Table of Contents

Beginning: The Development and Current Status of the Laser Industry

The laser industry has found wide acceptance across different industries since the invention of the laser in the 1950s. Lasers have become integral parts of our technological society and are at the very heart of the various technological revolution. This has been possible due to rapid progress and development in the laser industry.

Today, laser technology is used in various applications, including material processing, medical procedures, surgery, drilling, welding, marking, engraving, cutting, soldering, alignment, product marking, sensing, and so on.

A wide range of application industries with laser technology

3C products

In 3C products, lasers are used for marking, cutting, and welding. The laser marking method uses a laser to create permanent designs, words, symbols, and patterns on the product. Laser cutting is a non-contact, adaptive, and flexible process of cutting materials of different hardness.

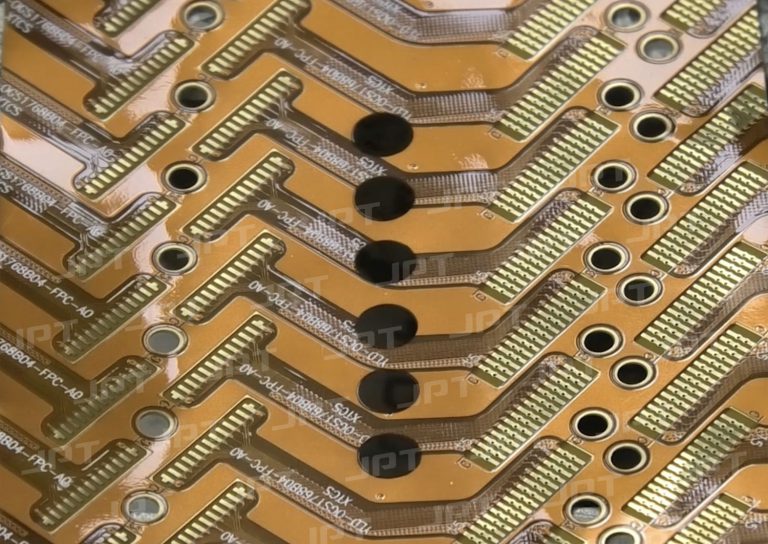

In 3C products, lasers can cut LCD glass, sapphire, OLED, FPC flexible circuit board, camera protection lens, mobile phone button, and other products. The JPT laser offers different laser machines, which deliver outstanding performance for marking, cutting, and welding 3C components. JPT’s M7 series fiber laser sources are compatible with almost all the 3C laser marking applications and provide high resolution marking while maintaining stability during marking.

SEMI conductor

With the availability of lasers in a wide range of power, lasers have become an essential part of the semiconductor industry. Laser technology is used on hard metals as well as create small markings on sensitive semiconductor devices. Laser sources of CW or pulse having different power range and wavelength output are used in the semiconductor manufacturing process to carry out various tasks.

Passive device

Passive components like resistors, inductors, and capacitors are required to build any electrical or electronic circuit. Applications of lasers in passive components include laser scriber, single-chip resistor tester, laser trimmer, high voltage resistor tester, hybrid trimmer, etc.

Laser-based technology provides the flexibility to change the test conditions to achieve the quality requirements of different specifications. JPT’s laser trimmer offers various advantages for passive device testing. Laser trimmer uses a customized fiber laser instead of a traditional solid laser, and proprietary control software delivers incredible customizability and a wide range of adjustable resistance.

Other advantages like compatibility with copper foil, alloy, thin film, thick film type resistance, and adaptability to various product types make laser trimmer the best choice for passive device testing.

Automobile

Laser technology is widely used in the automobile accessories hardware industry due to its high precision, small heat-influenced area, and great controllability.

Laser cutting technology can perform high-precision cutting of automotive central control displays, automotive doors, door frames, brake pads, roof covers, and various parts according to the need. Laser welding can perform different types of welding on metals such as stainless steel, carbon steel, aluminum, and other metals.

Laser welding technology is used for welding automobile bodies, gears, baffles, instrument panels, and splicing blank plates and other parts. JPT CW fiber laser is the most suitable laser source for industrial automobile laser welding, cutting, and other applications. The CW laser source offers the optimal combination of optical, mechanical, electrical, and software components.

The laser operating status can be monitored in real-time, alarm messages can be received in time, and data can be collected. The laser uses water-cooling and shelf case design. It offers competitive advantages like high energy conversion, low power consumption, zero maintenance, and easy assembly and operation.

Aerospace & defense

The laser-based remote sensing systems are used for atmospheric sensing and monitoring of global climate change, long-range tracking, 3D imaging and mapping, autonomous navigation, and more. Fiber lasers are extensively used for drilling different types of holes in aerospace components like combustors, nozzle guide vanes, blades, and cooling rings.

In defense, laser technology has been used for applications such as targeting and sensing, generating directed optical power with high power lasers, and navigating confidently across land, sea, and air.

Optical communications

Optical communication uses light as the transmission medium. Optical communication has been one of the driving forces in developing laser diode technology. Lasers are ideal light sources because of their high bandwidth range capability and narrow spectral range output. Today, diode lasers are the critical components of any broadband communication system.

They have been employed as high-speed transmitters in digital and analog fiber optic networks and high-power pulsed lasers in the test and measurement fields. Lasers are used as a pump for amplification of the signal over the fiber link.

Batteries

As a source of clean energy, batteries power electric vehicles and are used in many products such as emergency power backups, electric trains, electric bicycles, solar power storage, and many more. Lasers are used in the manufacturing process of batteries.

Laser welding can be used for various types of welding, such as valve welding, connection welding, tab welding, helmet spot welding, and battery shell sealing welding. Laser cutting is a key process and can be used to cut and drill battery tabs, pole pieces, and various conductive materials.

Dental

Laser technology are used in treatment of a number of different dental conditions, including hypersensitivity, tooth decay, gum disease, and teeth whitening. The laser-based dental treatment potentially offers a more comfortable treatment option for a number of dental procedures compared to drills and other non-laser tools. Also, dental treatments are more efficient, fast, and cost-effective.

Jewelry

Today’s manufacturing and retail jewelers have a wide range of new technologies available to enhance their ability to provide the highest level of quality, craftsmanship, and service to their clients. Manufacturing and retail jewelers are currently using lasers to engrave, mark, and wield jewelry items.

All jewelry metals such as gold, silver, stainless steel, titanium, and precious stones can be cut using laser technology. Laser welders can be used to fill porosity, repair bezel settings, resize rings without removing stones, and correct manufacturing defects.

Biomedical

Laser technology is used for clinical diagnosis, treatment, and medical research. The application of laser in diagnosis includes laser tumor diagnostic analyzer, laser holographic microscope, and laser CT.

Various laser-based instruments are used in medical procedures and treatments, such as laser knife, endoscopic laser, photodynamic therapy, and laser therapy machine. Apart from this, the laser can also treat eye diseases, perform blood tests, treat heart diseases, weld surgical wounds, etc.

3D printing

3D printing is playing an increasingly significant role in the manufacturing industry. It is very useful for prototyping and small-batch manufacturing. Due to the high flexibility and high efficiency of lasers, laser-assisted manufacturing technologies are recently getting much attention over traditional methods. Lasers can be applied to various 3D printing processes such as subtractive, additive, and formative processes as highly efficient energy sources.

Sensors

Laser sensors are widely used in various fields of application for industrial automation. Laser sensor technology gives several benefits over usual mechanical devices used for measurement, including non-contact measurement, tiny measurement area, data collection with high-speed, flexible operation, and solid-state design.

Therefore, laser sensors are used in many industries for a wide range of applications including, finding the location of the robot, track alignment of the railroad, quality control, measuring the thickness of the brake rotor, alignment of welding head position, and many more.

Solar

The solar industry is emerging as a viable source of clean energy. With lasers’ rapid, precise, and good thermal effect, the laser has demonstrated its outstanding superiority in the production of solar cells. Laser processing plays an important role in solar cells manufacturing process, such as laser grooved buried grids, laser scribing thin-film batteries, and laser drilling to make back contact solar cells, cut wafers and insulate edges.

The Forecast of Laser Industry Development Trends

The future of the laser industry looks bright for the existing applications and also novel applications. Scientists are experimenting with integrating tiny lasers directly in silicon chips to be used in photonic integrated circuits and using artificial intelligence to create smart lasers. By looking at laser exhibition trends and the perspective of the laser industry, laser technology in the next few years will play an essential role in the development of 5G communications, high-brightness solid-state displays, self-driving cars, new energy vehicles, and other industries.

Recommend Reading

The Complete Guide to Laser Drilling

What is Laser drilling process? Laser drilling process is a vital part of the manufacturing process. Laser-based drilling uses a fiber laser beam to create

Comparisons of MOPA fiber laser and Q-switched fiber laser

Pulsed fiber laser on current market can mainly be classified into two types, which are based on Q-switching technique and MOPA technique respectively. Between them,