Laser metal engraving, first choice JPT MOPA fiber laser!

Laser metal engraving

Laser metal engraving is a common application in laser processing, where the material is instantly melted or vaporized by a high-power density laser beam to achieve precise and intricate engraving. Compared to traditional metal etching processes, laser metal engraving has advantages such as pollution-free operation, high precision, and flexible engraving capabilities, making it widely used in the field of metal processing.

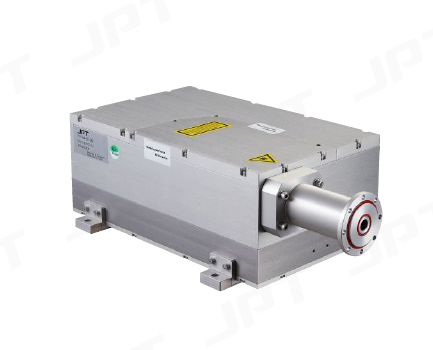

JPT's MOPA pulsed fiber laser covers a range of power options for metal engraving, allowing users to choose the appropriate laser based on their specific material and processing efficiency requirements. The following information is for reference purposes only.

Aluminum, brass, and stainless steel are three common types of metals, each with unique physical and chemical properties. Aluminum is widely used in multiple industries due to its lightweight nature, excellent conductivity and thermal properties, high reflectivity, and resistance to oxidation. Aluminum has a higher efficiency in laser deep engraving mainly due to its good thermal conductivity and lower melting point. Aluminum can quickly dissipate heat under laser irradiation, reducing the heat-affected zone and thus improving processing accuracy and efficiency.

Stainless steel is widely used for its exceptional corrosion resistance and strength in various fields. Due to its higher melting point and hardness, laser deep engraving on stainless steel requires higher laser power and longer processing time.

Brass is highly regarded for its excellent wear resistance, ductility, and malleability. However, the high reflectivity of brass to infrared light (nearly 97%) and its higher melting point significantly increase the processing time.

Therefore, selecting the appropriate laser is crucial for metal engraving. The diagram below shows the processing efficiency reference of different power lasers on various materials.

JPT's MOPA fiber lasers offer adjustable power, pulse width, and frequency features that allow users to adjust the processing parameters according to different materials. This ensures that the laser maintains optimum performance at all times.

Laser deep engraving technology has broad applications prospects in the field of metal processing. For different metal materials, it is essential to choose an appropriate laser based on specific application requirements and processing conditions to achieve optimal processing efficiency and results.

As a leader in China's commercial pulse width adjustable high-power fiber lasers industry,JPT will continue driving advancements in metal laser processing technology by leveraging core laser technologies while engaging in open communication with customers-EOM.

Recommended content

Boosting Efficiency | JPT Laser Solutions Help Improve Charging Efficiency of New Energy Lithium Batteries!

DateTime:2024/08/21

Laser metal engraving, first choice JPT MOPA fiber laser!

DateTime:2024/08/08

To prevent laser condensation in summer, this article is enough!

DateTime:2024/07/19

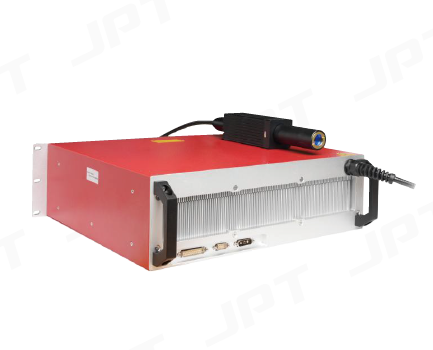

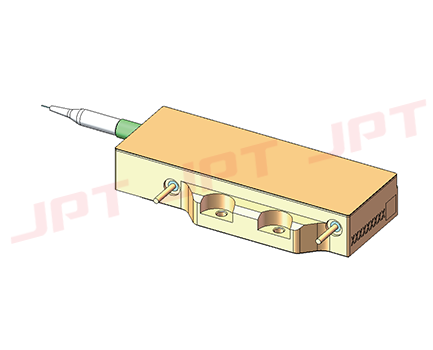

M7 20W-100W

M7 20W-100W

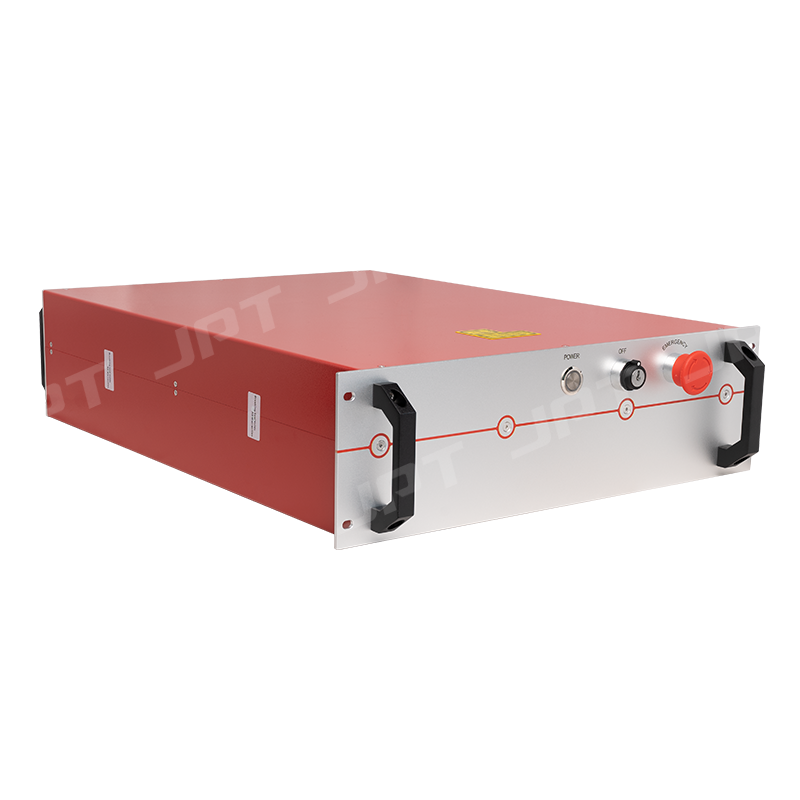

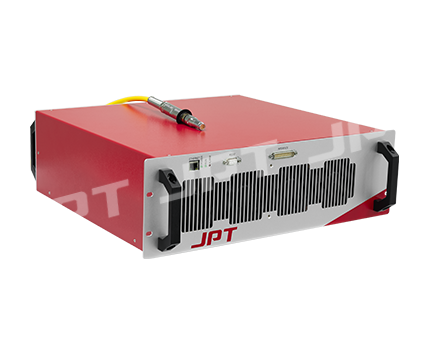

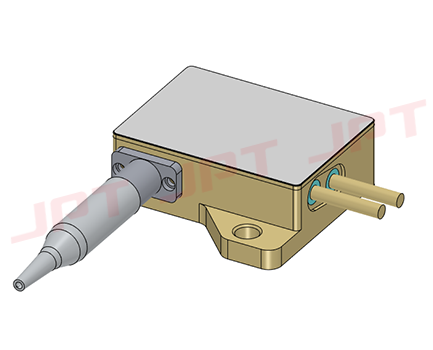

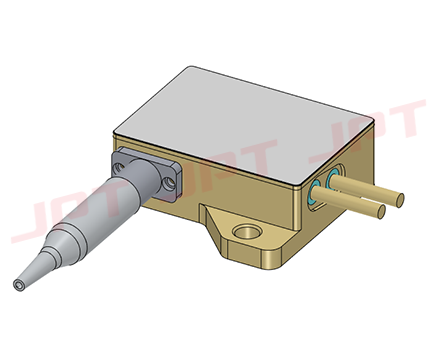

M7 200W-300W

M7 200W-300W

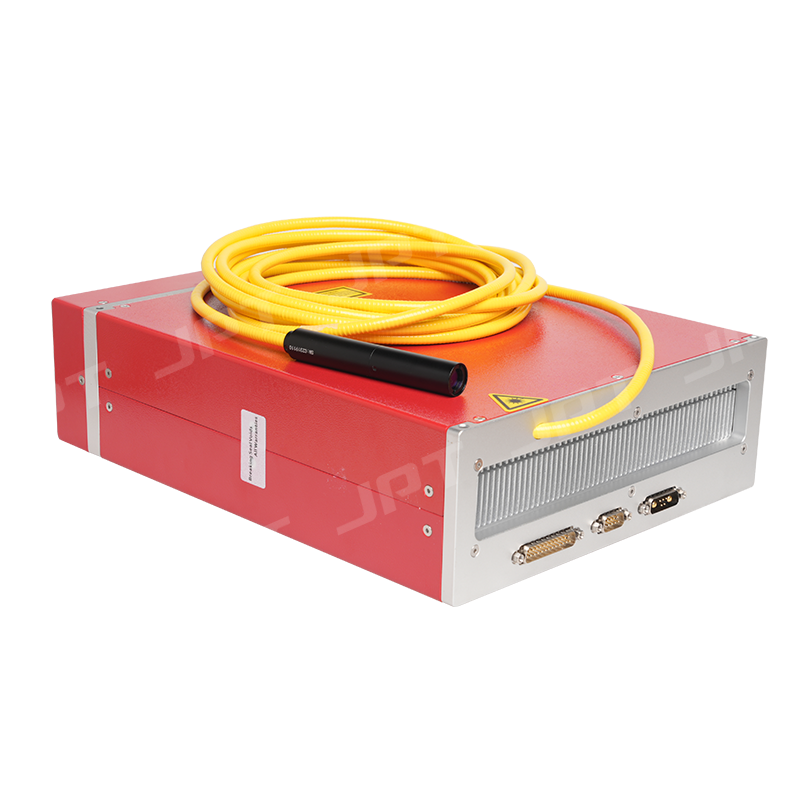

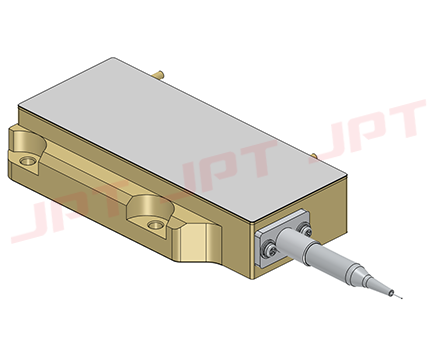

M7 500 - 1000W

M7 500 - 1000W

M8 20 - 50W

M8 20 - 50W

M8 120 - 300W

M8 120 - 300W

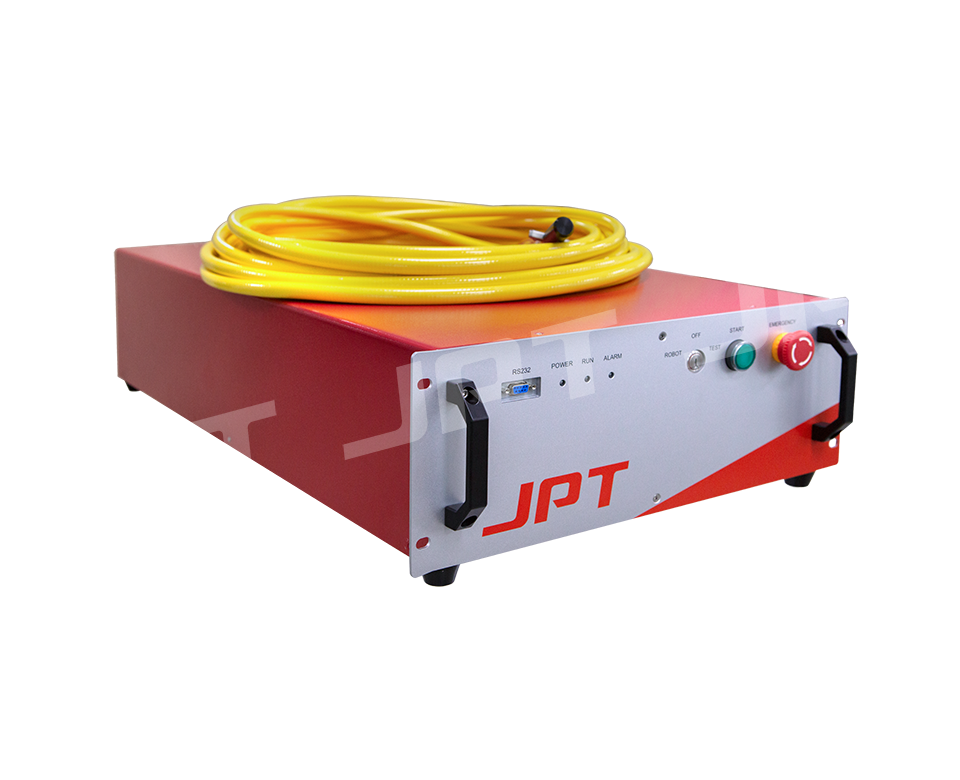

CL2 200W-300W

CL2 200W-300W

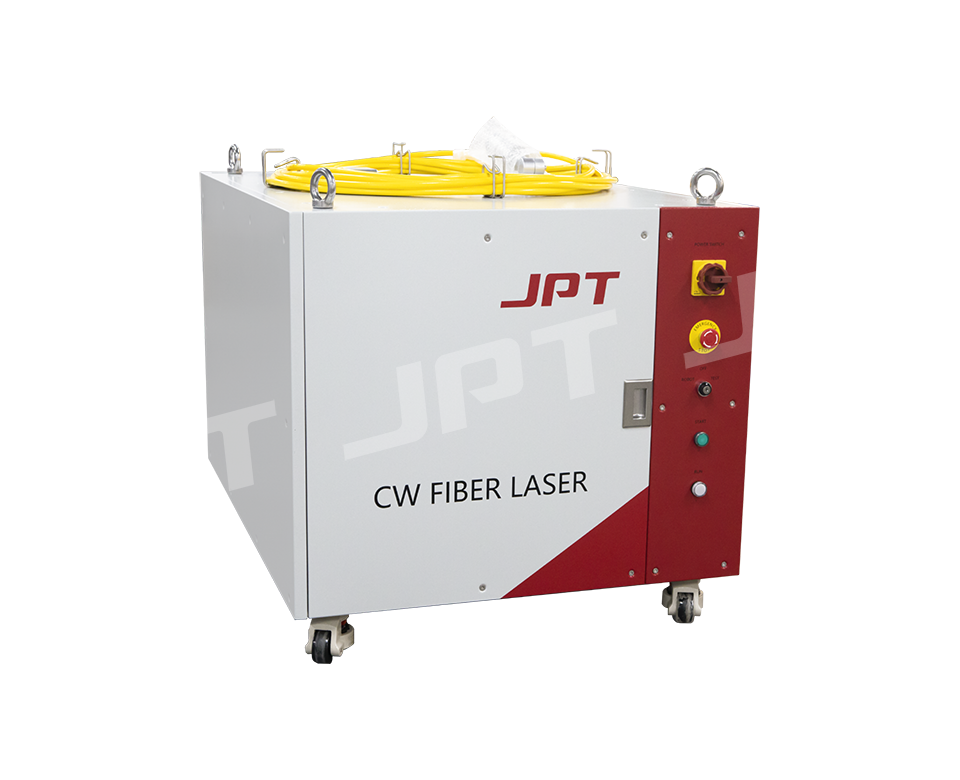

CL 500W~1000W

CL 500W~1000W

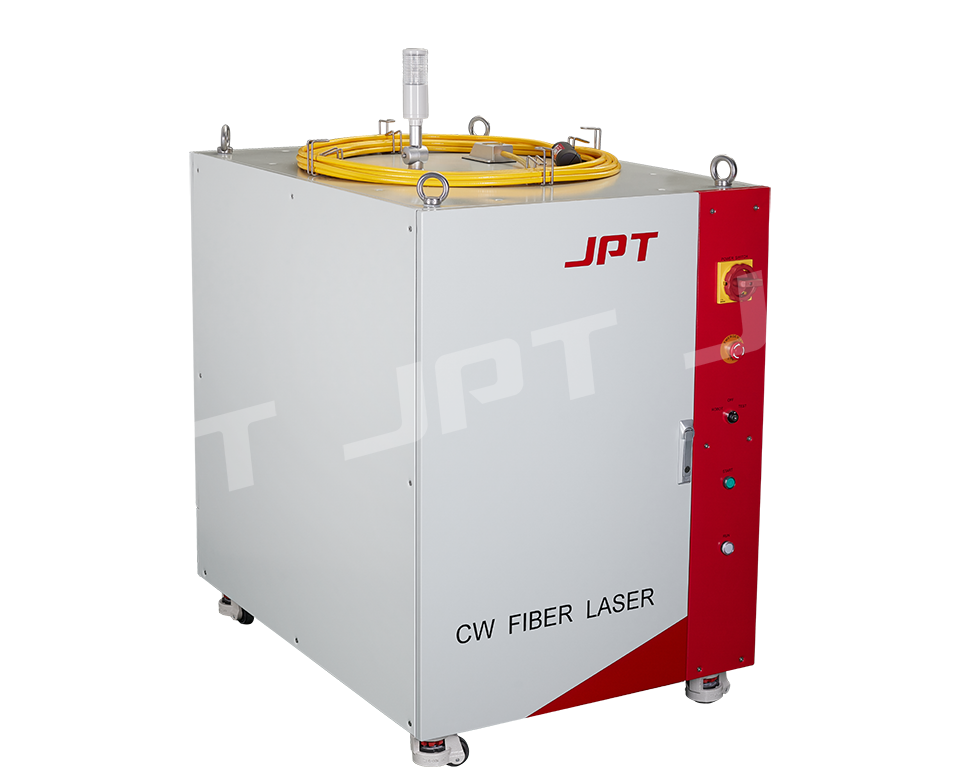

CL 2000W

CL 2000W

Multi-Module CW 6000W

Multi-Module CW 6000W

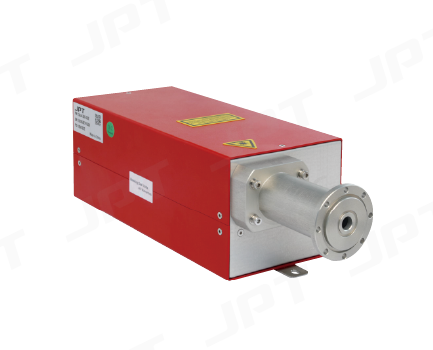

QCW 150W/1500W

QCW 150W/1500W

Multi-Module CW 12000W

Multi-Module CW 12000W

Single-Module CW 1500W-3000W

Single-Module CW 1500W-3000W

SEAL 355-3/5

SEAL 355-3/5

SEAL 532

SEAL 532

LARK 355-3/5

LARK 355-3/5

PS IR/GR/UV Picosecond Laser

PS IR/GR/UV Picosecond Laser

SEAL 355-10/15/20/30

SEAL 355-10/15/20/30

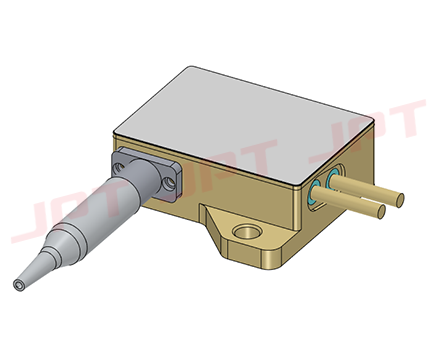

Semiconductor Laser with Red Light Series 200W

Semiconductor Laser with Red Light Series 200W

450nm—100W High Power Diode Laser

450nm—100W High Power Diode Laser

10W-1064-01 Silicon Transmission Series Detection Moduler

10W-1064-01 Silicon Transmission Series Detection Moduler

1060nm Series

1060nm Series

880nm Series

880nm Series

808nm Series

808nm Series

976nm Series

976nm Series

915nm Series

915nm Series

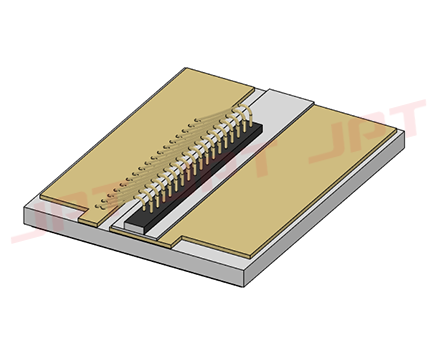

COS Encapsulated Semiconductor Laser

COS Encapsulated Semiconductor Laser

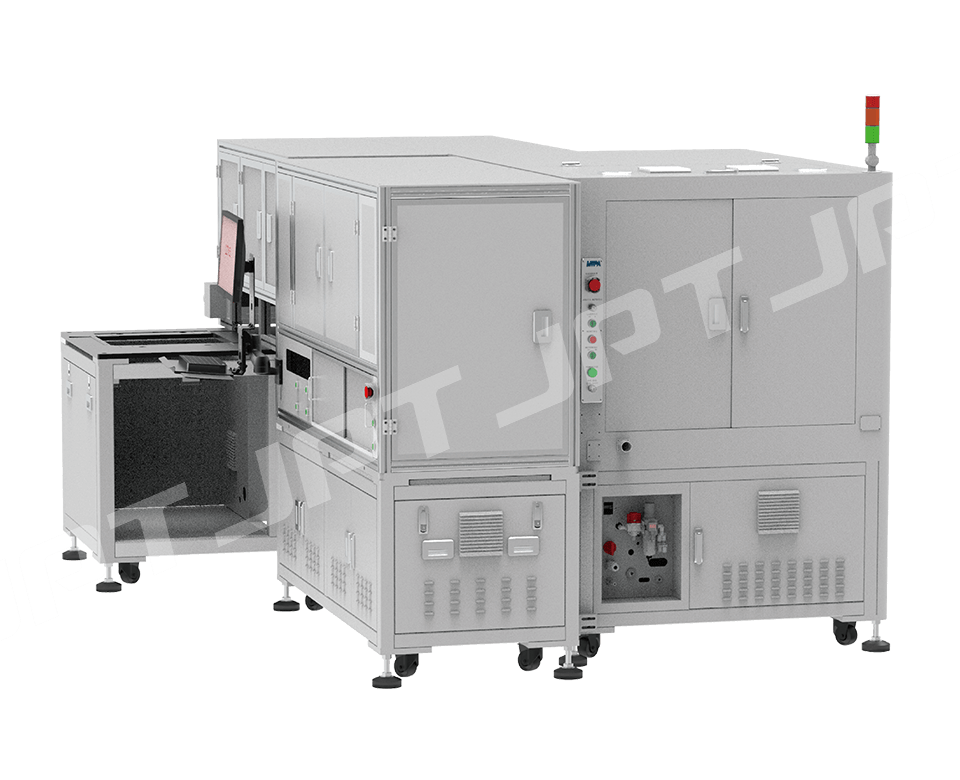

Laser Scriber

Laser Scriber

High Voltage Resistor Tester

High Voltage Resistor Tester

Single Chip Resistor Tester

Single Chip Resistor Tester

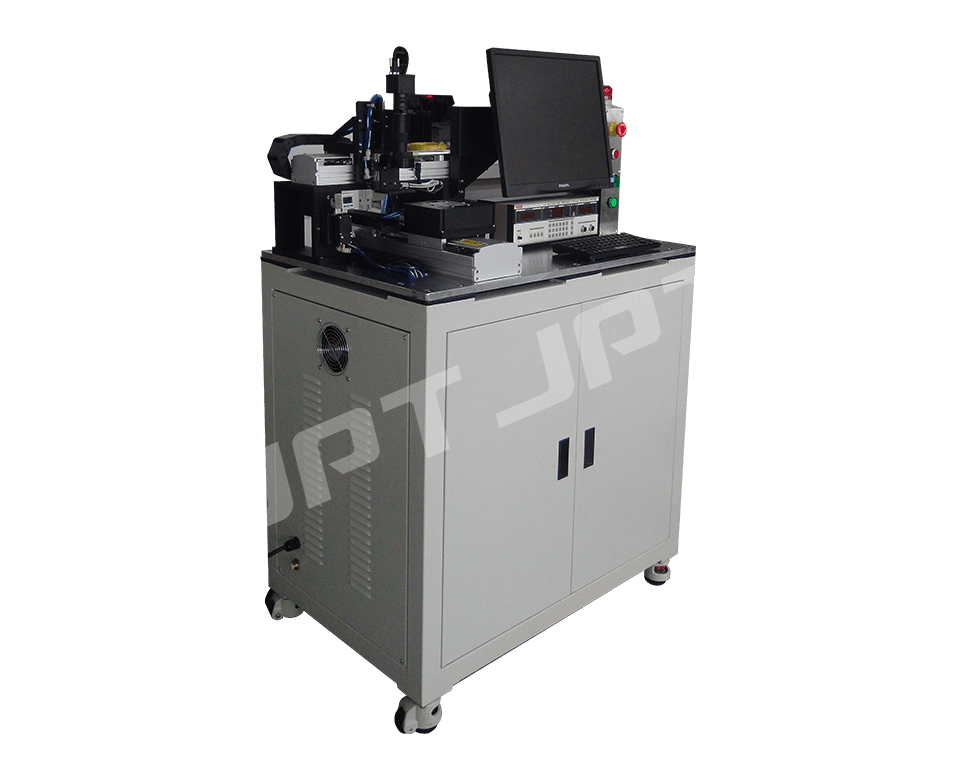

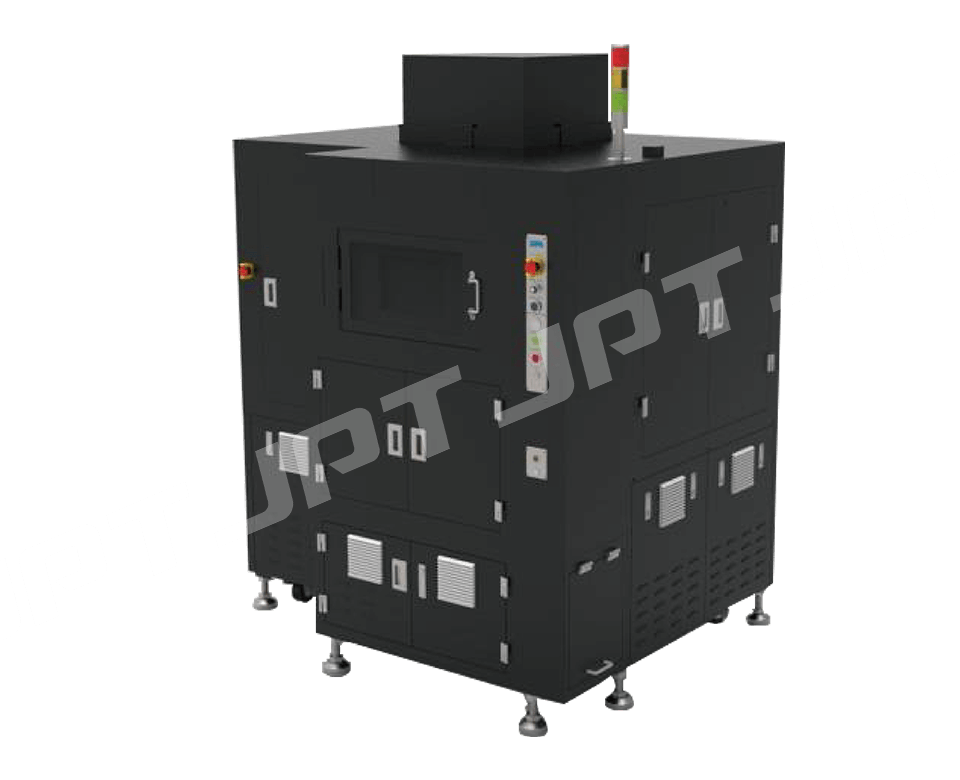

Laser Trimmer

Laser Trimmer

Hybrid Trimmer

Hybrid Trimmer

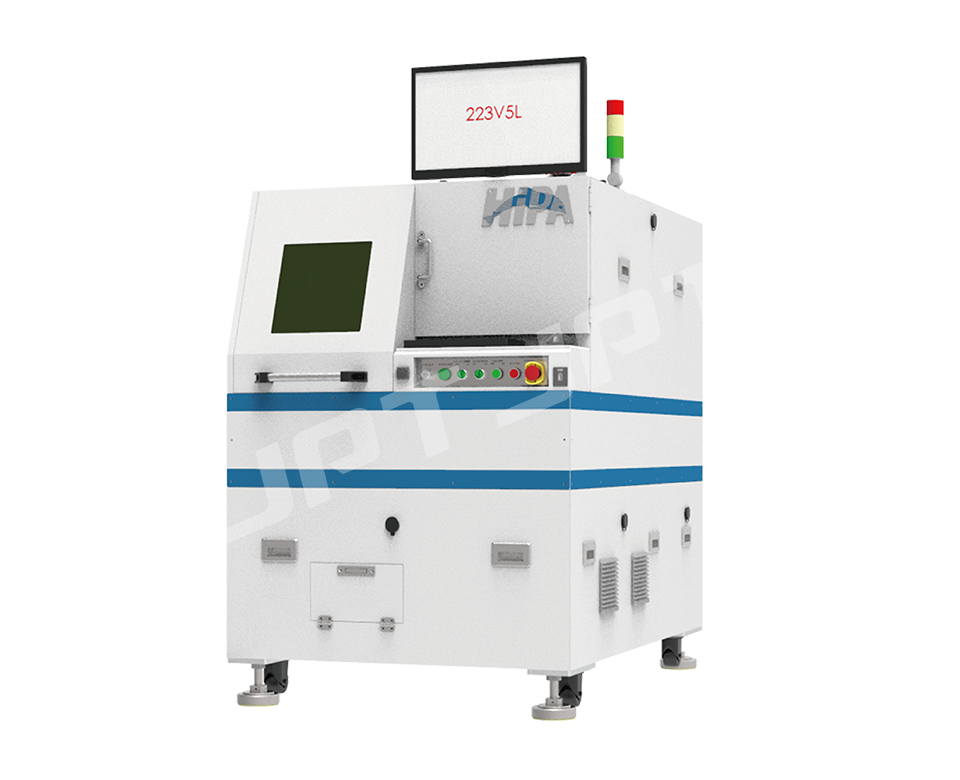

HiPA-TT Light Transmittance Tester

HiPA-TT Light Transmittance Tester

PCB Laser Marking System

PCB Laser Marking System

Ghost Writer & Reader - Subsurface 2D Barcode Marking & Reading System

Ghost Writer & Reader - Subsurface 2D Barcode Marking & Reading System

High Precision 2DBC Laser-marking

High Precision 2DBC Laser-marking

Comprehensive VCSEL Module tester

Comprehensive VCSEL Module tester

Comprehensive LED-PD Integrated Module Testing

Comprehensive LED-PD Integrated Module Testing

Six-sided Inspection Machine

Six-sided Inspection Machine