Fiber Lasers: Unclad Yb:YAG crystalline fiber acts as purely waveguided laser

As is true with bulk solid-state lasers, transitioning from the use of dopedglass to the use of a doped single-crystal gain medium is an important step inscaling up the output power of individual fiber lasers.

For this reason, single-crystal fiber(SCF) is under intensive development. Various configurations have been created,including crystalline-clad crystalline fiber created using adhesive-freebonding (difficult to fabricate and thus not suitable for mass production),glass-clad crystalline fiber (not suitable for power scaling because of thethermal insulating properties of the glass cladding), and unclad SCF (which isvery suitable for research, but will need a suitable cladding depositiontechnique for wider use).

Previous tested unclad SCFconfigurations have consisted of short (30–60 mm long) flood-illuminatedcrystalline rods with a 1-mm-or-less diameter in which the pump light bouncesalong inside the rod because of total internal reflection, but the modestructure of the output laser light itself is defined solely by the cavitymirrors—in other words, the SCF has not acted as a waveguide for the laserlight and is more a bulk than a fiber laser.

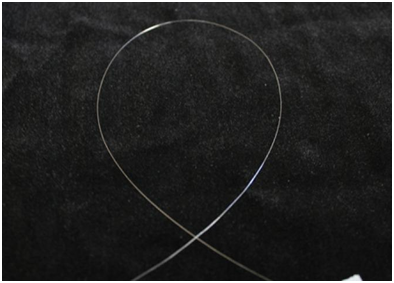

In contrast, a longer and thinnerdiode-pumped unclad ytterbium YAG (Yb:YAG) crystalline fiber recently developedand tested by researchers at the U.S. Army Research Laboratory (ARL, Adelphi,MD) and Shasta Crystals (San Francisco, CA) has demonstrated pure waveguidedlaser operation (see figure).

1 The SCF, which is 100 μm in diameterand 100 mm long with a 1% dopant concentration, was fabricated by ShastaCrystals using a laser-heated pedestal-growth (LHPG) technique potentiallysuitable for mass production of SCF (although it will require the developmentof a mass-producible crystalline cladding deposition method). The fiber enablesexperimentation and optimization of SCF.

High conversion efficiency

In the experimental setup, a non-antireflection-coatedsection of SCF is sandwiched between two laser cavity mirrors—light from alinearly polarized laser diode emitting at 969 nm with a 3 nm bandwidth isfocused onto one end of the fiber, passing through the rear (dichroic) cavity mirrorand into the fiber. The fiber sits loosely in a V-groove to confine it withminimal physical contact, while a convex lens collimates the laser's output. Aconverging lens, a laser-line filter, and a laser power meter allow collectionof data on the laser output.

Since no thermal grease was used to drawheat from the fiber because of a resulting adverse effect on waveguiding, thediode pump was operated in a quasi-continuous-wave (QCW) mode at a 1% dutycycle to keep the fiber cool. The 1 ms pump pulse length is on the same orderof the upper laser level lifetime of Yb3+ in YAG, and so the experimentalresults are representative of CW operation—just at a reduced thermal load.

Various output-mirror reflectivitiesfrom 18% to 70% were tried, with the optimum reflectivity found to be 25%. Witha QCW pump input of 91.6 W (averaging out to a bit less than a watt because ofthe 1% duty cycle), the QCW laser output was about 53 W at a 1030 nmwavelength, showing that the fiber laser was efficient even in its unrefinedexperimental configuration.

As for the SCF parameters themselves,Giselle Maxwell, president and CEO of Shasta Crystals, explains that the 1%dopant level was determined by spectroscopy studies to help decide whatconcentration would provide the best conditions for lasing; the length of thecrystal was determined by the same spectroscopy studies, which determine howlong a crystal should be for a certain concentration of dopant to achievemaximum absorption of the pump beam and the most efficient lasing effect in thecrystal; and the diameter of the crystal was determined as a function ofconvenience for the user and what effect was desired (smaller diameters lead tobetter waveguiding).

"Next steps are to improve oncladding technology (mostly thickness of the cladding) to provide a trueall-crystalline double-clad single-crystal fiber that will beat the performanceof any double-clad glass fiber because of improved thermal conductivityproperties," notes Maxwell.

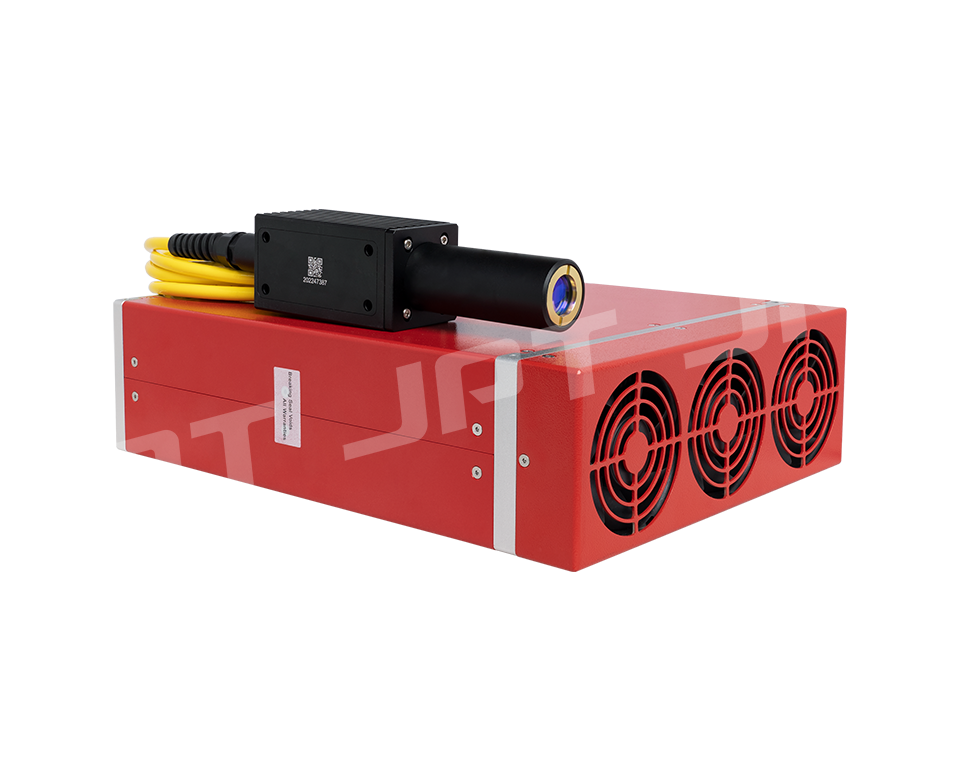

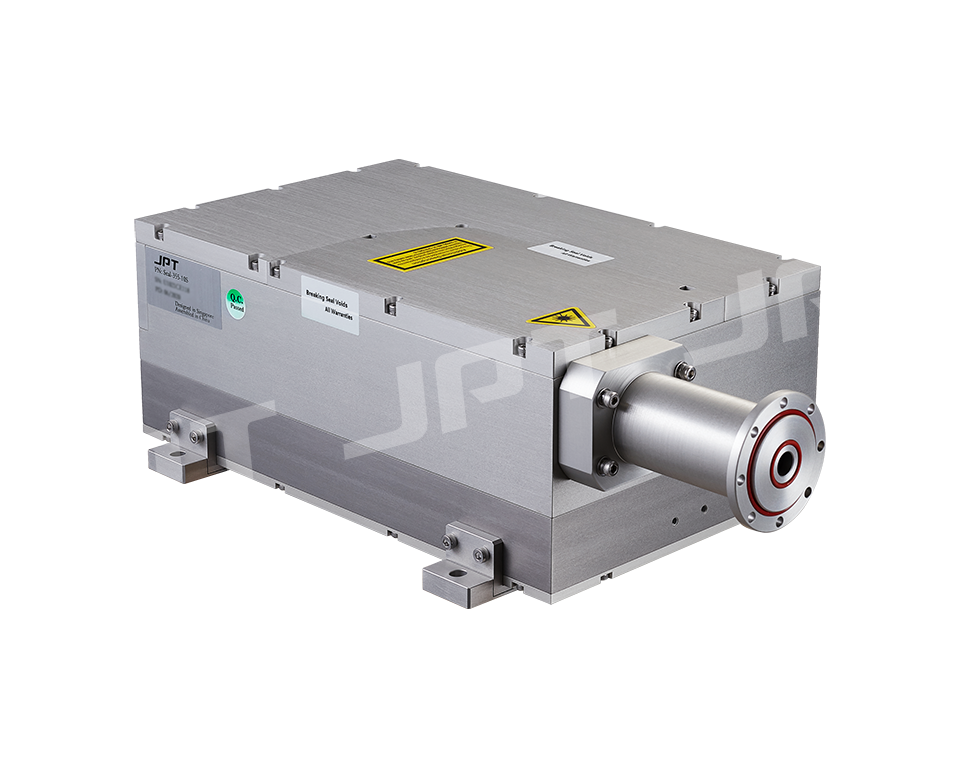

M7 20W/30W

M7 20W/30W

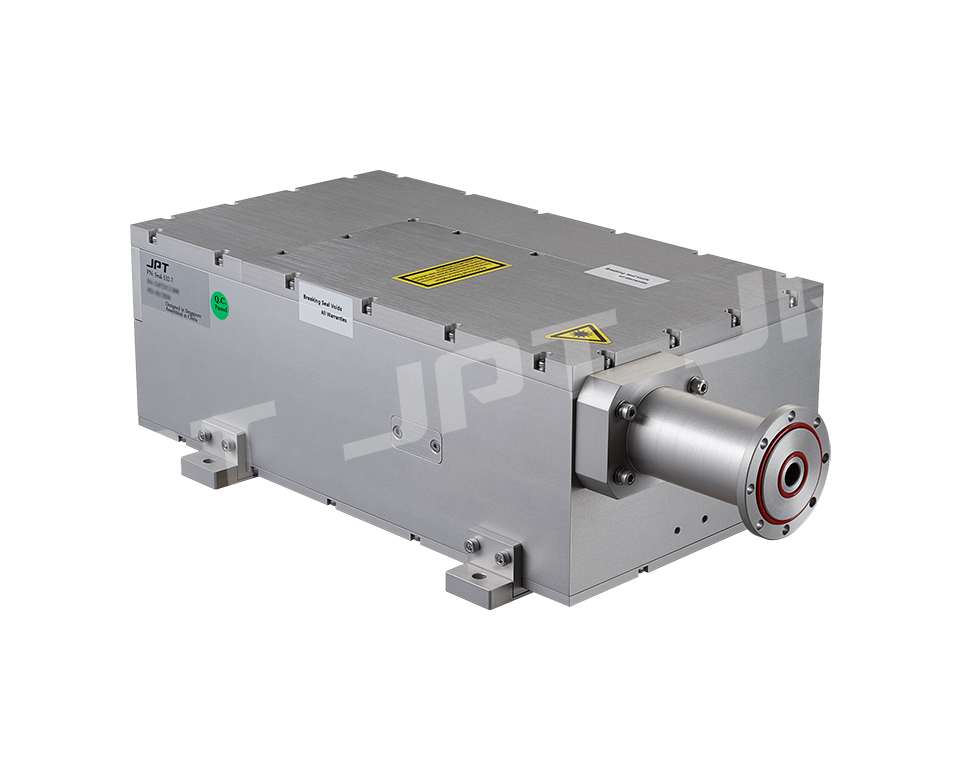

M7 60W/100W

M7 60W/100W

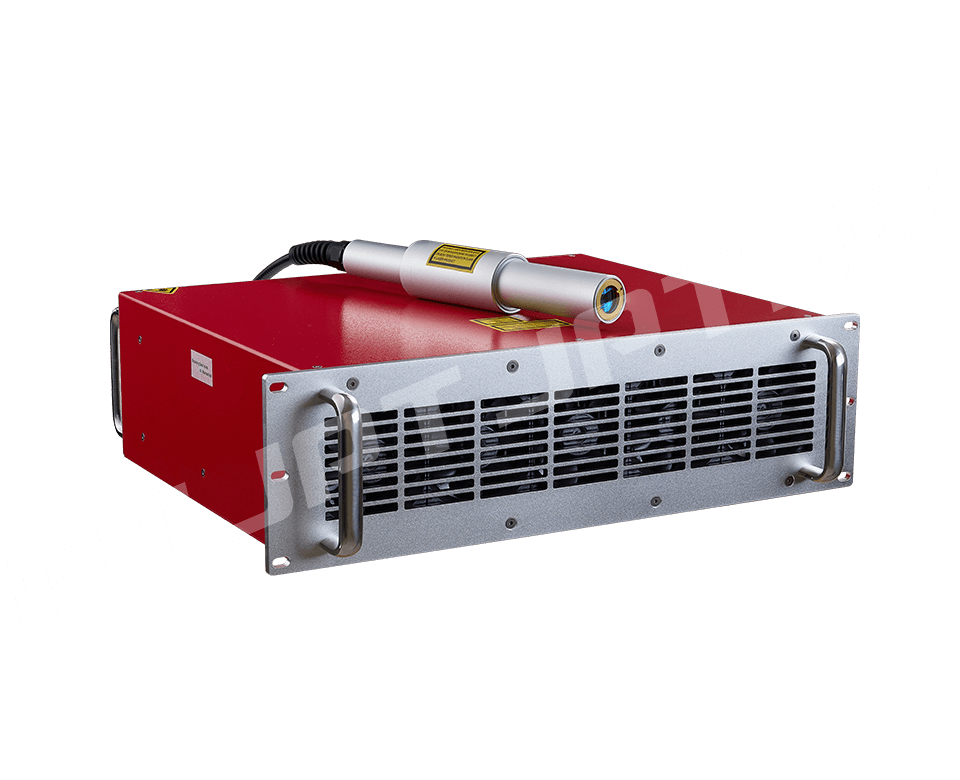

M7 200W/350W

M7 200W/350W

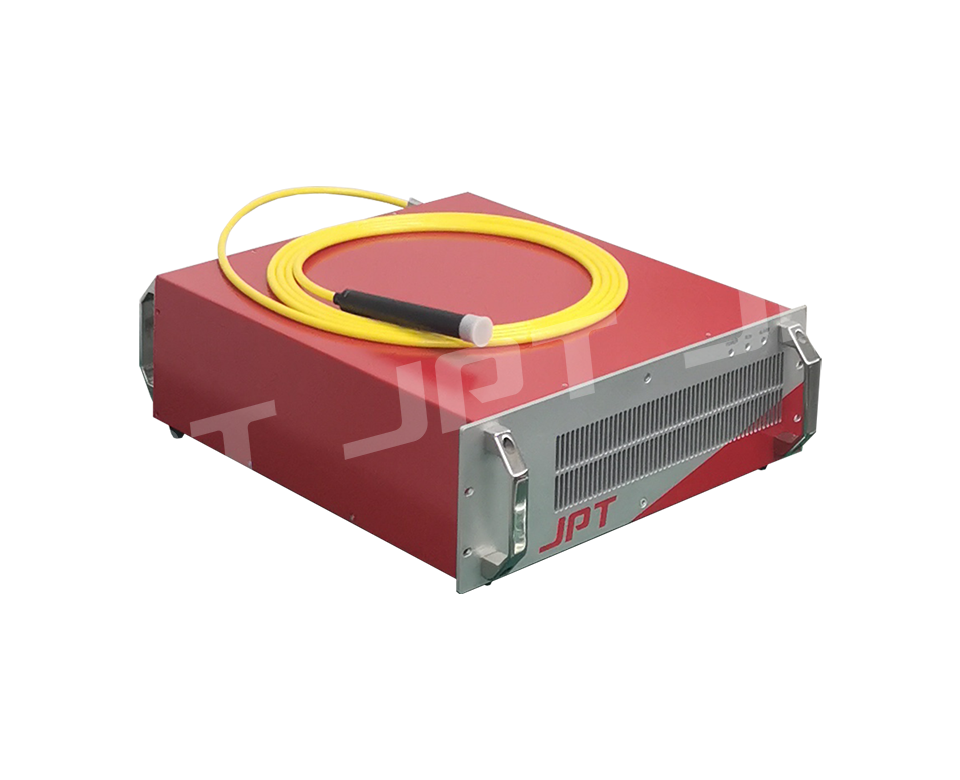

LP 20W/30W/50W

LP 20W/30W/50W

CL 100W/200W/300W

CL 100W/200W/300W

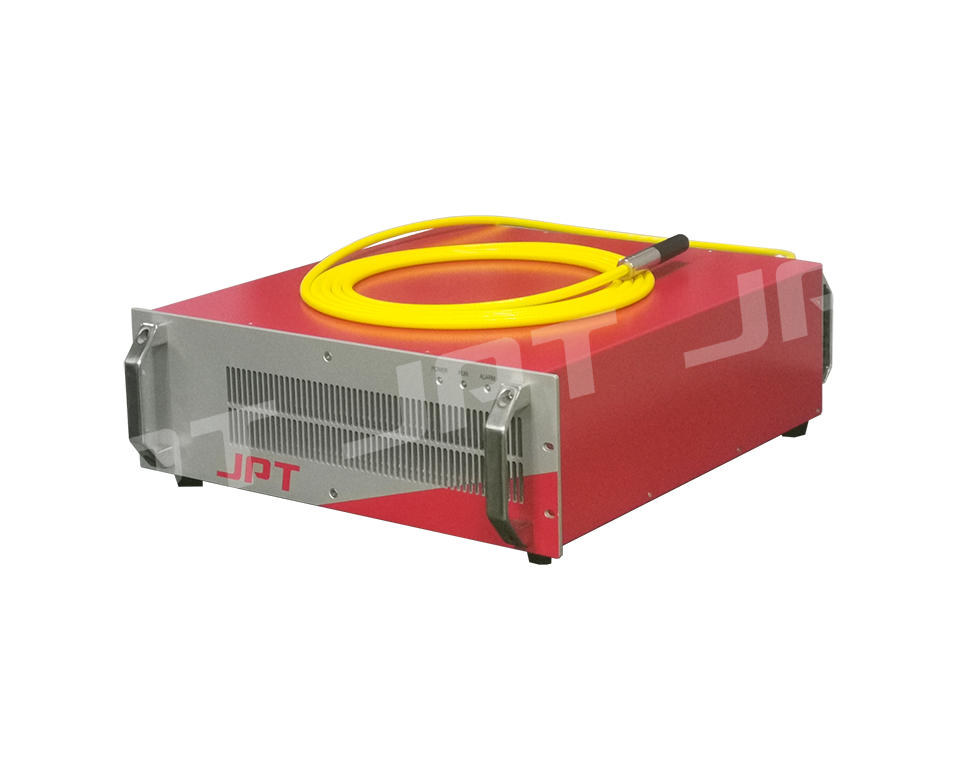

CW 200W/300W

CW 200W/300W

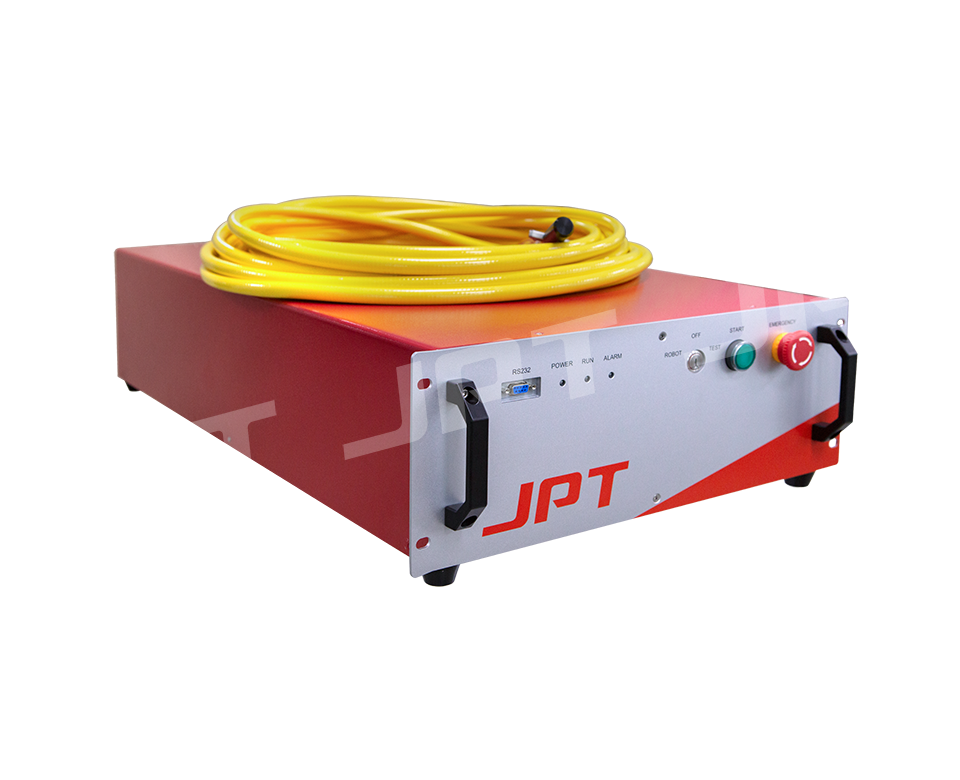

CW 500W-1000W

CW 500W-1000W

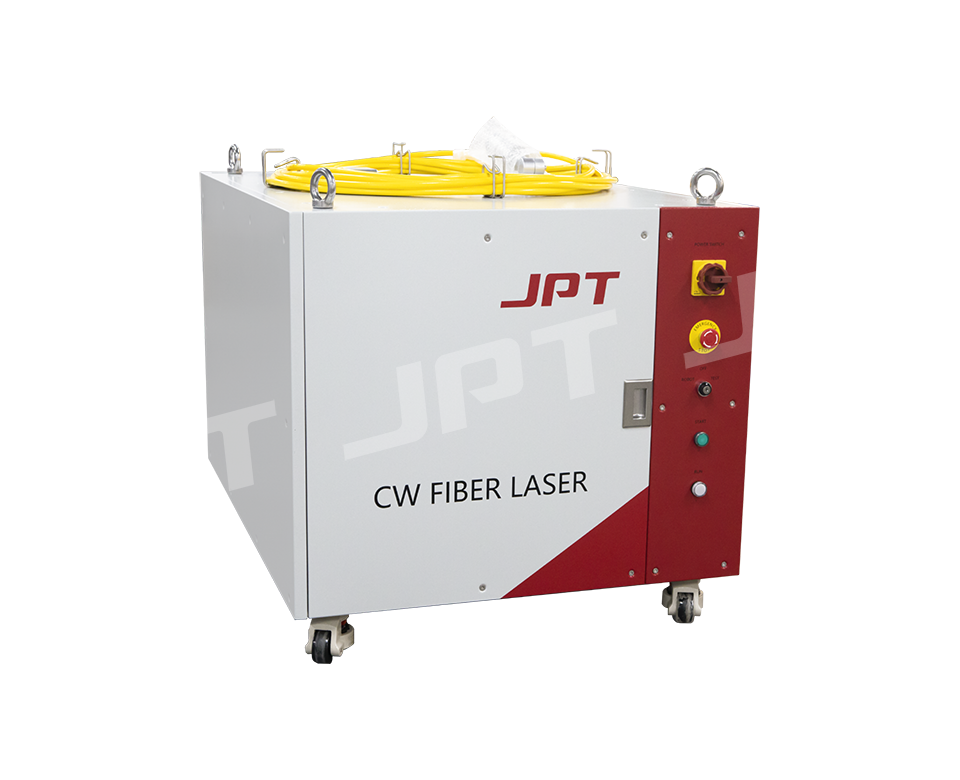

CW 4000W-6000W

CW 4000W-6000W

QCW 150W/1500W

QCW 150W/1500W

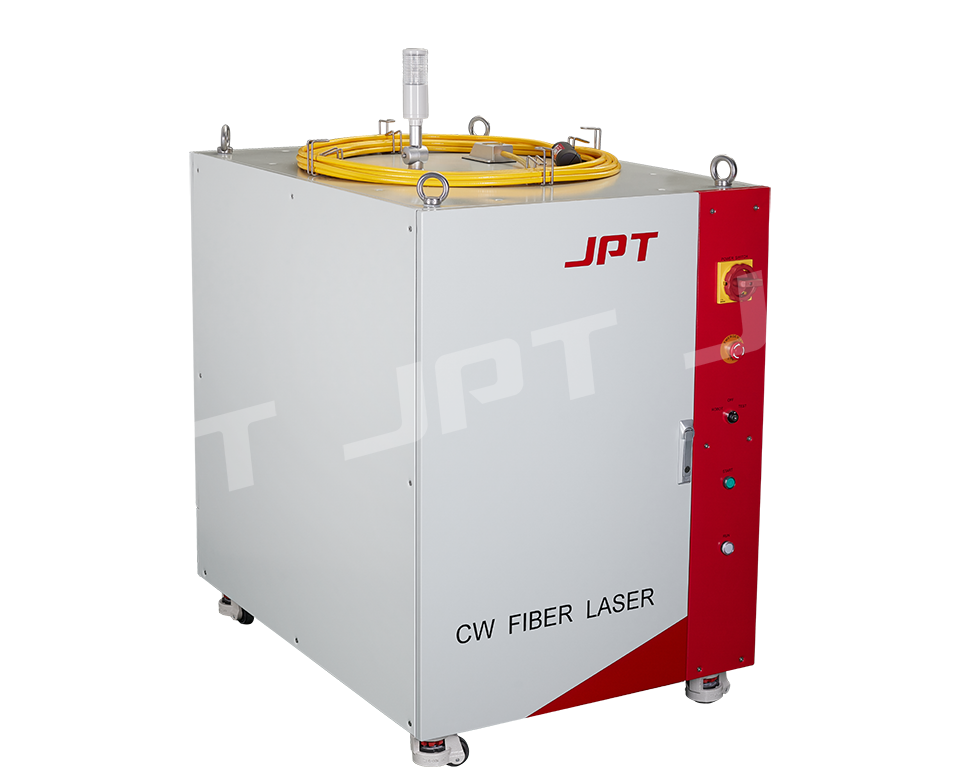

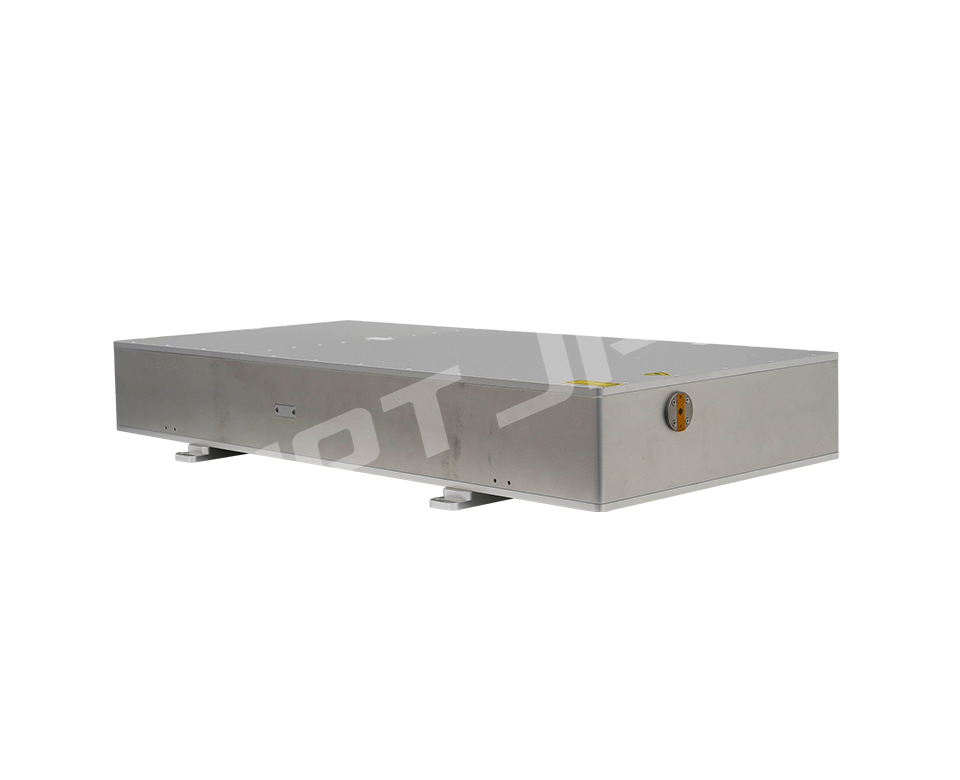

CW 8000W/12000W

CW 8000W/12000W

CW 1500W-3000W

CW 1500W-3000W

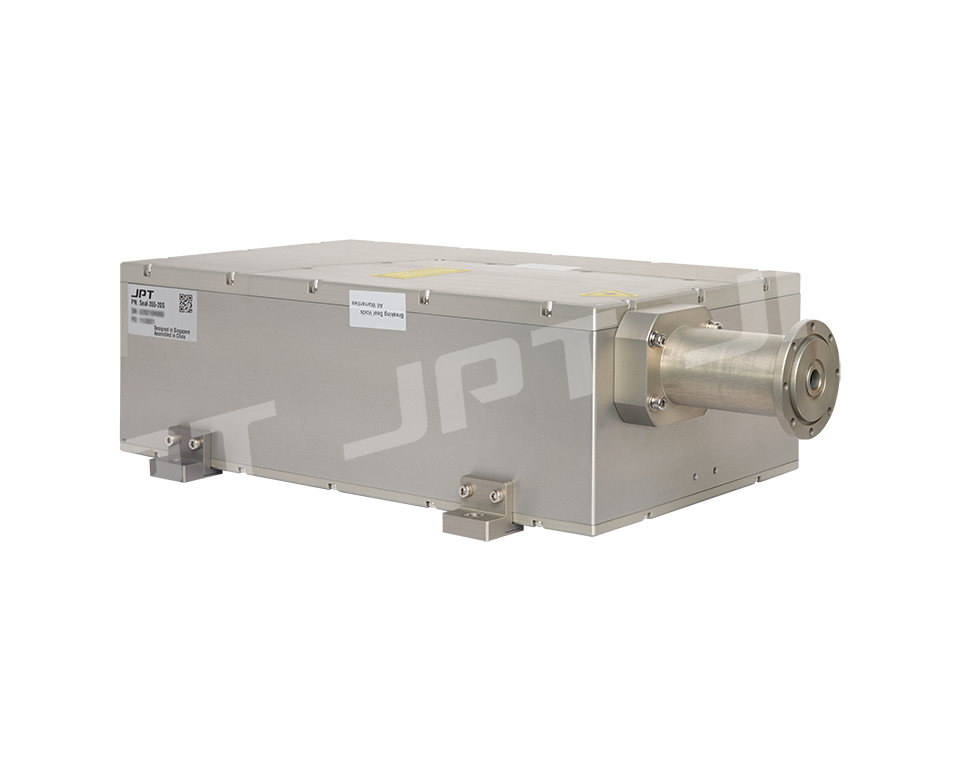

SEAL 355

SEAL 355

SEAL 532

SEAL 532

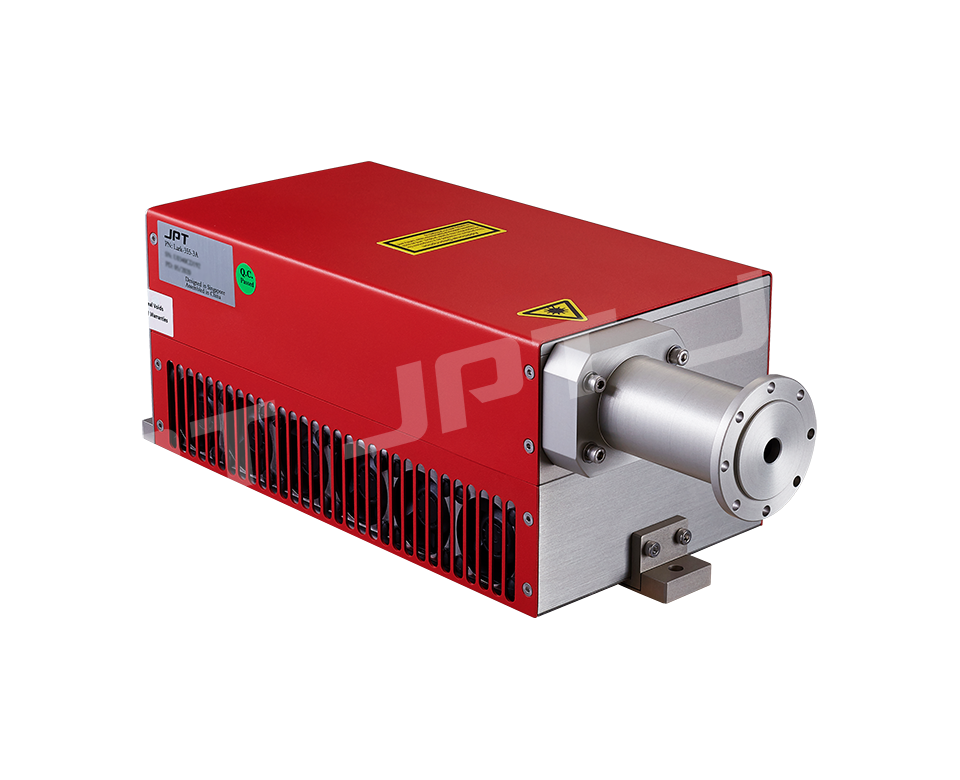

LARK 355

LARK 355

PS IR/UV Picosecond Laser

PS IR/UV Picosecond Laser

SEAL 355-20S

SEAL 355-20S

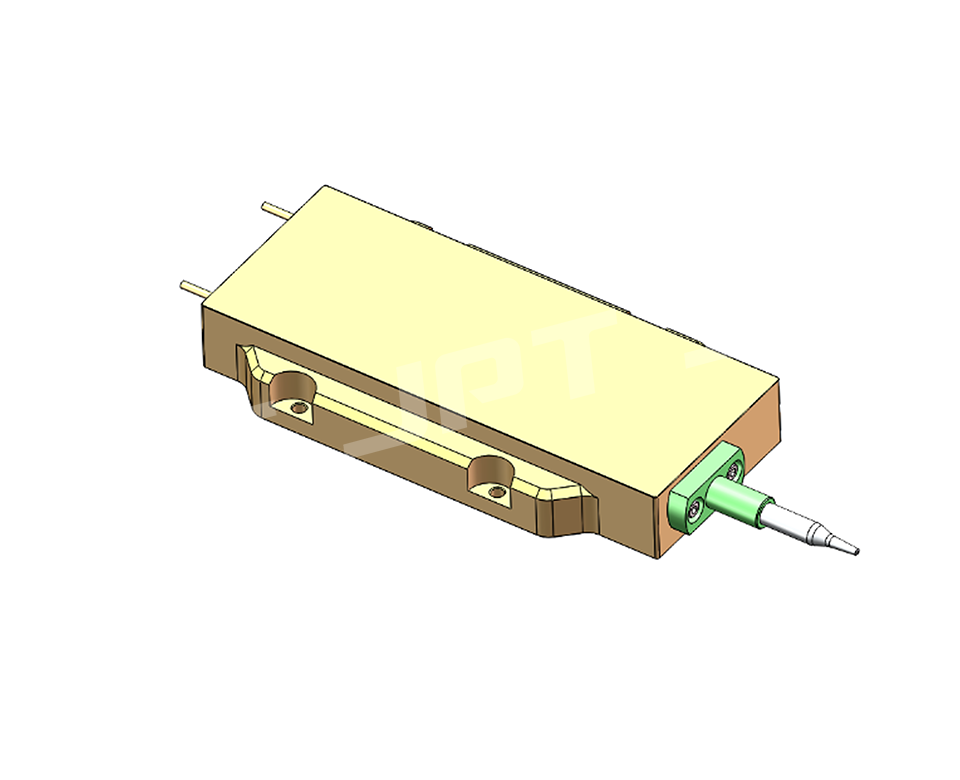

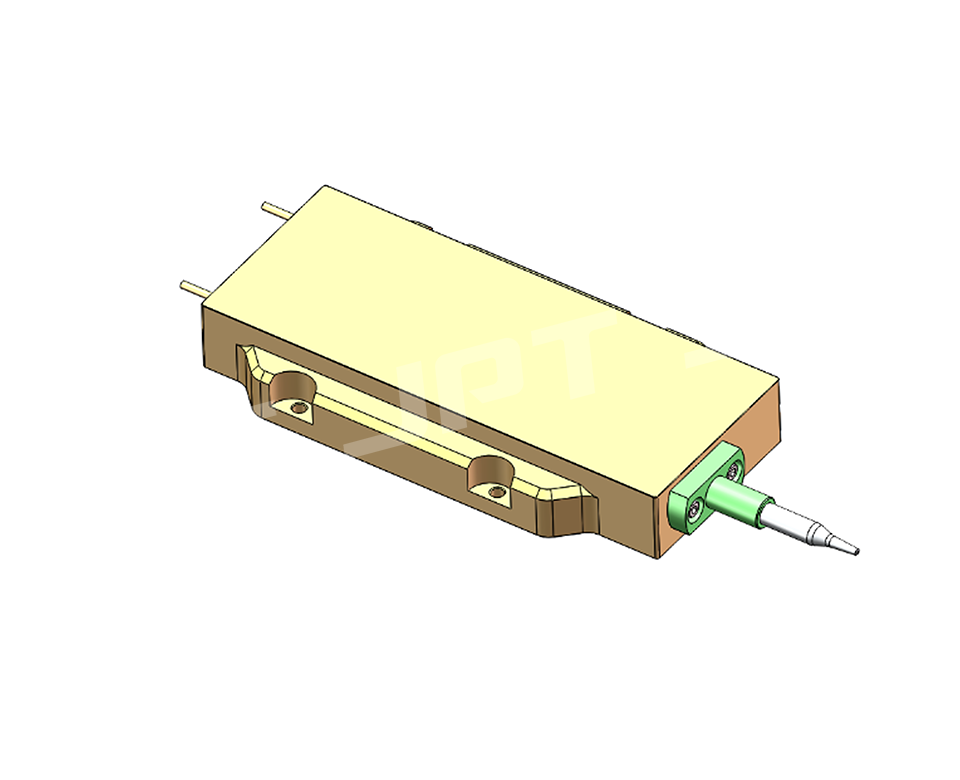

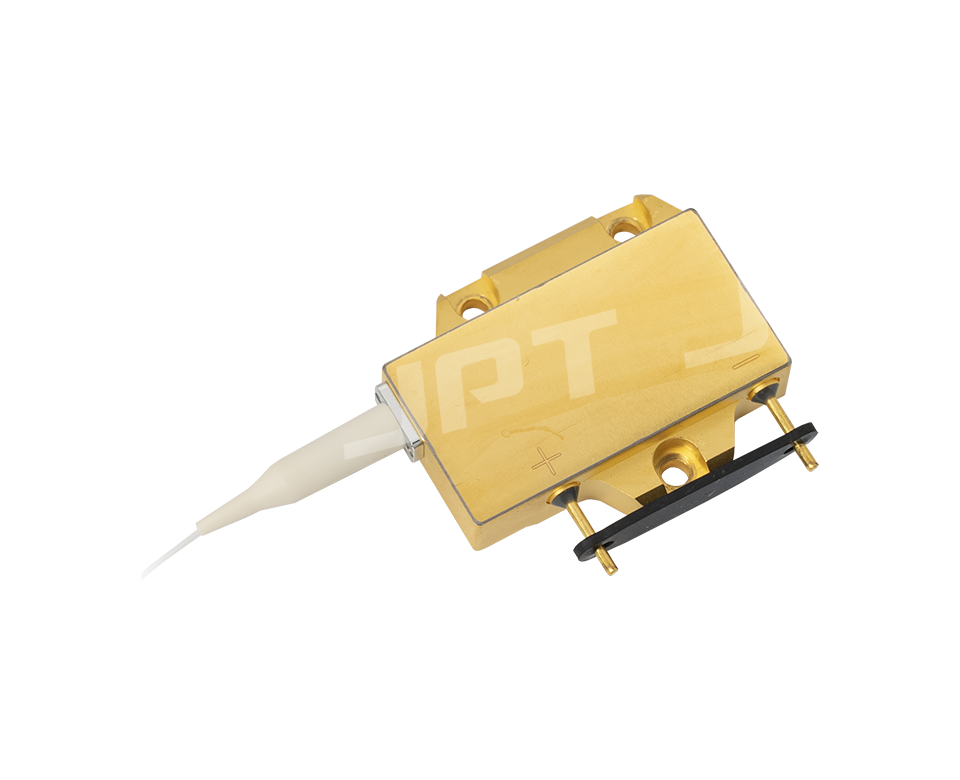

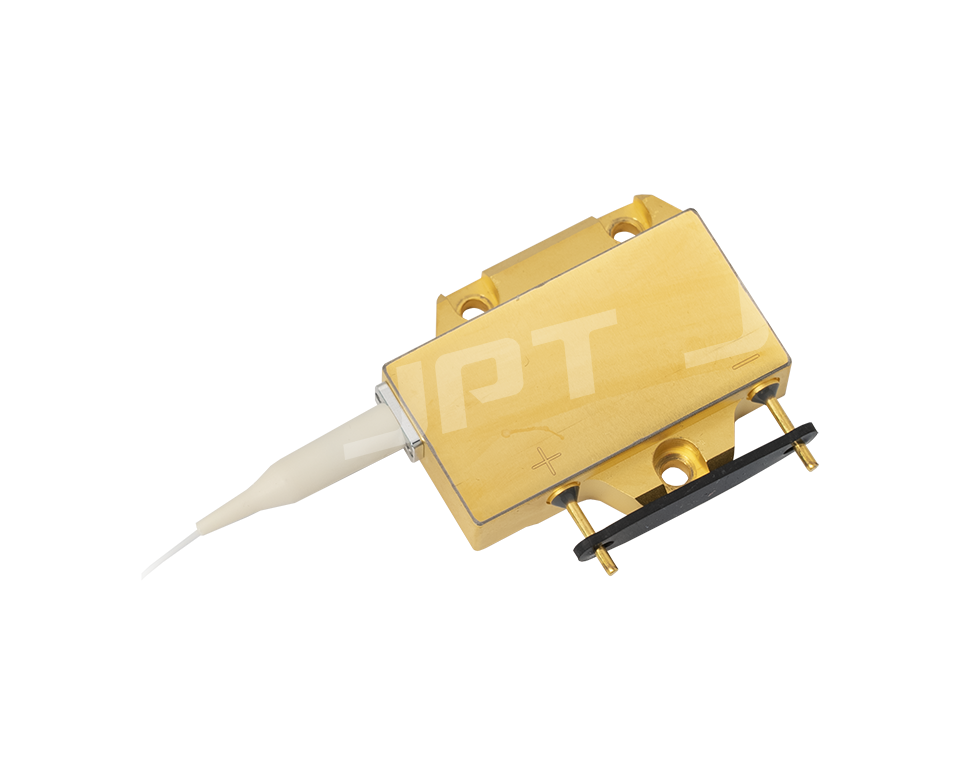

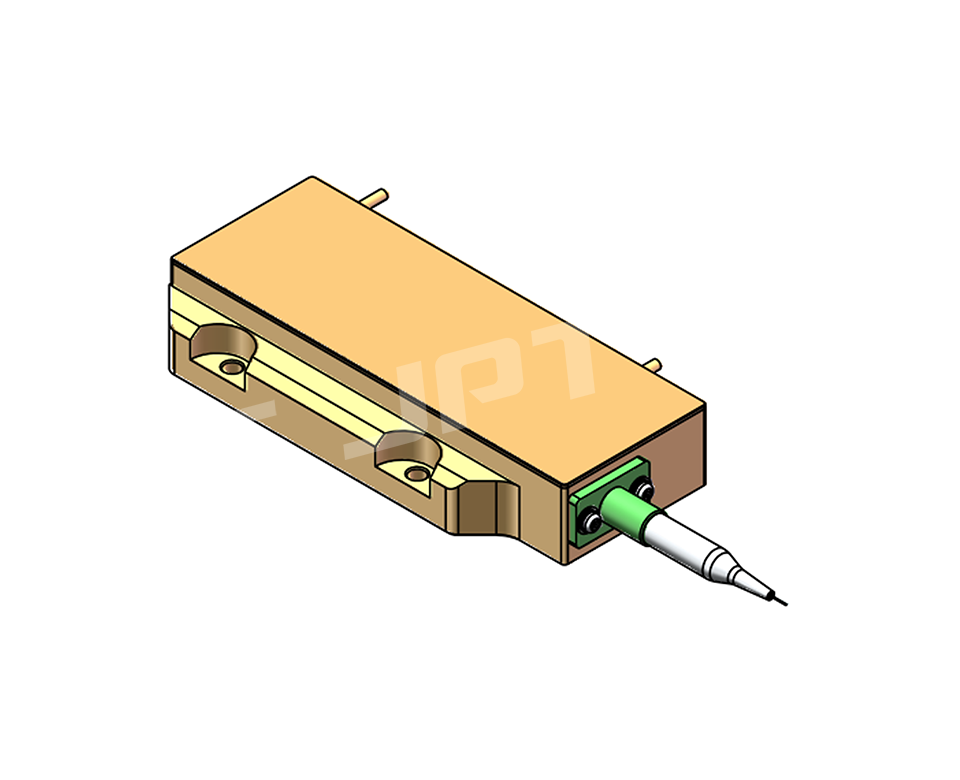

915nm/976nm - 240W - 135μm

915nm/976nm - 240W - 135μm

915nm - 280W - 135μm

915nm - 280W - 135μm

976nm - 420W - 200μm

976nm - 420W - 200μm

976nm - 500W - 200μm

976nm - 500W - 200μm

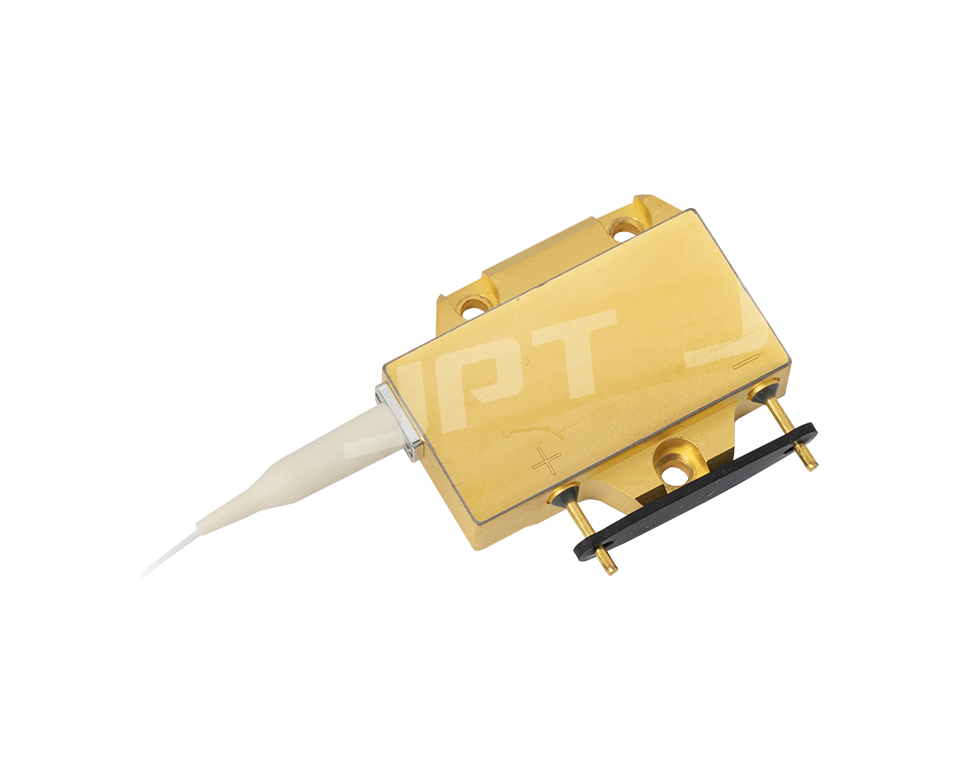

450nm - 15W - 105μm

450nm - 15W - 105μm

915nm - 15W - 105μm

915nm - 15W - 105μm

915nm - 30W - 105μm

915nm - 30W - 105μm

915nm - 45W - 105μm

915nm - 45W - 105μm

915nm - 60W - 105μm

915nm - 60W - 105μm

915nm - 110W - 105μm

915nm - 110W - 105μm

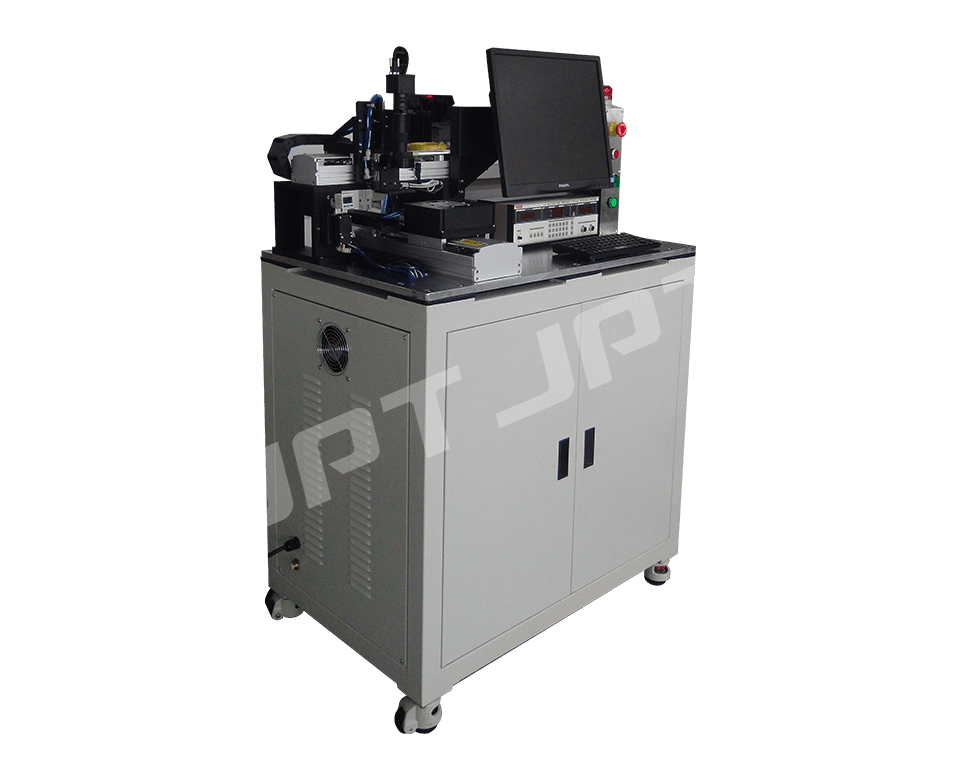

Laser Scriber

Laser Scriber

High Voltage Resistor Tester

High Voltage Resistor Tester

Single Chip Resistor Tester

Single Chip Resistor Tester

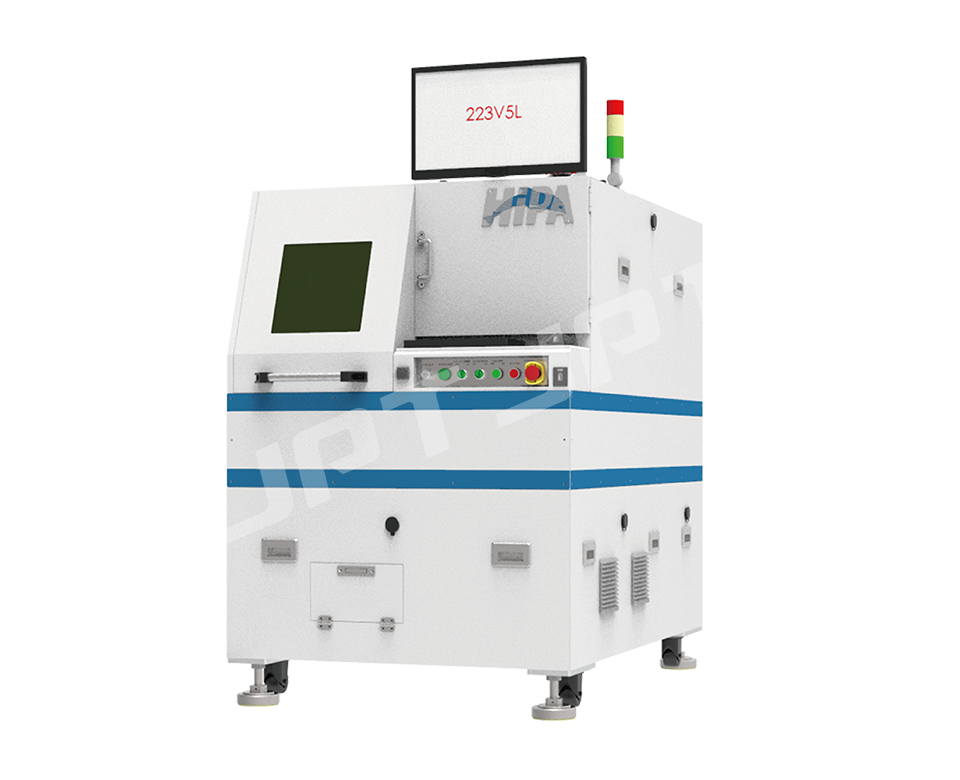

Laser Trimmer

Laser Trimmer

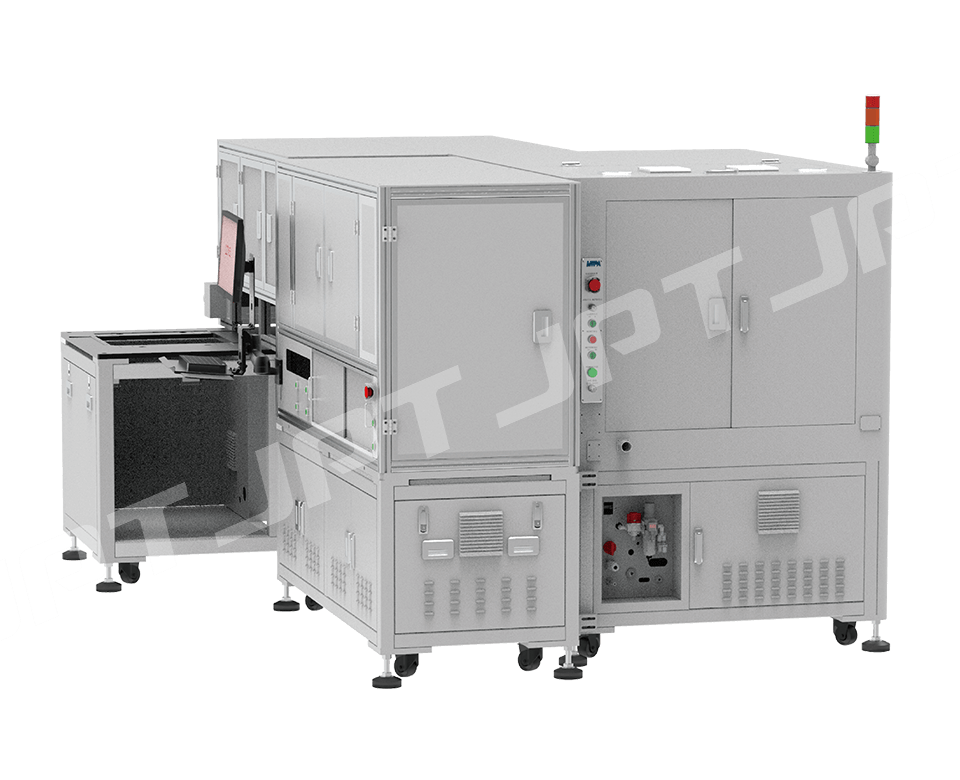

Hybrid Trimmer

Hybrid Trimmer

HiPA-TT Light Transmittance Tester

HiPA-TT Light Transmittance Tester

PCB Laser Marking System

PCB Laser Marking System

Ghost Writer & Reader - Subsurface 2D Barcode Marking & Reading System

Ghost Writer & Reader - Subsurface 2D Barcode Marking & Reading System

High Precision 2DBC Laser-marking

High Precision 2DBC Laser-marking

Comprehensive VCSEL Module tester

Comprehensive VCSEL Module tester

Comprehensive LED-PD Integrated Module Testing

Comprehensive LED-PD Integrated Module Testing

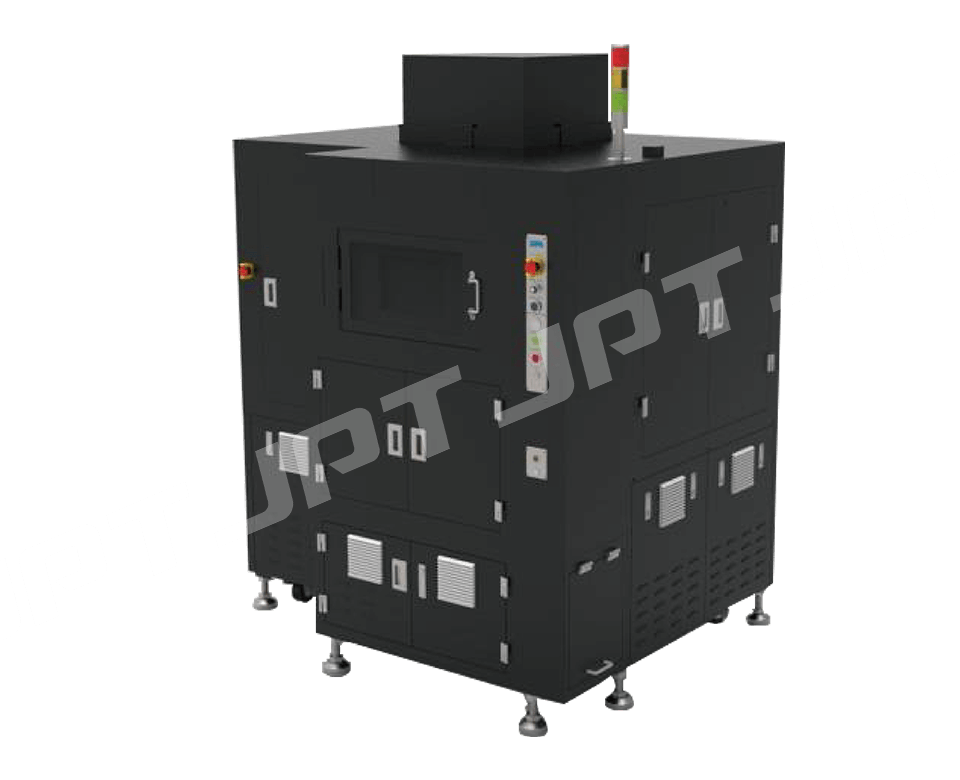

Six-sided Inspection Machine

Six-sided Inspection Machine