Table of Contents

Current scenario of laser usage in the automotive industry

Lasers play a major role in the automotive and automotive supplier industry. Over the years, laser applications in the automotive sector have increased dramatically. Although the main application of lasers is devoted to cutting and welding applications, a significant proportion of lasers are being used for numerous other applications such as marking, engraving, and labeling of automotive parts.

Lasers can cut or drill holes to fix points, lights, switches, and parking sensors and trim excess plastic leftovers after processing. In Modern automotive production, robots have been commonplace throughout the industry, and assembly lines are highly automated. Laser technology is used in conjunction with modern technology, replacing old manual tools and adding additional benefits to the manufacturing process.

Laser technology is widely used in the automobile accessories hardware industry due to its high precision, small heat-influenced area, and excellent controllability. Laser cutting technology can perform high-precision cutting of automotive central control displays, automotive doors, door frames, brake pads, roof covers, and various parts according to the need.

Laser welding can perform different types of welding on metals such as stainless steel, carbon steel, aluminum, and other metals. Laser welding technology is used for welding automobile bodies, gears, baffles, instrument panels, and splicing blank plates and other parts.

Laser applications in the automotive industry:

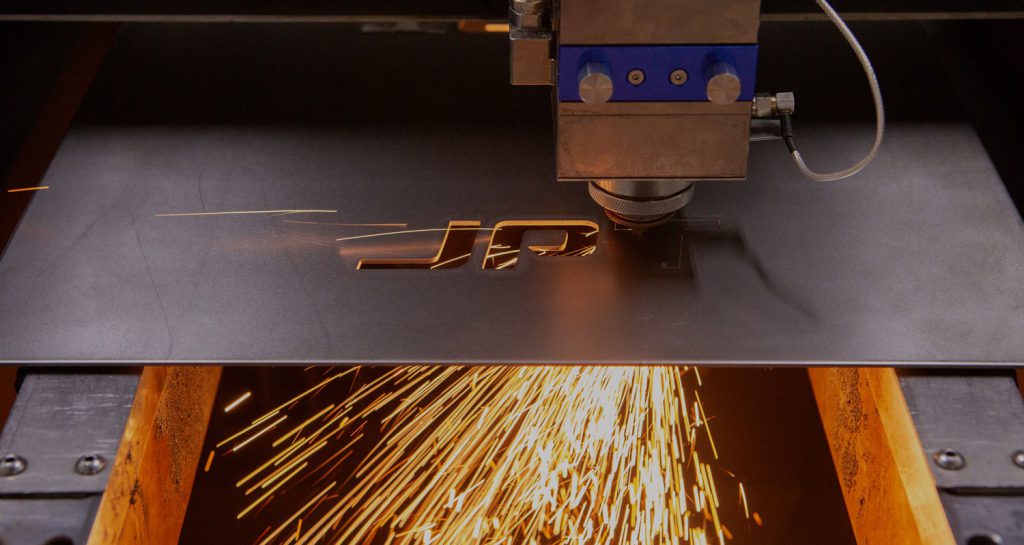

Manufacturing of automotive parts using Laser cutting

Laser cutting is the most frequently used application in the automotive industry. In the cutting process, enough laser power is supplied so that it altogether removes the material. Laser cutting can cut materials with various degrees of hardness. Different materials used in automotive and manufacturing can be cut by the laser beam including metal parts, plastics, airbag fabrics, composite materials, etc.

JPT’s Fiber lasers can be used for cutting al, stainless steel, and other metals. When processing different parts, advantages include high cutting edge quality, low heat input, and fast processing speed. The laser can act as a flexible processing tool and is easily integrated into assembly robots and other automation devices. Thus laser technology provides better solutions for cutting automotive parts in components and materials.

Assembly of automotive components using Laser welding

Laser welding is a fusion process in which two metals are joined using a high-energy laser beam. The laser beam provides a concentrated light beam on the cavity between the two metal pieces. The melting of the two materials fuses them into a joint. Using laser technology, you can weld components with precision and with minimal distortion. Compared to arc welding, laser welding produces high aspect ratio welds with relatively low heat input. The lasers offer increased productivity and a small amount of downtime compared to conventional methods.

The mass-produced automotive body parts have been processed using steel sheets and weld using resistance spot welding. The potential benefits of laser welding technology include reduced flange widths, increased torsional stiffness, low heat affected areas, less thermal stress and distortion, high-speed automatic processing, and flexibility.

JPT’s fiber laser is the best choice for automotive welding parts. The is produced in an active fiber medium in fiber lasers and guided to the work piece. The flexibility of this laser beam delivery is an essential feature of fiber lasers for laser welding. These lasers are available in continuous and pulsed mode operation.

Laser marking and engraving for automotive parts

Laser marking has more extensive capabilities and applications and is widely in the automotive and manufacturing industry. Stainless steel marking and engraving are most prevalent in various sectors. The laser marking can be performed on steel, titanium, transition metals, and chrome plated to ceramics and plastics.

JPT M7 series high power MOPA fiber lasers are best suited for marking applications. The higher output power has its advantages, especially in high-speed engraving applications. JPT MOPA fiber lasers are widely used in various marking and engraving processes, such as black marking on anodized aluminum, color marking on stainless steel, and deep engraving.

JPT laser

JPT laser offers advanced and innovative laser technology to automobiles and automotive parts manufacturers for small and large quantities. With various laser configurations available for the different automotive applications, we offer extensive applications knowledge and high expertise. Our laser systems produce precision parts, reduce production time, and increase productivity while lowering overall costs.

JPT laser understands customers’ requirements and provides easy-to-use laser system solutions for laser welding, cutting, and engraving. JPT can customize lasers according to your needs. To learn about lasers in the automotive industry, contact one of our laser application specialists today.

Recommend Reading

HiPA Solutions – Laser Micro Hole Drilling

Flexible circuit boards, referred to as FPC are widely used in consumer electronic products such as microelectronics, 5G mobile phones, laptop computers, and new energy vehicles. Also as electronic interconnects to connect products.

HiPA Solutions – Laser Ink Removal

Ink is an important material for printing. By printing or inkjet, patterns and characters are displayed on the substrate. Among them, screen printing inks are widely used on the cover glass of various display panels such as mobile phones, computers, smart watches, cameras, etc.