Comprehensive Laser Cleaning Guide – Advantages and Benefits

Table of Contents What is Laser Cleaning? Laser Cleaning is the process of removing the unwanted contaminants or impurities from the surface of a material

Table of Contents What is Laser Cleaning? Laser Cleaning is the process of removing the unwanted contaminants or impurities from the surface of a material

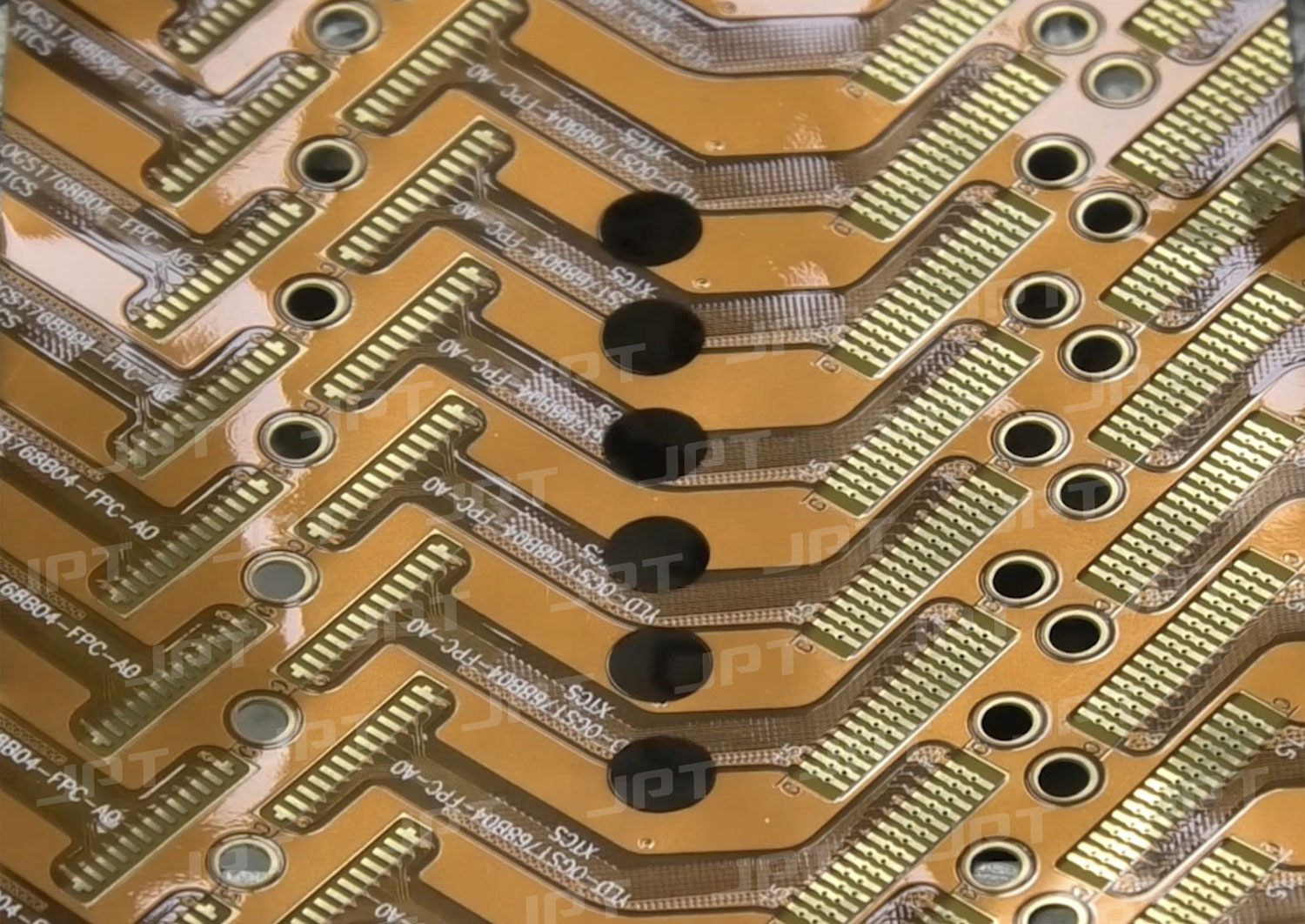

What is Laser drilling process? Laser drilling process is a vital part of the manufacturing process. Laser-based drilling uses a fiber laser beam to create

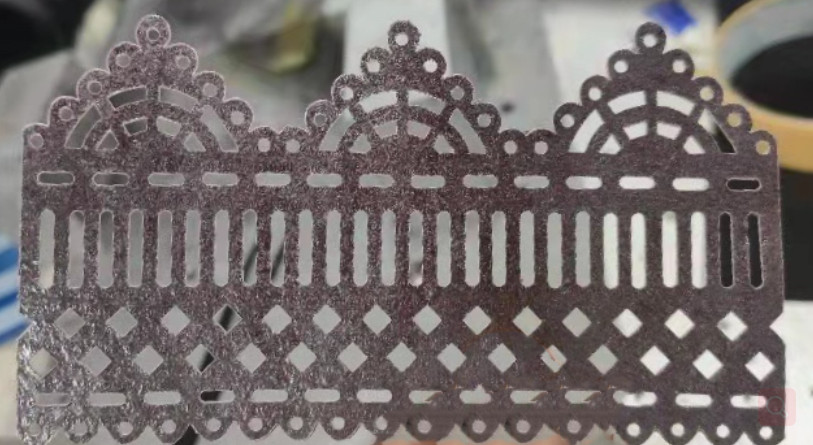

Leather cutting is the process of cutting on leather using knives, molds, lasers, or other tools. This process is widely used in automobile production, clothing,

As a tool, the laser has become a new favorite in the industrial age. Compared with other traditional processing methods, the laser has only a

JPT high power pulsed fiber lasers make use of master oscillator power amplifier (MOPA) configuration, and show excellent laser performance with high level of temporal

What is Additive Manufacturing? Materials are added to create the finished product, rather than removed such as in subtractive manufacturing (milling or turning for example).

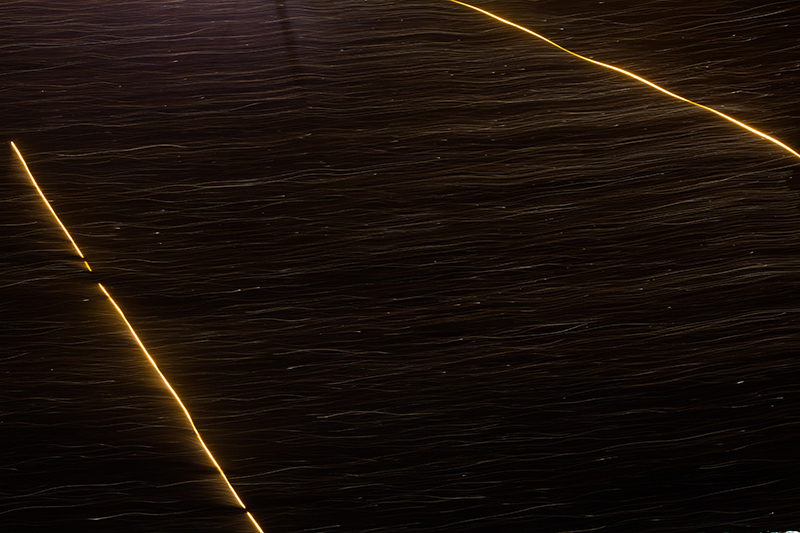

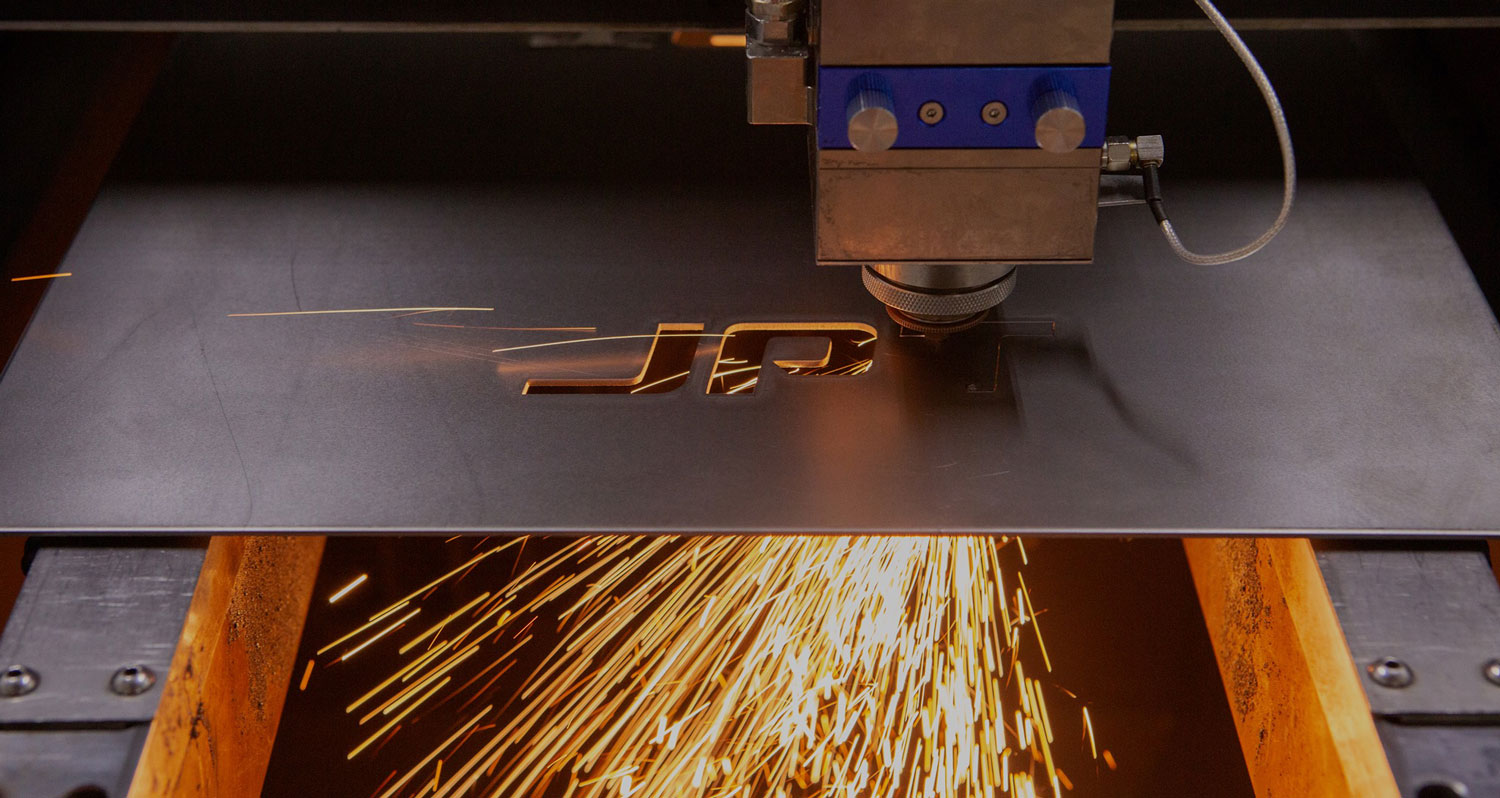

With the powerful technology of JPT CW & QCW laser, you can cut and weld almost metals, including Aluminum, Stainless Steel, Brass, Carbon Steel, Cooper,

Pulsed fiber laser on current market can mainly be classified into two types, which are based on Q-switching technique and MOPA technique respectively. Between them,

Company introduction: Established in 2006 , JPT Opto-electronics is a ‘National High-tech Enterprise’ with over 1000 employees. The company now focuses on the R&D, production,

Laser technology has been developed progressively over the past 60 years. It’s widely used in the field of traditional processing, for example, marking, welding, cutting,

Copyright © 2022 SHENZHEN JPT OPTO - ELECTRONICS CO.,LTD. all rights reserved

Copyright © 2020 SHENZHEN JPT OPTO - ELECTRONICS CO.,LTD. all rights reserved