PRODUCT CATEGORIES

JPT produce a wide range of laser equipments. Our laser equipments include Ghost Writer & Reader - Subsurface 2D Barcode Marking & Reading System, High Precision 2DBC Laser-marking, PCB Laser Marking System, Automatic FPCB Laser Cutting and Placing System, Brittle Material Cutting & Splitting System, Brittle Materials Drilling System and so on. Our Subsurface 2D Barcode Marking & Reading System can mark invisible micro-sized 2D barcode inside glasses / sapphires, we design this marking and reading system which can mark dots as small as 2.5 μm. This system marks each sample with unique informationon, which helps for the traceability and anti-counterfeiting.

The High Precision 2DBC Laser-marking marks μ m-precision 2D barcode (2DBC) with pulsed-laser. The 2DBC is for product traceability. This machine has integrated onloading & offloading, global/local alignment, marking & inspection. Fully automation delivers high UPH.

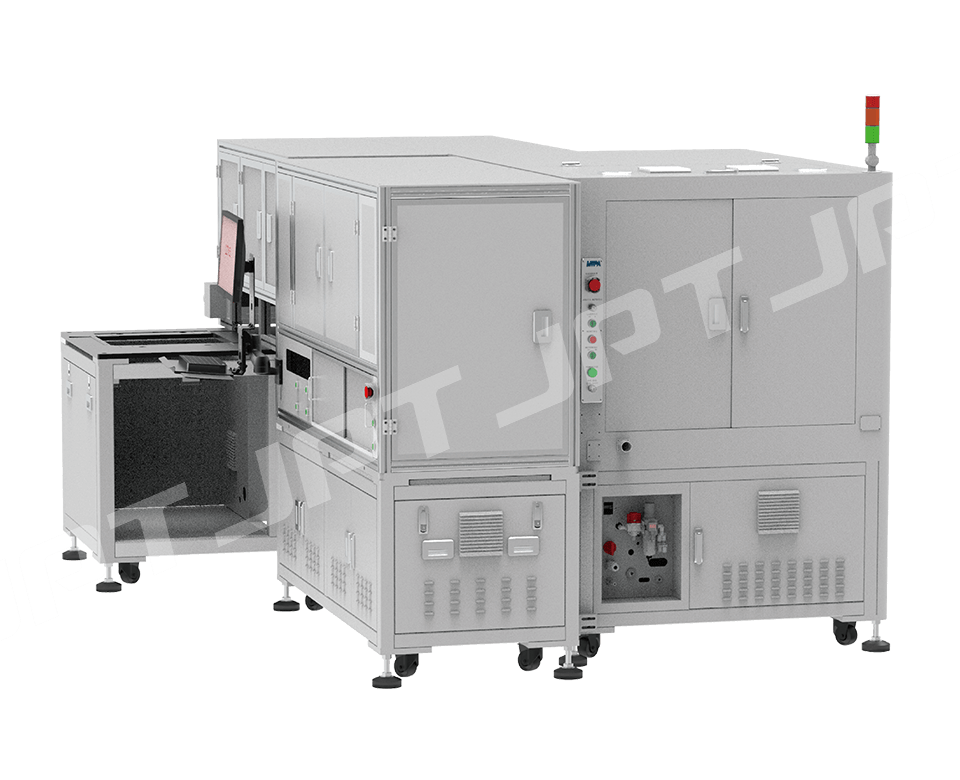

The PCB Laser Marking system is tailored for fully automatic inline dynamic marking in the PCB industry. It realizes automatic loading & unloading using the SMEMA standard.

Automatic FPCB Laser Cutting and Placing System enjoys Twin laser cutting station design, for high cutting speed and accuracy: Fully automated cutting, PNP, loading & unloading.

Brittle Material Cutting & Splitting System emits Ultrafast laser with compatible cutting head to cut britile materials like sapphire glass, etc., and use CO 2 laser system for spliting after the cutting.

The Brittle Materials Drilling System adopts ultra-fast laser and high-speed galvo mirrors, which can drill holes in materials such as sapphire, glass, and wafer.

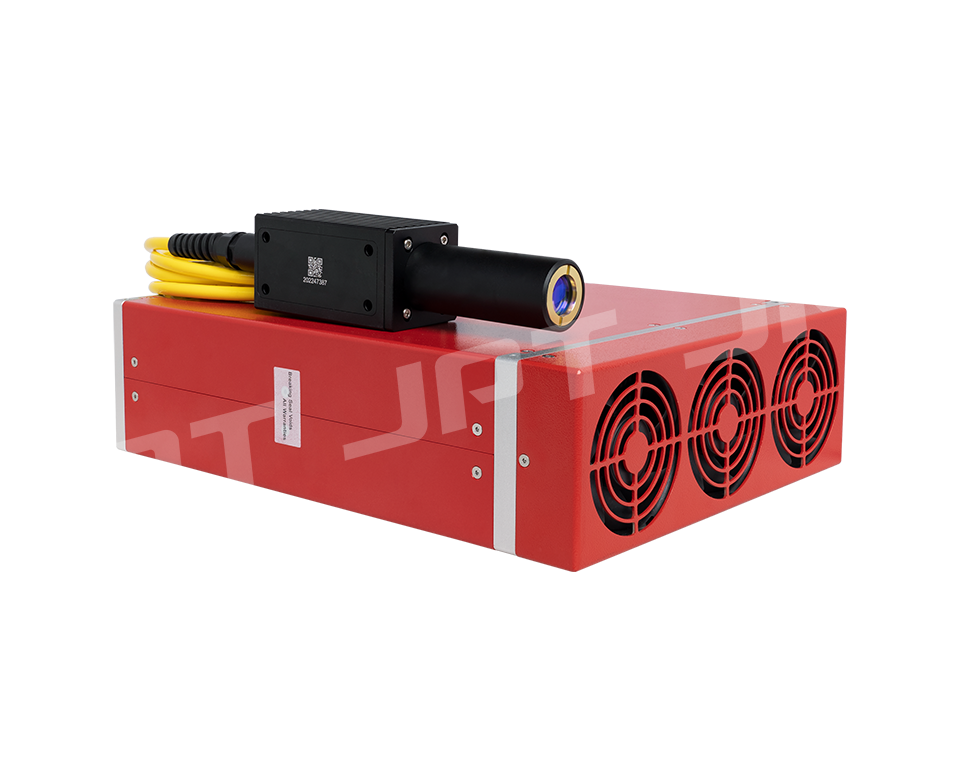

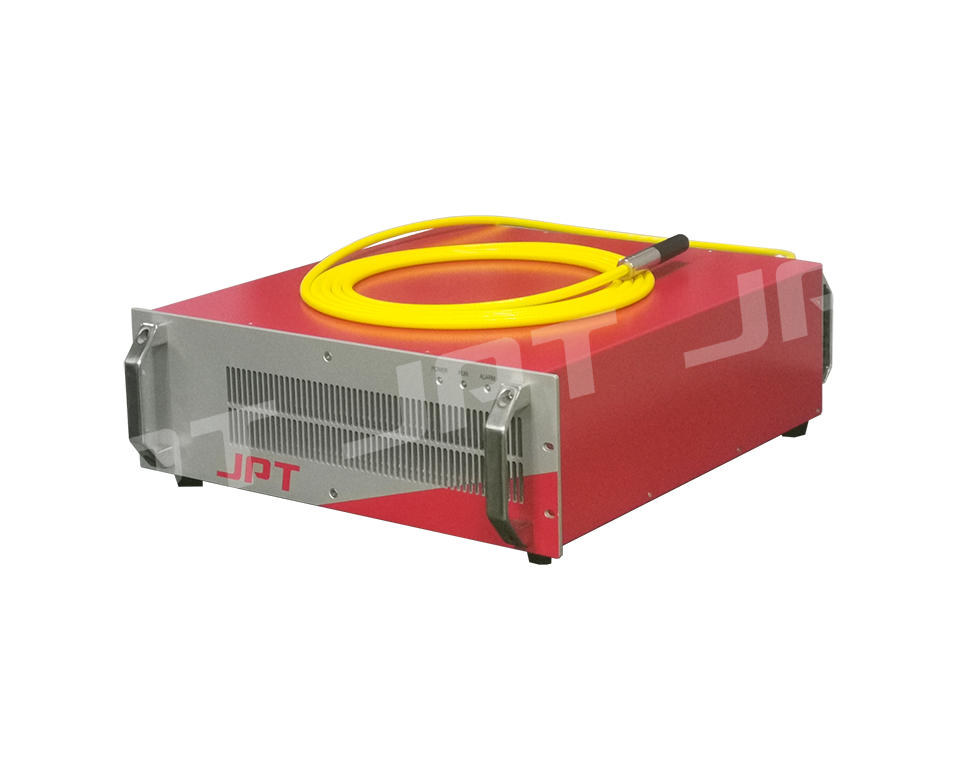

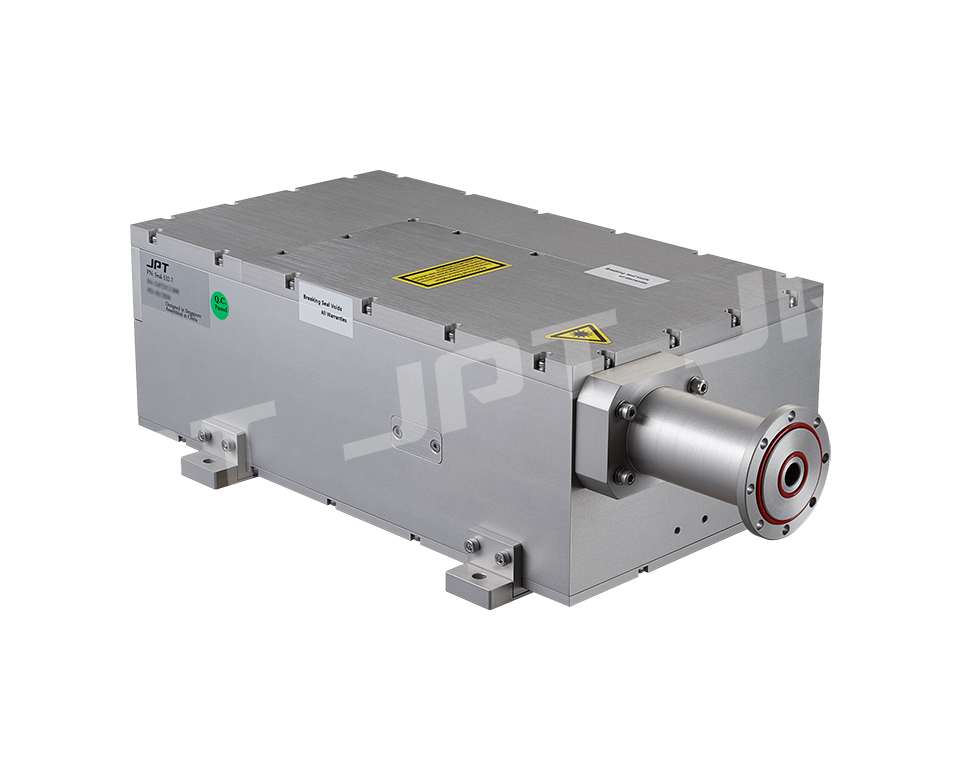

M7 20W/30W

M7 20W/30W

M7 60W/100W

M7 60W/100W

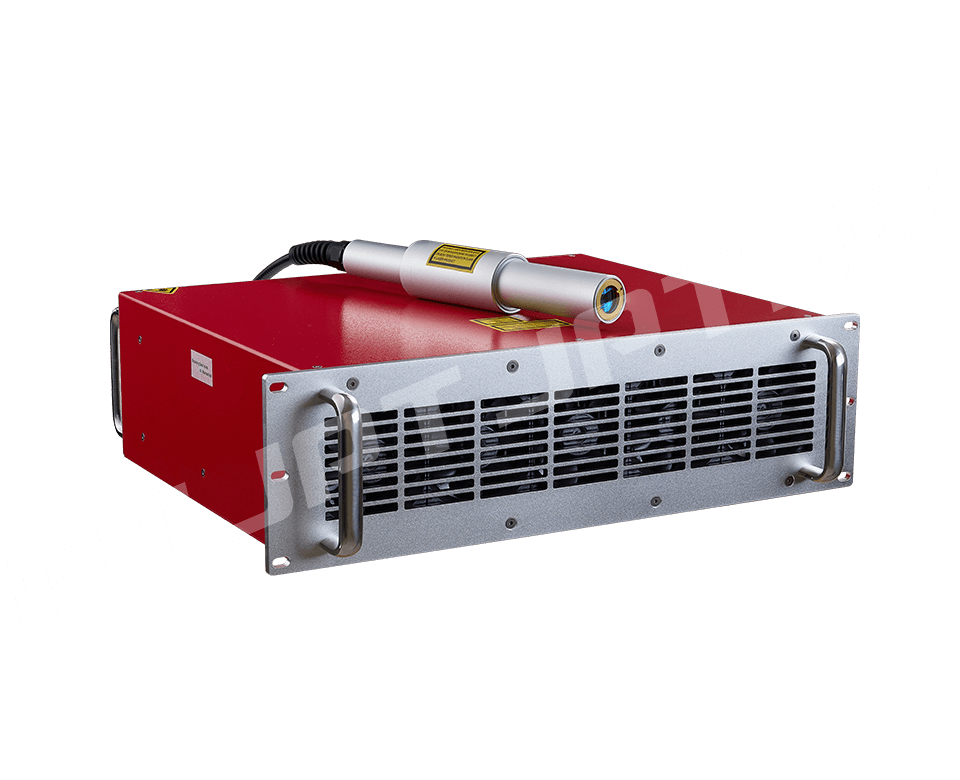

M7 200W/350W

M7 200W/350W

LP 20W/30W/50W

LP 20W/30W/50W

CL 100W/200W/300W

CL 100W/200W/300W

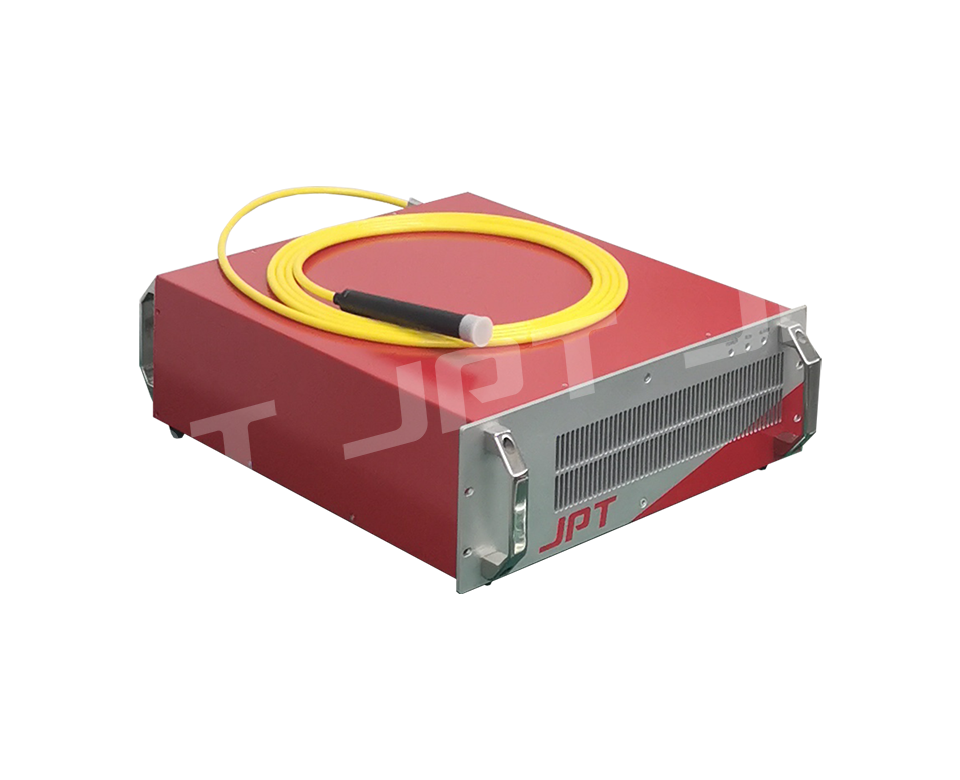

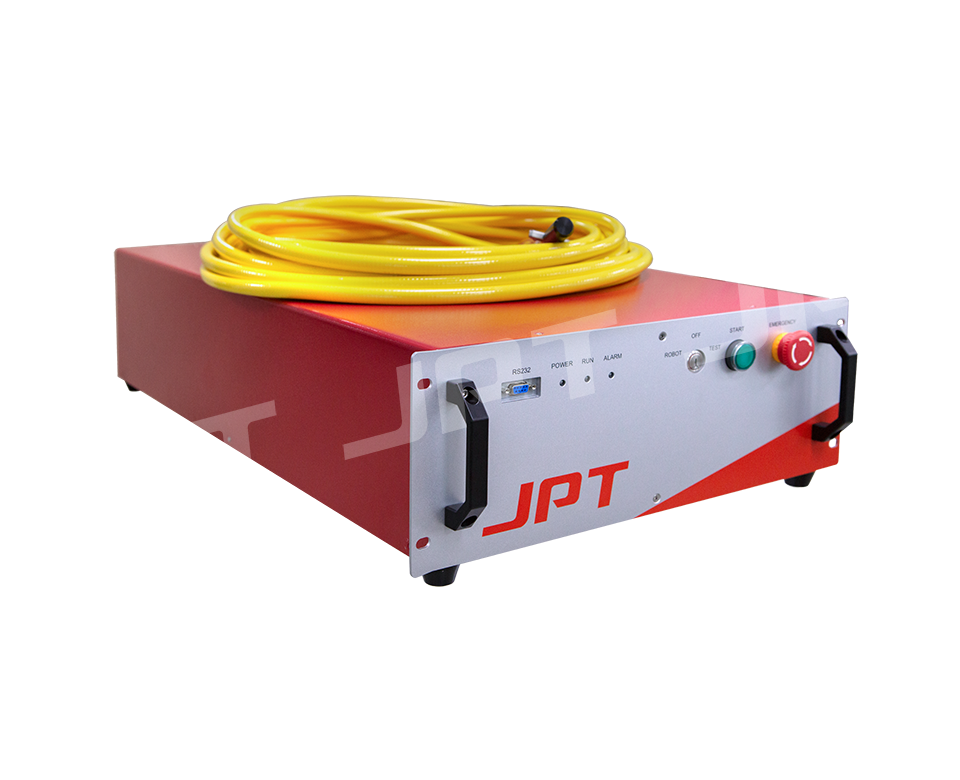

CW 200W/300W

CW 200W/300W

CW 500W-1000W

CW 500W-1000W

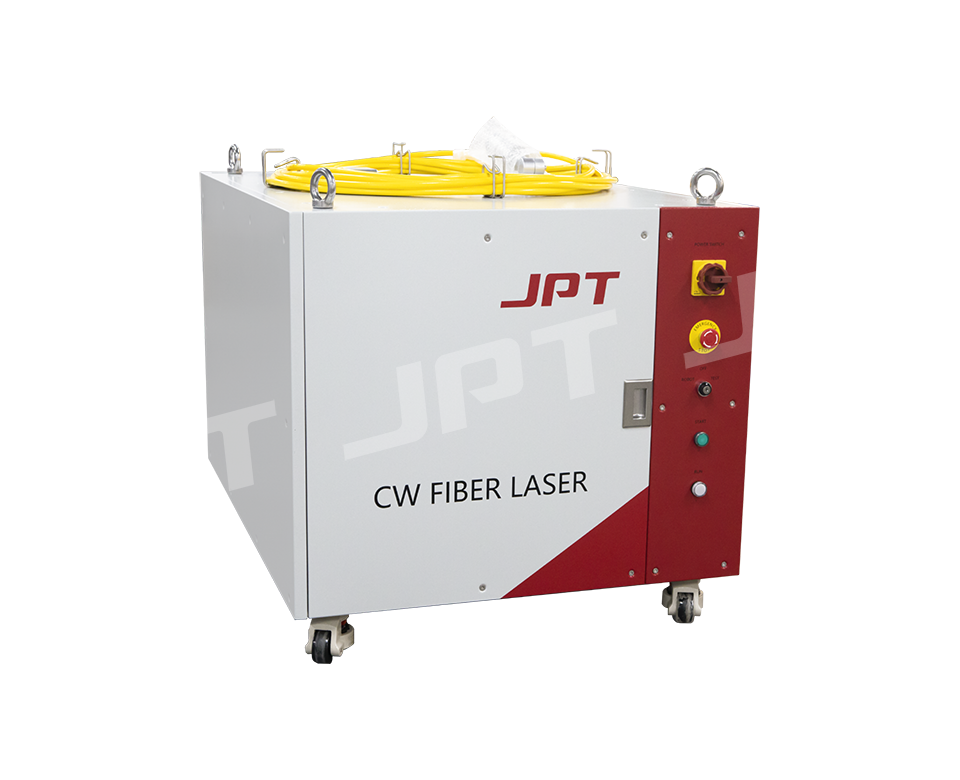

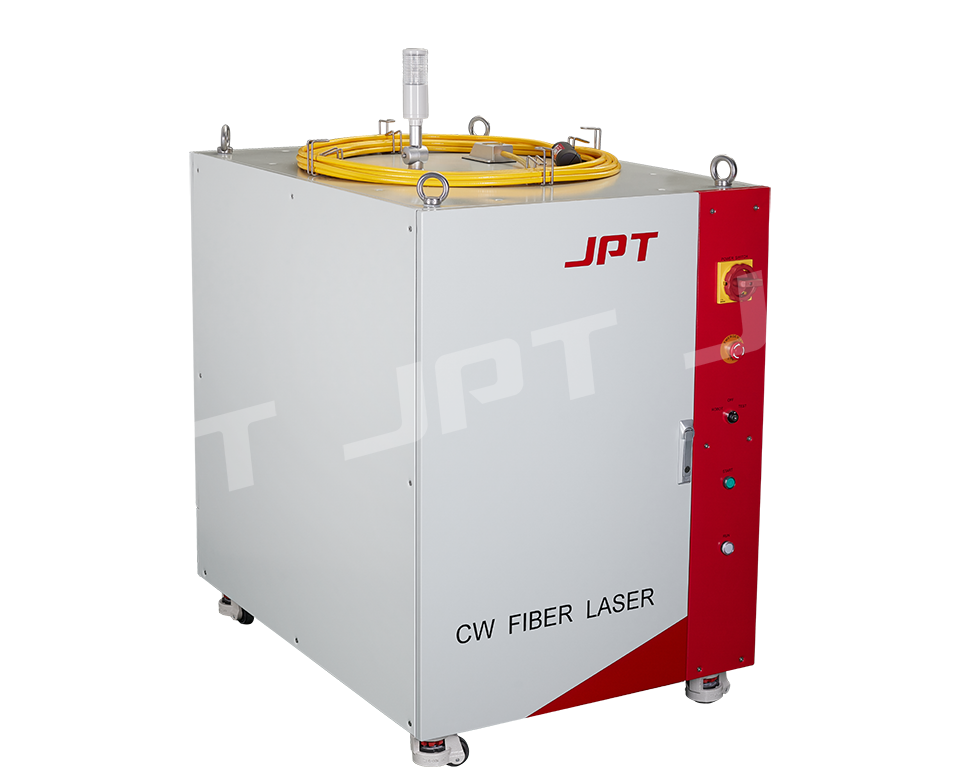

CW 4000W-6000W

CW 4000W-6000W

QCW 150W/1500W

QCW 150W/1500W

CW 8000W/12000W

CW 8000W/12000W

CW 1500W-3000W

CW 1500W-3000W

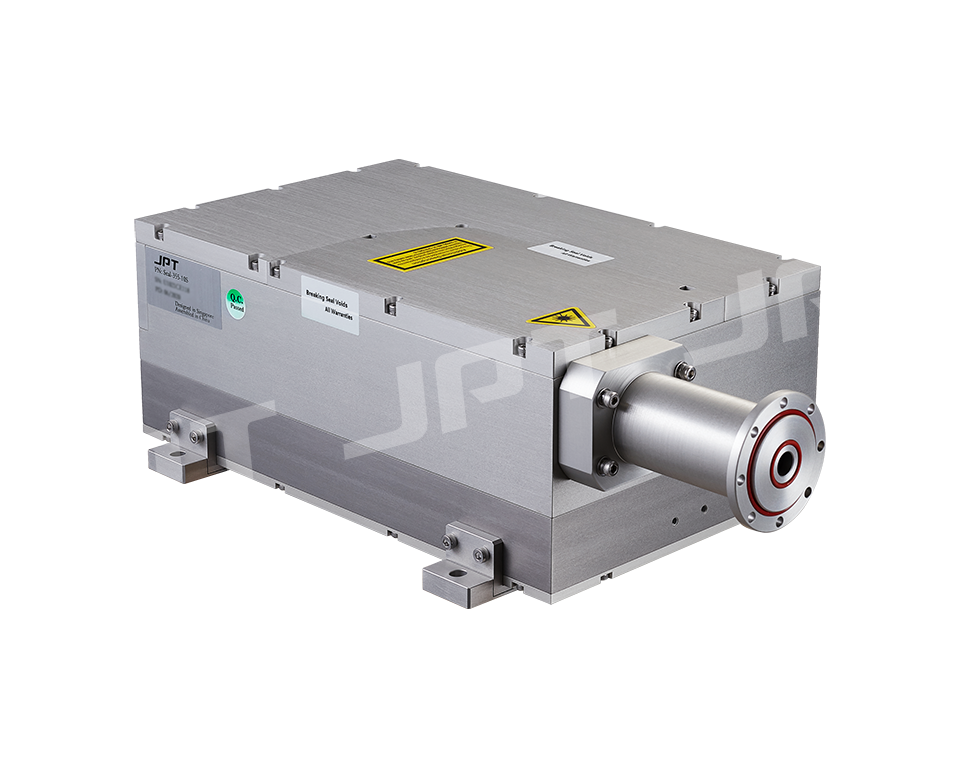

SEAL 355

SEAL 355

SEAL 532

SEAL 532

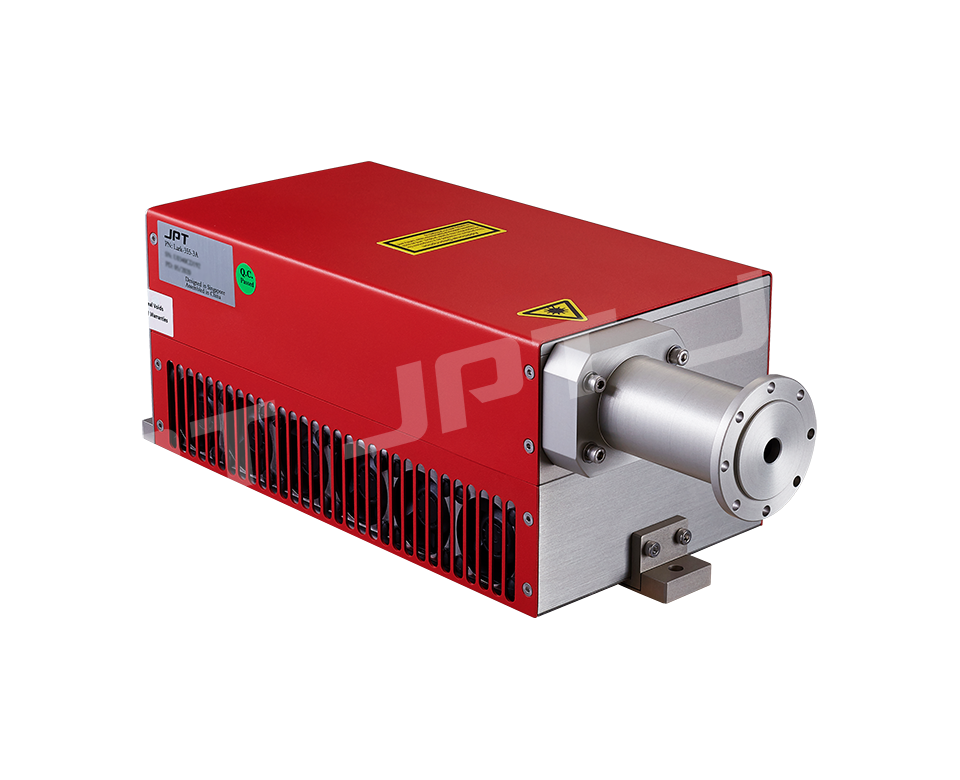

LARK 355

LARK 355

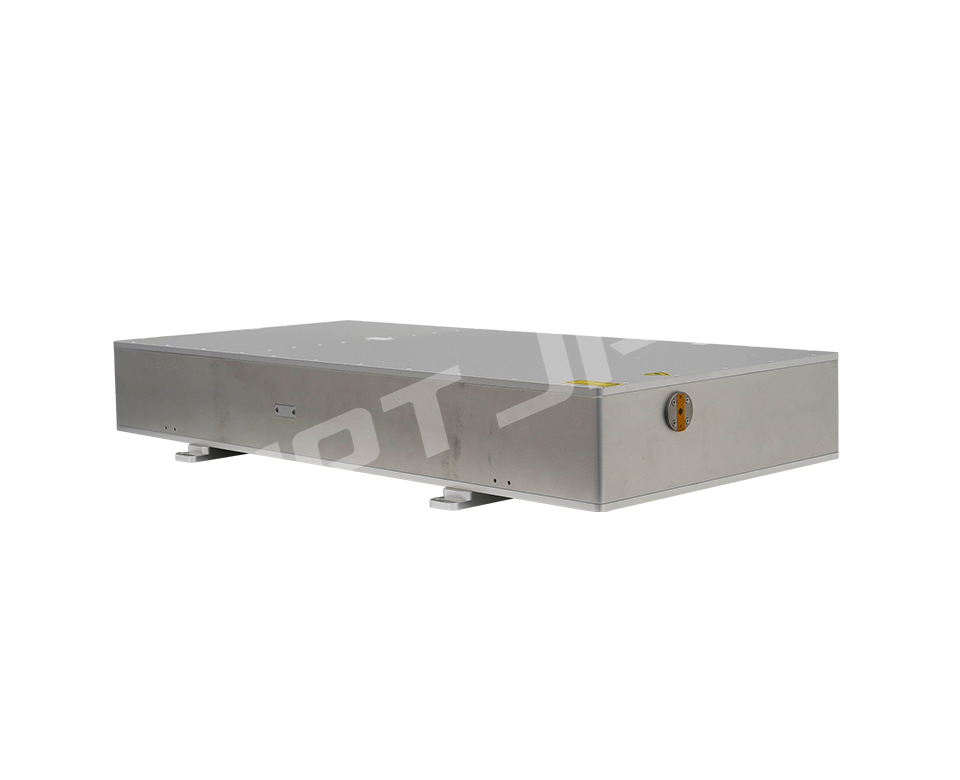

PS IR/UV Picosecond Laser

PS IR/UV Picosecond Laser

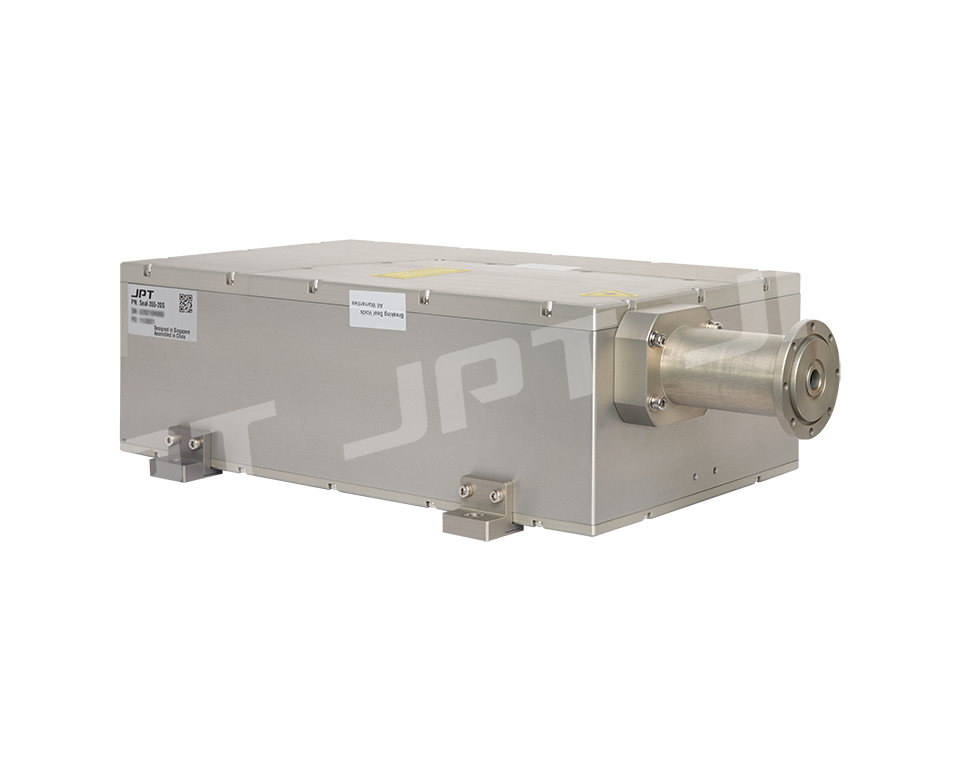

SEAL 355-20S

SEAL 355-20S

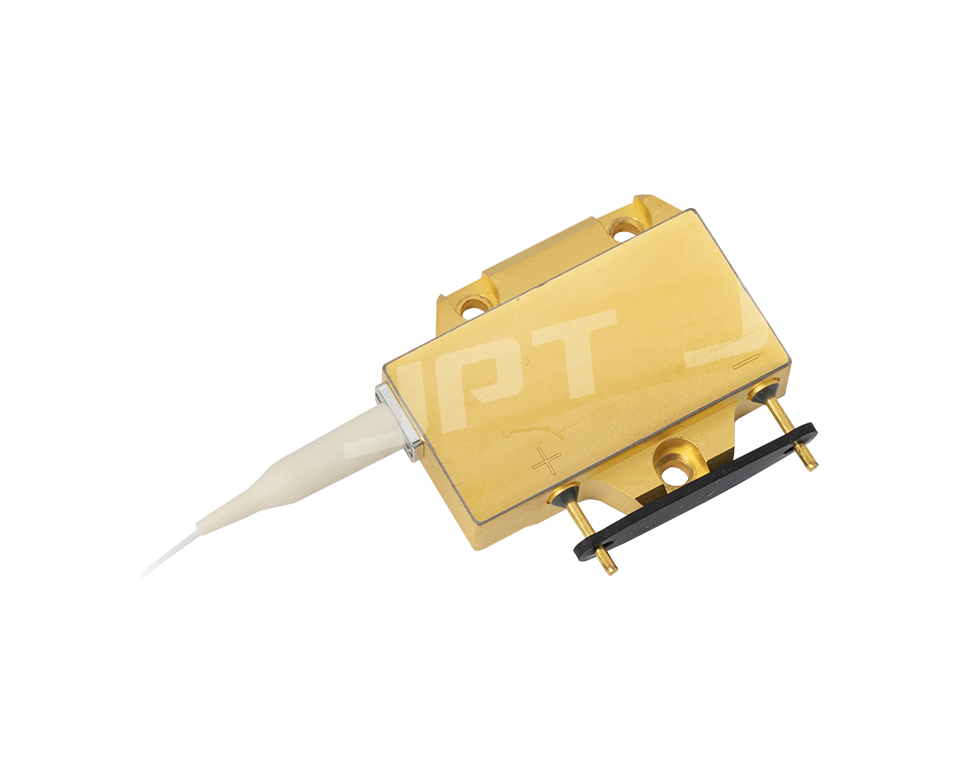

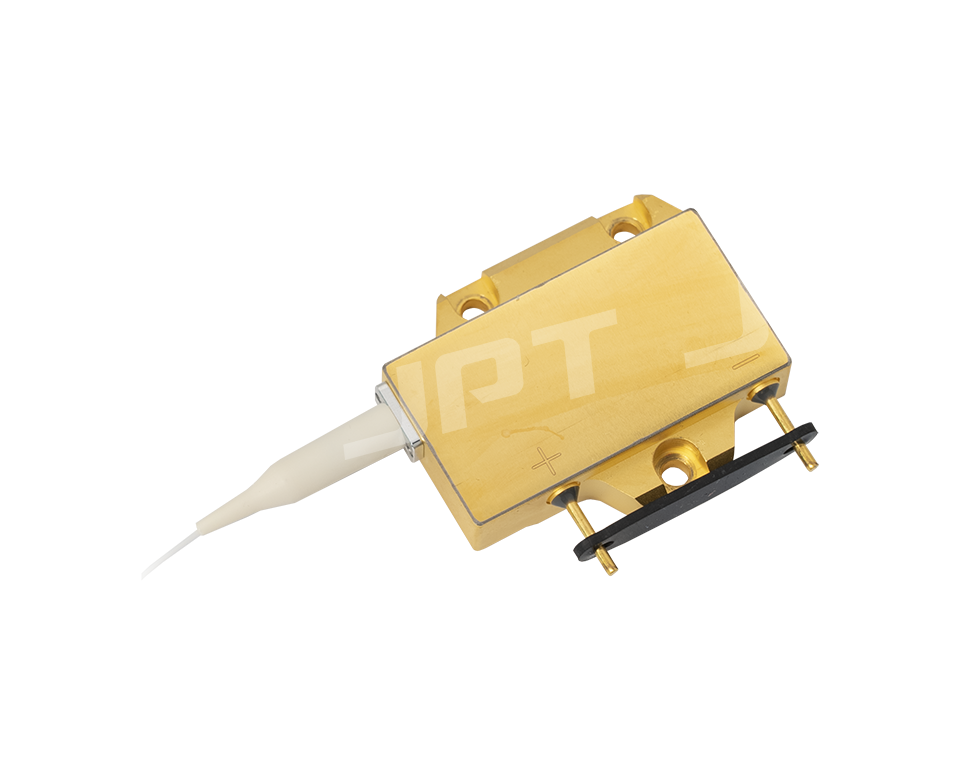

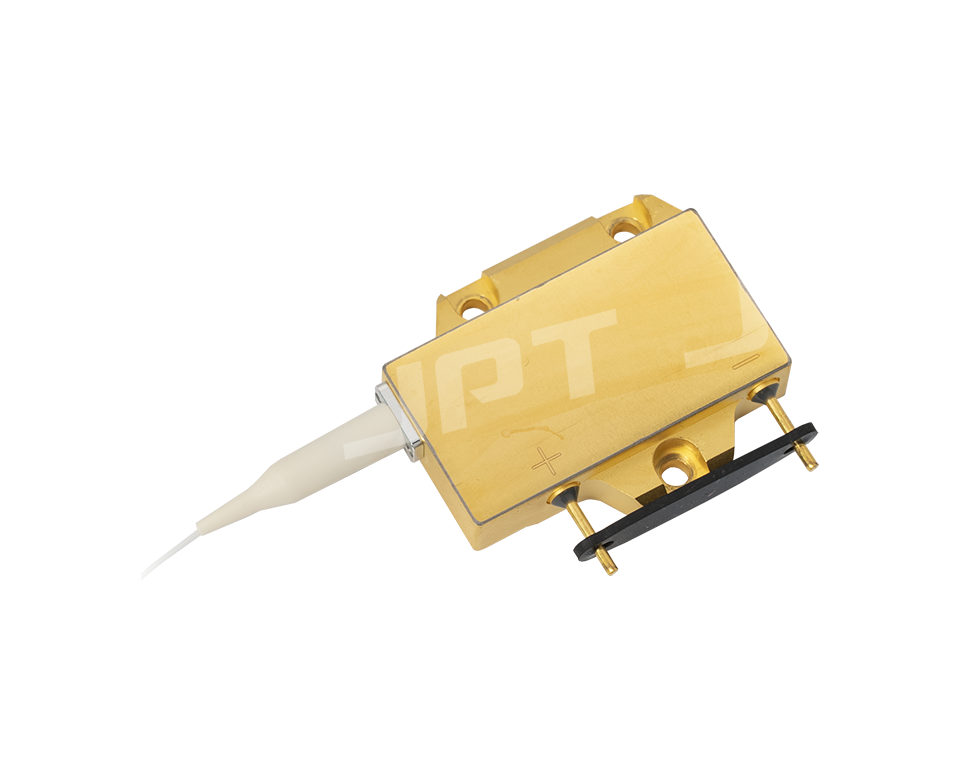

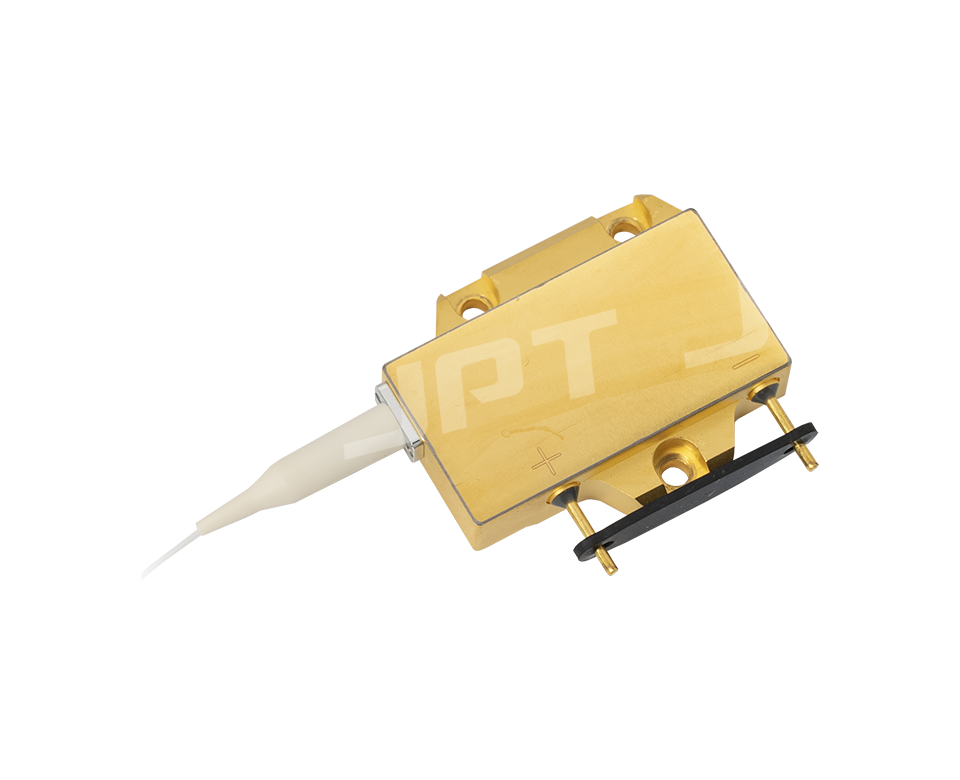

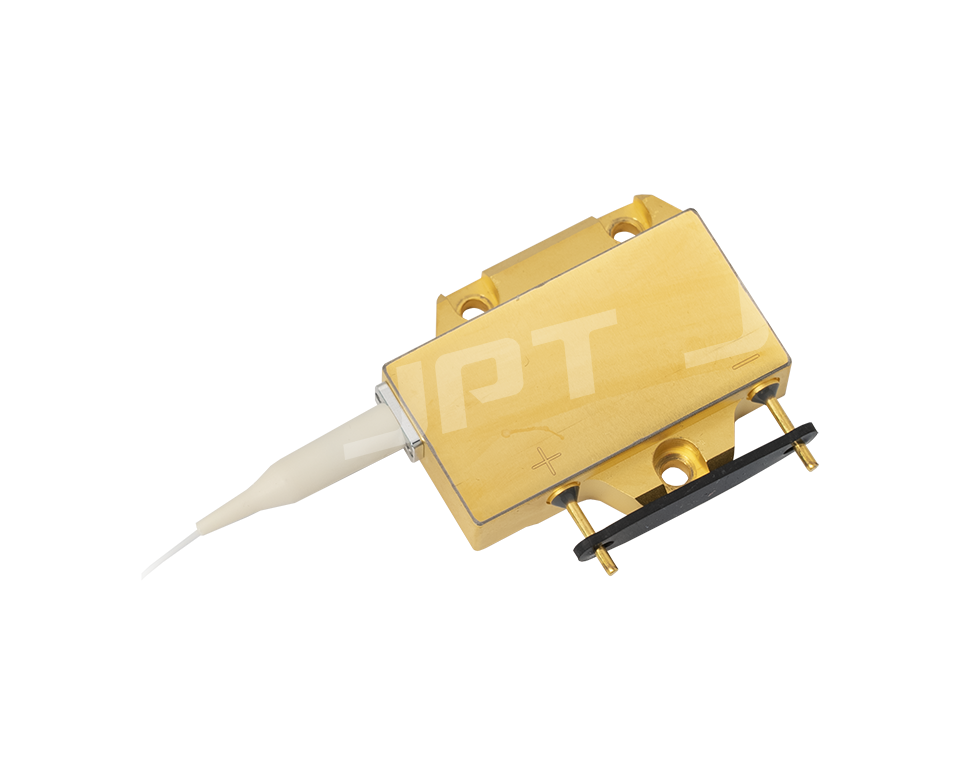

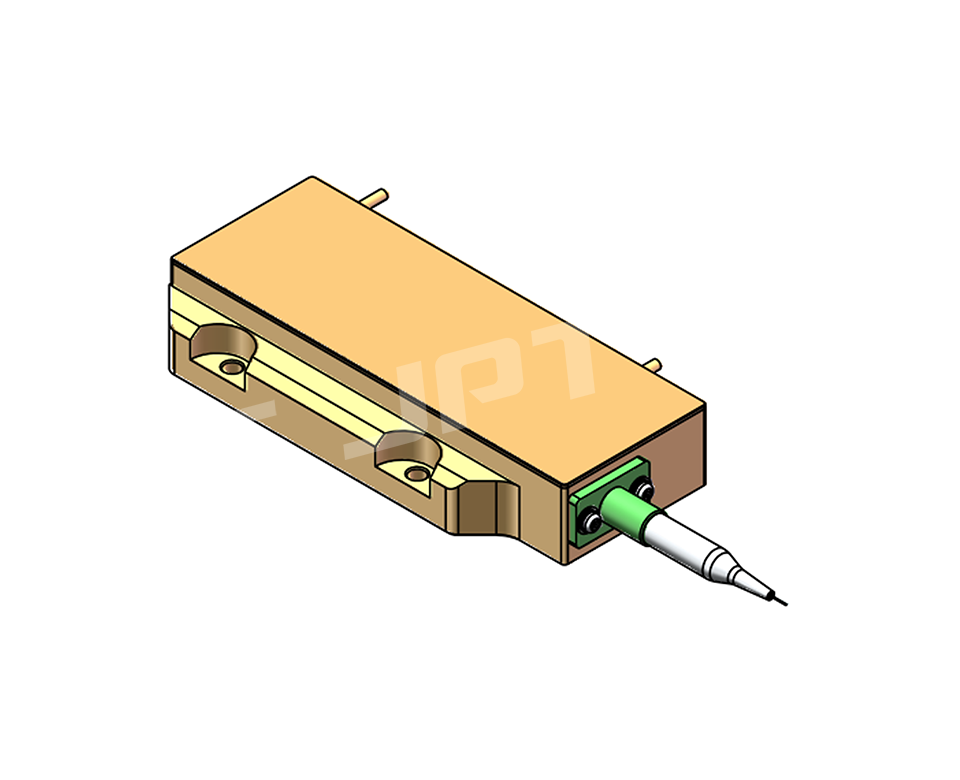

915nm/976nm - 240W - 135μm

915nm/976nm - 240W - 135μm

915nm - 280W - 135μm

915nm - 280W - 135μm

976nm - 420W - 200μm

976nm - 420W - 200μm

976nm - 500W - 200μm

976nm - 500W - 200μm

450nm - 15W - 105μm

450nm - 15W - 105μm

915nm - 15W - 105μm

915nm - 15W - 105μm

915nm - 30W - 105μm

915nm - 30W - 105μm

915nm - 45W - 105μm

915nm - 45W - 105μm

915nm - 60W - 105μm

915nm - 60W - 105μm

915nm - 110W - 105μm

915nm - 110W - 105μm

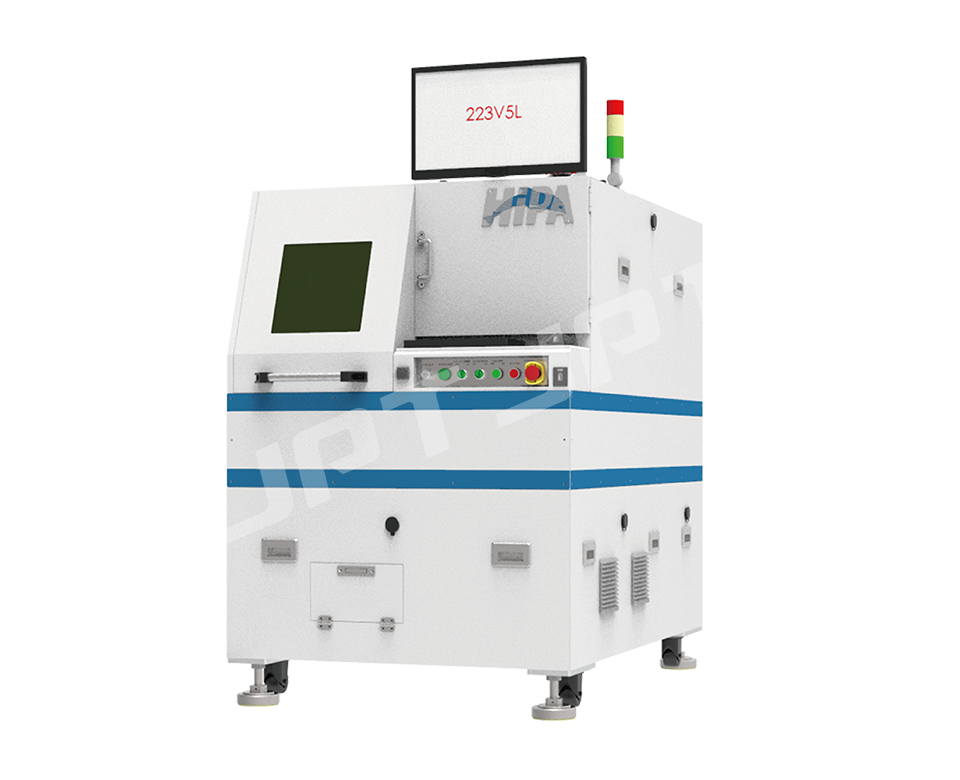

Laser Scriber

Laser Scriber

High Voltage Resistor Tester

High Voltage Resistor Tester

Single Chip Resistor Tester

Single Chip Resistor Tester

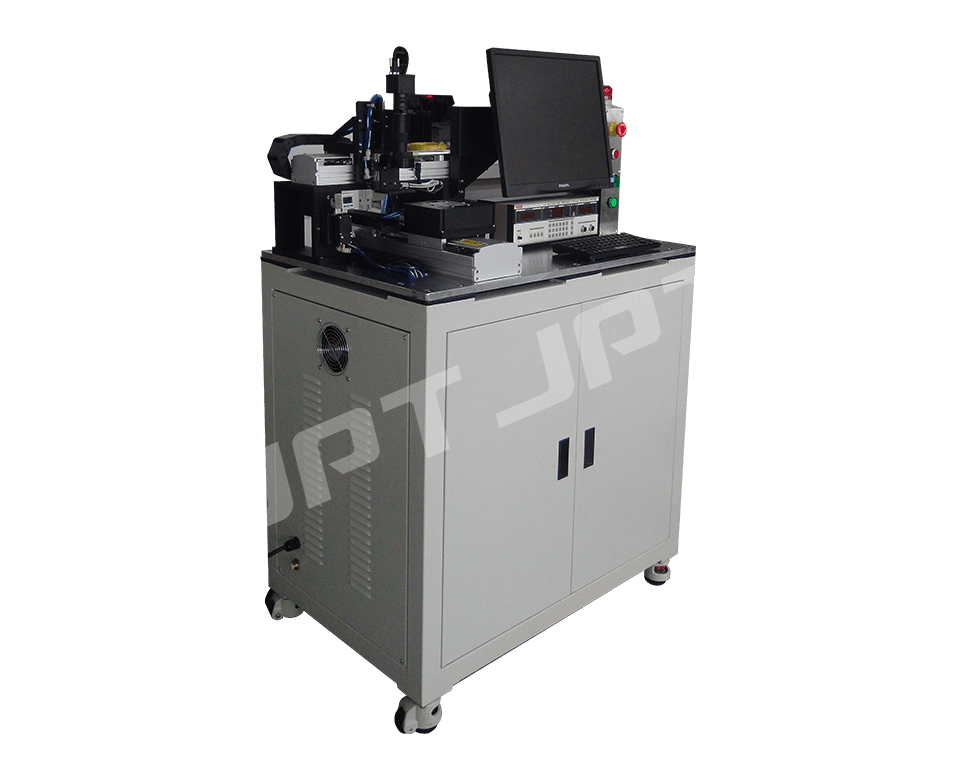

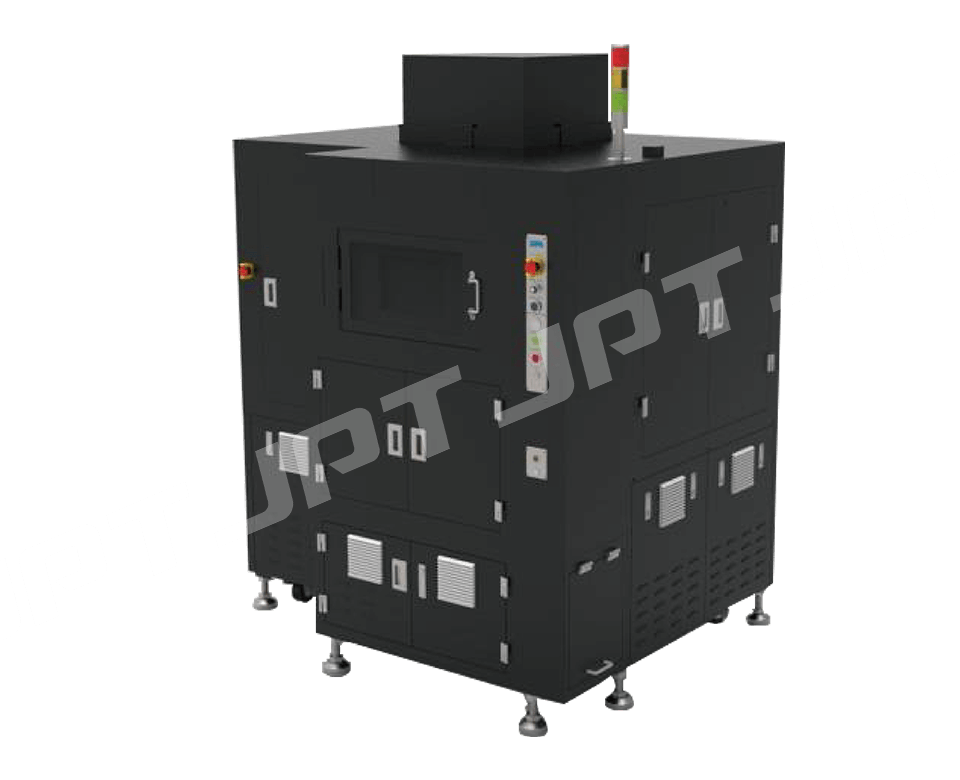

Laser Trimmer

Laser Trimmer

Hybrid Trimmer

Hybrid Trimmer

HiPA-TT Light Transmittance Tester

HiPA-TT Light Transmittance Tester

PCB Laser Marking System

PCB Laser Marking System

Ghost Writer & Reader - Subsurface 2D Barcode Marking & Reading System

Ghost Writer & Reader - Subsurface 2D Barcode Marking & Reading System

High Precision 2DBC Laser-marking

High Precision 2DBC Laser-marking

Comprehensive VCSEL Module tester

Comprehensive VCSEL Module tester

Comprehensive LED-PD Integrated Module Testing

Comprehensive LED-PD Integrated Module Testing

Six-sided Inspection Machine

Six-sided Inspection Machine