Table of Contents

What Exactly is Color Laser Marking?

Color laser marking is the process of creating color marking on objects using laser machines. Marking is formed by creating an oxide layer on the surface of the material.

Most materials react with oxygen present in the atmosphere to form a stable metal oxide. This process happens when the material temperature is raised well above room temperature using laser heating mechanisms.

The oxide layer can reflect a particular color of light that depends on the film’s thickness and material composition. In some cases, color dye powder is spread over the object surface that melted into the marking to form the color marking.

Compared to other color marking processes such as printing or labeling, laser marking uses no consumables, requires less maintenance, and operates at a much fast speed. A wide range of materials from plastics to metals can be color marked using color laser marking.

How Color Laser Marking Works?

Laser marking involves the heating of the material surface to create an oxide layer. Many materials are reactive in the atmosphere, and its element reacts with the oxygen present in the atmosphere to form an oxide layer.

The oxide layer thickness can be controlled by adjusting the laser parameters such as scanning velocity, power, and line spacing. The intensity of the laser beam depends on the material that needs to be marked.

For example, low-intensive beams are used to mark surfaces like plastic. On the other hand, high-intensive beams are preferred when marking harder materials such as metals.

Other valuable parameters of laser are marking direction, marking speed, focal spot diameter pulse length. Once a film is formed on the surface, it can reflect the white light of a particular color due to the thin film effect.

In the case of acrylic, the color marking requires pressing a color dye powder during the marking process to give it color of your choice.

Color Laser Marking on Metals

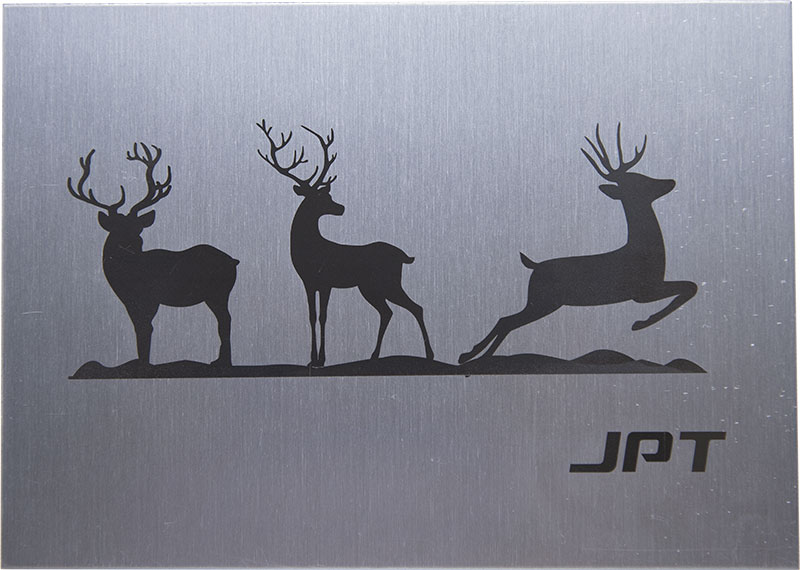

Using color for laser marking allows more capabilities and provides more versatility to product designs and offerings and attractive features. Color laser marking can be employed for a wide range of materials, including metals.

Color marking metal has more extensive capabilities and applications and is widely used for various applications. Stainless steel color marking is particularly most popular in various industries.

Raw or untreated metal surfaces are particularly best for marking as they can have many colors to select from. The actual color of the metal depends on the thickness of the layer formed and which interns depend upon the laser parameters such as laser frequency, speed, and power. Metals color laser can mark metals such as steel, titanium, transition metals, and chrome plated metals.

Applications of Color Laser Marking

Color laser markings can be used for diverse purposes, from creating your personalized design on any product to boosting your branding capabilities by marking a product with your company logo. A few possibilities of color laser marking applications are listed below.

Branding

Company branding capabilities can be boosted by color marking your company logos on a collection of products, including electronic equipment, automobiles, aircraft, and medical products.

You can create eye-catching designs, graphics, and images on a wide range of products. It will help your laser marked products look prettier, but the products will fetch a better price.

Marketing

Creating personalized product and product customizations according to the choice of customers is the best way to market your company. Any graphics, designs, and images can be color laser marked to enhance a product look.

Jewelry

Color laser marking is a great technique to provide a touch of beauty and personalization to your jewelry, watch and any other craft metal works.

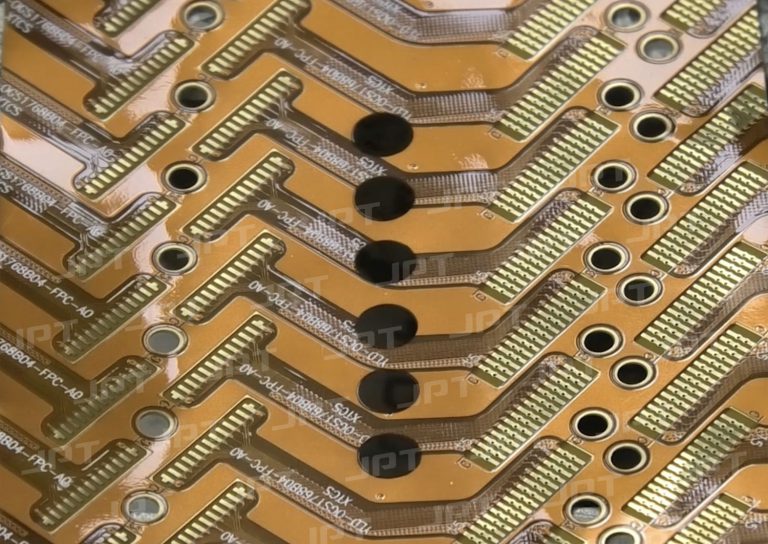

Electronic equipment

Custom designs of any kind can be color marked on cell phones, cameras, laptops, and other electronic equipment.

The Advantages of JPT MOPA Fiber for Color Laser Marking

JPT M7 series high power MOPA fiber lasers make use of master oscillator power amplifier (MOPA) configuration and show excellent laser performance with a high level of temporal pulse shaping controllability.

Compared to the Q-switch technology, in MOPA configuration, the pulse repetition frequency (PRF) and pulse width can be controlled independently. The laser peak power can be well maintained by adjusting different combination parameters. The high output power has its advantages, especially in high-speed marking applications.

JPT MOPA fiber lasers are best suited for marking and marking processes, such as black marking on anodized aluminum, color marking on stainless steel, and deep engraving.

Recommend Reading

Comprehensive Laser Cleaning Guide – Advantages and Benefits

Table of Contents What is Laser Cleaning? Laser Cleaning is the process of removing the unwanted contaminants or impurities from the surface of a material

The Complete Guide to Laser Drilling

What is Laser drilling process? Laser drilling process is a vital part of the manufacturing process. Laser-based drilling uses a fiber laser beam to create