Table of Contents

Laser Marking, as name suggest, is the process of creating permanent mark on the surface using laser. The laser parameters are controlled in such a manner that it only changes the property of surface by laser heating and therefore changing the appearance without surface removal.

Laser marking has found wide industrial application and frequently being used to mark part number or serial number in different products and to mark the codes such as bar codes, Unique ID codes, Data Matrix Codes etc. They are also employed in creating graphics.

Different Kind of Plastics that can be processed by Lasers

Laser marking is compatible with the materials like metals, ceramics, plastics and glass etc. Particularly, laser marking in plastic has large scope in different industries. There are different types of plastic materials which are in use for laser marking. It is important to understand the various properties of plastics as marking process may be quite different and will depend upon their physical and chemical properties:

Different plastics can be categorized in two categories i.e. thermosests vs thermoplastic.

Thermosets:

- Rubber based products

- Polyimide

- Epoxy Resins

- FR2/FR4

- Polyurathane

- Bakelite

Thermoplastic:

- Polypropylene

- Polyethylene

- Polystyrene

- Nylon

- ABS

- Polycarbonate

- PVC

Thermoset materials can withstand relatively higher temperature. They can remain in solid state without losing their structural integrity and if any additional heat is provided, they will produce discoloration and charring. This discoloration and charring is utilized in creating high contrasting marks.

In thermoplastics, marking is achieved by melting the plastic and creating a shallow engraved mark. Since in thermoplastic there is no discoloration or charring, it is difficult to create high contrast marks.

Different Lasers for Marking Plastics

Another important aspect of laser marking process is laser. It is important to understand the characteristics of different laser and select one depending upon material based marking requirement. Here we make a suitable comparison of following lasers that are extensively used in laser marking of plastic materials:

CO2 Laser:

It uses a gas filled tube. Electricity is passed through this tube to produce monochromatic light. CO2 lasers are excellent and fastest one to mark in different kind of plastic materials. The power and other characteristics can be well controlled by software’s driven automated system. Its wavelength is in infrared range (~10.6 um). They are also inexpensive comparing with other lasers.

Green Laser:

Green Laser, also known as Cold Marking Laser is a favorable option for laser marking in most sophisticated materials. Green laser beam can be achieved in Diode Pumped Solid State Laser (DPSS) module by frequency doubling mechanism. It works on 532 nm wavelength.

The wavelength is in between the UV laser and CO2 or Nd:YAG laser wavelength. Therefore, it offers just right power maintaining the delicacy of materials. In laser marking process, ‘heating’ should be properly managed as it can damage very sensitive or vey thin materials.

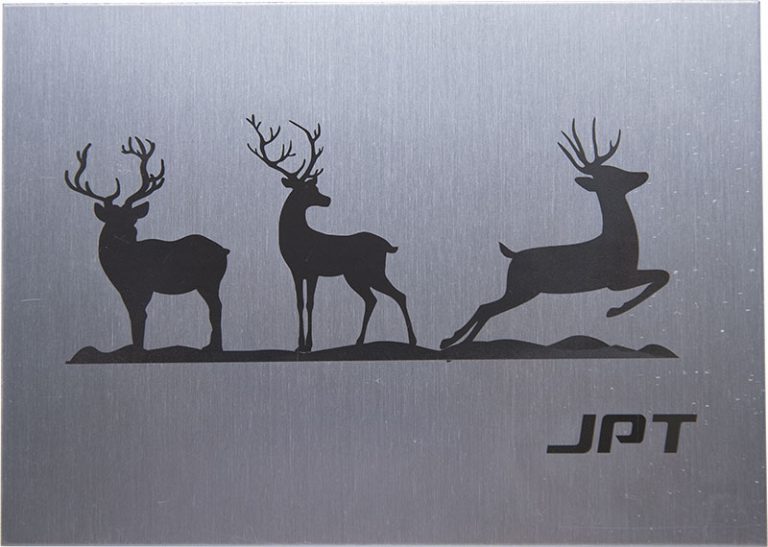

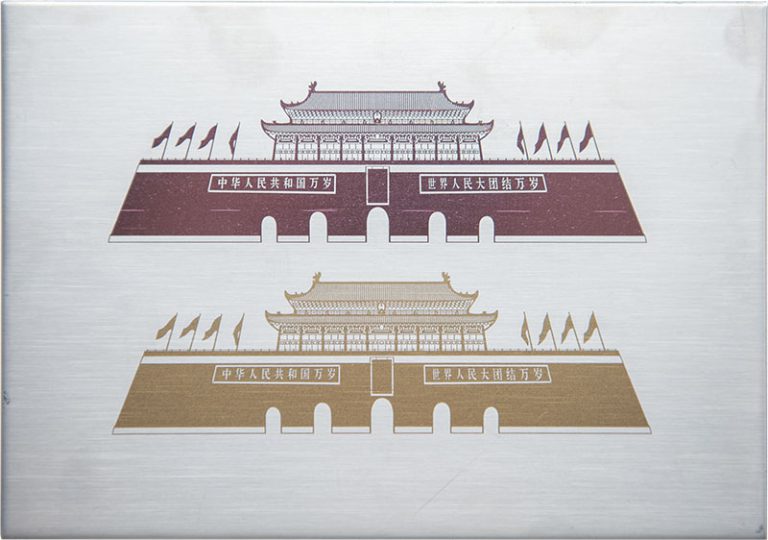

Therefore, ‘No heat generation’ in Green laser is a big advantage. Another advantage is their relatively small spot diameter that helps in achieving the micron level precision. Seal Family of JPT’s DPSS laser has excellent beam quality (M2<1.2) and perfect spot characteristics (circularity is more than 90%) suitable for high precision laser marking. Due ot anti moisture characteristics these laser ready to adapt harsh industrial environments.

UV Laser:

The UV laser (e.g. Excimer Laser) works on 355 nm wavelength. It is achieved by passing 1064 nm wave through non linear crystal reducing it into 532 nm and again passing it again through another nonlinear crystal to get 355 nm wavelength. The wavelength is directly proportional to power.

Therefore, in soft product where CO2 or Fibre laser becomes difficult to handle due to their higher power range, UV laser and Green laser proved to be ideal for laser marking. Although for ‘intricacy’ and ‘precision’ UV laser prove to be superior option than Green Laser due to very small spot size achievable and absence of heating.

Fiber Laser:

Fiber laser is a solid state laser works at 1064 nm wavelength. Ease of use, fast processing speed, and low maintenance are the main feature of fibre laser. In Fiber Laser, electricity is converted in to light photons in laser diodes that are further pumped into the fiber optic cable.

Although these lasers are more popular in laser marking in metals, they do mark into number of plastic materials, e.g. Acrylic and Polyamide.

Methods of Laser Marking on Plastics:

There are different possible methods by which laser marking in plastic can be done. These are illustrated herewith:

Foaming

When plastic absorbs laser light it can melt and vaporize due to localized heating. In this process, carbon oxidizes and creates froth on the surface. This frothing is capable to reflect light.

Color Change

Laser marking is actually achieved by creating contrast or appearance change but all this happen within the domain of same color. Although limited but now new technological advances allow to do color marking as well. This becomes possible through the application of pigments and graduals’ which are sensitive to typical laser wavelength.

Carbonizing

Carbonizing is particularly suitable for plastic materials. When laser beam irradiates plastic, it melts and hydrogen and oxygen both evaporates and released from the point of contact. In this way the affected reason is darkened. Since the affected reason color becomes dark it creates high contrast in light color materials.

Removing

This method is particularly applied in coated materials. Coating is selectively removed exposing the substrate material that is used as a mark as the color of coating and substrate material are different. Coating absorbs laser energy and due to heating, surface removal occurs.

JPT MOPA Fiber Laser for Plastic Marking

JPT offers a large variety of MOPA Fiber laser which has many distinctive advantages for plastic marking. For example

- JPT MOPA Fiber laser offers a great flexibility and customization. Pulse repetition frequency (PRF), pulse duration, pulse shape and their peak power all these important parameters can easily be changed in MOPA Fiber laser without changing the setup or operating principle of laser system.

- JPT MOPA Fiber offers efficient Laser beam power, beam quality and laser operation with relatively less power consumption.

- JPT MOPA Fiber laser creates reliable and long-lasting marking features. They are capable to create high contrast marking feature with negligible carbonization.

Recent technological advancement has revolutionized the laser marking field and they are extensively used in aerospace, mechanical, defense and medical field. Due to its overall cost effectiveness, flexibility to use and versatility, laser marking has a promising future.

Recommend Reading

Color Laser Marking Guide

Table of Contents What Exactly is Color Laser Marking? Color laser marking is the process of creating color marking on objects using laser machines. Marking

Laser Marking: Everything You Need to Know

Used exclusively by industrial manufacturers before, laser marking technology is today used by small business enterprises, makers, hobbyists, and product designers in many different ways.