PRODUCT CATEGORIES

-

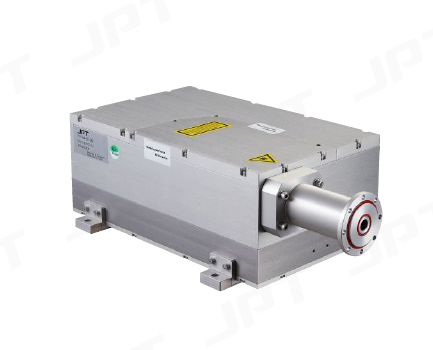

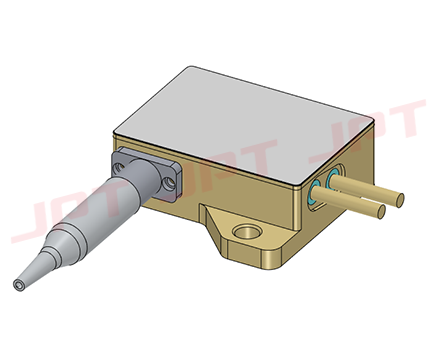

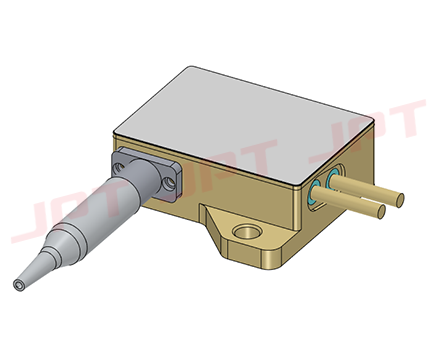

SEAL 532

532 LASER

LEARN MORE

-

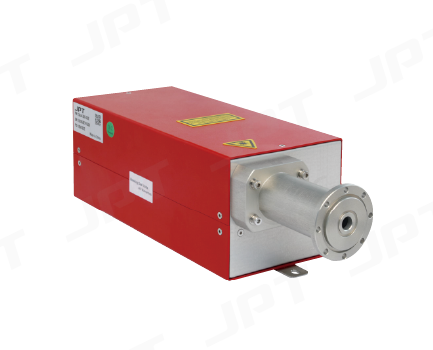

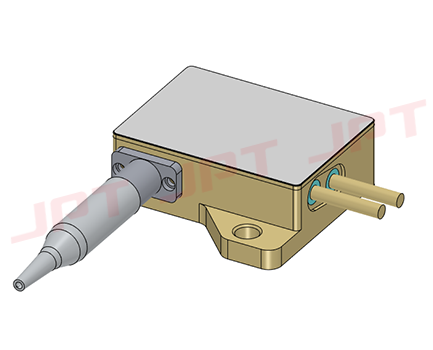

SEAL 355-3/5

355 LASER

LEARN MORE

-

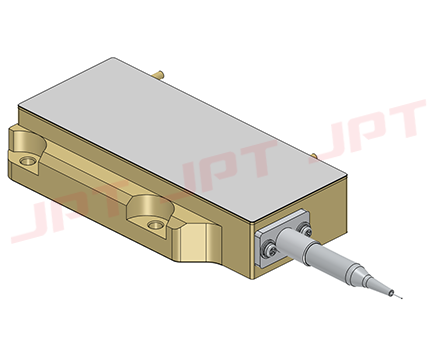

LARK 355-3/5

355 LASER

LEARN MORE

-

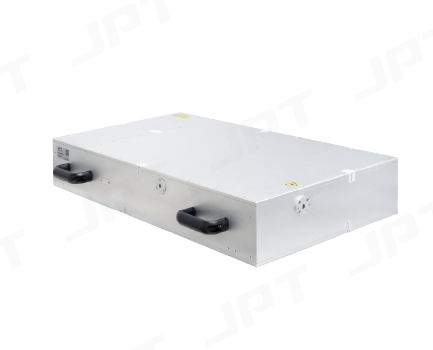

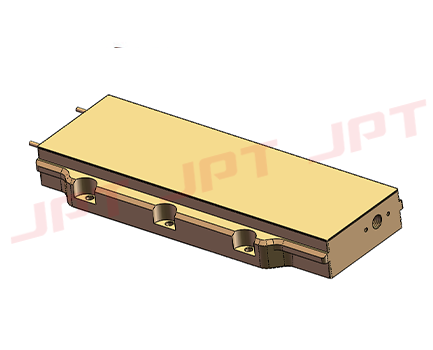

SEAL 355-10/15/20/30

JPT's Seal series in the power ultraviolet category includes a 10W, 20W and 30W ultraviolet laser.

LEARN MORE

-

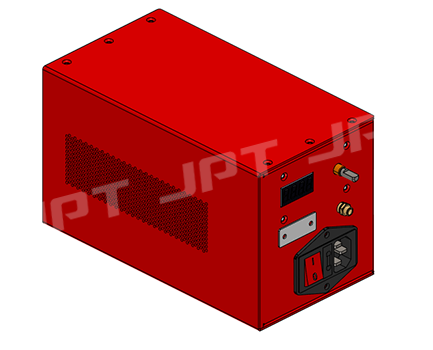

PS IR/GR/UV Picosecond Laser

PS IR/UV Picosecond Laser

LEARN MORE

-

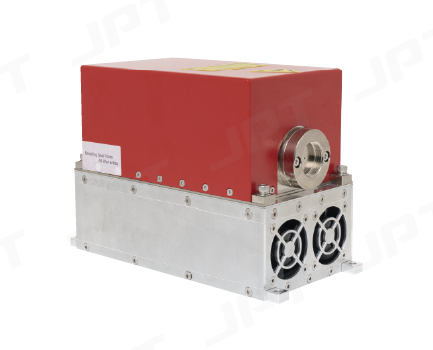

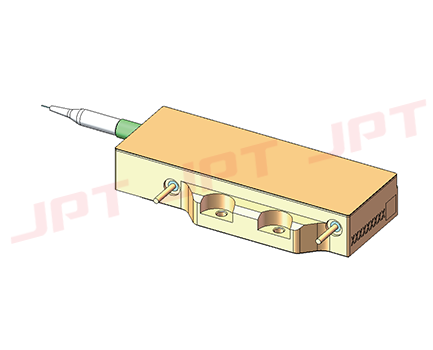

SPARROW-355/532

The Sparrow-355-2 UV solid-state laser is a newly revised air-cooled model, its size and weight are further reduced, saving the customer's installation space.

LEARN MORE

With the feature of the cold light source, DPSS laser series is mainly used in flying marking, PCB cutting, FPC cover film cutting, marking on plastic material and on glass material, and 3D printing, etc. The applications of DPSS laser include integrated circuit industry, crafts production industry, resin 3D printing, and marking industry.

DPSS Lasers FAQs

Question: How does a DPSS laser work?

Answer

DPSS laser is a solid-state laser that uses a gain medium that is solid. The gain medium of a DPSS laser consists of a glass or crystalline host material. The most common host materials are neodymium-doped yttrium aluminum garnet (Nd: YAG), ytterbium-doped glasses and neodymium-doped glass (Nd: glass). The gain medium is optically pumped by using laser diodes. The DPSS laser can generate a wide range of wavelengths based on the gain medium material. From the fundamental wavelengths, additional wavelengths can be generated by frequency doubling or second harmonic generation.

Question: What's the full form of DPSS laser?

Answer

Diode-pumped solid-state laser

Question: Does the output power of a DPSS laser depends only on its diode power?

Answer

The output power of the DPSS laser depends not only on the diode power but also on other parameters such as temperature of the laser, crystal gain medium, and optical assembly.

Question: What is the minimum time pulse length for a DPSS laser in order to get no strange transient responses?

Answer

The currently available minimum pulse width of the DPSS laser is about 8-10ns. This pulse width is achieved without effecting the laser operation and without any strange transient responses. If you need any other pulse width, we can customize our laser according to your specifications. Customizing lasers for different application is one of our advantages.

Question: DPSS vs. diode laser advantages?

Answer

DPSS lasers generally have a higher beam quality than diode lasers.

DPSS laser can reach very high powers and at the same time maintaining good beam quality. On the other hand, diode lasers can only reach a few hundred milliwatts unless they operate in multiple transverse modes. Such multi-mode lasers have a larger beam diameter and a greater divergence, which often makes them less desirable for single-mode operation.

In a DPSS laser, the crystal is pumped by the diode acts as its own laser, hence the quality of the output beam is independent of that of the input beam.

M7 20W-100W

M7 20W-100W

M7 200W-300W

M7 200W-300W

M7 500 - 1000W

M7 500 - 1000W

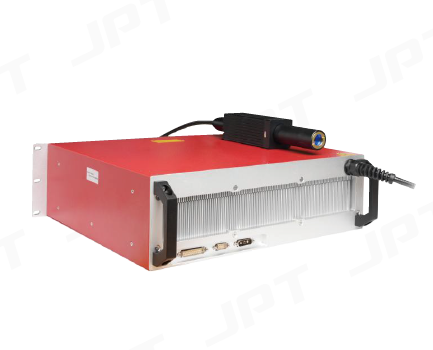

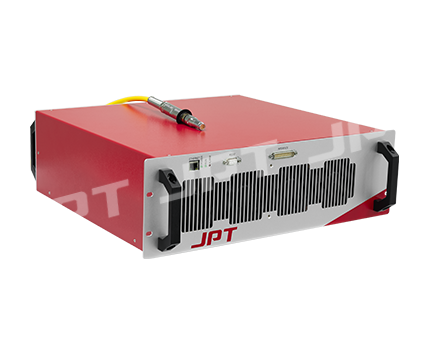

M8 20 - 50W

M8 20 - 50W

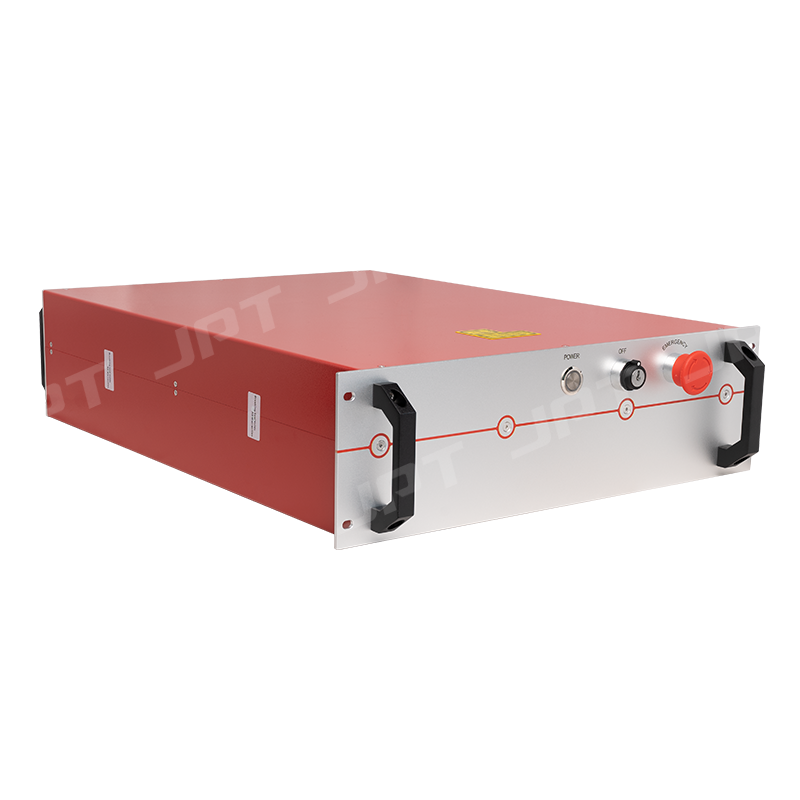

M8 120 - 300W

M8 120 - 300W

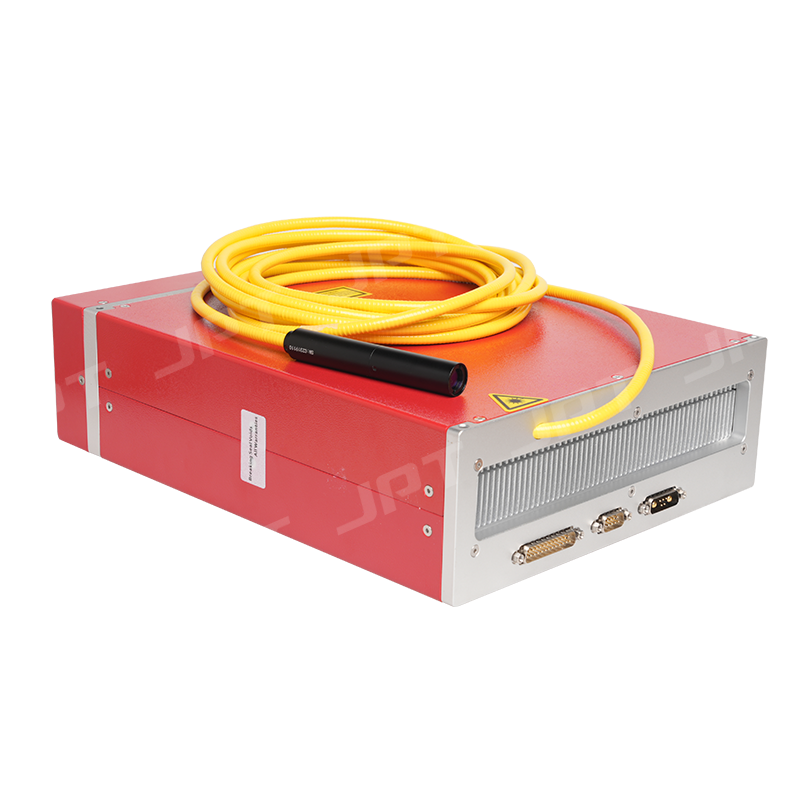

CL2 200W-300W

CL2 200W-300W

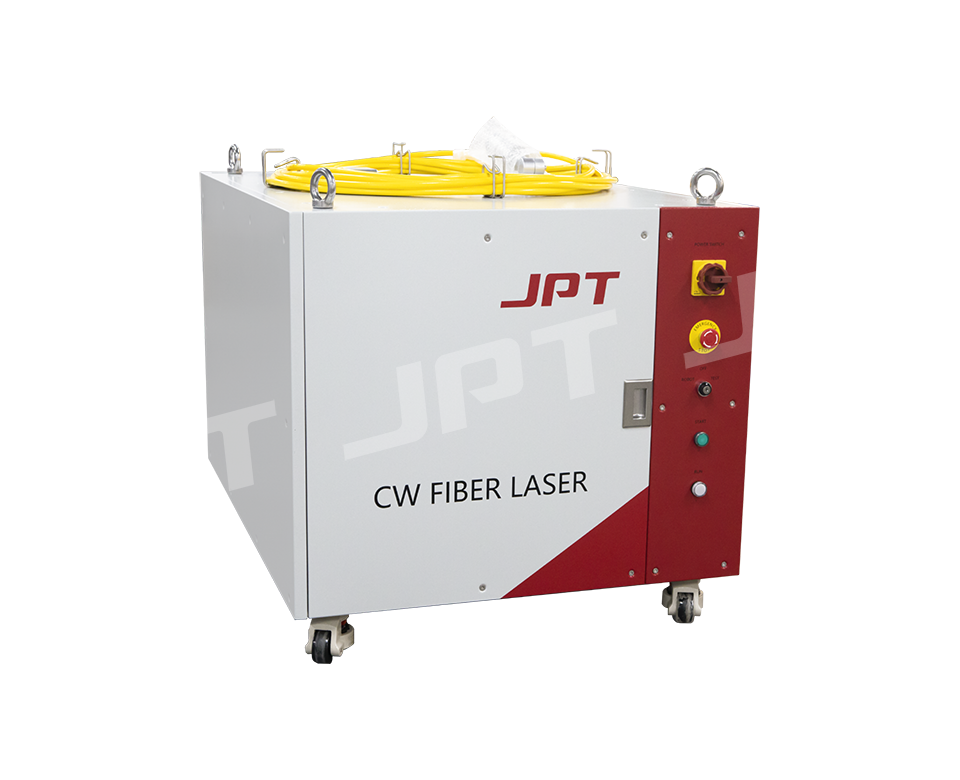

CL 500W~1000W

CL 500W~1000W

CL 2000W

CL 2000W

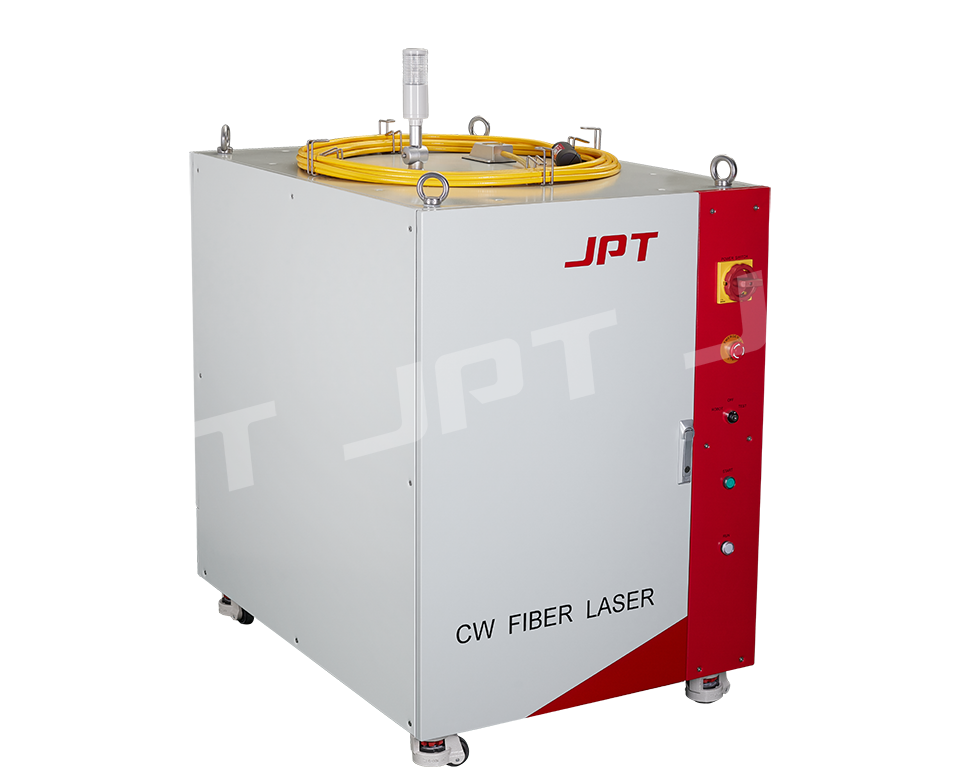

Multi-Module CW 6000W

Multi-Module CW 6000W

QCW 150W/1500W

QCW 150W/1500W

Multi-Module CW 12000W

Multi-Module CW 12000W

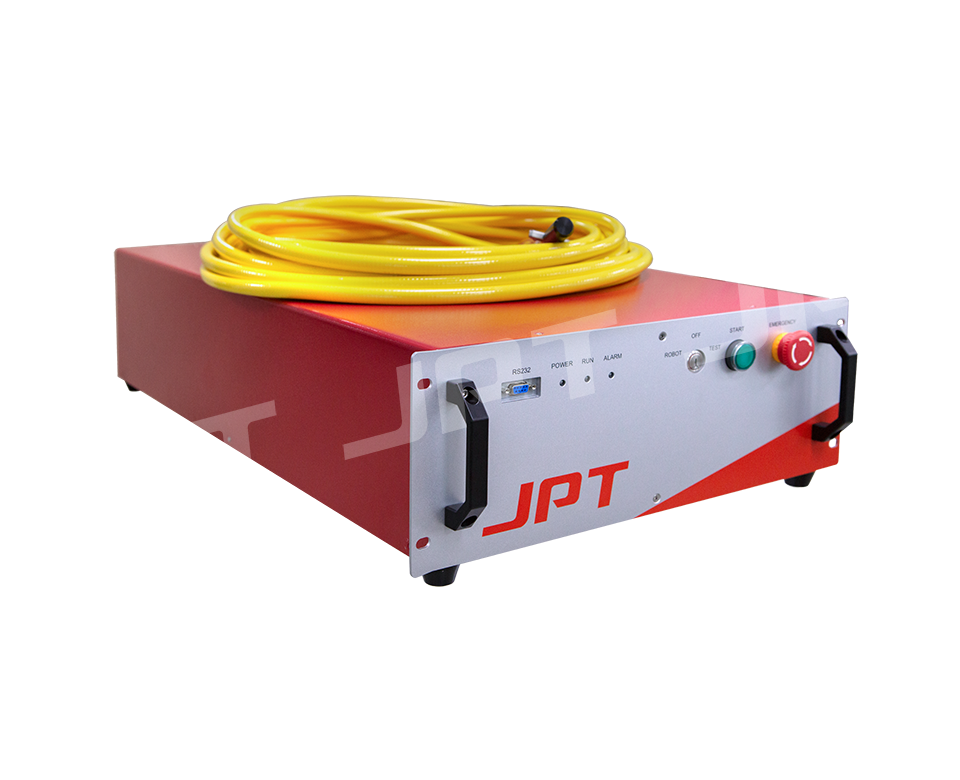

Single-Module CW 1500W-3000W

Single-Module CW 1500W-3000W

PS IR/GR/UV Picosecond Laser

PS IR/GR/UV Picosecond Laser

Semiconductor Laser with Red Light Series 200W

Semiconductor Laser with Red Light Series 200W

450nm—100W High Power Diode Laser

450nm—100W High Power Diode Laser

10W-1064-01 Silicon Transmission Series Detection Moduler

10W-1064-01 Silicon Transmission Series Detection Moduler

1060nm Series

1060nm Series

880nm Series

880nm Series

808nm Series

808nm Series

976nm Series

976nm Series

915nm Series

915nm Series

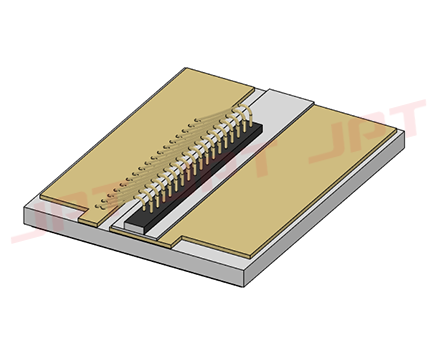

COS Encapsulated Semiconductor Laser

COS Encapsulated Semiconductor Laser

Laser Scriber

Laser Scriber

High Voltage Resistor Tester

High Voltage Resistor Tester

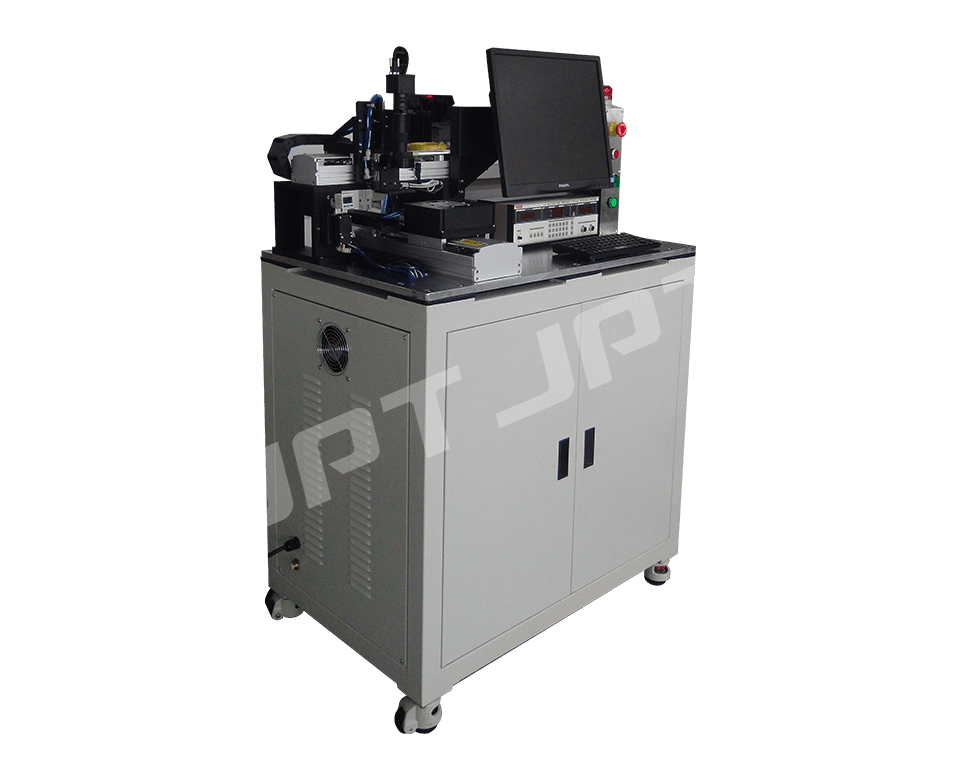

Single Chip Resistor Tester

Single Chip Resistor Tester

Laser Trimmer

Laser Trimmer

Hybrid Trimmer

Hybrid Trimmer

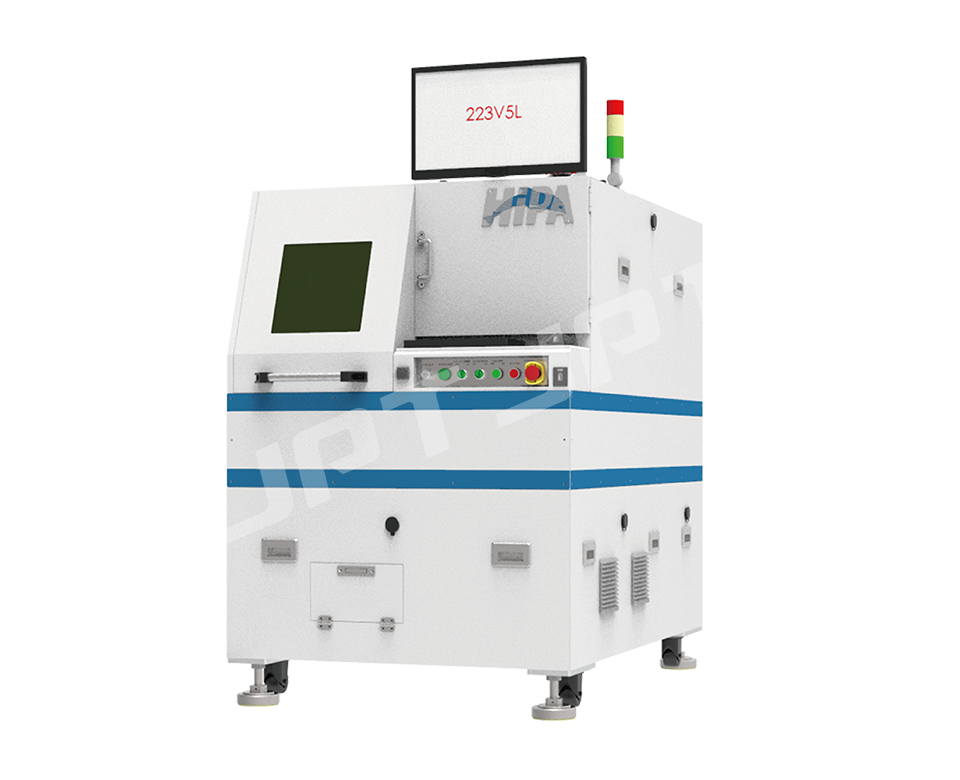

HiPA-TT Light Transmittance Tester

HiPA-TT Light Transmittance Tester

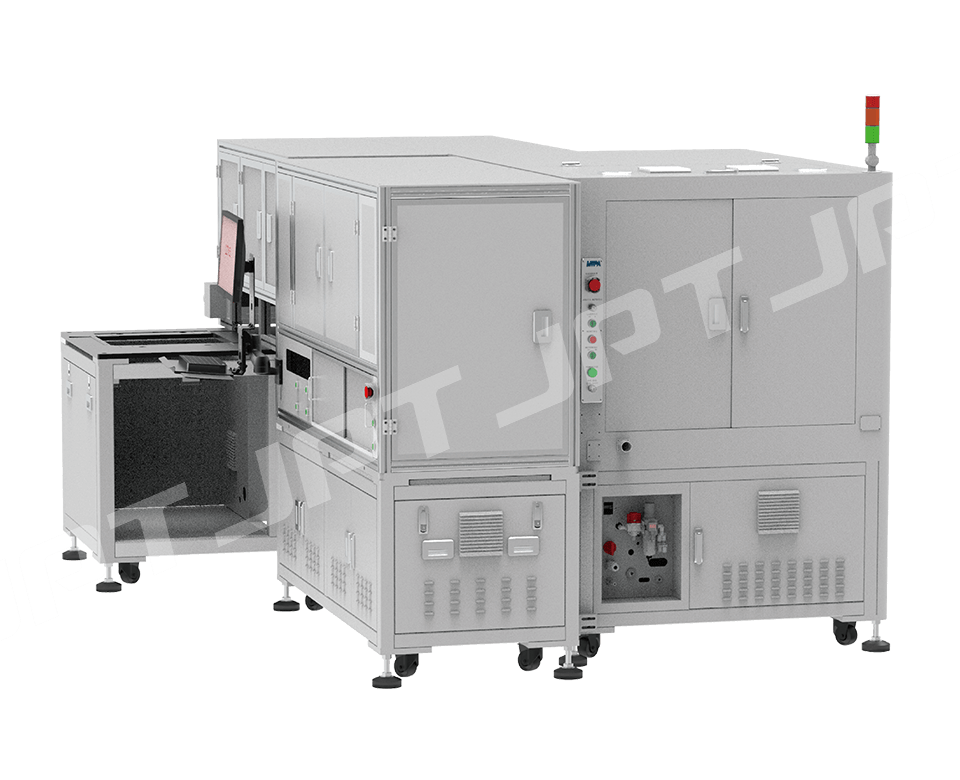

PCB Laser Marking System

PCB Laser Marking System

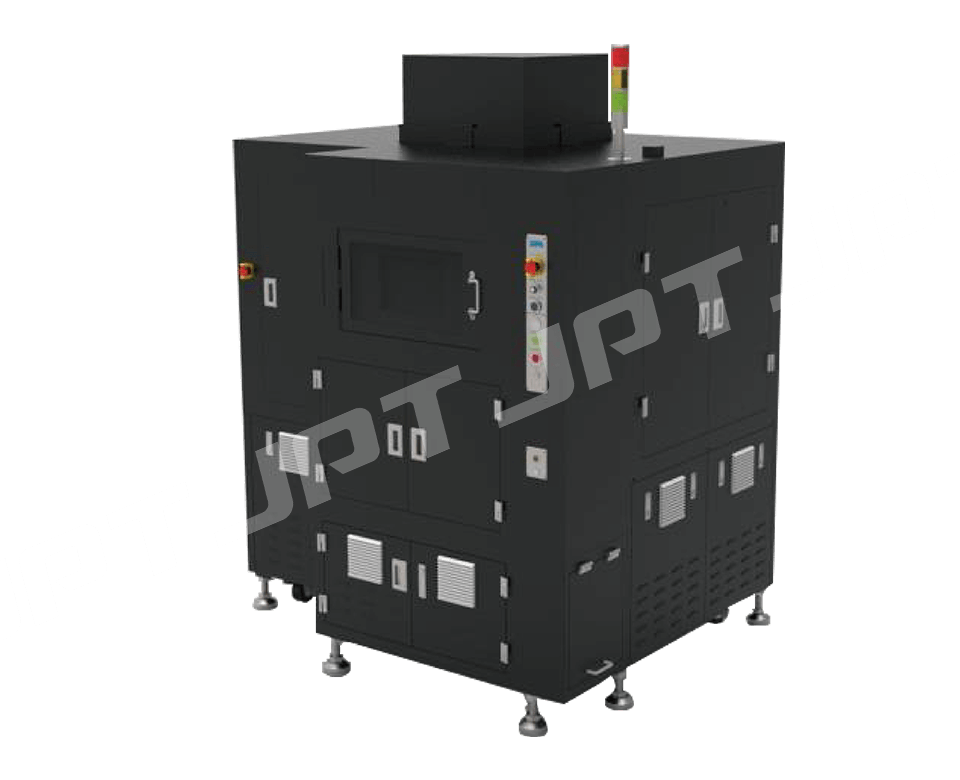

Ghost Writer & Reader - Subsurface 2D Barcode Marking & Reading System

Ghost Writer & Reader - Subsurface 2D Barcode Marking & Reading System

High Precision 2DBC Laser-marking

High Precision 2DBC Laser-marking

Comprehensive VCSEL Module tester

Comprehensive VCSEL Module tester

Comprehensive LED-PD Integrated Module Testing

Comprehensive LED-PD Integrated Module Testing

Six-sided Inspection Machine

Six-sided Inspection Machine