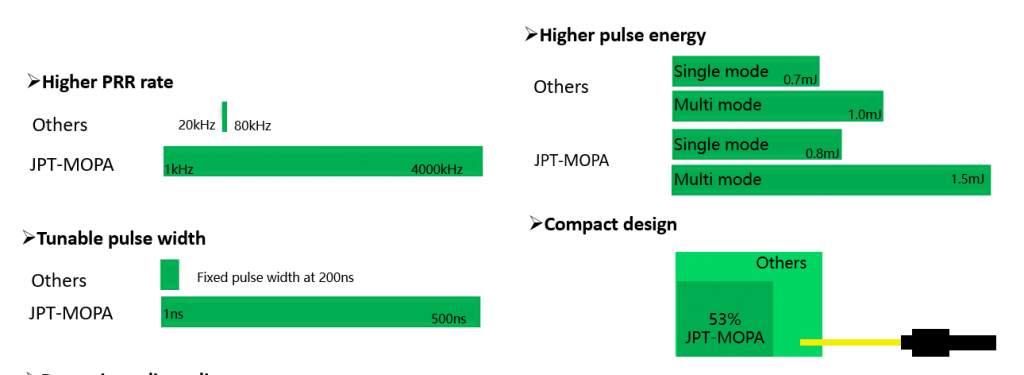

JPT high power pulsed fiber lasers make use of master oscillator power amplifier (MOPA) configuration, and show excellent laser performance with high level of temporal pulse shaping controllability. As compared to the Q-switch technology, the pulse repetition frequency (PRF) and pulse width can be controlled independently in MOPA configuration, through adjusting different combination of the above parameters, the peak power of laser can be well maintained. And enable JPT laser suitable for more material processing which Q-switch limited. The higher output power makes its advantages especially in high speed marking applications.

Today, let me introduce JPT’s popular MOPA fiber laser.

MOPA fiber laser is widely used in dozens of manufacturing processes, such as black marking on anodized aluminum, color marking on stainless steel, deep engraving, welding of dissimilar metal sheets, paint removal of plastic product, laser cleaning, flight marking, electrode tab & photovoltaic silicon wafer cutting, etc. Therefore, we can see the pulsed fiber laser is being used in an increased number of industries, including the 3C electronics, new energy battery, metal processing, food package, high-speed railway, ships.

Lasers Products Introduction - Fiber Laser AIO series

AIO-LP-20W/30W

AIO-M7-20W/30W

Advantages:

- Small compact size ;

- Easy to install and operate ;

- Saving installation space;

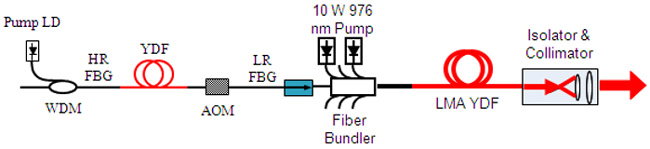

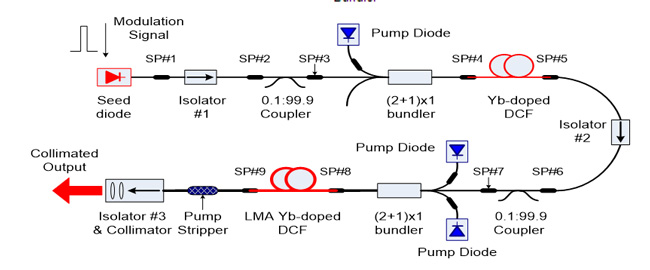

Fiber Laser Structures

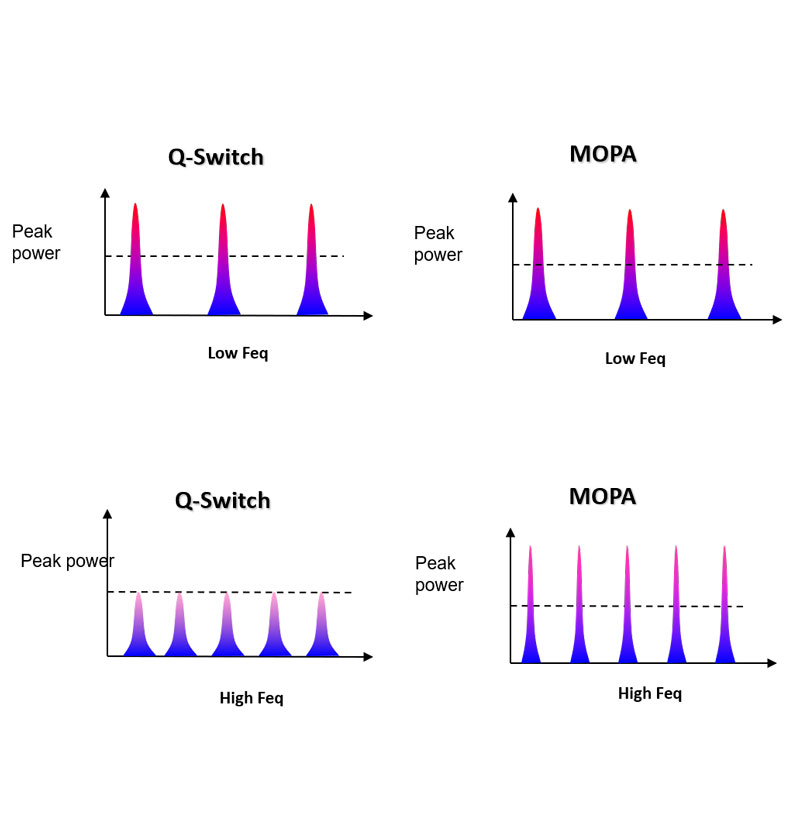

Why MOPA fiber laser

Peak power decrease a lot

Always keep high peak power

Advantage of MOPA laser - Pulse width tunable

JPT MOPA : With many different pulse width choice, and can always keep high peak power.

Q-Switched: Pulse width link to PRR adjustment, peak power will decrease at high PRR.

Waveform Advantage

Less heat effect with short pulse width.

Advantage of MOPA laser - Parameter

Dynamic cooling adjustment

Fans would adjust the running speed according to the temp of environment . Quiet and energy saving .

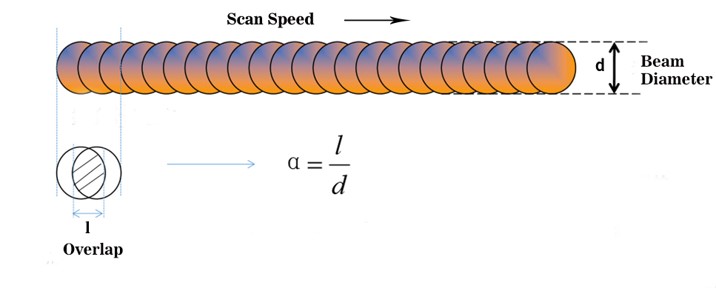

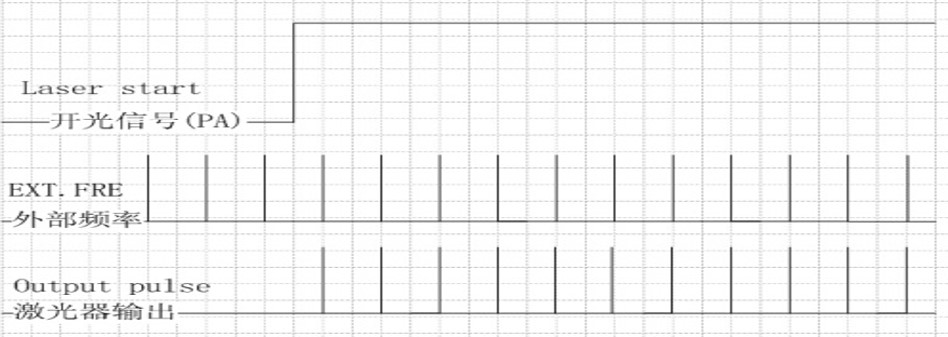

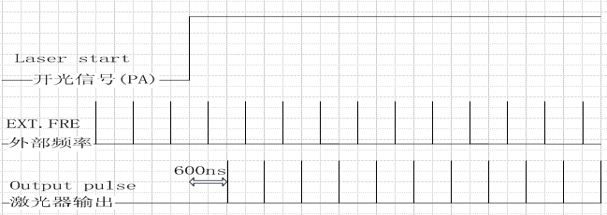

Precise Control of Pulses

You May Also Like

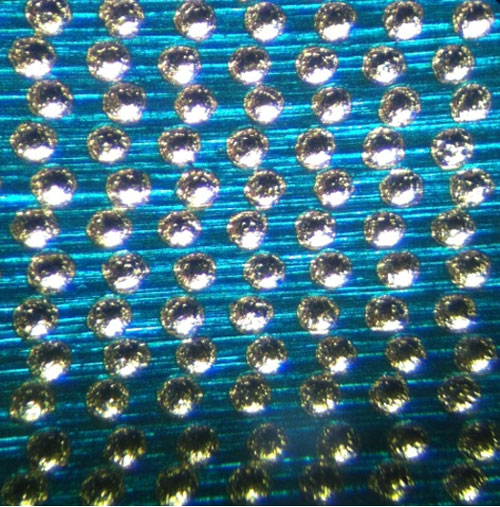

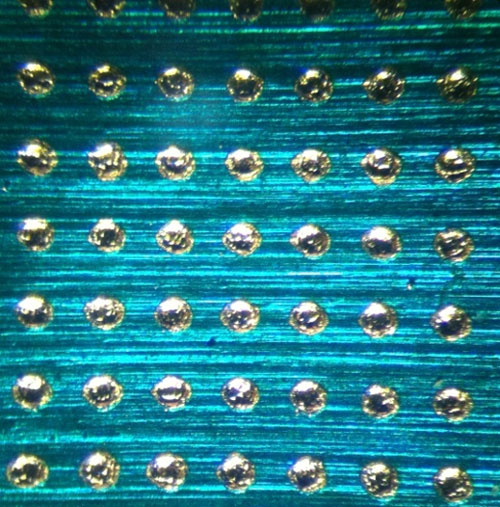

HiPA Solutions – Laser Micro Hole Drilling

Flexible circuit boards, referred to as FPC are widely used in consumer electronic products such as microelectronics, 5G mobile phones, laptop computers, and new energy vehicles. Also as electronic interconnects to connect products.

HiPA Solutions – Laser Ink Removal

Ink is an important material for printing. By printing or inkjet, patterns and characters are displayed on the substrate. Among them, screen printing inks are widely used on the cover glass of various display panels such as mobile phones, computers, smart watches, cameras, etc.

JPT Solutions – Thick Glass Cutting with Ultrafast Laser

Table of Contents Applied Industry Because of its excellent optical properties and unique wear resistance, cover glass is used in automotive display screens. The continuous

- HiPA Solutions – Laser Micro Hole Drilling - 09/12/2022

- HiPA Solutions – Laser Ink Removal - 03/12/2022

- JPT Solutions – Thick Glass Cutting with Ultrafast Laser - 03/12/2022