PRODUCT CATEGORIES

-

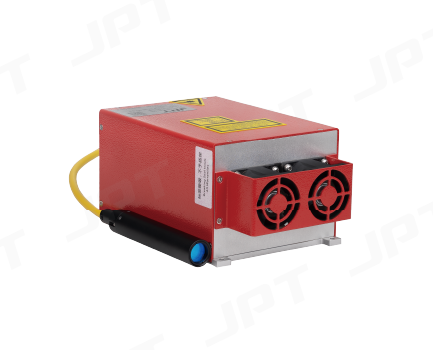

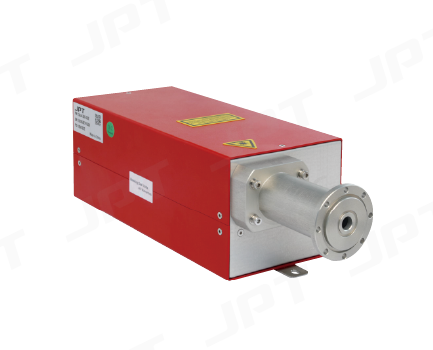

M7 20W-100W

MOPA FIBER LASER

LEARN MORE

-

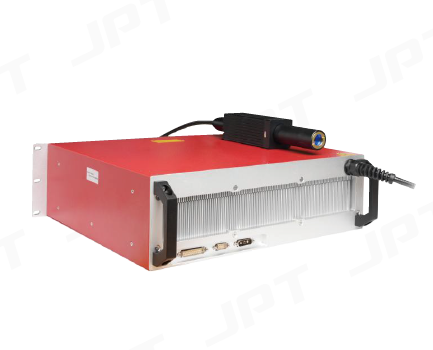

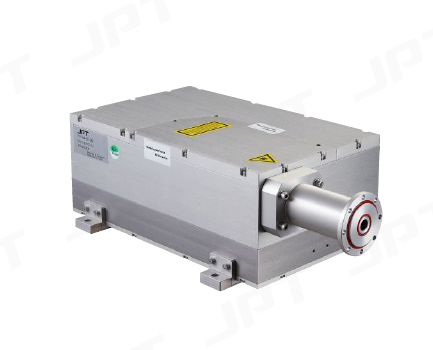

M7 200W-300W

MOPA FIBER LASER

LEARN MORE

-

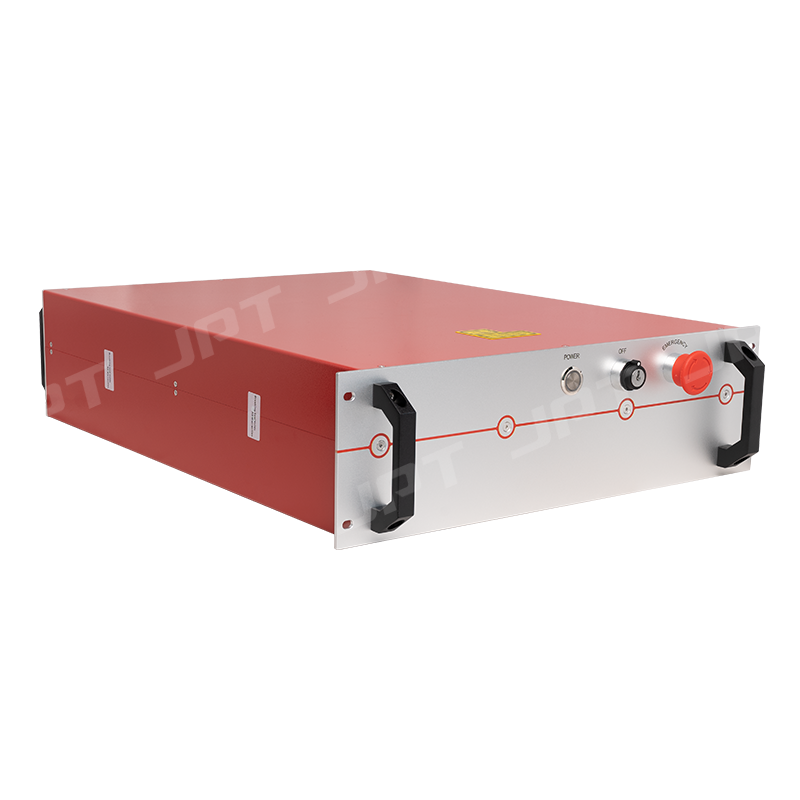

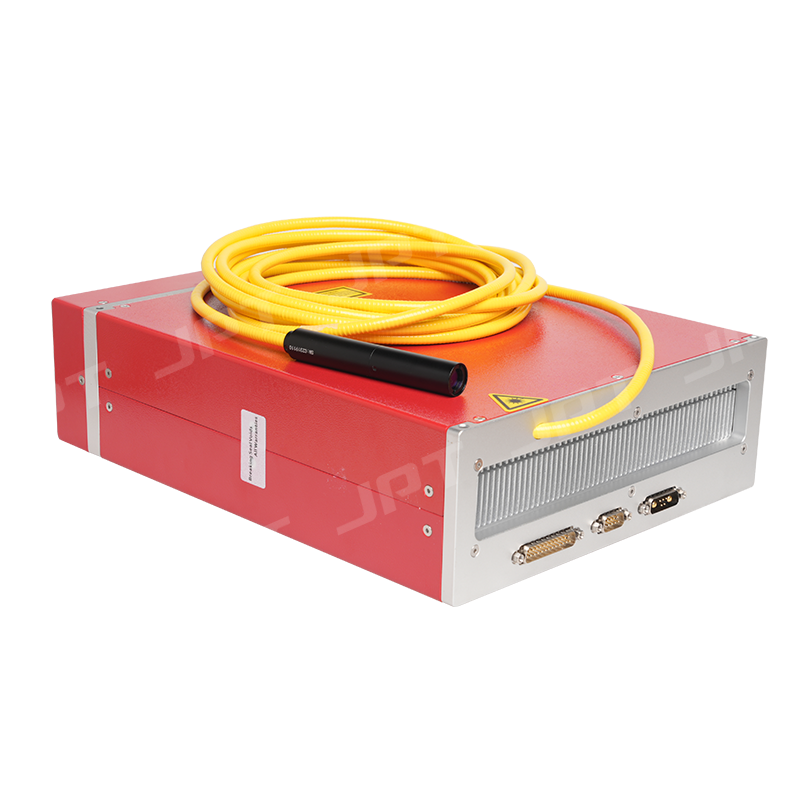

M7 500 - 1000W

MOPA FIBER LASER

LEARN MORE

-

M8 20 - 50W

JPT M8 series lasers feature a MOPA structure with main oscillation power amplification, which supports independently adjustable pulse width and pulse frequency.

LEARN MORE

-

M8 120 - 300W

JPT M8 series lasers feature a MOPA structure with main oscillation power amplification, which supports independently adjustable pulse width and pulse frequency.

LEARN MORE

-

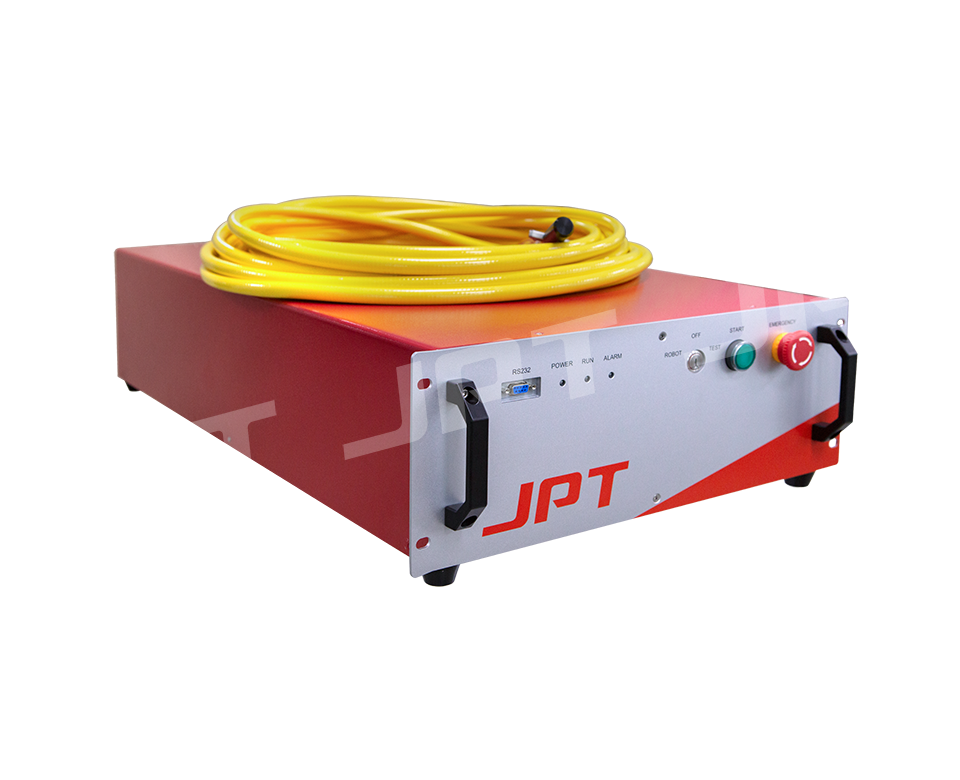

CL2 200W-300W

JPT CL series laser designed with ultra-light output connector, and still be anti-high reflection, definitely be the best option for handheld or robot cleaning system.

LEARN MORE

-

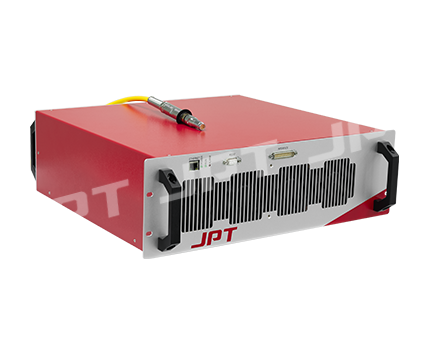

CL 500W

JPT CL series laser designed with ultra-light output connector, and still be anti-high reflection, definitely be the best option for handheld or robot cleaning system.

LEARN MORE

-

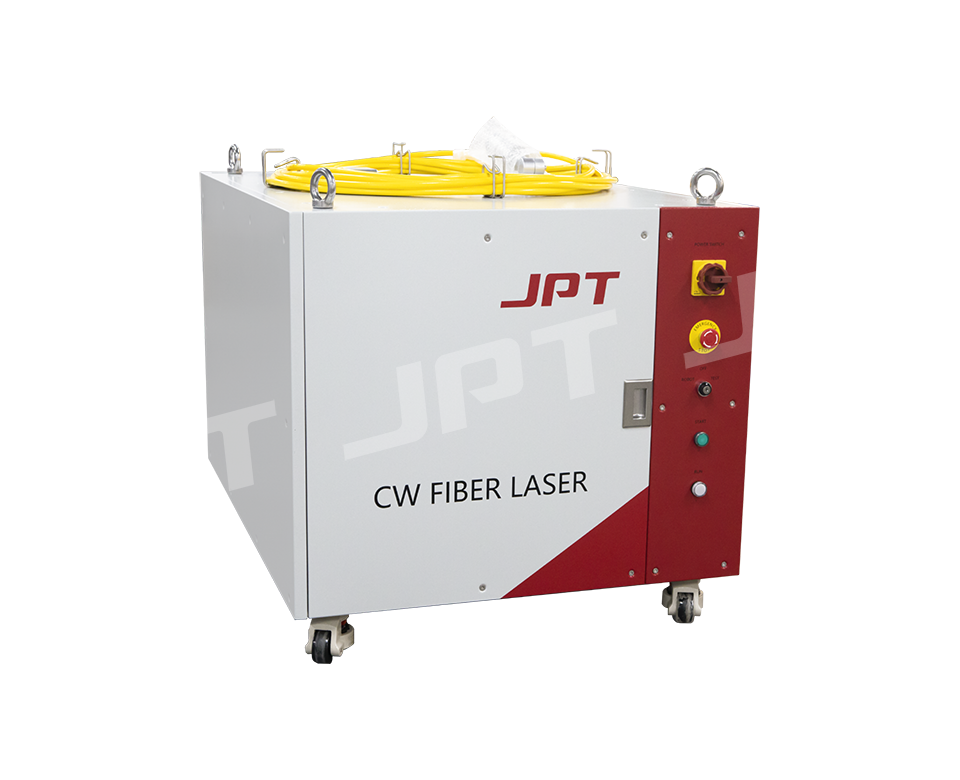

CL 500W~1000W

JPT CL series laser designed with ultra-light output connector, and still be anti-high reflection, definitely be the best option for handheld or robot cleaning system.

LEARN MORE

-

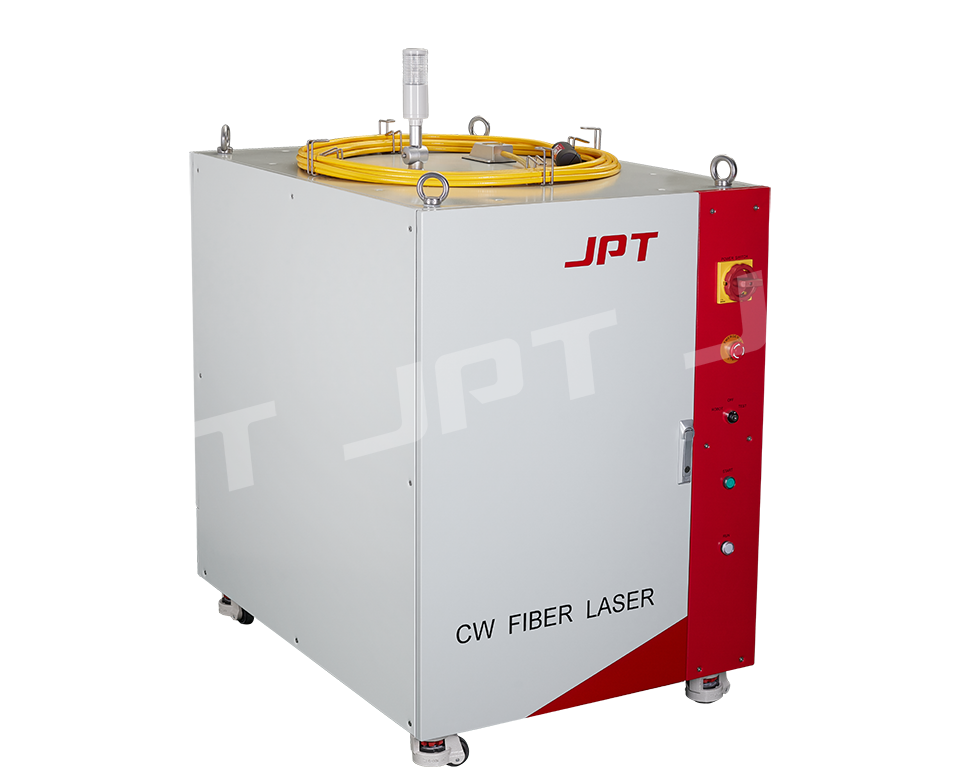

CL 2000W

JPT CL series laser designed with ultra-light output connector, and still be anti-high reflection, definitely be the best option for handheld or robot cleaning system.

LEARN MORE

JPT high power pulsed fiber lasers make use of master oscillator power amplifier (MOPA) configuration, and show excellent laser performance with high level of temporal pulse shaping controllability. As compared to the Q-switch technology, the pulse repetition frequency (PRF) and pulse width can be controlled independently in MOPA configuration, through adjusting different combination of the above parameters, the peak power of laser can be well maintained. And enable JPT laser suitable for more material processing which Q-switch limited. The higher output power makes its advantages especially in high speed marking applications.

Mopa fiber laser is widely used in dozens of manufacturing processes, such as black marking on anodized aluminum, color marking on stainless steel, deep engraving, welding of dissimilar metal sheets, paint removal of plastic product, laser cleaning, flight marking, electrode tab & photovoltaic silicon wafer cutting, etc. Therefore, we can see the pulsed fiber laser is being used in an increased number of industries, including the 3C electronics, new energy battery,metal processing, food package, high-speed railway, ships.

Mopa Fiber Lasers FAQs

Question: What is the difference between the MOPA and Q-switched laser marking application?

Answer

1. Both laser offers similar marking applications but MOPA laser offers great flexibly and adjustment of various laser parameters e.g. prf, pulse duration, peak power, pulse shape etc.

2. In color marking, MOPA laser offers more bright and clear marking compared to Q-switched laser marking.

3. Higher Pulse Repetition Frequency of MOPA Laser helps in creating precision marking.

4. The edges of marked feature are generally yellow and rougher in Q-switched however, in case of MOPA laser; edges are smooth without being yellow.

Question: What applications can a 50/60W MOPA fiber laser marking machine do?

Answer

1. Cutting gold silver sheet

2. Engraving of metallic and non-metallic materials

3. Engraving of curved surface like wedding ring or bracelet

4. Colorful marking in stainless steal

5. Black marking in oxygen aluminum

Question: How many types of materials can be processed by MOPA laser machine?

Answer

Stainless Steel

Aluminum

Anodized Aluminium Oxide (AAO)

Titanium

Platinum

Chrome

Copper

Coating materials

Polyethylene

ABS plastic

Carbide

Polycrystalline Diamond

PVC

PES

Rubber etc.

Question: How many colors can be made by MOPA laser machine?

Answer

The variation in mark color is achieved by controlling the laser energy. When the MOPA laser's energy is increased the color in exposed area changes in the following sequence:

Orange-red-purple-blue-green,

Blue-blue,

Green-green-yellow,

Green-yellow-orange-red.

Question: What's MOPA Laser?

Answer

MOPA stands for Master Oscillator Power Amplifier. Master Oscillator can produce light with a lesser amount of energy while Power Amplifier amplifies the light to achieve required power levels. At present, it is most advanced technology that provides great flexibility and customization of operation.

Question: What kinds of materials can I engrave with a MOPA laser?

Answer

Metals like gold, silver, aluminum, copper, titanium, platinum, brass, Tungsten, chrome, Nickel. Besides metals, ceramic, fiber glass and carbon, plastics and polymers etc.

M7 20W-100W

M7 20W-100W

Multi-Module CW 6000W

Multi-Module CW 6000W

QCW 150W/1500W

QCW 150W/1500W

Multi-Module CW 12000W

Multi-Module CW 12000W

Single-Module CW 1500W-3000W

Single-Module CW 1500W-3000W

SEAL 355-3/5

SEAL 355-3/5

SEAL 532

SEAL 532

LARK 355-3/5

LARK 355-3/5

PS IR/GR/UV Picosecond Laser

PS IR/GR/UV Picosecond Laser

SEAL 355-10/15/20/30

SEAL 355-10/15/20/30

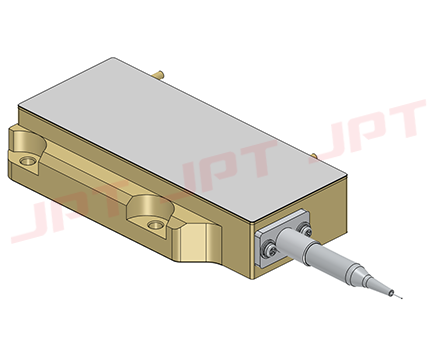

Semiconductor Laser with Red Light Series 200W

Semiconductor Laser with Red Light Series 200W

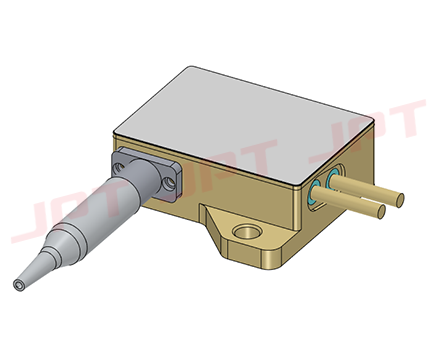

450nm—100W High Power Diode Laser

450nm—100W High Power Diode Laser

10W-1064-01 Silicon Transmission Series Detection Moduler

10W-1064-01 Silicon Transmission Series Detection Moduler

1060nm Series

1060nm Series

880nm Series

880nm Series

808nm Series

808nm Series

976nm Series

976nm Series

915nm Series

915nm Series

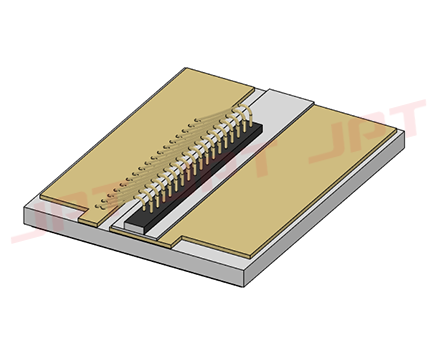

COS Encapsulated Semiconductor Laser

COS Encapsulated Semiconductor Laser

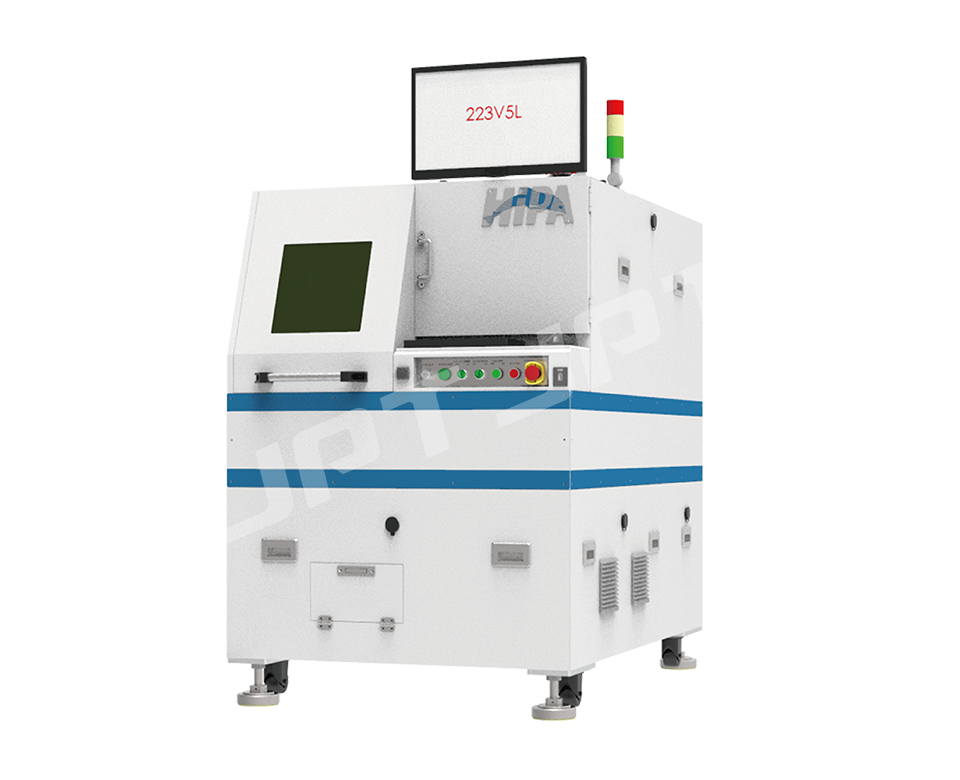

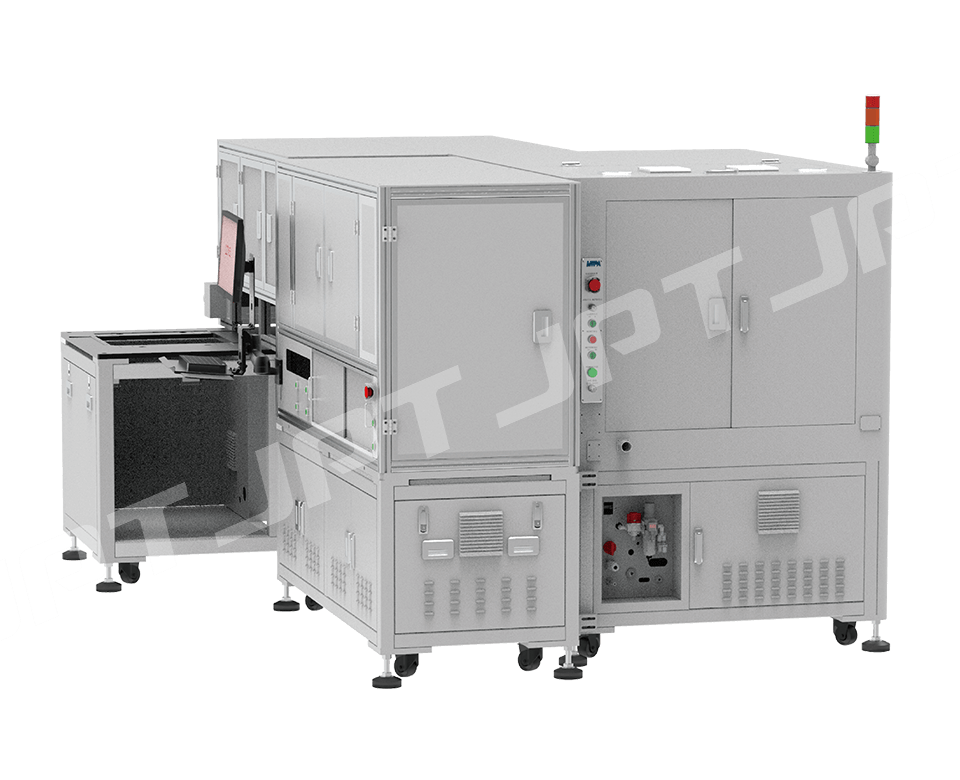

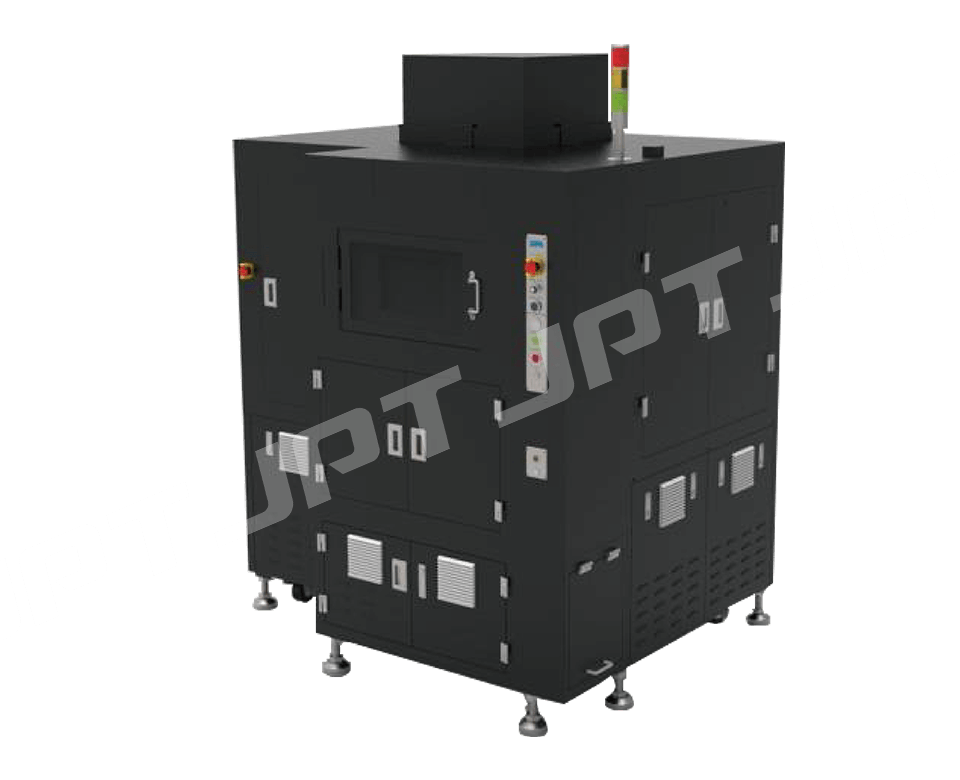

Laser Scriber

Laser Scriber

High Voltage Resistor Tester

High Voltage Resistor Tester

Single Chip Resistor Tester

Single Chip Resistor Tester

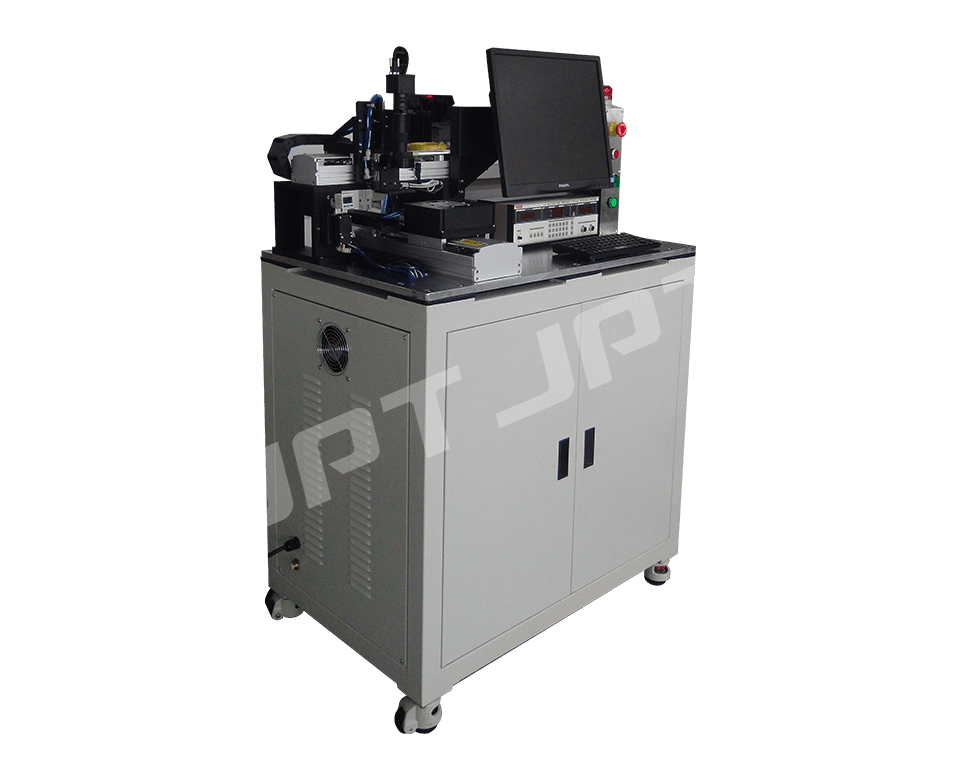

Laser Trimmer

Laser Trimmer

Hybrid Trimmer

Hybrid Trimmer

HiPA-TT Light Transmittance Tester

HiPA-TT Light Transmittance Tester

PCB Laser Marking System

PCB Laser Marking System

Ghost Writer & Reader - Subsurface 2D Barcode Marking & Reading System

Ghost Writer & Reader - Subsurface 2D Barcode Marking & Reading System

High Precision 2DBC Laser-marking

High Precision 2DBC Laser-marking

Comprehensive VCSEL Module tester

Comprehensive VCSEL Module tester

Comprehensive LED-PD Integrated Module Testing

Comprehensive LED-PD Integrated Module Testing

Six-sided Inspection Machine

Six-sided Inspection Machine