Table of Contents

The UDI system when combined with a picosecond laser enables quicker and more accurate tracking of multiple medical devices. What’s more, it also improves the viability of additional safety-specific tasks for multiple devices enabling better and more consistent monitoring by the concerned professionals. This is also an excellent way to reduce medical inconsistencies and single out false or erroneous devices.

What is a picosecond laser?

The picosecond laser is an iconic laser-based technology and is widely sought-after in the skincare and industrial domains for its significantly short pulse duration. When it comes to industrial applications, the picosecond laser is being used in medical UDI labeling for accurate labels that can be interpreted by machines and are highlighted by the shallow surface markings.

The picosecond laser is also a non-invasive technology that is primarily being used to address the various imperfections in one’s skin. One can use this technology to remove spots induced by damage from the sun, and scarring from acne, among other issues.

Picosecond laser applications

Currently, the picosecond laser is being extensively used in many industries such as medical instruments, chemistry, micromachining, skin treatments, semiconductor manufacturing and etc. While the applications of the technology are myriad, in this article, we will focus on one of the cutting-edge applications: UDI (unique device identifier) labeling of medical device marking.

What is UDI labeling?

UDI can be best defined as a medical device that is primarily used for identification. It includes two main parts, namely:

- Device identifier

- Production identifier

UDI makes way for simple and uncomplicated identification when it comes to locating specific medical devices.

High contrast and deep black

Picosecond laser makes way for high-contrast UDI labeling by targeting specific areas. This ensures that the labeling is accurate and highlighted in black.

Permanent, non-fading, corrosion-resistant

Thanks to the powerful Pico laser technology, the UDI label is permanent, and this can be achieved in much fewer sessions than conventional results. The labeling is also resistant to any form of corrosion and is permanent.

Machine readable

Because Pico laser is a highly advanced technology, the UDI labeling through it is fully readable and can be interpreted by the machine.

Shallow marking with small surface undulations to prevent bacterial aggregation

The technology also makes way for shallow markings as opposed to deeper ones. This prevents bacterial infections and any other similar aggregation.

UDI label corrosion resistance test: outstanding deep black marking result of JPT picosecond laser machine

Test method - Corrosion resistance test

Grade 304 stainless steel, one of the most commonly used stainless steel, is widely used in industry, food, medical, construction materials and other fields. Taking 304 stainless steel as an example, we can mark black on the surface of 304 stainless steel with a picosecond infrared solid-state laser (JPT-PS-IR-30).

Immerse the stainless steel marked black in the NaCl solution with a mass fraction of ~5% to simulate the common medical environment, so as to test for corrosion resistance of black marks. The experimental process is as follows:

- Wipe with alcohol. Wipe the stain off the 304 stainless steel with alcohol.

- Passivate with citric acid. After laser marking, immerse the stainless steel sheet in citric acid solution and passivate for 6 minutes

- Laser marking. Laser mark 304 stainless steel with JPT-PS-IR-30

- Passivate with citric acid. Soak 304 stainless steel sheet in citric acid solution for 10 minutes before laser marking

- Soak in NaCI solution. Soak the passivated stainless steel sheet in NaCI solution (mass fraction: ~5%)

The corrosion resistance of black marks

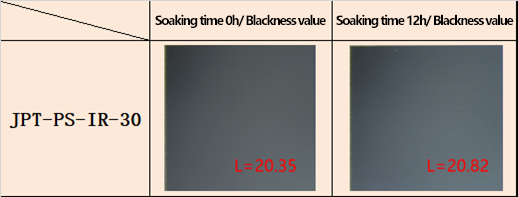

Compared to the stainless steel sheets marked with JPT-PS-IR-30, the result showed that the blackness value changed very little after soaking in NaCl solution for 72h:

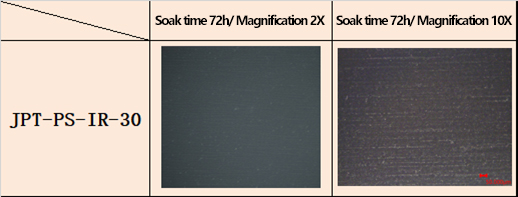

The surface of the soaked stainless steel sheet was magnified and observed. After soaking for 72 hours, the black surface marked with JPT-PS-IR-30 shows no signs of color peeling or color fading:

When subjected to ordinary laser irradiation, the heating effect of stainless steel predominates. The black oxide film is formed by an oxidation reaction, and marking black is achieved. On the one hand, a variety of oxides will lead to the blackness that is not enough or uneven. On the other hand, the oxide layer is also more prone to peeling off or producing a chemical reaction in an acid, alkali, and salt environment, thus degrading the corrosion resistance of stainless steel.

However, ultrashort pulse (picosecond) laser can create microstructure on the stainless steel surface, which can absorb light in a selective way. In this case, the stainless steel will appear black. Finally, the corrosion resistance of stainless steel can be preserved.

Note: The above conclusions apply only to the assembly and parameters used in this test.

Why do JPT-PS picosecond laser perform so differently?

With the state-of-art picosecond laser amplification solution, the JPT-PS series picosecond laser adopts a compact dual-cavity structure and simple & reliable control design and meets the requirements of all-weather industrial production and cutting-edge scientific characterization testing. The JPT-PS series is currently available in infrared and ultraviolet versions with a pulse width of up to 6ps. With Pulse on Demand and Burst Mode, the JPT-PS picosecond series laser can emit a single pulse of up to 1MHz.

Recommend Reading

You Will Never Believe Laser Technology Could be So Useful

Table of Contents Beginning: The Development and Current Status of the Laser Industry The laser industry has found wide acceptance across different industries since the

How to Choose a Suitable Laser Source – MOPA Series

As a tool, the laser has become a new favorite in the industrial age. Compared with other traditional processing methods, the laser has only a