Leather cutting is the process of cutting on leather using knives, molds, lasers, or other tools. This process is widely used in automobile production, clothing, sports equipment, and other industries.

Traditional leather cutting uses knives and molds, which is a physical contact method for cutting. This method for leather cutting may warp the edge of the leather. Also, since it is contact cutting, the knives would be worn when using, so the knives need to replaced frequently.

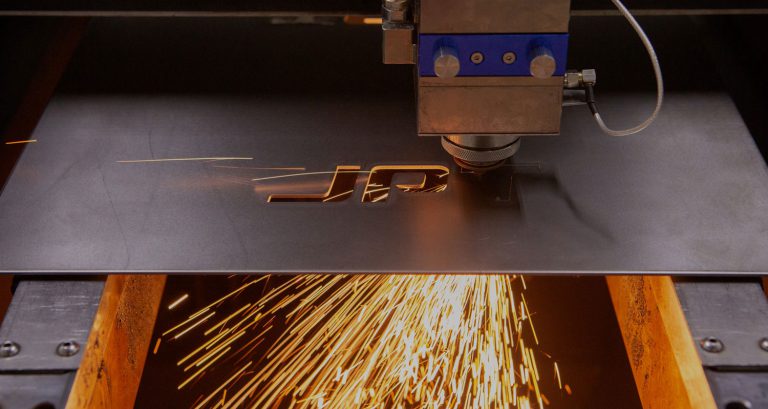

Different from the traditional cutting, laser cutting uses high energy density laser beam irradiation on the surface of artificial leather, so that it is quickly heated to the vaporized and melting temperature to finally form a hole, and then cut the figure on the leather under high-precision CNC platform operation. Since it is non-contact cutting so during the process there is no need of frequent replacement of tools or other devices, only dust purification equipment installation is needed in the laser cutting to ensure the purification of waste gas.

Why to Choose Laser Cutting

Advantages of laser cutting:

- Laser cutting doesn’t require preparing several stamping dies for cutting different graphics. You only need to switch the corresponding cutting file.

- After focusing, the laser beam will form a high energy density at the focal point, which is conducive to the formation of a burr-free and narrower slit and processing of precise patterns.

- Unlike traditional stamping cutting, laser cutting belongs to “no contact” processing. Processing does not cause a deformation of the material.

- Easily matched with automatic control, achieve automatic cutting, high cutting precision.

Comparison of the Different Lasers in Leather Cutting

There are many types of lasers on the market, divided by the wavelength of their output. Among them, the UV laser achieves a better edge effect because of its shorter wavelength compared with the long-wavelength laser, which can effectively reduce the heat input.

Effect comparison:

Tips:

“UV” is short for Ultra Violet, which is divided according to the wavelength. The visual band of human eyes is usually about 400 nm-780 nm, and the beam at 400 nm appears purple in human eyes, so we call the light with a wavelength less than 400 nm ultraviolet light.

Hereby, we introduce the SEAL-355-15S of JPT, which is very suitable for leather cutting. It is a laser with a central wavelength of 355 nm and has an excellent optical parameter M2 (beam quality) < 1.2.

In order to adapt to the processing environment of the factory we give it more powerful waterproof and dustproof ability, service life can be greatly extended.

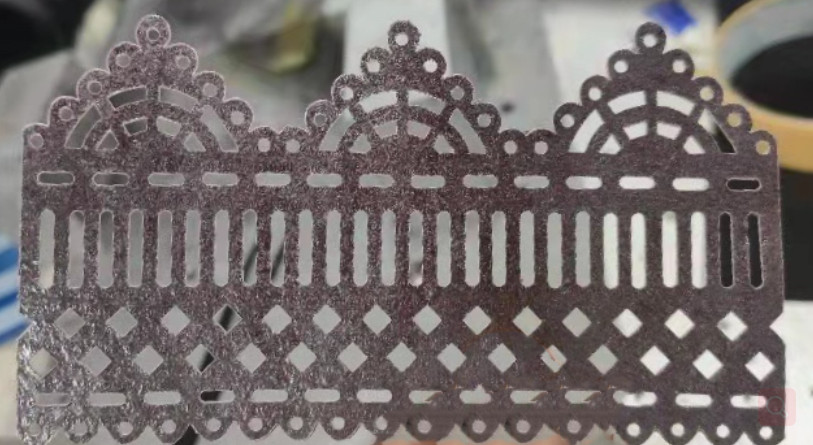

Actual application effect of laser cutting for leather

Summary

Laser cutting, as one of the mature ways of cutting, can obtain better results by the collocation of different lasers. UV laser beam carrying fewer calories when cutting leather, so it can make the leather edge closer to the color of the raw material and not lead to a burning phenomenon, that is why UV laser is recommended as the best choice of leather cutting.

Recommend Reading

Comparisons of MOPA fiber laser and Q-switched fiber laser

Pulsed fiber laser on current market can mainly be classified into two types, which are based on Q-switching technique and MOPA technique respectively. Between them,

Comparing Sheet Metal Welding Performance by Different Types of Lasers

Laser technology has been developed progressively over the past 60 years. It’s widely used in the field of traditional processing, for example, marking, welding, cutting,

- HiPA Solutions – Laser Micro Hole Drilling - 09/12/2022

- HiPA Solutions – Laser Ink Removal - 03/12/2022

- JPT Solutions – Thick Glass Cutting with Ultrafast Laser - 03/12/2022