Laser marking technique, with its rapid development in recent years, has been widely used in electronics, mechanical industry, food industry, and packaging.

Compared to conventional marking technique, laser marking has unique advantages such as well controlled spillage of material and high resolutions.

In order to achieve a better marked pattern and a higher marking efficiency, people tend to compare different lasers produced by various companies and subsequently choose the most suitable one according to the wishing tasks.

Pulsed fiber laser on current market can mainly be classified into two types, which are based on Q-switching technique and MOPA technique respectively.

Between them, Q switching technique has been introduced into industry for several years and has occupied a large part of the current market share, whereas MOPA technique, as a brand-new technique, only breaks into industry and gets developed very recently.

What are the differences between these two techniques and in what aspects does MOPA win?

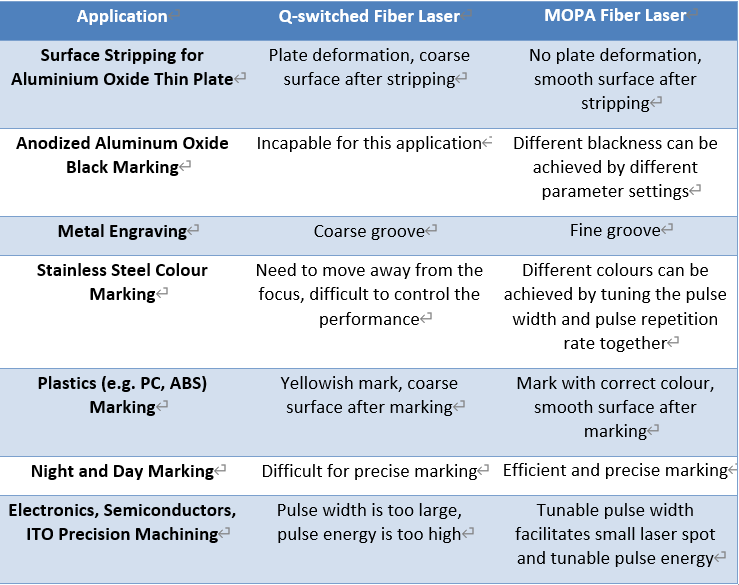

Differences of MOPA and Q-switched Fiber Lasers in Various Applications

1. Surface Stripping for Aluminium Oxide Thin Plate

In order to cater for the light-weight tendency, phones and laptops are now gradually adopting aluminium oxideplates as their covers. In this case when marking the covers, Q-switched fiber lasers will easily cause the deformation of the material and thus produce many small convex bulges which badly affect the appearances of the products.

However, by using MOPA fiber lasers, pulses with ultra-short pulse widths have enough energy to strip anodic layer yet the short laser residence time on material. This gives no deformation of the plate itself, leaves a smooth and bright surface after stripping, and makes MOPA a better choice for the marking of aluminium oxidethin plates.

2. Anodized Aluminum Oxide Black Marking

Many electronics makers such as Apple, Huawei, ZTE, Lenovo and Meizu are adopting laser to mark their logos, model numbers and characters in black colour on their product covers.

To achieve this, MOPA fiber laser is the exclusive choice. With its wide pulse width tuning range and pulse frequency tuning range, MOPA fiber laser can mark in black color by using pulses with narrow pulse width and high frequency. Tuning and recombining different parameters can even make different grey scales realisable.

3. Electronics, semiconductors and ITO Precision Machining

In the areas stated above, precise lining is frequently needed. It is difficult to achieve precise lining by using a Q-switched fiber laser due to its unchangeable pulse width. Alternatively, a MOPA fiber laser is able to finish the job well and ends up with smooth edges with its flexibly tuned pulse width and frequency.

Moreover, there are many other differences between these two techniques which have been listed below:

From comparison above, it is obvious that MOPA fiber lasers can replace Q-switched fiber lasers in many applications, especially in some high-end applications.

Why MOPA fiber lasers are superior to Q-switched fiber lasers in various applications? Now we will elaborate this on different specifications.

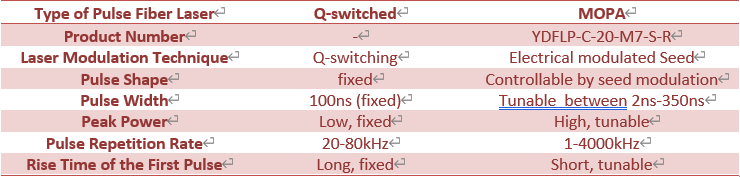

Comparisons of MOPA fiber laser and Q-switched fiber laser

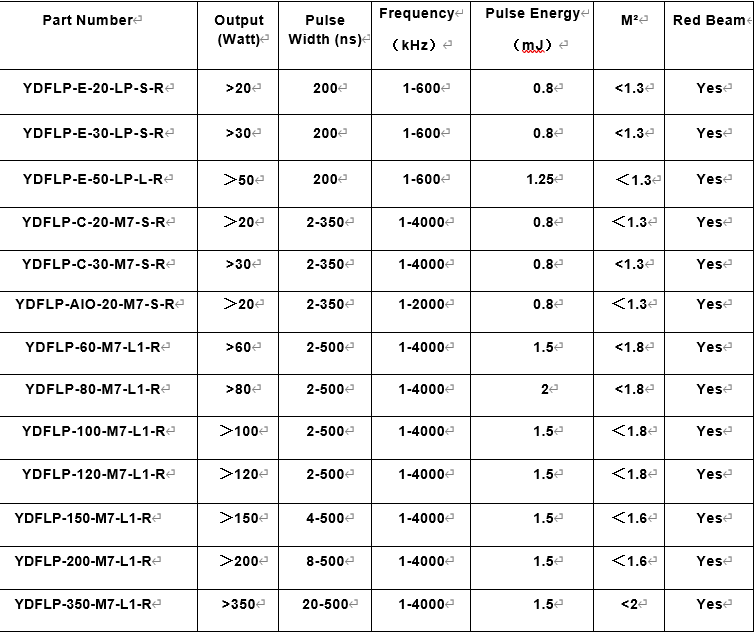

Here we compare the specifications of M7 Series Fiber Lasers with typical Q-swithced fiber lasers in the market:

Compared with traditional Q-swithced fiber lasers, MOPA M7 series Fiber Lasers have much larger tunable range in the aspects of pulse width, pulse repetition rate and pulse shape control. This makes it possible to customize specifications for different materials and for different effects. If a specific model is desired by the customer, the specifications can be further tailored in order to provide a full range of solutions for the customer.

Blockbuster Product with 12Years’ Painstaking Research – Series M7 Fiber Laser with Tunable Pulse Width.

What is a M7 Fiber Laser?

M7 Fiber Laser is a high-end MOPA fiber laser with tunable pulse width, which involves 12 years’ painstaking research from Shenzhen JPT Opto-Electronics. Co., Ltd.

This is a MOPA fiber laser for which JPT adopts unique techniques. By modulating the seed signal, the output pulse shape can be controlled flexibly, the pulse width can be tuned in the range of 1ns-500ns, and the pulse repetition rate can be in a broad range of 1-4000kHz.

All these make M7 Fiber Laser suitable for a very large number of applications. Furthermore, with high peak power, short rise time of the first pulse, a M7 Fiber Laser has high energy and high efficiency for fabrication; therefore it is a solid choice of high-end fiber laser for fabrication industry with no alternatives.

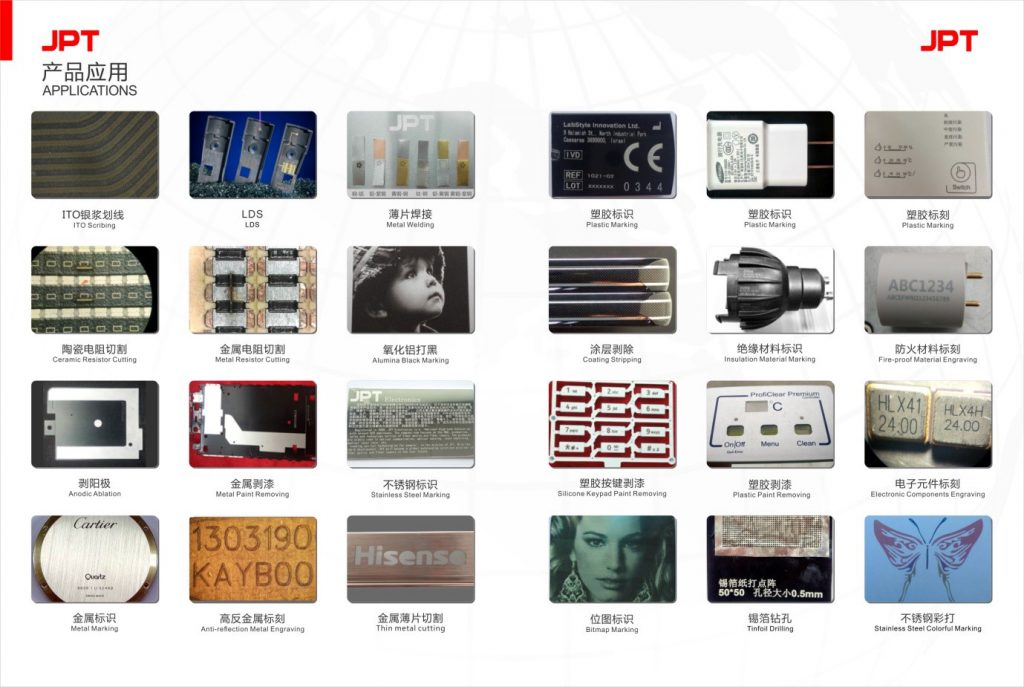

Applications of MOPA Fiber Lasers

MOPA Fiber laser can do more applications, based on flexible feature. Especially precision processing on plastic, thin plate, alumina, etc. Attached some pictures as below:

About JPT

Registered in 2006, JPT Opto-electronics is a ‘National High-tech Enterprise’ with over 1000 employees now. JPT focuses on the R&D, production, sales and technology service of fiber optics and fiber lasers. The products are widely used in optical communication, optical sensing, laser machining, medical laser care, etc.

JPT has a very strong R&D team with several PhDs and Masters. The team is always ready for technical service for the valued customers. JPT carries out several research projects and owns over 500 patents and other intellectual properties.

JPT has its own production lines, warehouses, offices, research laboratories, etc. Its total area is around 20,000 square meters. During past few years, JPT has got several certifications like quality system ISO 9001:2008, TL certification, UL, RoHS, etc.

‘Leading optical technologies for people‘ is our mission. With the rapid development, JPT will become a global outstanding solutions provider of fiber optics and fiber lasers in near future.

JPT MOPA Fiber Lasers-E series & M7 series

You May Also Like

Leading-edge Laser Solutions for Surface Processing

Company introduction: Established in 2006 , JPT Opto-electronics is a ‘National High-tech Enterprise’ with over 1000 employees. The company now focuses on the R&D, production,

Ultrafast Lasers From-Basics to Its Applications

Table of Contents What is special about Ultrafast Lasers? We know that laser energy can be delivered in two modes – continuous wave mode (CW)

Need A Laser for UID Marking, Let JPT help!

Table of Contents What is a UID Marking? UID means Unique Identifier. It makes record unique, unambiguous and traceable. These labels are permanent marked labels

- HiPA Solutions – Laser Micro Hole Drilling - 09/12/2022

- HiPA Solutions – Laser Ink Removal - 03/12/2022

- JPT Solutions – Thick Glass Cutting with Ultrafast Laser - 03/12/2022