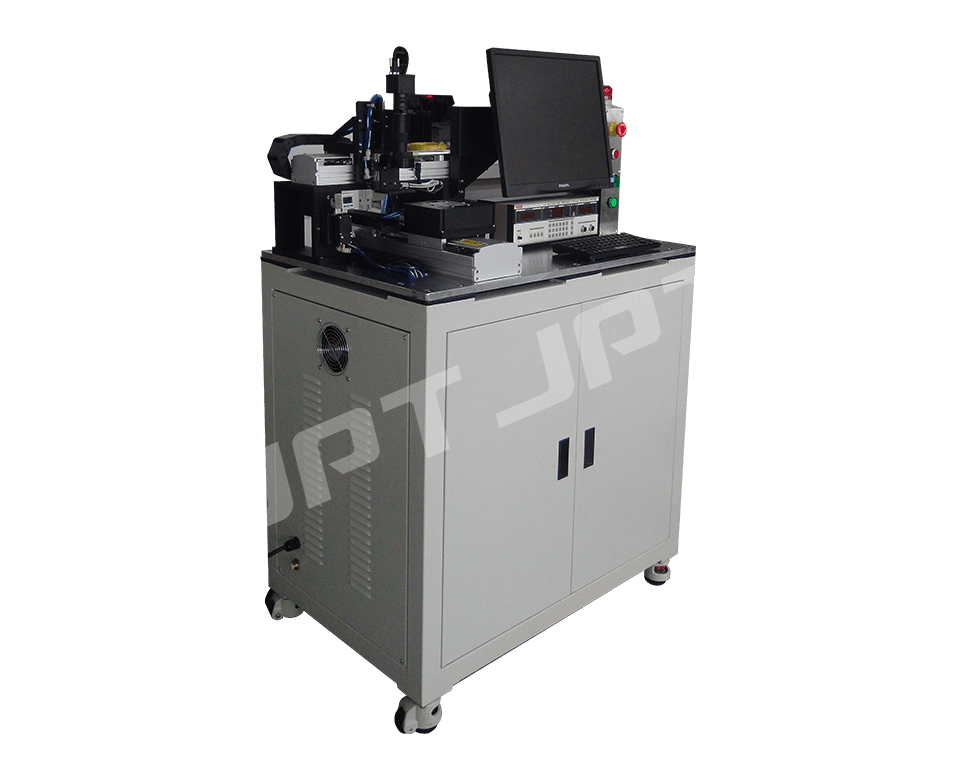

Laser Trimmer

Laser Trimmer

Hybrid Trimmer

Hybrid Trimmer

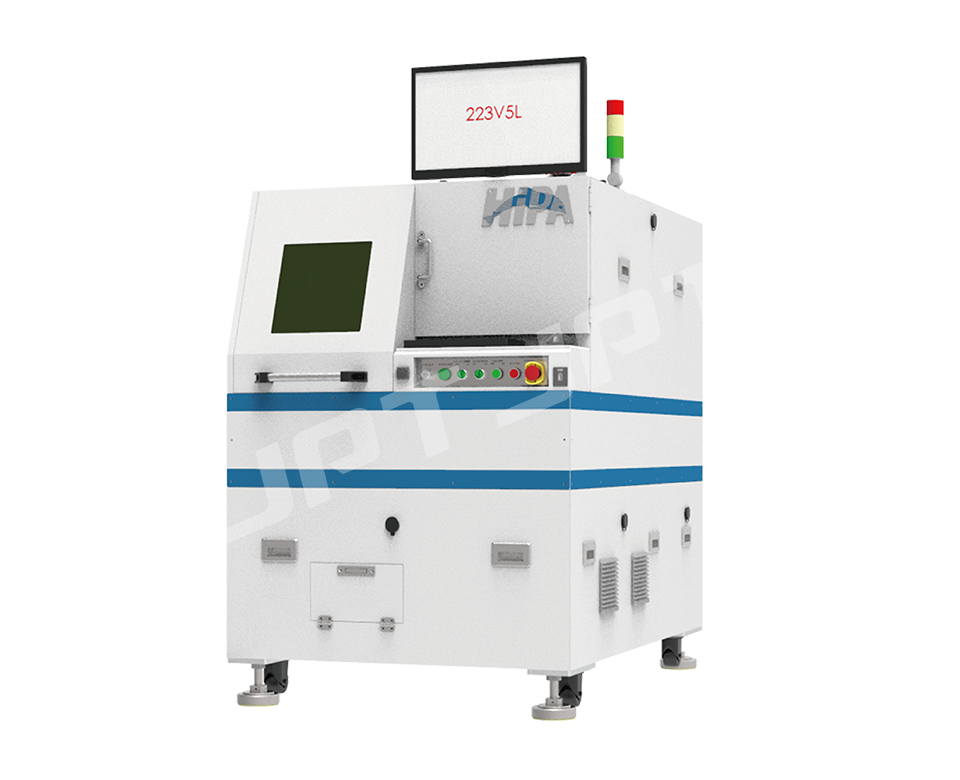

HiPA-TT Light Transmittance Tester

HiPA-TT Light Transmittance Tester

PCB Laser Marking System

PCB Laser Marking System

Ghost Writer & Reader - Subsurface 2D Barcode Marking & Reading System

Ghost Writer & Reader - Subsurface 2D Barcode Marking & Reading System

High Precision 2DBC Laser-marking

High Precision 2DBC Laser-marking

Comprehensive VCSEL Module tester

Comprehensive VCSEL Module tester

Comprehensive LED-PD Integrated Module Testing

Comprehensive LED-PD Integrated Module Testing

Six-sided Inspection Machine

Six-sided Inspection Machine